Home

>

Reprappers

>

Topic

Over-constrained smooth Z rods

Posted by qrp-gaijin

|

Over-constrained smooth Z rods March 18, 2021 06:53AM |

Registered: 3 years ago Posts: 93 |

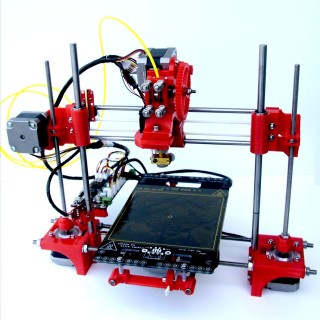

My Portabee printer has two smooth Z-rods that are "floating" and not connected at the top with any horizontal bar.

On the other hand, one user claims at [www.thingiverse.com] that adding an additional constraining horizontal rod between tops of the two smooth Z rods will improve print quality and reduce "the wiggling Z-axis Problem".

However, I have read that too many constraints will, instead of preventing a wiggling Z problem, actually cause it. But the discussions I have read seem to emphasize not constraining the threaded Z rods (the lead screws), but I wasn't able to find any information about constraining the smooth (not the threaded) Z rods.

So is it a good idea, or not, to constrain the smooth Z rods together at the top?

Edited 1 time(s). Last edit at 03/18/2021 06:57AM by qrp-gaijin.

On the other hand, one user claims at [www.thingiverse.com] that adding an additional constraining horizontal rod between tops of the two smooth Z rods will improve print quality and reduce "the wiggling Z-axis Problem".

However, I have read that too many constraints will, instead of preventing a wiggling Z problem, actually cause it. But the discussions I have read seem to emphasize not constraining the threaded Z rods (the lead screws), but I wasn't able to find any information about constraining the smooth (not the threaded) Z rods.

So is it a good idea, or not, to constrain the smooth Z rods together at the top?

Edited 1 time(s). Last edit at 03/18/2021 06:57AM by qrp-gaijin.

|

Re: Over-constrained smooth Z rods March 18, 2021 07:54AM |

Registered: 11 years ago Posts: 5,780 |

Day one, Intro to Machine Design 101, first sentence from the professor's mouth: "that which should be kept parallel should be kept parallel at all times, that which should be kept square should be kept square at all times."

The relative positions of the guide rails of the machine define the axes of the machine's coordinate space. Guide rails are not something that you want to have flopping around if you want accurate or even recognizable prints from your printer.

The flexibility of end supported round guide rails is enough to inspire many to use linear guides bolted to metal plates which are in turn bolted to the printer's frame to constrain motion to one direction only.

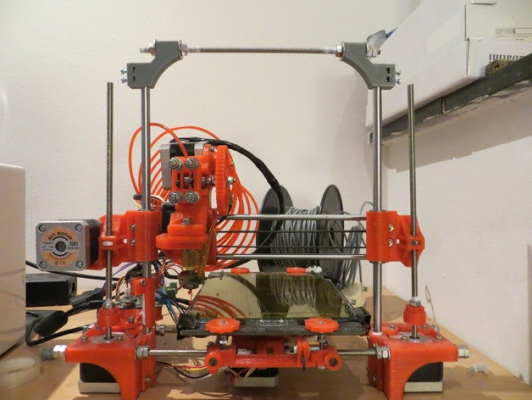

When you look at printer designs, try to imagine what mechanical force applied in different places will do to the frame of the machine and what that will do to the guide rail positions. In the second photo you posted the Z axis rails have been constrained to try to keep them parallel to each other, but pushing on one corner will cause them to twist. The constraint is incomplete.

If you're shopping for a printer design to build, I suggest you start by looking at good, expensive machines, and then start comparing them to crappy ones. Ask yourself why the differences exist and what are the possible consequences of the differences. If you start at the crappy end of the spectrum, it's all you'll see and you'll end up building a crappy machine.

Edited 1 time(s). Last edit at 03/18/2021 08:04AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The relative positions of the guide rails of the machine define the axes of the machine's coordinate space. Guide rails are not something that you want to have flopping around if you want accurate or even recognizable prints from your printer.

The flexibility of end supported round guide rails is enough to inspire many to use linear guides bolted to metal plates which are in turn bolted to the printer's frame to constrain motion to one direction only.

When you look at printer designs, try to imagine what mechanical force applied in different places will do to the frame of the machine and what that will do to the guide rail positions. In the second photo you posted the Z axis rails have been constrained to try to keep them parallel to each other, but pushing on one corner will cause them to twist. The constraint is incomplete.

If you're shopping for a printer design to build, I suggest you start by looking at good, expensive machines, and then start comparing them to crappy ones. Ask yourself why the differences exist and what are the possible consequences of the differences. If you start at the crappy end of the spectrum, it's all you'll see and you'll end up building a crappy machine.

Edited 1 time(s). Last edit at 03/18/2021 08:04AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Over-constrained smooth Z rods April 02, 2021 01:31AM |

Registered: 3 years ago Posts: 93 |

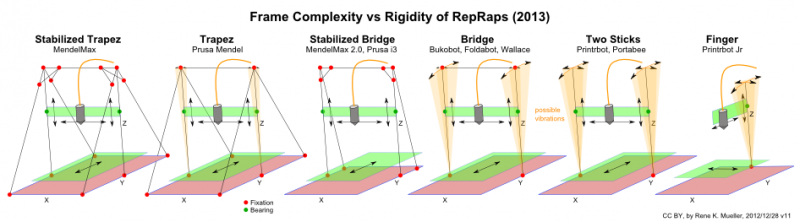

I found an interesting summary from 2013 of some stability characteristics of various RepRap setups in one user's page at the RepRap wiki:

[reprap.org]

While I have my Portabee disassembled for maintenance on the hot end, I'm taking the opportunity to physically align and tighten the axes as much as possible given the simplified "two sticks" frame, and then do some tests to determine the best print quality I can get with this setup. For the moment I mostly am printing functional 3D parts to repair or enhance my printer, so I'm more interested in functionality (e.g. correctly-meshing gears) rather than a pristine appearance (e.g. perfectly smooth surfaces).

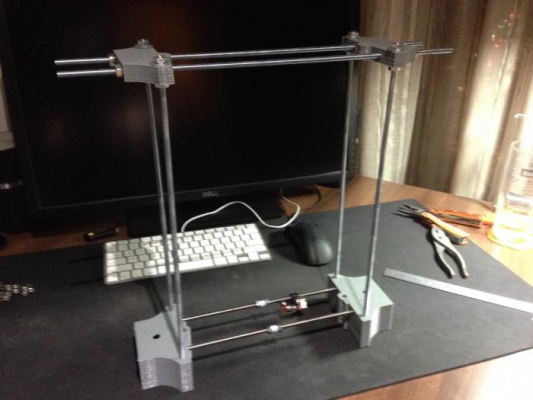

I've also seen a simple external frame for the Portabee that seems more stable than the simple "bridge across the Z rods" that I posted previously (and that is also shown in the above summary diagram). The external frame looks like this -- note that the straight Z rods and the threaded Z rods are omitted from this photo. The idea of the frame is that it leaves the Z rods floating, but tries to stabilize the whole base. This user also used flex couplers to connect the threaded screws to the motors, which I think also reduces the ability of a wobbling threaded rod to push the motor and flex the frame.

[www.igorkromin.net]

[reprap.org]

While I have my Portabee disassembled for maintenance on the hot end, I'm taking the opportunity to physically align and tighten the axes as much as possible given the simplified "two sticks" frame, and then do some tests to determine the best print quality I can get with this setup. For the moment I mostly am printing functional 3D parts to repair or enhance my printer, so I'm more interested in functionality (e.g. correctly-meshing gears) rather than a pristine appearance (e.g. perfectly smooth surfaces).

I've also seen a simple external frame for the Portabee that seems more stable than the simple "bridge across the Z rods" that I posted previously (and that is also shown in the above summary diagram). The external frame looks like this -- note that the straight Z rods and the threaded Z rods are omitted from this photo. The idea of the frame is that it leaves the Z rods floating, but tries to stabilize the whole base. This user also used flex couplers to connect the threaded screws to the motors, which I think also reduces the ability of a wobbling threaded rod to push the motor and flex the frame.

[www.igorkromin.net]

|

Re: Over-constrained smooth Z rods April 02, 2021 06:22AM |

Registered: 11 years ago Posts: 5,780 |

Gears mesh on their surfaces. If those surfaces aren't pristine, why would you expect them to mesh correctly?

Have you tried square wheels on your car/bicycle yet?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Have you tried square wheels on your car/bicycle yet?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Over-constrained smooth Z rods April 04, 2021 01:52AM |

Registered: 3 years ago Posts: 93 |

I think I only need the gears to mesh "correctly enough" so as to prevent generational degradation, meaning that:

Having replaced basically all of the extruder parts with self-printed replacements, I think the printer has not suffered any generational degradation due to the self-printed replacement gears, even though the surfaces of the replacement gears show some very slight z-wobble artifacts. I think that the gear quality is not the main limiting factor in print quality at the moment.

I think the larger factor impacting the print quality (and causing the z-wobble) is the frame stability, meaning that making improvements in frame stability (by using my existing printer to print new parts for a better frame) should lead to successive improvements in print quality. This eventually will also result in more accurate gears, but again, I don't think that improvements in the gear meshing will bring big gains to me just right now, at the current stage of my printer's evolution.

Edited 1 time(s). Last edit at 04/04/2021 01:53AM by qrp-gaijin.

- The printer should be able to print its own replacement gears (Wade's extruder gears, in particular) with sufficient accuracy to allow the printer to continue operating with at least as much precision as before the repair, and

- The printer should be able to print new parts with sufficient accuracy to enable building a new printer with better precision.

Having replaced basically all of the extruder parts with self-printed replacements, I think the printer has not suffered any generational degradation due to the self-printed replacement gears, even though the surfaces of the replacement gears show some very slight z-wobble artifacts. I think that the gear quality is not the main limiting factor in print quality at the moment.

I think the larger factor impacting the print quality (and causing the z-wobble) is the frame stability, meaning that making improvements in frame stability (by using my existing printer to print new parts for a better frame) should lead to successive improvements in print quality. This eventually will also result in more accurate gears, but again, I don't think that improvements in the gear meshing will bring big gains to me just right now, at the current stage of my printer's evolution.

Edited 1 time(s). Last edit at 04/04/2021 01:53AM by qrp-gaijin.

|

Re: Over-constrained smooth Z rods April 05, 2021 02:09AM |

Registered: 8 years ago Posts: 1,671 |

Sorry, only registered users may post in this forum.