Home

>

Reprappers

>

Topic

Help with designing a belt tensioner

Posted by drmaestro

|

Help with designing a belt tensioner March 28, 2021 06:07AM |

Registered: 9 years ago Posts: 330 |

Hi,

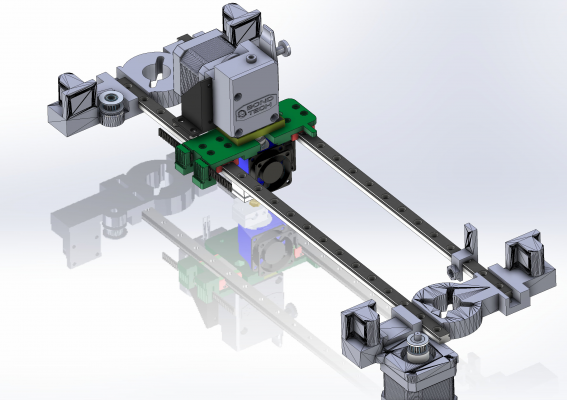

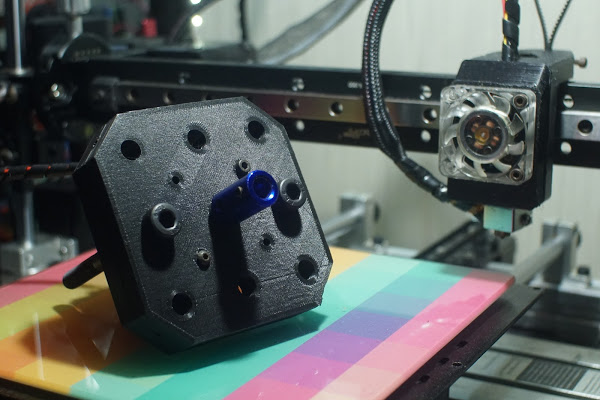

I am trying to add a belt tensioner to my current Z car design. Here's how it looks right now:

The hole in the middle of the car is for the leadscew. The 2 vertical rectangular parts at the lateral sides are used to connect the car to linear rails. The small circular space with a hole in the middle just next to the left rectangular connector is used the idler. I have 2 problems with this design.

1) The GT2 belt wobbles on this side of the printer, while it doesn't on the side with the motor. Please see the following video for a better description of the "wobble" [www.youtube.com]

This wobble is probably due to a misalignment of the idler but I am sure that it isn't a horizontal misalignement, as I've designed the entire axis on Solidworks as an assembly. Also, there is no major visible wobble on the side with the motor. However it is possible that the pulling force exerted by the belt is bending the hole where the bolt for holding the idler in place (it can't bend the motor's shaft and probably the plastic part where the motor is connected). I can't really see a major bend, but I also can't explain why the movement exists.

2) The other major problem is that I don't have any way to tension the belt easily, as the idler is fixed in place. The only way to tension the system is at the part where the belt is connected to the X car, and it is quite difficult to do, because I have to pull the belt very hard with plyers, push it in the slot on the X car and immediately use zip-ties to bend it and fix it. This is not ideal. There are some belt tensioners being sold like the one at the following link and I want to design something similar for the Z car instead of its current iteration. I am open to suggestions on how to design it. The major problem is, how the part will resist the pulling force of the belt. Putting a simple screw would not be enough as the tensioning force might unscrew it.

Thanks....

Edited 1 time(s). Last edit at 03/28/2021 06:07AM by drmaestro.

I am trying to add a belt tensioner to my current Z car design. Here's how it looks right now:

The hole in the middle of the car is for the leadscew. The 2 vertical rectangular parts at the lateral sides are used to connect the car to linear rails. The small circular space with a hole in the middle just next to the left rectangular connector is used the idler. I have 2 problems with this design.

1) The GT2 belt wobbles on this side of the printer, while it doesn't on the side with the motor. Please see the following video for a better description of the "wobble" [www.youtube.com]

This wobble is probably due to a misalignment of the idler but I am sure that it isn't a horizontal misalignement, as I've designed the entire axis on Solidworks as an assembly. Also, there is no major visible wobble on the side with the motor. However it is possible that the pulling force exerted by the belt is bending the hole where the bolt for holding the idler in place (it can't bend the motor's shaft and probably the plastic part where the motor is connected). I can't really see a major bend, but I also can't explain why the movement exists.

2) The other major problem is that I don't have any way to tension the belt easily, as the idler is fixed in place. The only way to tension the system is at the part where the belt is connected to the X car, and it is quite difficult to do, because I have to pull the belt very hard with plyers, push it in the slot on the X car and immediately use zip-ties to bend it and fix it. This is not ideal. There are some belt tensioners being sold like the one at the following link and I want to design something similar for the Z car instead of its current iteration. I am open to suggestions on how to design it. The major problem is, how the part will resist the pulling force of the belt. Putting a simple screw would not be enough as the tensioning force might unscrew it.

Thanks....

Edited 1 time(s). Last edit at 03/28/2021 06:07AM by drmaestro.

|

Re: Help with designing a belt tensioner March 28, 2021 08:45PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Help with designing a belt tensioner March 29, 2021 06:16PM |

Registered: 9 years ago Posts: 330 |

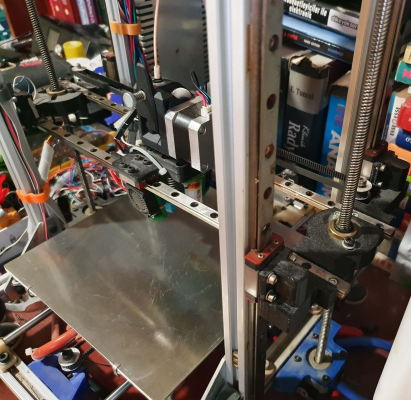

Basically, here is how the entire X-Z axis looks like:

The only way to tension the belt is at its junction level at the X car (tthe green part - here are two ribbed parts where the GT2 belt is put in. I first tie one end (let's say the left one), then I have to use pliers to tension the second end manually (which is hard) and put it in place and fix with zip-ties. Instead of doing that, I prefer displacing the idler after it belt is put in place, using screws or bolts to retract the idler in a slot or a similar mechanism. Of course, having a second part on top of the pulley is a bonus to prevent the bending force.

The only way to tension the belt is at its junction level at the X car (tthe green part - here are two ribbed parts where the GT2 belt is put in. I first tie one end (let's say the left one), then I have to use pliers to tension the second end manually (which is hard) and put it in place and fix with zip-ties. Instead of doing that, I prefer displacing the idler after it belt is put in place, using screws or bolts to retract the idler in a slot or a similar mechanism. Of course, having a second part on top of the pulley is a bonus to prevent the bending force.

|

Re: Help with designing a belt tensioner March 30, 2021 06:24AM |

Registered: 8 years ago Posts: 1,671 |

I see now, most of my designs tension at the X head, I just pass the belt through a thin 3mm slot(both belt ends) & anchor with a screw 3mm(but bigger ones would be better), prefer that to the belt in a groove like on green part(even if your using strong materials), could always use more screws & extra shim parts to compress belt if you wanted, but one seems to do it, hi-speed may need more securing. Or something more fancy with some sort of screw mechanism for adjustment.

Edited 1 time(s). Last edit at 03/30/2021 06:25AM by MechaBits.

Edited 1 time(s). Last edit at 03/30/2021 06:25AM by MechaBits.

|

Re: Help with designing a belt tensioner March 30, 2021 07:40AM |

Registered: 11 years ago Posts: 5,780 |

In your build the working side of the X belt loop is the side closest to the extruder. It has to be parallel to the X guide rails. The other side of the loop doesn't. Add an idler on the nonworking side that can push against the belt to increase its tension.

That whole assembly looks a bit too flexy for me...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

That whole assembly looks a bit too flexy for me...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Help with designing a belt tensioner March 30, 2021 05:07PM |

Registered: 9 years ago Posts: 330 |

Quote

MechaBits

cant understand why the belt is tensioned on the Z, would need to see more, doesnt look like enough material for the idler post, what about another part to secure top of idler?

Is there a specific idler post to use for the idlers? I use bolts but I am not sure they are the exact fit.

|

Re: Help with designing a belt tensioner March 30, 2021 05:12PM |

Registered: 9 years ago Posts: 330 |

Quote

the_digital_dentist

In your build the working side of the X belt loop is the side closest to the extruder. It has to be parallel to the X guide rails. The other side of the loop doesn't. Add an idler on the nonworking side that can push against the belt to increase its tension.

That whole assembly looks a bit too flexy for me...

Where can I add the idler you have mentioned? The belt is practically floating on air on the nonworking side, I don't see where I can add an idler.

Also about the flexibility of the assembly, is it because it contains too much plastic? The Z cars and the X car are on rails which I think provides some rigidity but I think there is a possibility for motion along the long axis of the Z cars.

|

Re: Help with designing a belt tensioner March 30, 2021 08:04PM |

Registered: 8 years ago Posts: 1,671 |

Idler post depends, if you are using the 5mm idlers with bearings or 2 flange on a 5 or 8mm post, I have tried a few options, shoulder bolts are great, other bolts that arent fully threaded can also be used but finding the right one with the right bearing a little trickier. I too thought it was a bit flimsy but didnt know how thick it is 10mm 15 or 20 but the slot in the Z nut trap makes it weaker at a point, not sure why you have that, is it for some Z wobble thing?

In one of my printers I am using 2 rails with no support (though one rail is acting just as stiffener), I think I could go with one rail, but in yours maybe you could use 2 but closer together, back to back or above below, you might get more room, you wont have to worry about another idler pressing on the belt or more complicated belt paths, though adjusting idler can push or pull and throws up alternative ideas.

Is this for a bed slinger, 4x Z rails ?

Edited 1 time(s). Last edit at 03/30/2021 08:24PM by MechaBits.

In one of my printers I am using 2 rails with no support (though one rail is acting just as stiffener), I think I could go with one rail, but in yours maybe you could use 2 but closer together, back to back or above below, you might get more room, you wont have to worry about another idler pressing on the belt or more complicated belt paths, though adjusting idler can push or pull and throws up alternative ideas.

Is this for a bed slinger, 4x Z rails ?

Edited 1 time(s). Last edit at 03/30/2021 08:24PM by MechaBits.

|

Re: Help with designing a belt tensioner March 31, 2021 12:04PM |

Registered: 9 years ago Posts: 330 |

Quote

MechaBits

I too thought it was a bit flimsy but didnt know how thick it is 10mm 15 or 20 but the slot in the Z nut trap makes it weaker at a point, not sure why you have that, is it for some Z wobble thing?

In one of my printers I am using 2 rails with no support (though one rail is acting just as stiffener), I think I could go with one rail, but in yours maybe you could use 2 but closer together, back to back or above below, you might get more room, you wont have to worry about another idler pressing on the belt or more complicated belt paths, though adjusting idler can push or pull and throws up alternative ideas.

Is this for a bed slinger, 4x Z rails ?

Here's how it looks:

You are right, the slots around Z nut may act as weaker points and no, there is no specific reason for them, it was just to be sure that the trap would fit, as I didn't have that part with me when designing and wanted to provide some tolerance. The Z cars are 15 mm thick and they have never had a problem at that area (I've been using this design for 4-5 years now). The weakest point (which failed 2 times in that period) was where the idler post went through the idler. This part is thinner compared to the rest and there is a great pulling force due to the belt, so it broke 2 times. Nothing serious in the last 2-3 years though.

|

Re: Help with designing a belt tensioner March 31, 2021 04:41PM |

Registered: 8 years ago Posts: 1,671 |

also the slots for the rails dont really need to be there, thicker material in that point, shifting things up a tad might help with moving & improving the idler. I'd redesign the whole of x & z, just 2 rails for Z an one for X with a piece of 2020 for support....then with the 2 free linear guides maybe alter the bed next.

Edited 1 time(s). Last edit at 03/31/2021 04:45PM by MechaBits.

Edited 1 time(s). Last edit at 03/31/2021 04:45PM by MechaBits.

|

Re: Help with designing a belt tensioner April 04, 2021 07:33AM |

Registered: 9 years ago Posts: 330 |

Quote

MechaBits

also the slots for the rails dont really need to be there, thicker material in that point, shifting things up a tad might help with moving & improving the idler. I'd redesign the whole of x & z, just 2 rails for Z an one for X with a piece of 2020 for support....then with the 2 free linear guides maybe alter the bed next.

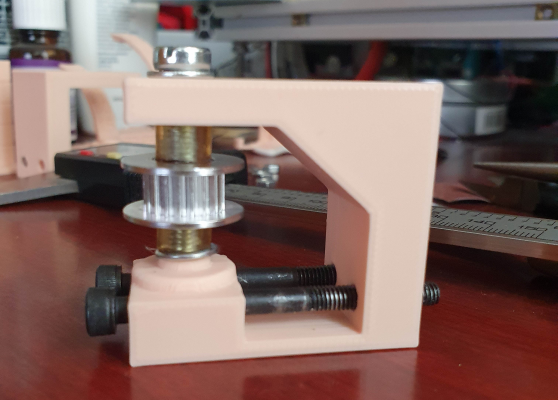

I'll definitely take these suggestions into consideration for my next build but for now I have to modify this one, as I don't have the time (also the space) for an extensive redesign. I have modified the Z car a little bit and came up with a solution, which could have worked if I could figure out a way to move it for tensioning. I first tried to cut the idler from the car and make it a separate piece, which can be moved independently from the car. I also added a top part, so that the idler's post could be supported on the top also. Here's what I came with:

The 2 long black bolts were supposed to go through the front part under the idler, then pass through 2 holes in the Z car and end up in the back side of the part. The middle portion was 5 mm longer than the Z car's width so I thought I could use this empty space to tension the idler, but then I've realized that there was no way to move the idler when the beginning and the ending of the bolts were on the same part, so I modified it as follows:

I'll add the 2 holes which will go through the whole assembly. I need to figure a way for tensioning. Do you think it would be enough to just add some nuts on the outside od the Z car and use the bolts to tension the system?

Thanks...

|

Re: Help with designing a belt tensioner April 04, 2021 09:14AM |

Registered: 8 years ago Posts: 1,671 |

I think its too free floating(cant tell), ie at least have it guided by surrounding part material, also you seem to be fixing one thing and then introducing the possibility of the bearing axis tilting under tension(bolts dont seem long enough either), I would have just added 2 holes on top of main part and attached an L piece or something for the top of bearing. It seem the side you need to be flush, isnt or you could have made a part that needs printing 90 deg from this, on the bearing block faces, you could have squeezed in a stronger supported idler mount, also the rail slot is the base material about 5mm? a 2mm trench would be enough.

|

Re: Help with designing a belt tensioner April 05, 2021 05:11PM |

Registered: 9 years ago Posts: 330 |

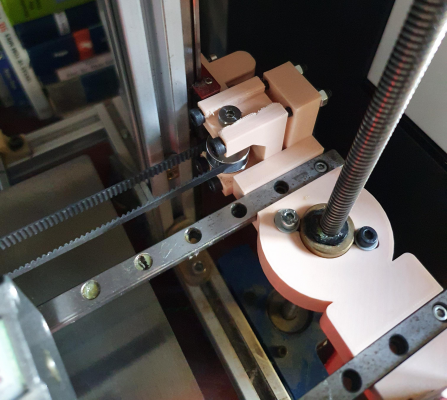

You are right, while tha part was stable with the 2 bolts in place without any pulling force by the belt, it was bending slightly under load, so I have tried to modify it according to your suggestions:

I've added 2 bolts on top and also raised the part on the Z car to provide support for the top part. On the picture, the piece on the rear is the section of the Z car where the idler tensioner will be put into (didn't want to print the entire car just to test this part). It is stable now and I think it can withstand the tension of the belt. I might even try to change from 6 mm belts to 9 mm belts to decrease artifacts (there was a post somewhere about the effect of increasing belt width).

At the same time, I am also wondering how much effect does the actual wobbling have on the print quality or dimensional stability. I assume my X and Y axis are vertical and the circles I print look like circles but if I join 2 circular objects (like 2 gears) I can feel a small resistence periodically, suggesting a very slight ovoid shape. Could the wobbling compress the X axis slightly, as there is a rotational movement on the belt's long axis, which could delay the transmission of the movement to the X car?

I've added 2 bolts on top and also raised the part on the Z car to provide support for the top part. On the picture, the piece on the rear is the section of the Z car where the idler tensioner will be put into (didn't want to print the entire car just to test this part). It is stable now and I think it can withstand the tension of the belt. I might even try to change from 6 mm belts to 9 mm belts to decrease artifacts (there was a post somewhere about the effect of increasing belt width).

At the same time, I am also wondering how much effect does the actual wobbling have on the print quality or dimensional stability. I assume my X and Y axis are vertical and the circles I print look like circles but if I join 2 circular objects (like 2 gears) I can feel a small resistence periodically, suggesting a very slight ovoid shape. Could the wobbling compress the X axis slightly, as there is a rotational movement on the belt's long axis, which could delay the transmission of the movement to the X car?

|

Re: Help with designing a belt tensioner April 06, 2021 07:28AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Help with designing a belt tensioner April 07, 2021 12:21PM |

Registered: 9 years ago Posts: 330 |

I've printed the Z car with the modified idler. Here's how it looks:

I think it is much more practical to tension this way compared to manually pulling the belt while trying to put it in its connection point on the X car. The problem with wobbling is also gone (almost):

[youtu.be]

Now I have to find a way to preserve the tension, as I feel like the pulling force may decrease it after a while. Maybe fiber nuts?

I think it is much more practical to tension this way compared to manually pulling the belt while trying to put it in its connection point on the X car. The problem with wobbling is also gone (almost):

[youtu.be]

Now I have to find a way to preserve the tension, as I feel like the pulling force may decrease it after a while. Maybe fiber nuts?

|

Re: Help with designing a belt tensioner April 07, 2021 01:27PM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Help with designing a belt tensioner April 07, 2021 01:38PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Help with designing a belt tensioner April 07, 2021 02:18PM |

Registered: 9 years ago Posts: 330 |

Quote

MKSA

With all these linear rails and Al extrusions why not build for example a CoreXY based on a proven built ?

Only a couple to choose from, so the choice is easy.

If I ever build a 3D printer from scratch again, it'll definitely be a CoreXY, as the moving mass is lighter. This one is 7 years old now (it's this model) and I have modified it with a lot of improvements (steppers with native leadscrews, linear rails, Duet mainboard, etc) and quite happy with the print quality. I enjoy finding the remianing correctable problems and build solutions for them (thanks to this community

). However, I mostly use resin printing now, as I print very small anatomical models with very thin vessels, so FDM printing's resolution and print quality isn't really adequate for my general needs (I don't say that the same quality is not achievable with FDM, as 0.15-0.2 mm nozzles printing with 0.05-0.06 thick layers can create some amazing objects but I find it more practical when you get used to the differences between 2 techniques).

). However, I mostly use resin printing now, as I print very small anatomical models with very thin vessels, so FDM printing's resolution and print quality isn't really adequate for my general needs (I don't say that the same quality is not achievable with FDM, as 0.15-0.2 mm nozzles printing with 0.05-0.06 thick layers can create some amazing objects but I find it more practical when you get used to the differences between 2 techniques).

|

Re: Help with designing a belt tensioner April 07, 2021 03:03PM |

Registered: 6 years ago Posts: 1,007 |

Don't try to build from scratch, just follow the instruction for a proper working machine.

The reference you gave on Thingiverse is a good example of a bad design hiding its flaws with a truckload of "high end" parts like Al profiles and linear rails (cheap junk most probably) and its unnecessary complexity.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

The reference you gave on Thingiverse is a good example of a bad design hiding its flaws with a truckload of "high end" parts like Al profiles and linear rails (cheap junk most probably) and its unnecessary complexity.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Help with designing a belt tensioner April 07, 2021 03:20PM |

Registered: 9 years ago Posts: 330 |

|

Re: Help with designing a belt tensioner April 08, 2021 02:58AM |

Registered: 6 years ago Posts: 1,007 |

Quote

drmaestro

Any suggestions on which CoreXY models to choose from?

For example, the one from Digital Dentist who is active here (see the CoreXY threat):

[www.instructables.com]

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Help with designing a belt tensioner April 08, 2021 06:47AM |

Registered: 11 years ago Posts: 5,780 |

The corexy machine is Ultra MegaMax Dominator (UMMD). The link for the original post on the topic is here..

There have been numerous, mostly small improvements to the original build, so be sure to look at more recent posts before ordering parts or building.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

There have been numerous, mostly small improvements to the original build, so be sure to look at more recent posts before ordering parts or building.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Help with designing a belt tensioner April 08, 2021 08:15AM |

Registered: 8 years ago Posts: 1,671 |

where's your core XY MKSA?

In this pic you can just about see the belt tension point and single screw, i have a closed loop belt on here, though it doesnt need to be, it makes it easy to pull the loop tight.

what kind of leadscrew are you using?

Edited 2 time(s). Last edit at 04/08/2021 11:55AM by MechaBits.

In this pic you can just about see the belt tension point and single screw, i have a closed loop belt on here, though it doesnt need to be, it makes it easy to pull the loop tight.

what kind of leadscrew are you using?

Edited 2 time(s). Last edit at 04/08/2021 11:55AM by MechaBits.

|

Re: Help with designing a belt tensioner April 08, 2021 11:32AM |

Registered: 6 years ago Posts: 1,007 |

Quote

MechaBits

where's your core XY MKSA?

[1.bp.blogspot.com]

In this pic you can just about see the belt tension point and single screw, i have a closed loop belt on here, though it doesnt need to be, it makes it easy to pull the loop tight.

I don't have a CoreXY.

Just have a look at the "Prusa" of the OP. It has more rails and Al profiles than a CoreXY but arranged in a quasi erratic way all assembled with flimsy 3D printed parts. A good belt tensioner won't change much and the one "designed" is a joke (not yours).

The OP could make two decents Prusa or one CoreXY

So ?

So ?It happens DD gives all the details to build a good CoreXY.

Edited 1 time(s). Last edit at 04/08/2021 11:42AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Help with designing a belt tensioner April 08, 2021 05:56PM |

Registered: 9 years ago Posts: 330 |

Quote

MKSA

Just have a look at the "Prusa" of the OP. It has more rails and Al profiles than a CoreXY but arranged in a quasi erratic way all assembled with flimsy 3D printed parts. A good belt tensioner won't change much and the one "designed" is a joke (not yours).

The OP could make two decents Prusa or one CoreXYSo ?

It happens DD gives all the details to build a good CoreXY.

Well, the one "designed" works better than the original desgin for me, as it solved 2 problems that I had (the wobble and the difficulty in tensioning the belt) so I'd say it isn't a complete joke. Also, the original question was whether the idler could be ameliorated for this purpose, and not if the printer itself was a good design, as I am not building a printer from scratch.

I know that the printer, especially in its original unmodified form, has lots of structural problems, including the use of 20x20 aluminum extrusions (which makes it too light and unstable), using linear rods instead of rails, using threaded rods instead of leadscrews, a custom extruder with suboptimal hobbed bolts but that was one of the few options that I could source locally in 2014 (I am not an engineer and didn't have lots of info on how to build a 3D printer back then, so I had to source a kit locally). However each modification I've added (I've designed most of them myself thanks to this community's inputs) made it better. It never will compare to Digital Dentist's design of course. I know how he meticulously thinks about everything and does it the way it should be done (I took some hints from how he was using the idler in his printer to modify mine). He even was kind enough to evaluate my printer a few years ago and comment on its flaws, some of which I've tried to correct (some of the other corrections required major design changes, which I couldn't implement due to lack of space and free time). I am a radiologist and I've used the prints on my daily practice and also won the first prize for best scientific presentation in our national society of radiology's yearly meeting in 2016, using these prints, so the print quality was adequate for my purpose. I still think it is quite reliable now with good output.

My aim is not to advocate this design, I know its problems, went through many of them myself, but to find ways to make it better whenever it is possible. I think trying to come up with solutions is a very entertaining process and you end up learning a lot, even if you fail some times.

And I promise, I'll build a proven CoreXY design next time, whenever next time is

|

Re: Help with designing a belt tensioner April 13, 2021 01:18PM |

Registered: 8 years ago Posts: 1,671 |

Feeling Idle today...in all these iterations I didnt need to support both ends of shaft, all have a good combo of shaft & bearing, though some shafts could be shorter, some where just dupes when I felt the printer was spitting out nicer parts than was already in use, seems a shame none are in use, found 3 more after pics.

|

Re: Help with designing a belt tensioner April 14, 2021 02:19PM |

Registered: 9 years ago Posts: 330 |

Wow, lots of choices. So many models, so little time

Meanwhile, I continue with experimenting with a slightly different approach. One goal that I had, to increase the rigidity of the system, was to try to replace some plastic parts with industrial alternatives or metal ones: With that goeal in mind, I tried to simplify the Z car's design, so that it can be made from metal. It is still work in progress but it looks like this now:

As I have no idea how to produce parts in metal I tried to upload the design to various CNC sites with online quotes (like 3DHubs) but the price suggestions I get makes this project somehow a vain attempt. The cheapest suggestion was around 350-400 USD for a single part (which drops to 30 if I order 100 ). So, I probably cannot go the CNC way. Someone suggested it was expensive because the vertical parts used to connect to Z rails required a lot of cutting and shaving from the metal block and also setup costs are high for CNC. A suggestion was to use sheat metal cutting but I don't know if an exact 90 degree angle can be made with sheet metal folding (that angle is quite important).

). So, I probably cannot go the CNC way. Someone suggested it was expensive because the vertical parts used to connect to Z rails required a lot of cutting and shaving from the metal block and also setup costs are high for CNC. A suggestion was to use sheat metal cutting but I don't know if an exact 90 degree angle can be made with sheet metal folding (that angle is quite important).

A solution could be to remove the vertical parts entirely, and use some kind of 90 degree brackets to make the connection. This would require me to find a bracket with the exact hole spaces, or try to drill them myself (which I don't know if it is possible with my dremel). I also have no idea how thick the car has to be. I just made it 5 mm thick, but this is just a number I came up with.

For the idler, I'd already bought this part form China, which arrived yesterday, and I think it can be attached to the new design by adding 2 additional holes to the car.

The question is wheter the tensioning mechanism is powerful enough to preserve the tension level.

Edited 1 time(s). Last edit at 04/14/2021 02:22PM by drmaestro.

Meanwhile, I continue with experimenting with a slightly different approach. One goal that I had, to increase the rigidity of the system, was to try to replace some plastic parts with industrial alternatives or metal ones: With that goeal in mind, I tried to simplify the Z car's design, so that it can be made from metal. It is still work in progress but it looks like this now:

As I have no idea how to produce parts in metal I tried to upload the design to various CNC sites with online quotes (like 3DHubs) but the price suggestions I get makes this project somehow a vain attempt. The cheapest suggestion was around 350-400 USD for a single part (which drops to 30 if I order 100

). So, I probably cannot go the CNC way. Someone suggested it was expensive because the vertical parts used to connect to Z rails required a lot of cutting and shaving from the metal block and also setup costs are high for CNC. A suggestion was to use sheat metal cutting but I don't know if an exact 90 degree angle can be made with sheet metal folding (that angle is quite important).

). So, I probably cannot go the CNC way. Someone suggested it was expensive because the vertical parts used to connect to Z rails required a lot of cutting and shaving from the metal block and also setup costs are high for CNC. A suggestion was to use sheat metal cutting but I don't know if an exact 90 degree angle can be made with sheet metal folding (that angle is quite important). A solution could be to remove the vertical parts entirely, and use some kind of 90 degree brackets to make the connection. This would require me to find a bracket with the exact hole spaces, or try to drill them myself (which I don't know if it is possible with my dremel). I also have no idea how thick the car has to be. I just made it 5 mm thick, but this is just a number I came up with.

For the idler, I'd already bought this part form China, which arrived yesterday, and I think it can be attached to the new design by adding 2 additional holes to the car.

The question is wheter the tensioning mechanism is powerful enough to preserve the tension level.

Edited 1 time(s). Last edit at 04/14/2021 02:22PM by drmaestro.

|

Re: Help with designing a belt tensioner April 14, 2021 02:39PM |

Registered: 8 years ago Posts: 1,671 |

I bought one too, even though the plastic one was fine, I prefer the slimmed down look, time will tell if it needs upgrading with some flanged bearings instead of the pulley. I think getting the part made in metal would be costly & a mistake. Better smaller custom parts for a simpler machine would be a better investment, finding a good mounting plate for linear rails is something i'm after, something small to make, but something with useful hole spacings, but something that doesnt need to be just for the carts, it could be used as a useful joint, or to mount hotend, then on your machine a span of 2020 on Z if you kept same design(though once your into it you could think of many ways to rebuild). but first try to do it with available parts

|

Re: Help with designing a belt tensioner April 14, 2021 03:26PM |

Registered: 11 years ago Posts: 5,780 |

@drmaestro

If you look at the shape of your proposed metal Z axis part it could easily be cut from a cheap piece of aluminum L stock. You might have to move a few parts around a little to make it work, but it isn't going to cost $400 to have someone mill it for you from a solid billet of aluminum. You don't need much more than a hack saw and drill to make it yourself.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you look at the shape of your proposed metal Z axis part it could easily be cut from a cheap piece of aluminum L stock. You might have to move a few parts around a little to make it work, but it isn't going to cost $400 to have someone mill it for you from a solid billet of aluminum. You don't need much more than a hack saw and drill to make it yourself.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Help with designing a belt tensioner April 15, 2021 01:19PM |

Registered: 8 years ago Posts: 1,671 |

Sorry, only registered users may post in this forum.