Home

>

Reprappers

>

Topic

Exoslide Core XY with "trough" down the middle of the bed?

Posted by dlc60

|

Exoslide Core XY with "trough" down the middle of the bed? May 30, 2022 02:34PM |

Registered: 7 years ago Posts: 619 |

I have an odd one. I built a custom CoreXY using a Duet Maestro and Exoslide "rail runners".

I built it using "standard" length extruded aluminum rails so I didn't need to do any custom cutting or finishing.

It uses a standard 200mm square aluminum hotbed with 3mm borosilicate glass for its surface and a Bowden E3Dv6 hot end. The bed clamped on the edges.

Now the weird part.

If I am printing single pieces or relatively large X/Y surface parts it works great.

If I print something with lots of islands, like the "cute octopus" for instance, at some point in the print, an island will take a hit and come dislodged.

I have checked my clearances, trammed the bed, made sure my surface doesn't cantilever, raised my Z-hop to 1mm, and even slowed the printer down to 40mm/s print, 80mm/s travel.

Still, I get an island hit and the print goes sideways. The PLA I am using sticks solidly to the glass, and I hear the "clink" when the strike happens.

I spent some time with my gap gauge at .1mm measuring the nozzle to plat height. At all four corners I will get a setting of 0.1mm and at the center of the bed, 0.15mm. Running with that, I find that I have a 0.5mm "ditch" that runs across the bed at around 100mm X and all along the Y axis.

Huh? The way that I designed this printer is that the hotend carriage travels along the rail in the Y axis and that rail is carried in the X axis.

I have not over constrained any of the Exoslide rollers, and I have very carefully tensioned the belts so that they run as close to perfectly parallel to each other as I can measure them.

So, why does it look like there is a trough down the middle of the plate at Y = (about) 100mm? It appears that when the nozzle leaves the center, shortly thereafter it is not as high as the controller thinks it is and it strikes a island. The strikes always occur along the X axis.

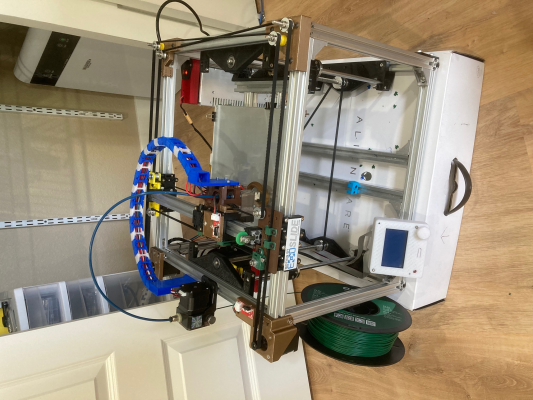

Has anyone ever seen an oddity like this? I'd love another idea of where to look. I am completely baffled and ready to scrap the whole thing or just relegate it to only certain jobs. Here is a picture of it.

Sorry, for some reason the picture got rotated...

oddly,

DLC

Edited 1 time(s). Last edit at 05/30/2022 02:36PM by dlc60.

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

I built it using "standard" length extruded aluminum rails so I didn't need to do any custom cutting or finishing.

It uses a standard 200mm square aluminum hotbed with 3mm borosilicate glass for its surface and a Bowden E3Dv6 hot end. The bed clamped on the edges.

Now the weird part.

If I am printing single pieces or relatively large X/Y surface parts it works great.

If I print something with lots of islands, like the "cute octopus" for instance, at some point in the print, an island will take a hit and come dislodged.

I have checked my clearances, trammed the bed, made sure my surface doesn't cantilever, raised my Z-hop to 1mm, and even slowed the printer down to 40mm/s print, 80mm/s travel.

Still, I get an island hit and the print goes sideways. The PLA I am using sticks solidly to the glass, and I hear the "clink" when the strike happens.

I spent some time with my gap gauge at .1mm measuring the nozzle to plat height. At all four corners I will get a setting of 0.1mm and at the center of the bed, 0.15mm. Running with that, I find that I have a 0.5mm "ditch" that runs across the bed at around 100mm X and all along the Y axis.

Huh? The way that I designed this printer is that the hotend carriage travels along the rail in the Y axis and that rail is carried in the X axis.

I have not over constrained any of the Exoslide rollers, and I have very carefully tensioned the belts so that they run as close to perfectly parallel to each other as I can measure them.

So, why does it look like there is a trough down the middle of the plate at Y = (about) 100mm? It appears that when the nozzle leaves the center, shortly thereafter it is not as high as the controller thinks it is and it strikes a island. The strikes always occur along the X axis.

Has anyone ever seen an oddity like this? I'd love another idea of where to look. I am completely baffled and ready to scrap the whole thing or just relegate it to only certain jobs. Here is a picture of it.

Sorry, for some reason the picture got rotated...

oddly,

DLC

Edited 1 time(s). Last edit at 05/30/2022 02:36PM by dlc60.

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Exoslide Core XY with "trough" down the middle of the bed? May 30, 2022 07:31PM |

Registered: 3 years ago Posts: 92 |

My guess is that it's due to the bowden extruder. It can't be the X/Y motion system or the previous layers would follow the same curved shape and wouldn't hit.

If the 1/8" aluminum bed is mounted solidly to that 2020 extrusion carrier, heat expansion could cause it to bow. It needs to be mounted in a way that it can expand freely. But again, as long as the temperature remains stable throughout the print, it should only cause issue with the first few layers and then level out.

The bowden, however, is nothing but trouble. The time delay between motor movement and flow through the nozzle means that when printing an island, a little bit of extra plastic is extruded at the end before the nozzle moves away. And with Z hop, it will be pulled upward into an even taller obstacle.

Go check out rq3's threads in the tech-talk section and make a Schnekenstruder. It's the best

If the 1/8" aluminum bed is mounted solidly to that 2020 extrusion carrier, heat expansion could cause it to bow. It needs to be mounted in a way that it can expand freely. But again, as long as the temperature remains stable throughout the print, it should only cause issue with the first few layers and then level out.

The bowden, however, is nothing but trouble. The time delay between motor movement and flow through the nozzle means that when printing an island, a little bit of extra plastic is extruded at the end before the nozzle moves away. And with Z hop, it will be pulled upward into an even taller obstacle.

Go check out rq3's threads in the tech-talk section and make a Schnekenstruder. It's the best

|

Re: Exoslide Core XY with "trough" down the middle of the bed? May 31, 2022 08:30AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Exoslide Core XY with "trough" down the middle of the bed? June 05, 2022 12:12PM |

Registered: 8 years ago Posts: 4 |

Given that a flat surface across the bed measures differences on the bed itself, I ask the sale as DDentist, is the glass flat? Easiest way to tel lis rotate it 90º (you have a square bed?), and test again, if the issue repeats now in X axis trough, then try turning the glass over, the other side may be flatter...

(glass made by "floating" is not normally calibrated, and will have differences of thickness, can depend on where you got your glass from too)

Also, the Bowden could be dragging the head if it has friction in a certain point.. I prefer to make my cable chains vertical and let them rotate freely around the pivot point on carriage and frame, I feel it doesn't "weigh" so much on the mech..

However, as you mentioned measuring the bed had a trough, I feel this is less likely to be the cause of the trough

HTH!

(glass made by "floating" is not normally calibrated, and will have differences of thickness, can depend on where you got your glass from too)

Also, the Bowden could be dragging the head if it has friction in a certain point.. I prefer to make my cable chains vertical and let them rotate freely around the pivot point on carriage and frame, I feel it doesn't "weigh" so much on the mech..

However, as you mentioned measuring the bed had a trough, I feel this is less likely to be the cause of the trough

HTH!

Sorry, only registered users may post in this forum.