Folger Prusa i3 Kit from ebay

Posted by Waltermixx

|

Re: Folger Prusa i3 Kit from ebay November 18, 2014 09:14PM |

Registered: 9 years ago Posts: 134 |

Actually what it's doing now is just going back and forth again like I have the pins on the ramps miswired.

It WAS feeding to where I could see it go through the extruder...but now it's stopped, and instead just turns one click to feed, then the next click to reverse, ad nauseum.

I don't have a problem with figuring things out like this, but when the same thing doesn't create the same result...that's a touch infuriating.

It WAS feeding to where I could see it go through the extruder...but now it's stopped, and instead just turns one click to feed, then the next click to reverse, ad nauseum.

I don't have a problem with figuring things out like this, but when the same thing doesn't create the same result...that's a touch infuriating.

|

Re: Folger Prusa i3 Kit from ebay November 18, 2014 10:54PM |

Registered: 9 years ago Posts: 110 |

Quote

Gannicus

Actually what it's doing now is just going back and forth again like I have the pins on the ramps miswired.

It WAS feeding to where I could see it go through the extruder...but now it's stopped, and instead just turns one click to feed, then the next click to reverse, ad nauseum.

I don't have a problem with figuring things out like this, but when the same thing doesn't create the same result...that's a touch infuriating.

This sounds like the same problem that nuked worker was reporting a few pages back. This was his response when he figured out his issue

Quote

NukedWorker

So I went ahead and switched the X and Extruder motors. And it still was doing the jig. So I knew then it had to be something I did. After sitting a few minutes just brewing and stewing, I figured, go back to the beginning - and there it was. The 2 middle wires were in the pin connector wrong. Switched them up and VOILA! I didn't know whether to laugh or cry.

Hope this helps

Edited 1 time(s). Last edit at 11/18/2014 11:53PM by louspinuso.

|

Re: Folger Prusa i3 Kit from ebay November 18, 2014 11:12PM |

Registered: 9 years ago Posts: 134 |

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 12:01AM |

Registered: 9 years ago Posts: 110 |

Quote

Gannicus

Is the pin out on the RAMPS side for the extruder not the same as all the other steppers? Cause I have all five pinned out the same way:

GREEN

YELLOW

GREY

RED

Pin out should be the same for all the steppers I was just commenting that this sounds exactly like the problem you are having and was hoping the information could help. Have you tried swapping the motor?

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 07:23AM |

Registered: 9 years ago Posts: 134 |

So here are my morning list of issues I need to get fixed, if anyone has had similar issues and found the fix, I'd love to hear it, as I am out of ideas.

1) Extruder isn't extruding. Extruder just turning one click forward, then one click back it just won't pull in the filament. - Everything else works correctly, VREFS have been adjusted to the amounts specified in this thread by the Folgertech guys

2) My reprap discount full graphic smart controller won't display anything. Just goes to a blue screen. I've tried every fix I could find on the internet, and it still will not work. Board beeps when I push in the knob, but otherwise screen light blue. Adjust contrast pot, it's not that. Added U8glib to my libraries etc as well...no dice. Folgertech's Marlin code is pretty straight forward, and the line was actually already uncommented...so it should have just been plug and play. However, like everything else in this project that, despite the code, and the electronics being correct...it simply isn't. Maybe I have to do a rain dance while standing on my head with a mason jar full of snake skin in one hand and a slim jim in the other to get everything to work?

3) Leveling the heat bed/ build platform. Here's another one. The Y trolley HAS to be level...the way the frame on which it rides is built assures that. I throw the bed on, put the springs on and the bolts, and regardless of what I do, one end needs to go further down than is possible to make it level. When I adjust my Z for the home position, it's perfect. Can barely move a sheet of paper under it. It goes to the center, and there's an eight of inch between the nozzle and the bed. I'm planning on getting taller springs, and longer screws. That's the only reasonable fix for that. But if someone has some other idea for this, or the ones above...I'd greatly appreciate it. I'm a tech tinklerer and maker by nature, but this project, nothing is working as programmed / installed, and it's driving me bat shit crazy.

Edited 1 time(s). Last edit at 11/19/2014 07:25AM by Gannicus.

1) Extruder isn't extruding. Extruder just turning one click forward, then one click back it just won't pull in the filament. - Everything else works correctly, VREFS have been adjusted to the amounts specified in this thread by the Folgertech guys

2) My reprap discount full graphic smart controller won't display anything. Just goes to a blue screen. I've tried every fix I could find on the internet, and it still will not work. Board beeps when I push in the knob, but otherwise screen light blue. Adjust contrast pot, it's not that. Added U8glib to my libraries etc as well...no dice. Folgertech's Marlin code is pretty straight forward, and the line was actually already uncommented...so it should have just been plug and play. However, like everything else in this project that, despite the code, and the electronics being correct...it simply isn't. Maybe I have to do a rain dance while standing on my head with a mason jar full of snake skin in one hand and a slim jim in the other to get everything to work?

3) Leveling the heat bed/ build platform. Here's another one. The Y trolley HAS to be level...the way the frame on which it rides is built assures that. I throw the bed on, put the springs on and the bolts, and regardless of what I do, one end needs to go further down than is possible to make it level. When I adjust my Z for the home position, it's perfect. Can barely move a sheet of paper under it. It goes to the center, and there's an eight of inch between the nozzle and the bed. I'm planning on getting taller springs, and longer screws. That's the only reasonable fix for that. But if someone has some other idea for this, or the ones above...I'd greatly appreciate it. I'm a tech tinklerer and maker by nature, but this project, nothing is working as programmed / installed, and it's driving me bat shit crazy.

Edited 1 time(s). Last edit at 11/19/2014 07:25AM by Gannicus.

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 07:34AM |

Registered: 9 years ago Posts: 1,011 |

1) Check pololu's output voltage. You need 0.18v on extruder, X and Z drivers ; and 0.66v on the Y driver output.

2) Check Marlin's configuration and library installation, it's a soft problem.

3) Your glass plate/support plate is not flat. It's maybe two fails working together. Try to flip or rotate it to get a better balance between hi and low points.

Edited 2 time(s). Last edit at 11/19/2014 07:38AM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

2) Check Marlin's configuration and library installation, it's a soft problem.

3) Your glass plate/support plate is not flat. It's maybe two fails working together. Try to flip or rotate it to get a better balance between hi and low points.

Edited 2 time(s). Last edit at 11/19/2014 07:38AM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 09:31AM |

Registered: 9 years ago Posts: 134 |

Quote

Zavashier

1) Check pololu's output voltage. You need 0.18v on extruder, X and Z drivers ; and 0.66v on the Y driver output.

2) Check Marlin's configuration and library installation, it's a soft problem.

3) Your glass plate/support plate is not flat. It's maybe two fails working together. Try to flip or rotate it to get a better balance between hi and low points.

Actually Zavashier, John from Folgertech recommends the following voltages on the driver boards:

Y 0.55V

Z 0.35V

X 0.33V

E0 0.35V

This is all assuming Volt DC on your multimeter.

As far as the LCD, I made no changes to the code. As I said, the support for the LCD was already un-commented. That being said, in the Folgertech provided Marlins file, the line reads: "#define REPRAP_DISCOUNT_SMART_CONTROLLER" where the reprap approved code is supposed to be "#define REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER"

I even tried that. Commenting out the #define REPRAP_DISCOUNT_SMART_CONTROLLER, and adding the other, un-commented. Even found a post where it was recommended to add: "#define U8glib.h" to line 1 of configuration.h.

Neither worked. So I've reverted it back to stock.

As you can see, I've tried everything I can find on the internet as to how to get it working. This stuff isn't rocket science after all, which is what is getting under my skin at this point. I should have had this thing up and printing like a boss days ago. But things aren't working as they are supposed to when set correctly, or work reliably when they should.

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 10:02AM |

Registered: 9 years ago Posts: 1,011 |

That voltage is much higher thant the Pololu's calculation formula (provided in the Folger's drive thru...) shows. Some of my motors was too hot with some loose steps. So I did the calculation and found that values. My i3 is now pretty quiet, the motors are cold, and everything is working propperly. Choose the values you like.

I have the same display. Working. Here's my configuration.h. The library have to be installed into the Arduino library folder to compile properly. Maybe you already know.

Edited 1 time(s). Last edit at 11/19/2014 10:03AM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

I have the same display. Working. Here's my configuration.h. The library have to be installed into the Arduino library folder to compile properly. Maybe you already know.

Edited 1 time(s). Last edit at 11/19/2014 10:03AM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 11:28AM |

Registered: 10 years ago Posts: 477 |

Quote

louspinuso

Quote

SteveRoy

As Gannicus posted - for the Y end stop, if it's at the back it's a MIN, if at the front it's a MAX. You need to change the firmware and the position on the RAMPS to suit.

Same with X, if it's on the left it's a MIN, on the right a MAX

Steve

See, this is what's blowing my mind. The X endstop is on the right but it's in the MIN position. I think that the more I look at this, what's really going on is that the printer is just moving to whatever direction it thinks home is stopping when it hits the endstop and then this is taking over:

If your X endstop is on the right, and when you press + in pronterface the carriage should go right. Then if you set X to a MAX end stop in Marlin and click the X home in pronterface the carriage should go right.

The end stop should be wired to X MAX on the RAMPS otherwise it won't stop the carriage when tripped.

Quote

#define min_software_endstops true // If true, axis won't move to coordinates less than HOME_POS. #define max_software_endstops true // If true, axis won't move to coordinates greater than the defined lengths below.

Which is what I think was messing with my ability to move the motors in both directions until it forced an endstop touch on the home position and then it was like "Oh, you have plenty of space to go in this direction" and allowed me to go. I really believe this was the source of the endstop errors I was getting ("echo:endstops hit: X:-49.94").

Don't need to change this

Quote

And still the HOME_DIR for all of my axis are set to -1

// ENDSTOP SETTINGS: // Sets direction of endstops when homing; 1=MAX, -1=MIN #define X_HOME_DIR -1 #define Y_HOME_DIR -1 #define Z_HOME_DIR -1

X end stop on the left, Y at the back, Z on the bottom

Quote

which should indicate that the motors should move to the opposite of where I would expect them to go (except for Z) but they don't. I almost feel like I need to drag myself through the code for Marlin to figure out what the thing is doing but I think just flipping my y axis plug will actually make this work how I want, as opposed to switching the line:

#define INVERT_Y_DIR false // for Mendel set to true, for Orca set to false

to true, though that may cause even more trouble for me.

You can either change the code between true/false or reverse the plug on the RAMPS - stand difference

Steve

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 11:45AM |

Registered: 9 years ago Posts: 134 |

Steve, I just gave in and relocated the X end stop to the left. No matter what I did, it didn't want to work on the right hand side. /shrug

In the end, cutting some wire ties fiddling with wire loom was worth the time spent instead of the Vodoo Magic I was trying in order to get it to work properly.

In the end, cutting some wire ties fiddling with wire loom was worth the time spent instead of the Vodoo Magic I was trying in order to get it to work properly.

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 11:46AM |

Registered: 9 years ago Posts: 134 |

Quote

Zavashier

That voltage is much higher thant the Pololu's calculation formula (provided in the Folger's drive thru...) shows. Some of my motors was too hot with some loose steps. So I did the calculation and found that values. My i3 is now pretty quiet, the motors are cold, and everything is working propperly. Choose the values you like.

I have the same display. Working. Here's my configuration.h. The library have to be installed into the Arduino library folder to compile properly. Maybe you already know.

Those figures seem entirely way too low to me...based on the suggested values,but will check it out.

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 12:12PM |

Registered: 10 years ago Posts: 477 |

Quote

Gannicus

Steve, I just gave in and relocated the X end stop to the left. No matter what I did, it didn't want to work on the right hand side. /shrug

In the end, cutting some wire ties fiddling with wire loom was worth the time spent instead of the Vodoo Magic I was trying in order to get it to work properly.

I just looked at their ebay store and noticed they put the X motor on the right side, though that shouldn't make a difference to end stops etc, the motor still has to turn clockwise to make the carriage move right.

Steve

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 02:26PM |

Registered: 9 years ago Posts: 110 |

Quote

SteveRoy

If your X endstop is on the right, and when you press + in pronterface the carriage should go right. Then if you set X to a MAX end stop in Marlin and click the X home in pronterface the carriage should go right.

The end stop should be wired to X MAX on the RAMPS otherwise it won't stop the carriage when tripped.

Quote

louspinuso

And still the HOME_DIR for all of my axis are set to -1

// ENDSTOP SETTINGS: // Sets direction of endstops when homing; 1=MAX, -1=MIN #define X_HOME_DIR -1 #define Y_HOME_DIR -1 #define Z_HOME_DIR -1

X end stop on the left, Y at the back, Z on the bottom

Quote

louspinuso

which should indicate that the motors should move to the opposite of where I would expect them to go (except for Z) but they don't. I almost feel like I need to drag myself through the code for Marlin to figure out what the thing is doing but I think just flipping my y axis plug will actually make this work how I want, as opposed to switching the line:

#define INVERT_Y_DIR false // for Mendel set to true, for Orca set to false

to true, though that may cause even more trouble for me.

You can either change the code between true/false or reverse the plug on the RAMPS - stand difference

Steve

This really helped, thanks. And also this is exactly as I expected it be since 0,0,0 being the top right corner of the bed means everything on the X and Y planes are negative (z is still positive since negative is down through the bed) since X,Y coordinates of 0,0 for your home give you four coordinates to plot into and if you want it all to be + (all x and y values in their positive values) you would have to set your home to the bottom left of your bed and at that point you could set the endstops all to MIN since 0,0 will be the minimum x and minimum y coordinate. This would also indicate a setting of:

// ENDSTOP SETTINGS: // Sets direction of endstops when homing; 1=MAX, -1=MIN #define X_HOME_DIR -1 #define Y_HOME_DIR -1 #define Z_HOME_DIR -1

If you were to set the bottom right of the bed as your 0,0 then all your y is positive but all your x is negative so you should set your y min endstop to home there and your x would be at it's MAX endstop since 0 x coordinate is the highest value in that quadrant (which is all negatives at that point) and you should have the code set as:

// ENDSTOP SETTINGS: // Sets direction of endstops when homing; 1=MAX, -1=MIN #define X_HOME_DIR 1 #define Y_HOME_DIR -1 #define Z_HOME_DIR -1

Setting your 0,0 home location to the Top Left, your Y coords are all negative and your X's are all positive so you should be set like this:

// ENDSTOP SETTINGS: // Sets direction of endstops when homing; 1=MAX, -1=MIN #define X_HOME_DIR -1 #define Y_HOME_DIR 1 #define Z_HOME_DIR -1

And setting it as I've seen everyone here setting it as home to the top right means that all the x and all the y coordinates are going to be negative so that section should look like this:

// ENDSTOP SETTINGS: // Sets direction of endstops when homing; 1=MAX, -1=MIN #define X_HOME_DIR 1 #define Y_HOME_DIR 1 #define Z_HOME_DIR -1

Which is what my code is now and home for each axis goes in the appropriate direction.

At this point I'm >99% sure I understand this correctly and this is working well for me. Once I'm done with work, I'll go home and start test feeding filament through my extruder and if that goes smoothly, I'll run a print job for my first calibration cube tonight.

Thanks to everyone on this forum for helping out

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 05:27PM |

Registered: 9 years ago Posts: 134 |

Here's the new news.

During the day, I got to thinking...the Folgertech Marlin software on their Google Drive was probably the cause of EVERY problem I was having.

So, I downloaded the fresh copy of Marlin from github and Dooms101 configuration.h he posted on page 2, and recompiled and uploaded.

Plugged in the LCD... and poof. Magic. Everything works. EXCEPT for the hotend.

Here's where I'm at. The extruder IS feeding INTO the hotend now. But once the entire length gets to the hotend, while the extruder will TRY to push it into the hotend, it just sits there.

I've included a youtube video. You can see the screen working, and the temp. I turned the hotend all the way up to 245C...and STILL you can hear it once I hit extrude, the bang sound of the extruder feeding it into the hotend, and it sounds like it just bouncing off a solid object in the hotend.

I want to get this thing printing already. The stepper drivers have all been dialed in to John's specifications from an earlier post received from the guys at Folgertech that everyone says work like a dream.

Well, without further dudes...on with the show.

YOUTUBE LINK

During the day, I got to thinking...the Folgertech Marlin software on their Google Drive was probably the cause of EVERY problem I was having.

So, I downloaded the fresh copy of Marlin from github and Dooms101 configuration.h he posted on page 2, and recompiled and uploaded.

Plugged in the LCD... and poof. Magic. Everything works. EXCEPT for the hotend.

Here's where I'm at. The extruder IS feeding INTO the hotend now. But once the entire length gets to the hotend, while the extruder will TRY to push it into the hotend, it just sits there.

I've included a youtube video. You can see the screen working, and the temp. I turned the hotend all the way up to 245C...and STILL you can hear it once I hit extrude, the bang sound of the extruder feeding it into the hotend, and it sounds like it just bouncing off a solid object in the hotend.

I want to get this thing printing already. The stepper drivers have all been dialed in to John's specifications from an earlier post received from the guys at Folgertech that everyone says work like a dream.

Well, without further dudes...on with the show.

YOUTUBE LINK

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 05:28PM |

Registered: 9 years ago Posts: 110 |

Quote

Gannicus

Actually what it's doing now is just going back and forth again like I have the pins on the ramps miswired.

It WAS feeding to where I could see it go through the extruder...but now it's stopped, and instead just turns one click to feed, then the next click to reverse, ad nauseum.

I don't have a problem with figuring things out like this, but when the same thing doesn't create the same result...that's a touch infuriating.

Ok, so I just finally got to the point where I'm putting plastic through the extruder and I had the same problem so I pulled the filament out and made sure the tip was as straight as possible and re-fed it. I gave it the slightest twist as it was taking it in and then, just like that, it started feeding. I'm thinking that the filament might be catching an edge in extruder assembly and just getting stuck.

Lou

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 05:35PM |

Registered: 9 years ago Posts: 110 |

Ok, so I've finally put plastic through my hot end and everything seems to be working right so I went to load a calibration cube to print and I watched the hot end temp get up to about 70C and then start dropping. The hot bed kept heating, but really slowly. I know I got the hot end up to temp to get the test piece to feed so I'm not sure what's going on. At this point I've umplugged everything and I'm letting the whole thing cool off. I know that there has been talk about taking a long time to heat up, but has anyone ever seen their hotend suddenly start losing heat? Also it's a bit colder in my house than regular. At the moment it's probably right around 20c but normally closer to 24c. Could that make that much of a difference? I do plan on making an enclosure for the kit anyway (like I stated in an earlier post) Anyone think that will help? Maybe a fan to cool the ramps board? one of those mosfets does seem to get pretty warm.

Thoughts?

Thoughts?

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 05:38PM |

Registered: 9 years ago Posts: 110 |

Quote

Gannicus

Here's the new news.

During the day, I got to thinking...the Folgertech Marlin software on their Google Drive was probably the cause of EVERY problem I was having.

So, I downloaded the fresh copy of Marlin from github and Dooms101 configuration.h he posted on page 2, and recompiled and uploaded.

Plugged in the LCD... and poof. Magic. Everything works. EXCEPT for the hotend.

Here's where I'm at. The extruder IS feeding INTO the hotend now. But once the entire length gets to the hotend, while the extruder will TRY to push it into the hotend, it just sits there.

I've included a youtube video. You can see the screen working, and the temp. I turned the hotend all the way up to 245C...and STILL you can hear it once I hit extrude, the bang sound of the extruder feeding it into the hotend, and it sounds like it just bouncing off a solid object in the hotend.

I want to get this thing printing already. The stepper drivers have all been dialed in to John's specifications from an earlier post received from the guys at Folgertech that everyone says work like a dream.

Well, without further dudes...on with the show.

YOUTUBE LINK

That's teh same sound mine was making when it got stuck on feeding. I pulled the filament out and I was able to straighten the tip out just enough to get it to feed (though it seems like you're already feeding now) so my guess is that there is something in the way in your extruder. I hate to say it, but you may need to take it apart to check. I still haven't taken mine apart so I'm not sure what is involved in that feat.

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 05:55PM |

Registered: 9 years ago Posts: 134 |

Quote

louspinuso

Quote

Gannicus

Here's the new news.

During the day, I got to thinking...the Folgertech Marlin software on their Google Drive was probably the cause of EVERY problem I was having.

So, I downloaded the fresh copy of Marlin from github and Dooms101 configuration.h he posted on page 2, and recompiled and uploaded.

Plugged in the LCD... and poof. Magic. Everything works. EXCEPT for the hotend.

Here's where I'm at. The extruder IS feeding INTO the hotend now. But once the entire length gets to the hotend, while the extruder will TRY to push it into the hotend, it just sits there.

I've included a youtube video. You can see the screen working, and the temp. I turned the hotend all the way up to 245C...and STILL you can hear it once I hit extrude, the bang sound of the extruder feeding it into the hotend, and it sounds like it just bouncing off a solid object in the hotend.

I want to get this thing printing already. The stepper drivers have all been dialed in to John's specifications from an earlier post received from the guys at Folgertech that everyone says work like a dream.

Well, without further dudes...on with the show.

YOUTUBE LINK

That's teh same sound mine was making when it got stuck on feeding. I pulled the filament out and I was able to straighten the tip out just enough to get it to feed (though it seems like you're already feeding now) so my guess is that there is something in the way in your extruder. I hate to say it, but you may need to take it apart to check. I still haven't taken mine apart so I'm not sure what is involved in that feat.

Yeah I'm SO not interested in going that route. LOL

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 06:21PM |

Registered: 9 years ago Posts: 208 |

taking apart the extruder is pretty straight forward, examining it will help you understand why it works and why it wont.

I have to admit i was initially intimidated by the idea, but then the air-prints and jamming started to annoy me,

since i re-arranged the assemply (very little to it...) my prints are solid.

[www.flickr.com]

here are the pictures i took with mine apart, and re configuring the hot end, cool end, and nozzle.

Be sure to unload the filament before taking it apart, (heat up the extruder to 230, then extrude -100 mm (chances are it will come out before you get to 100)

Be sure to unload the filament before taking it apart, (heat up the extruder to 230, then extrude -100 mm (chances are it will come out before you get to 100)

but you can stop the motor once you do. ( this is all done in repetier host)

Cheers.

to take it appart:

unscrew the two screws securing the fan to the extruder assembly - it's a very long screw and screws into the stepper motor...

gently pull out the screws the fan, and the heat sink from the assembly, the cooling block and hot end/nozzle will fall abit, but the heater wire and termister will hold it up so be careful.

next you remove the two top screws that hold the filament feeder assembly it's in three pieces... front, back and small pulley/bearing to press the filament against the teeth of the gear on the stepper motor.

that's pretty much it for dissembling the extruder/hot end... be careful if you are removing the tube/hot end from the cooling block... loosen the two bolts first... and then the little set scree holding the hot end tube in the cooling block.

just loosen that set screw, dont remove it, so you dont lose it.

hope that helps a bit

Edited 1 time(s). Last edit at 11/19/2014 06:50PM by Waltermixx.

I have to admit i was initially intimidated by the idea, but then the air-prints and jamming started to annoy me,

since i re-arranged the assemply (very little to it...) my prints are solid.

[www.flickr.com]

here are the pictures i took with mine apart, and re configuring the hot end, cool end, and nozzle.

Be sure to unload the filament before taking it apart, (heat up the extruder to 230, then extrude -100 mm (chances are it will come out before you get to 100)

Be sure to unload the filament before taking it apart, (heat up the extruder to 230, then extrude -100 mm (chances are it will come out before you get to 100)but you can stop the motor once you do. ( this is all done in repetier host)

Cheers.

to take it appart:

unscrew the two screws securing the fan to the extruder assembly - it's a very long screw and screws into the stepper motor...

gently pull out the screws the fan, and the heat sink from the assembly, the cooling block and hot end/nozzle will fall abit, but the heater wire and termister will hold it up so be careful.

next you remove the two top screws that hold the filament feeder assembly it's in three pieces... front, back and small pulley/bearing to press the filament against the teeth of the gear on the stepper motor.

that's pretty much it for dissembling the extruder/hot end... be careful if you are removing the tube/hot end from the cooling block... loosen the two bolts first... and then the little set scree holding the hot end tube in the cooling block.

just loosen that set screw, dont remove it, so you dont lose it.

hope that helps a bit

Edited 1 time(s). Last edit at 11/19/2014 06:50PM by Waltermixx.

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 06:44PM |

Registered: 9 years ago Posts: 134 |

Got it. Had to push it in harder, and twist it. Finally grabbed.

Tried to print a test box, and from home to start printing, the nozzle lifted way higher than the paper thick closeness I had set previously.

And just squirted out black strands all over the place.

Why would it raise up higher than where I had set my homes?

I want it right on the glass, not 1/4 inch above it.

Tried to print a test box, and from home to start printing, the nozzle lifted way higher than the paper thick closeness I had set previously.

And just squirted out black strands all over the place.

Why would it raise up higher than where I had set my homes?

I want it right on the glass, not 1/4 inch above it.

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 09:33PM |

Registered: 11 years ago Posts: 18 |

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 09:53PM |

Registered: 9 years ago Posts: 7 |

Quote

louspinuso

Ok, so I've finally put plastic through my hot end and everything seems to be working right so I went to load a calibration cube to print and I watched the hot end temp get up to about 70C and then start dropping. The hot bed kept heating, but really slowly. I know I got the hot end up to temp to get the test piece to feed so I'm not sure what's going on. At this point I've umplugged everything and I'm letting the whole thing cool off. I know that there has been talk about taking a long time to heat up, but has anyone ever seen their hotend suddenly start losing heat? Also it's a bit colder in my house than regular. At the moment it's probably right around 20c but normally closer to 24c. Could that make that much of a difference? I do plan on making an enclosure for the kit anyway (like I stated in an earlier post) Anyone think that will help? Maybe a fan to cool the ramps board? one of those mosfets does seem to get pretty warm.

Thoughts?

I am guessing that you hit start print and this happened. My bed took a while to heat up too, sometimes up to 20 min to hit 100c. Normal operation of the printer is to heat the bed to the set temp, then heat the extruder(it heats much faster). If you have the extruder at temp while waiting on the bed, the filament inside the extruder will get soft and fail to feed properly. I see this anytime my extruder is sitting for more than a few minutes without feeding. I put some insulation between the bed and the y carriage. This sped up my bed heat time a small amount. I recently added an enclosure. Now, the bed is up to temp in about 5min.

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 10:23PM |

Registered: 9 years ago Posts: 110 |

Quote

Gannicus

Got it. Had to push it in harder, and twist it. Finally grabbed.

Tried to print a test box, and from home to start printing, the nozzle lifted way higher than the paper thick closeness I had set previously.

And just squirted out black strands all over the place.

Why would it raise up higher than where I had set my homes?

I want it right on the glass, not 1/4 inch above it.

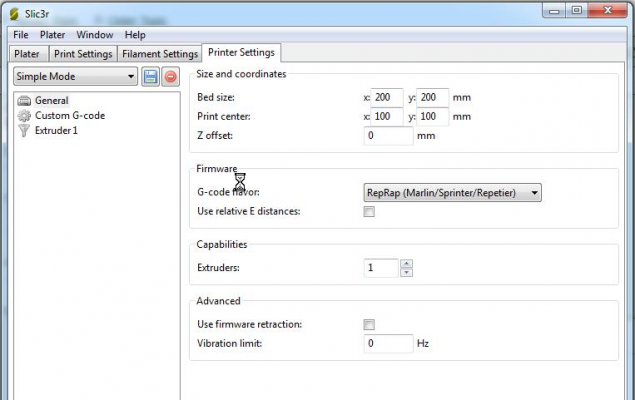

Just curious but in your slic3r settings, do you have a Z offset?

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 10:31PM |

Registered: 9 years ago Posts: 134 |

Quote

louspinuso

Quote

Gannicus

Got it. Had to push it in harder, and twist it. Finally grabbed.

Tried to print a test box, and from home to start printing, the nozzle lifted way higher than the paper thick closeness I had set previously.

And just squirted out black strands all over the place.

Why would it raise up higher than where I had set my homes?

I want it right on the glass, not 1/4 inch above it.

Just curious but in your slic3r settings, do you have a Z offset?

[attachment 44000 ScreenShot057.jpg]

Don't user slic3r.

I'm trying cura now, but have simplify3d that I plan to use instead.

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 10:41PM |

Registered: 9 years ago Posts: 110 |

Quote

zorg1179

I am guessing that you hit start print and this happened. My bed took a while to heat up too, sometimes up to 20 min to hit 100c. Normal operation of the printer is to heat the bed to the set temp, then heat the extruder(it heats much faster). If you have the extruder at temp while waiting on the bed, the filament inside the extruder will get soft and fail to feed properly. I see this anytime my extruder is sitting for more than a few minutes without feeding. I put some insulation between the bed and the y carriage. This sped up my bed heat time a small amount. I recently added an enclosure. Now, the bed is up to temp in about 5min.

Yeah, that's what I did the first time and then I decided to try to set the bed temp but it kept dying just shy of 100c so I just set it to 90c in my slic3r settings and resliced the test cube and I was able to start printing.

I managed to print off my first calibration cube with ABS and it is almost dead on.

I forgot to note the X direction and teh Y direction before removing the piece from the glass, but here is one side

And here is the other side

And here is the measurement from bottom to top

As you can see I have some tuning to do top to bottom and a very small amount in one of the xy axis, but other than that I'm pretty happy with the results.

I think I'll build the foam board enclosure that was built in the beginning of this thread as a temporary measure and play with some more adjustments to get that top/bottom down that .52 mm/cm that it's off and then Saturday I'll cut a solid melamine platform for the printer (I've got a 1/2 sheet sitting in the garage) and see if there are enough scraps to make an all wood enclosure over the weekend (with openings for glass). And I'll do my final writeup/thoughts on the printer and the pitfalls that I hit during the build process in the hopes that it will be useful to someone else.

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 10:45PM |

Registered: 9 years ago Posts: 110 |

Quote

Gannicus

Don't user slic3r.

I'm trying cura now, but have simplify3d that I plan to use instead.

Well I would look to see if there is a z offset anywhere in the settings before trying to print again.

Here is teh calibration cube I used. I went with something hollow so I wouldn't waste a ton of filament seeing if it worked:

[www.thingiverse.com]

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 11:07PM |

Registered: 9 years ago Posts: 45 |

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 11:18PM |

Registered: 9 years ago Posts: 110 |

|

Re: Folger Prusa i3 Kit from ebay November 19, 2014 11:38PM |

Registered: 9 years ago Posts: 7 |

|

Re: Folger Prusa i3 Kit from ebay November 20, 2014 05:46AM |

Registered: 9 years ago Posts: 1,011 |

@ louspinuso : [www.youtube.com]

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Sorry, only registered users may post in this forum.