Home

>

Reprappers

>

Topic

Assembling V6-clone hot end for first time

Posted by qrp-gaijin

|

Assembling V6-clone hot end for first time June 01, 2021 06:39AM |

Registered: 3 years ago Posts: 93 |

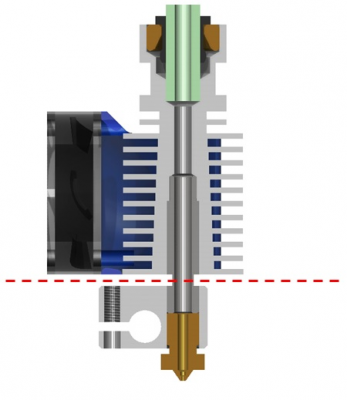

I have some questions about assembling a V6-clone hot end:

1. Is it correct that the threads on the cold end of the heat break should be coated with thermal grease, and the threads on the hot end of the heat break should be coated with anti-seize compound?

2. My hot end came with no thermal grease, so I bought some thermal grease intended for use on CPU heat sinks, to apply on the heat break threads. This paste is described as “HY-883-2g Thermal Grease: > 6.5W / mk cpu grease, sheet silicone grease, silver grease” that is “composed of carbon particulates that produce extremely high thermal conductivity”. Does this sound OK?

3. What would be a recommended anti-seize compound?

4. How do you ensure you apply an appropriate amount of torque when hot tightening? The advice at [wiki.e3d-online.com] says “3Nm of torque on the hot nozzle - this is about as much pressure as you can apply with one finger on a small spanner.” In practice, how do you measure that 3Nm of torque? Do you use a torque wrench before-hand to get a feeling for how much physical exertion is required to apply a torque of 3Nm, then simply use muscle memory to apply approximately the correct torque? Or are there any other ways of judging that you have applied enough, but not too much, torque?

1. Is it correct that the threads on the cold end of the heat break should be coated with thermal grease, and the threads on the hot end of the heat break should be coated with anti-seize compound?

2. My hot end came with no thermal grease, so I bought some thermal grease intended for use on CPU heat sinks, to apply on the heat break threads. This paste is described as “HY-883-2g Thermal Grease: > 6.5W / mk cpu grease, sheet silicone grease, silver grease” that is “composed of carbon particulates that produce extremely high thermal conductivity”. Does this sound OK?

3. What would be a recommended anti-seize compound?

4. How do you ensure you apply an appropriate amount of torque when hot tightening? The advice at [wiki.e3d-online.com] says “3Nm of torque on the hot nozzle - this is about as much pressure as you can apply with one finger on a small spanner.” In practice, how do you measure that 3Nm of torque? Do you use a torque wrench before-hand to get a feeling for how much physical exertion is required to apply a torque of 3Nm, then simply use muscle memory to apply approximately the correct torque? Or are there any other ways of judging that you have applied enough, but not too much, torque?

|

Re: Assembling V6-clone hot end for first time October 06, 2021 06:14AM |

Registered: 3 years ago Posts: 93 |

Quick update and a question. I ended up using neither thermal grease nor anti-seize compound on the threads, and for the hot tightening step I just judged torque by "feeling". The result was that hot end has been working more or less fine for the past couple of months. However, I had some bad jams recently. I think the cause was accidental unscrewing of the heat sink from the heat break.

During periodic maintenance, I would often give a quick twist on the heater block to ensure that the whole hot end was firmly mounted on the extruder and could not move relative to it. One day, when twisting the heat block, it in turn twisted the heat break, and since the heat sink was immovably gripped by its mounting hardware, the result was that the heat sink became slightly unscrewed from the heat break. I thought nothing of it and screwed it back on, but got occasional jams after that (sudden complete loss of extrusion, which could only be solved by rather forcefully pushing the filament through the hot nozzle). I think what must have happened is that by unscrewing the heat sink, it moved upwards relative to the heat break, and the plastic collar on the heat sink pulled the PTFE tube upwards with it. Then, even if I rescrewed things back together, the PTFE tube may have had a slight gap relative to the nozzle, if the plastic collar that holds the PTFE tube allowed the PTFE tube to slip.

Over some days the hot end jams got worse and worse, so I disassembled and reassembled the whole thing, and it seems to be working again now. I think the critical part was reseating the PTFE tube tightly against the nozzle.

It was a mistake for me to twist the heater block, which led to unscrewing the heat sink from the heat break. But even without such operator error, is the PTFE tube prone to become loose over time during normal usage? The whole hot end is subject to vibration, so it seems plausible that this might dislodge the PTFE tube over time, which might call for periodic re-seating of the PTFE tube. Is this periodic re-seating needed?

Also, is it possible for a poorly-seated PTFE tube to cause "partial" jams, where the printer is temporarily unable to extrude enough filament, but then recovers soon thereafter, which would cause inconsistent extrusion?

During periodic maintenance, I would often give a quick twist on the heater block to ensure that the whole hot end was firmly mounted on the extruder and could not move relative to it. One day, when twisting the heat block, it in turn twisted the heat break, and since the heat sink was immovably gripped by its mounting hardware, the result was that the heat sink became slightly unscrewed from the heat break. I thought nothing of it and screwed it back on, but got occasional jams after that (sudden complete loss of extrusion, which could only be solved by rather forcefully pushing the filament through the hot nozzle). I think what must have happened is that by unscrewing the heat sink, it moved upwards relative to the heat break, and the plastic collar on the heat sink pulled the PTFE tube upwards with it. Then, even if I rescrewed things back together, the PTFE tube may have had a slight gap relative to the nozzle, if the plastic collar that holds the PTFE tube allowed the PTFE tube to slip.

Over some days the hot end jams got worse and worse, so I disassembled and reassembled the whole thing, and it seems to be working again now. I think the critical part was reseating the PTFE tube tightly against the nozzle.

It was a mistake for me to twist the heater block, which led to unscrewing the heat sink from the heat break. But even without such operator error, is the PTFE tube prone to become loose over time during normal usage? The whole hot end is subject to vibration, so it seems plausible that this might dislodge the PTFE tube over time, which might call for periodic re-seating of the PTFE tube. Is this periodic re-seating needed?

Also, is it possible for a poorly-seated PTFE tube to cause "partial" jams, where the printer is temporarily unable to extrude enough filament, but then recovers soon thereafter, which would cause inconsistent extrusion?

|

Re: Assembling V6-clone hot end for first time October 07, 2021 10:45AM |

Registered: 11 years ago Posts: 5,780 |

The unscrewing of the heat break from the heatsink is one of the major flaws in the E3D design. There is no way to tighten the threads enough to ensure it won't loosen without twisting the little neck of the heatbreak. I replaced the V6 with a cheapo hot-end that has worked perfectly for the two years or so it has been on my printer. It's a little longer than the V6, but holds the heatbreak into the heatsink using set screws. The fan bracket is metal and screws to the heatsink too, so it never rotates and never bumps into the heater block and melts. IRIC I paid $15 for the kit via Aliexpress- it came with a 50W heater and perfectly adequate thermistor cartridge that I eventually replaced with a PT100 sensor. The fan it comes with is crap, so I spent an extra $7 to buy a Sunon fan.

[drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

[drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Assembling V6-clone hot end for first time October 07, 2021 10:12PM |

Registered: 6 years ago Posts: 61 |

I also have the XCR3D hot end (thanks to your blog post) and I replaced the M3 set screws with M3 countersunk screws long enough to reach past the fins. So much easier to find when I'm doing maintenance, and less likely to strip out the hex socket. I still use anti-seize since it's stainless into aluminum, and I haven't had a problem.

I replaced the fan with a 40mm noctua and printed a slim adapter to the 30mm frame.

I replaced the fan with a 40mm noctua and printed a slim adapter to the 30mm frame.

Sorry, only registered users may post in this forum.