Home

>

Reprappers

>

Topic

Replace 3mm-filament hot end with 1.75mm-filament hot end

Posted by qrp-gaijin

|

Replace 3mm-filament hot end with 1.75mm-filament hot end March 20, 2021 11:12AM |

Registered: 3 years ago Posts: 93 |

My old Portabee printer has a hot end that accepts the older 3 mm-diameter filament. I am planning how to upgrade this to a new hot end that accepts 1.75 mm-diameter filament.

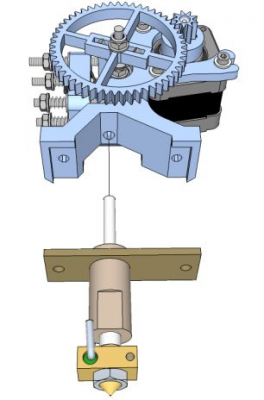

The old hot end looks like this:

[github.com]

There's a short PTFE tube that guides the filament from the top of the extruder block down into the hot end.

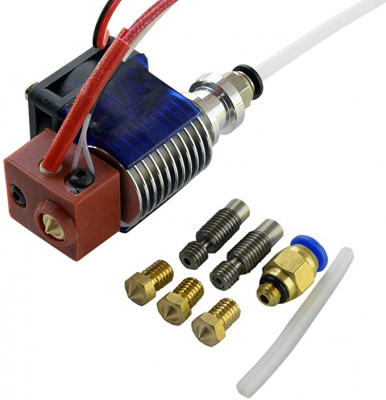

As a replacement, that would take 1.75 mm-diameter filament, I'm thinking about the following hot end: "ACAMPTAR All Metal V6 Hotend 1.75mm Bowden Extruder For Prusa I3 Reprap 3D Printer".

[www.amazon.de]

The ACAMPTAR hot end has a long PTFE tube intended for a Bowden-tube arrangement.

Since my printer uses a direct drive mechanism, my plan would be to cut the long PTFE tube shorter, so that its length passes exactly into my extruder block and, as before, can guide the filament from the top of the extruder block down into the hot end. Also, since the filament guide holes in the old extruder block are designed for 3 mm-diameter filament, I would probably need to slightly rework the extruder block to have smaller holes to accommodate the narrower 1.75 mm-diameter filament.

My question: does my plan sound all right? Any tricky things to be aware of when upgrading my hot end in this way?

The old hot end looks like this:

[github.com]

There's a short PTFE tube that guides the filament from the top of the extruder block down into the hot end.

As a replacement, that would take 1.75 mm-diameter filament, I'm thinking about the following hot end: "ACAMPTAR All Metal V6 Hotend 1.75mm Bowden Extruder For Prusa I3 Reprap 3D Printer".

[www.amazon.de]

The ACAMPTAR hot end has a long PTFE tube intended for a Bowden-tube arrangement.

Since my printer uses a direct drive mechanism, my plan would be to cut the long PTFE tube shorter, so that its length passes exactly into my extruder block and, as before, can guide the filament from the top of the extruder block down into the hot end. Also, since the filament guide holes in the old extruder block are designed for 3 mm-diameter filament, I would probably need to slightly rework the extruder block to have smaller holes to accommodate the narrower 1.75 mm-diameter filament.

My question: does my plan sound all right? Any tricky things to be aware of when upgrading my hot end in this way?

|

Re: Replace 3mm-filament hot end with 1.75mm-filament hot end March 20, 2021 07:23PM |

Admin Registered: 13 years ago Posts: 7,000 |

|

Re: Replace 3mm-filament hot end with 1.75mm-filament hot end June 20, 2021 08:03AM |

Registered: 3 years ago Posts: 93 |

Quote

Dust

Most (not all) extruders (the part pushing the filament) also cannot do both 3mm and 1.75

The 3mm tooth profile is wrong and often to large to grab 1.75.

My hot-end upgrade is done and working now. Yay! I finally have dragged my 9-year-old printer into modern times with a 1.75mm-capable hot end. I still had to use the old 3 mm hot end to print out a new plastic holder (in PLA) that would fit the new hot end. I was a little worried that the PLA might melt, but touching the top of the hot end during printing (at 180 degrees) reveals that it is cool to the touch, so the plastic holder should hopefully not be exposed to temperatures high enough to deform the holder.

And the above problem about lack of filament grip did indeed occur. I first ran some tests feeding the 1.75 mm filament through the existing extruder and, by rotating the large gear wheel by hand, I could confirm that the filament was being pushed through the extruder block. But after final assembly, the extruder was slipping and unable to push the filament in actual use.

The problem was that the hobbed bolt could sometimes, but not always, grip the filament, due to a loose fit and a slightly misaligned axis on the hobbed bolt. Fortunately, the solution was simple: shave off (with a rotary tool) a few mm from the face of extruder block where it meets idler block, so that the idler block can then press the bearing more tightly against the hobbed bolt, and grip the filament better. So the hobbed bolt itself (originally designed for 3 mm filament) is in fact able to grip the 1.75 mm filament, provided that I apply enough pressure on the filament.

When replacing the hot end, I briefly gave some thought to experimenting with a Bowden-tube setup, but in the end I decided to stay with the direct-drive extruder, because I think that ultimately will give better control of and fewer problems with retraction and stringing.

I'm already noticing improvements in my printing quality because now I can finally use a brand-new spool of 1.75 mm filament instead of trying to print with my years-old 3 mm filament. Also, the ceramic heater on my new hot end has better temperature stability during printing than the silicone-coated wire-wound resistor from my old hot end.

Sorry, only registered users may post in this forum.