Folger Prusa i3 Kit from ebay

Posted by Waltermixx

|

Re: Folger Prusa i3 Kit from ebay November 20, 2014 09:52AM |

Registered: 9 years ago Posts: 110 |

Based on that my configuration.h is wrong since this is not set to 80,80

#define DEFAULT_AXIS_STEPS_PER_UNIT {79.7, 80.3, 4030, 101} // default steps per unit for Ultimaker

I think I'll spend soem time measuring movement later and see what I can get to work

|

Re: Folger Prusa i3 Kit from ebay November 20, 2014 08:21PM |

Registered: 9 years ago Posts: 134 |

Anyone want to buy a completely built Prusa I3?

Apparently, I'm an effing retard.

I've spent now...4 nights...about 15 hours with a COMPLETED printer, and can't print a god damn thing.

I've tried Pronterface, Cura, and Simplify3D (that name is a total lie by the way) and they all do the same thing.

First, I've got my heated bed leveled, so that at every corner, the hotend nozzle is a paper thickness away.

Every one of those software don't seem to behave properly. By the time everything gets up to temp, and it goes to print, it does nothing, but starts cooling down the bed and nozzle. That's infuriating, especially where there is no good reason.

The COUPLE times I've got it to go through the paces of the Gcode, the printer decides it's going to lift off my Z home, 5mm and just spews melted abs everywhere.

I about to take a sledge to this GD thing.

Apparently, I'm an effing retard.

I've spent now...4 nights...about 15 hours with a COMPLETED printer, and can't print a god damn thing.

I've tried Pronterface, Cura, and Simplify3D (that name is a total lie by the way) and they all do the same thing.

First, I've got my heated bed leveled, so that at every corner, the hotend nozzle is a paper thickness away.

Every one of those software don't seem to behave properly. By the time everything gets up to temp, and it goes to print, it does nothing, but starts cooling down the bed and nozzle. That's infuriating, especially where there is no good reason.

The COUPLE times I've got it to go through the paces of the Gcode, the printer decides it's going to lift off my Z home, 5mm and just spews melted abs everywhere.

I about to take a sledge to this GD thing.

|

Re: Folger Prusa i3 Kit from ebay November 20, 2014 09:05PM |

Registered: 12 years ago Posts: 76 |

Been there, almost done that

If you look at the gcode I suspect you will find a command to lift the extruder 5mm before it begins printing so it doesn't drag the nozzle across the bed until it gets to the initial print location. On mine when I used Cura to slice initially it was doing that but slamming the head into the bed trying to go 5mm down, like it thought the bed was moving up and down instead of the nozzle. What I did is comment out that piece of code and then I got my first decent print.

I'm still having issues but they tolerable since I can at least get things to print now.

If you look at the gcode I suspect you will find a command to lift the extruder 5mm before it begins printing so it doesn't drag the nozzle across the bed until it gets to the initial print location. On mine when I used Cura to slice initially it was doing that but slamming the head into the bed trying to go 5mm down, like it thought the bed was moving up and down instead of the nozzle. What I did is comment out that piece of code and then I got my first decent print.

I'm still having issues but they tolerable since I can at least get things to print now.

|

Re: Folger Prusa i3 Kit from ebay November 20, 2014 10:28PM |

Registered: 9 years ago Posts: 110 |

Quote

Gannicus

Anyone want to buy a completely built Prusa I3?

Apparently, I'm an effing retard.

I've spent now...4 nights...about 15 hours with a COMPLETED printer, and can't print a god damn thing.

I've tried Pronterface, Cura, and Simplify3D (that name is a total lie by the way) and they all do the same thing.

First, I've got my heated bed leveled, so that at every corner, the hotend nozzle is a paper thickness away.

Every one of those software don't seem to behave properly. By the time everything gets up to temp, and it goes to print, it does nothing, but starts cooling down the bed and nozzle. That's infuriating, especially where there is no good reason.

The COUPLE times I've got it to go through the paces of the Gcode, the printer decides it's going to lift off my Z home, 5mm and just spews melted abs everywhere.

I about to take a sledge to this GD thing.

There are a few things to try.

In Slic3r, under print settings, then select "Layers and Perimeters" on the left, there is a "Layer Height" and a "First Layer Height". Make sure that Layer height is .3 and First Layer Height is .35 (note the decimal at the front of that number).

After you've verified this setting and then saved using the little disk icon, re-slice your object.

Next open gcode file that gets created. You'll see a bunch of lines at the top that have ; in front of them, those are comments just so you know what it's going to do. The actual code is below that. Here are the first 32 lines in one of my objects:

; generated by Slic3r 1.0.0RC2 on 2014-11-20 at 14:28:25 ; layer_height = 0.3 ; perimeters = 3 ; top_solid_layers = 3 ; bottom_solid_layers = 3 ; fill_density = 0.4 ; perimeter_speed = 30 ; infill_speed = 60 ; travel_speed = 130 ; nozzle_diameter = 0.4 ; filament_diameter = 1.75 ; extrusion_multiplier = 1 ; perimeters extrusion width = 0.40mm ; infill extrusion width = 0.42mm ; solid infill extrusion width = 0.42mm ; top infill extrusion width = 0.42mm ; first layer extrusion width = 0.70mm

Now, those first few lines tell the person reading the file that it will be using a .3 layer height and a 40% fill density along with my filament diameter, number of extruders and the speed with which the printer will print. Read these and make sure that the settings are what you expect them to be based on what you set in your slicing program

G21 ; set units to millimeters M107 M190 S105 ; wait for bed temperature to be reached M104 S225 ; set temperature G28 ; home all axes

These are the first lines of actual directions sent to the printer that the printer reads. Everything after the ; is a comment to let you know what that line will be doing. The only line there that is not documented is "M107" which is turn off fan (this code should technically be replaced with "M106 S0" but whatever)

G1 Z5 F5000 ; lift nozzle M109 S225 ; wait for temperature to be reached G90 ; use absolute coordinates G92 E0 M82 ; use absolute distances for extrusion G1 F1800.000 E-1.00000 G92 E0 G1 Z0.350 F7800.000 G1 X73.310 Y71.310 F7800.000

You'll note that the very next line in the code tells my z axis to lift to 5 millimeters (G1 Z5 F5000). I suspect that you're seeing the same thing in your code.

After this the extruder temperature is set and it waits for that to be reached.

Once the extruder temperature is reached it sets the printer to use all points specified from now on to be absolute

Next it Extrudes 0 (a Google search implies that this may be related to fixing retraction)

Next it will use absolute distances for the extrusion

Next, it will extrud -1 mm at 1800 mm/min

Next it again extrudes 0 (before and after the retraction)

and then it moves the Z axis to 0.350 level (the height of the first layer)

and then it starts moving the extruder all over the place to do it's thing

There's a good bit of documentation over at [reprap.org] and if you want to post the first 40 or so lines of your gcode I will try to take a look at it and see if I can't figure out why it's not coming back down to the right layer height after starting.

Oh, one other thing, make sure that there isn't a setting to use "relative" coordinates. Some people like them, but if you use relative coordinates (instead of absolute) and you forget to move the z axis -4.65 before starting to print, you'll just start printing in the middle of the air (since you've moved to 5 mm and then next move will just move it another 0.35 up as opposed to moving it to a height of 0.35)

Hope this helps. And if you were nearby I'd come take a look at what you have to see if I can help but I think I'm the only person for 30 miles that knows what a 3D printer is so I doubt you're even remotely close.

|

Re: Folger Prusa i3 Kit from ebay November 20, 2014 10:42PM |

Registered: 9 years ago Posts: 134 |

Thanks guys...I've calmed myself...and will really crack down on this this weekend to get it running once and for all.

I just wish there was some way to really pick your brains. A web forum takes too long to get replies etc. LOL

I know the issue now is that I don't know how to use the software. I know that.

It's all software issues at this point. I don't get why all four of those programs turn the heat to the bed and nozzle off when the temps are reached, instead of printing like it's supposed to either.

It's maddening.

I just wish there was some way to really pick your brains. A web forum takes too long to get replies etc. LOL

I know the issue now is that I don't know how to use the software. I know that.

It's all software issues at this point. I don't get why all four of those programs turn the heat to the bed and nozzle off when the temps are reached, instead of printing like it's supposed to either.

It's maddening.

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 12:47AM |

Registered: 10 years ago Posts: 477 |

Quote

Gannicus

Thanks guys...I've calmed myself...and will really crack down on this this weekend to get it running once and for all.

I just wish there was some way to really pick your brains. A web forum takes too long to get replies etc. LOL

I know the issue now is that I don't know how to use the software. I know that.

It's all software issues at this point. I don't get why all four of those programs turn the heat to the bed and nozzle off when the temps are reached, instead of printing like it's supposed to either.

It's maddening.

Keep plugging away, ou are 99% there (and learning lots right?)

As I mentioned in a PM to you, it took my friend and I probably 2 or 3 nights to get the end stops sorted and working properly, but it was really easy in our second build.

Steve

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 04:40AM |

Registered: 9 years ago Posts: 1,011 |

Only 15 hours ? it's half the wayQuote

Gannicus

I've spent now...4 nights...about 15 hours with a COMPLETED printer, and can't print a god damn thing.

Up to 60 hours I'm still refining to get better prints ! For slicer, go to page 11 and download waltermixx's Slic3r_config_bundle.ini it's a good start point. It things goes once again wrong, there's still something to fix on the machine or electronics.

Up to 60 hours I'm still refining to get better prints ! For slicer, go to page 11 and download waltermixx's Slic3r_config_bundle.ini it's a good start point. It things goes once again wrong, there's still something to fix on the machine or electronics.Edited 1 time(s). Last edit at 11/21/2014 04:41AM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 07:39AM |

Registered: 11 years ago Posts: 18 |

Unpacked my box last night to compile a list of any missing parts. I am only missing a bolt and a lock nut so far and have a question about the printed pieces.

I have five belt guide pieces. Is that the correct number?

Everything had nice packaging, labeled quantities and part descriptions except the printed pieces. No problem except for this specific component (an odd number threw up warning bells).

Today is day one.

I have five belt guide pieces. Is that the correct number?

Everything had nice packaging, labeled quantities and part descriptions except the printed pieces. No problem except for this specific component (an odd number threw up warning bells).

Today is day one.

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 08:58AM |

Registered: 9 years ago Posts: 110 |

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 10:12AM |

Registered: 9 years ago Posts: 1,011 |

Yes, one extra. I gued that two pulley parts together because it used to slip out the bearing. In my kit there was a plexiglass broken par (glued), some zip tie missing, 1 pololu out of order, 2 LM8UU out of balls, and few M3 hadware missing and other extra. The kit is not composed with as care as I thought. Hopefully I had some spares in the workshop. Beware of the PLA parts, they can break easily. Don't try to instert the LM8UU by force, check the hole diameter and pre-drill if necessary. My LM8UU were too long (or the part too small) I had to do some handwork to make them fit into the Z carriage plate. In this part, the hole for the Zip ties were both obturated. I'm not very happy with the acrylic bed plate which is too low (the adjusting bolts may hit the frame in tight position) and may flex or bend when getting hot. I'll make a custom one.

Just an advice, the Z endstop is realy hard to adjust. Expecialy beacause the 8mm rods may rotate often and unscrewing the Whatever side it will be installed, find a way to install a end screw on X ends to make adjusting easy. If you own another printer, print another x end or an adjustable enstop holder.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Just an advice, the Z endstop is realy hard to adjust. Expecialy beacause the 8mm rods may rotate often and unscrewing the Whatever side it will be installed, find a way to install a end screw on X ends to make adjusting easy. If you own another printer, print another x end or an adjustable enstop holder.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 03:37PM |

Registered: 10 years ago Posts: 136 |

Quote

Gannicus

Thanks guys...I've calmed myself...and will really crack down on this this weekend to get it running once and for all.

I just wish there was some way to really pick your brains. A web forum takes too long to get replies etc. LOL

I know the issue now is that I don't know how to use the software. I know that.

It's all software issues at this point. I don't get why all four of those programs turn the heat to the bed and nozzle off when the temps are reached, instead of printing like it's supposed to either.

It's maddening.

Patience with this new consumer technology is key. If you're using Simplify3D, take a look at the communication log (in the Machine Control Panel, little gear icon in the bottom right-ish of the software). It may give you some sort of message to clue you in on why it's happening.

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 05:04PM |

Registered: 9 years ago Posts: 208 |

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 06:02PM |

Registered: 9 years ago Posts: 134 |

Quote

louspinuso

Quote

Gannicus

Anyone want to buy a completely built Prusa I3?

Apparently, I'm an effing retard.

I've spent now...4 nights...about 15 hours with a COMPLETED printer, and can't print a god damn thing.

I've tried Pronterface, Cura, and Simplify3D (that name is a total lie by the way) and they all do the same thing.

First, I've got my heated bed leveled, so that at every corner, the hotend nozzle is a paper thickness away.

Every one of those software don't seem to behave properly. By the time everything gets up to temp, and it goes to print, it does nothing, but starts cooling down the bed and nozzle. That's infuriating, especially where there is no good reason.

The COUPLE times I've got it to go through the paces of the Gcode, the printer decides it's going to lift off my Z home, 5mm and just spews melted abs everywhere.

I about to take a sledge to this GD thing.

There are a few things to try.

In Slic3r, under print settings, then select "Layers and Perimeters" on the left, there is a "Layer Height" and a "First Layer Height". Make sure that Layer height is .3 and First Layer Height is .35 (note the decimal at the front of that number).

After you've verified this setting and then saved using the little disk icon, re-slice your object.

Next open gcode file that gets created. You'll see a bunch of lines at the top that have ; in front of them, those are comments just so you know what it's going to do. The actual code is below that. Here are the first 32 lines in one of my objects:

; generated by Slic3r 1.0.0RC2 on 2014-11-20 at 14:28:25 ; layer_height = 0.3 ; perimeters = 3 ; top_solid_layers = 3 ; bottom_solid_layers = 3 ; fill_density = 0.4 ; perimeter_speed = 30 ; infill_speed = 60 ; travel_speed = 130 ; nozzle_diameter = 0.4 ; filament_diameter = 1.75 ; extrusion_multiplier = 1 ; perimeters extrusion width = 0.40mm ; infill extrusion width = 0.42mm ; solid infill extrusion width = 0.42mm ; top infill extrusion width = 0.42mm ; first layer extrusion width = 0.70mm

Now, those first few lines tell the person reading the file that it will be using a .3 layer height and a 40% fill density along with my filament diameter, number of extruders and the speed with which the printer will print. Read these and make sure that the settings are what you expect them to be based on what you set in your slicing program

G21 ; set units to millimeters M107 M190 S105 ; wait for bed temperature to be reached M104 S225 ; set temperature G28 ; home all axes

These are the first lines of actual directions sent to the printer that the printer reads. Everything after the ; is a comment to let you know what that line will be doing. The only line there that is not documented is "M107" which is turn off fan (this code should technically be replaced with "M106 S0" but whatever)

G1 Z5 F5000 ; lift nozzle M109 S225 ; wait for temperature to be reached G90 ; use absolute coordinates G92 E0 M82 ; use absolute distances for extrusion G1 F1800.000 E-1.00000 G92 E0 G1 Z0.350 F7800.000 G1 X73.310 Y71.310 F7800.000

You'll note that the very next line in the code tells my z axis to lift to 5 millimeters (G1 Z5 F5000). I suspect that you're seeing the same thing in your code.

After this the extruder temperature is set and it waits for that to be reached.

Once the extruder temperature is reached it sets the printer to use all points specified from now on to be absolute

Next it Extrudes 0 (a Google search implies that this may be related to fixing retraction)

Next it will use absolute distances for the extrusion

Next, it will extrud -1 mm at 1800 mm/min

Next it again extrudes 0 (before and after the retraction)

and then it moves the Z axis to 0.350 level (the height of the first layer)

and then it starts moving the extruder all over the place to do it's thing

There's a good bit of documentation over at [reprap.org] and if you want to post the first 40 or so lines of your gcode I will try to take a look at it and see if I can't figure out why it's not coming back down to the right layer height after starting.

Oh, one other thing, make sure that there isn't a setting to use "relative" coordinates. Some people like them, but if you use relative coordinates (instead of absolute) and you forget to move the z axis -4.65 before starting to print, you'll just start printing in the middle of the air (since you've moved to 5 mm and then next move will just move it another 0.35 up as opposed to moving it to a height of 0.35)

Hope this helps. And if you were nearby I'd come take a look at what you have to see if I can help but I think I'm the only person for 30 miles that knows what a 3D printer is so I doubt you're even remotely close.

Thanks! Here is my code for the thin walled test box.

; generated by Slic3r 1.0.0RC2 on 2014-11-20 at 19:29:47

; layer_height = 0.3

; perimeters = 3

; top_solid_layers = 3

; bottom_solid_layers = 3

; fill_density = 0.4

; perimeter_speed = 30

; infill_speed = 60

; travel_speed = 130

; nozzle_diameter = 0.4

; filament_diameter = 1.75

; extrusion_multiplier = 1

; perimeters extrusion width = 0.40mm

; infill extrusion width = 0.42mm

; solid infill extrusion width = 0.42mm

; top infill extrusion width = 0.42mm

; first layer extrusion width = 0.70mm

G21 ; set units to millimeters

M107

M104 S225 ; set temperature

G28 ; home all axes

G1 Z5 F5000 ; lift nozzle

M109 S225 ; wait for temperature to be reached

G90 ; use absolute coordinates

G92 E0

M82 ; use absolute distances for extrusion

G1 F1800.000 E-1.00000

G92 E0

G1 Z0.350 F7800.000

G92 E0

M107

M104 S0 ; turn off temperature

G28 X0 ; home X axissub()[/sub]

M84 ; disable motors

; filament used = 58.9mm (0.4cm3)

Seems to me it's exactly as yours...But it goes up the 5mm, and never comes back down.

Edited 1 time(s). Last edit at 11/21/2014 06:04PM by Gannicus.

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 07:11PM |

Registered: 9 years ago Posts: 134 |

Got it all figured out. I just deleted the "G1 Z5 F5000 ; lift nozzle" from the gcode.

However...my issue is that it isn't laying down enough to stick. It goes to the center to begin printing, and nothing comes out till it's halfway through the first couple outlines.

By that time, it's too late. It comes out super slow, and too thin I feel to stick to the bed.

I'm using dooms101 configuration.h...which everyone says works amazing...but I can't get anything but black strings.

Edited 1 time(s). Last edit at 11/21/2014 07:12PM by Gannicus.

However...my issue is that it isn't laying down enough to stick. It goes to the center to begin printing, and nothing comes out till it's halfway through the first couple outlines.

By that time, it's too late. It comes out super slow, and too thin I feel to stick to the bed.

I'm using dooms101 configuration.h...which everyone says works amazing...but I can't get anything but black strings.

Edited 1 time(s). Last edit at 11/21/2014 07:12PM by Gannicus.

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 07:25PM |

Registered: 9 years ago Posts: 110 |

Quote

Gannicus

Thanks! Here is my code for the thin walled test box.

; generated by Slic3r 1.0.0RC2 on 2014-11-20 at 19:29:47 ; layer_height = 0.3 ; perimeters = 3 ; top_solid_layers = 3 ; bottom_solid_layers = 3 ; fill_density = 0.4 ; perimeter_speed = 30 ; infill_speed = 60 ; travel_speed = 130 ; nozzle_diameter = 0.4 ; filament_diameter = 1.75 ; extrusion_multiplier = 1 ; perimeters extrusion width = 0.40mm ; infill extrusion width = 0.42mm ; solid infill extrusion width = 0.42mm ; top infill extrusion width = 0.42mm ; first layer extrusion width = 0.70mm G21 ; set units to millimeters M107 M104 S225 ; set temperature G28 ; home all axes G1 Z5 F5000 ; lift nozzle M109 S225 ; wait for temperature to be reached G90 ; use absolute coordinates G92 E0 M82 ; use absolute distances for extrusion G1 F1800.000 E-1.00000 G92 E0 G1 Z0.350 F7800.000G92 E0 M107 M104 S0 ; turn off temperature G28 X0 ; home X axissub()[/sub] M84 ; disable motors ; filament used = 58.9mm (0.4cm3)

Seems to me it's exactly as yours...But it goes up the 5mm, and never comes back down.

Ok, well I notice that you're not turning on your heat bed, that line would start with M190. I also see that there is definitely a move back down for the Z axis, but you're saying that's not happening, which is weird. Why are you not heating your bed? I'm assuming you're using ABS since you're at 225c for your extruder temp (M104 S225 ; set temperature).

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 07:37PM |

Registered: 9 years ago Posts: 110 |

Quote

Gannicus

Got it all figured out. I just deleted the "G1 Z5 F5000 ; lift nozzle" from the gcode.

However...my issue is that it isn't laying down enough to stick. It goes to the center to begin printing, and nothing comes out till it's halfway through the first couple outlines.

By that time, it's too late. It comes out super slow, and too thin I feel to stick to the bed.

I'm using dooms101 configuration.h...which everyone says works amazing...but I can't get anything but black strings.

That at least gets you past the point where the nozzle isn't coming back down (is it hitting home before going up 5mm?) but your new issue sounds like:

a) the bed is not hot enough to hold stuff

b) It sounds like you're not printing a skirt, which is not *necessary* but it's useful to make sure that there is filament coming out of the extruder

the skirts don't usually have any plastic until more than 1/2 way around the printed area in my experience. This is a good way to make sure that you *will* have plastic coming out when it actually gets to the part.

Thinking about your other problem, do you have pronterface? If so, can you humor me and get it all hooked up, hit home, then raise your z 10 then lower it 1 at a time till you are back at the endstop switch and count how many times you click the down button.

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 07:51PM |

Registered: 9 years ago Posts: 208 |

i print a skirt of about 3 rotations, it give me plenty of time to make sure the exturder is extuding, and it also give you a good indication if your bed is leveled properly, and if the skirt sticks and stays down then most likely so will your print... it's a very good idea to do a skirt of at least 3 rotations...

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 08:23PM |

Registered: 10 years ago Posts: 136 |

Gannicus,

If your nozzle is not going down, your z limit switch may not be configured properly, i havent read the whole thread, so I'm not sure what state your printer is in, but if you move the Z-Axis up manually 10mm and then tell it to home and it doesnt move, your Z endstop may be giving out a "TRIGGERED" command. Send in an M119 command to check the status of your endstops. They should all be open until you press them in. When you press the limit switch and send in M119, you should see TRIGGERED on the axis' endstop you're pressing on.

If the print is not extruding until part way in, it means your hot end is not primed. Most likely at the end of the previous print or last time you heated it up, plastic oozed out as the hot end was cooling down, causing a gap between the filament and the tip of the nozzle.

After the M82 you want to put a "prime" script in for example:

This will extrude 20mm of filament in the corner of your bed where you home, making sure there is filament ready when you start printing.

If your nozzle is not going down, your z limit switch may not be configured properly, i havent read the whole thread, so I'm not sure what state your printer is in, but if you move the Z-Axis up manually 10mm and then tell it to home and it doesnt move, your Z endstop may be giving out a "TRIGGERED" command. Send in an M119 command to check the status of your endstops. They should all be open until you press them in. When you press the limit switch and send in M119, you should see TRIGGERED on the axis' endstop you're pressing on.

If the print is not extruding until part way in, it means your hot end is not primed. Most likely at the end of the previous print or last time you heated it up, plastic oozed out as the hot end was cooling down, causing a gap between the filament and the tip of the nozzle.

M109 S225 ; wait for temperature to be reached G90 ; use absolute coordinates G92 E0 M82 ; use absolute distances for extrusion

After the M82 you want to put a "prime" script in for example:

G1 Z0.1 F3600 G92 E0 G1 E20 F150 G92 E0

This will extrude 20mm of filament in the corner of your bed where you home, making sure there is filament ready when you start printing.

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 09:20PM |

Registered: 9 years ago Posts: 134 |

How do you do the skirt??

Here is a video of where I'm currently at.

Seems like the ABS coming out isn't as thick or liquid as other videos I've seen. It's pretty much dry and hard looking as soon as it comes out the nozzle. I'm running it at 235c. As you can see, I don't get any filament till a minute into the print, and which point, it's too late.

My heat bed settings are only 85c, it doesn't seem to want to go up to 100. And the 85c takes FOREVER to get to.

[youtu.be]

Edited 1 time(s). Last edit at 11/21/2014 09:26PM by Gannicus.

Here is a video of where I'm currently at.

Seems like the ABS coming out isn't as thick or liquid as other videos I've seen. It's pretty much dry and hard looking as soon as it comes out the nozzle. I'm running it at 235c. As you can see, I don't get any filament till a minute into the print, and which point, it's too late.

My heat bed settings are only 85c, it doesn't seem to want to go up to 100. And the 85c takes FOREVER to get to.

[youtu.be]

Edited 1 time(s). Last edit at 11/21/2014 09:26PM by Gannicus.

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 09:23PM |

Registered: 9 years ago Posts: 134 |

Quote

isonoob

Gannicus,

If your nozzle is not going down, your z limit switch may not be configured properly, i havent read the whole thread, so I'm not sure what state your printer is in, but if you move the Z-Axis up manually 10mm and then tell it to home and it doesnt move, your Z endstop may be giving out a "TRIGGERED" command. Send in an M119 command to check the status of your endstops. They should all be open until you press them in. When you press the limit switch and send in M119, you should see TRIGGERED on the axis' endstop you're pressing on.

If the print is not extruding until part way in, it means your hot end is not primed. Most likely at the end of the previous print or last time you heated it up, plastic oozed out as the hot end was cooling down, causing a gap between the filament and the tip of the nozzle.

M109 S225 ; wait for temperature to be reached G90 ; use absolute coordinates G92 E0 M82 ; use absolute distances for extrusion

After the M82 you want to put a "prime" script in for example:

G1 Z0.1 F3600 G92 E0 G1 E20 F150 G92 E0

This will extrude 20mm of filament in the corner of your bed where you home, making sure there is filament ready when you start printing.

That's some really great info...THANK YOU. And that is exactly what is happening, every time I'm done doing some testing, it keeps oozing out for about 20 secs or so.

As for the endstops, I have done all those tests, and they read open when not triggered, and triggered when I hold them down and run the command.

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 09:31PM |

Registered: 9 years ago Posts: 110 |

Ugh so today I had my first air print and I think it might just be because of something I did to help heat things up quicker. I found some Styrofoam insulation in my garage and cut enough to cover three sides of the printer and then I put a blanket over top front. I think the filament that was feeding in got too soft and just stopped feeding. When I noticed I applied a little pressure to the filament and it stayed feeding again. Too bad I was about an inch above where it stopped though. Anyway after everything cooled I was looking at it and noticed everything that was attached to printed parts was loose so tomorrow I'm going to tighten everything down, place the printer on a sheet of MDF and print new printed parts in abs while I build an enclosure with a fan (though I'll have to manually turn it on and off for now till I get a dedicated controller for it).

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 09:40PM |

Registered: 9 years ago Posts: 7 |

Quote

Gannicus

How do you do the skirt??

Here is a video of where I'm currently at.

Seems like the ABS coming out isn't as thick or liquid as other videos I've seen. It's pretty much dry and hard looking as soon as it comes out the nozzle. I'm running it at 235c. As you can see, I don't get any filament till a minute into the print, and which point, it's too late.

My heat bed settings are only 85c, it doesn't seem to want to go up to 100. And the 85c takes FOREVER to get to.

[youtu.be]

From the video, it looks like your extruder it too far from your bed. When you set your z-endstop, you should only have about two sheets of paper thicknes between the bed and the nozzzle. This doesn't explain the filament not extruding. Is you extruder temp high enough for the abs you are usin? Mine extrudes nicely at 235.

|

Re: Folger Prusa i3 Kit from ebay November 21, 2014 09:54PM |

Registered: 9 years ago Posts: 110 |

Gannicus,

I agree that the bed takes forever to get to temp, which is why I made a blanket fort for my printer, that helped a lot, but it also softened some parts so I'll have to make sure it doesn't stay hot in the enclosure. Trust me, you want that 100 or higher temp on your bed for ABS. I tried getting away with 90 because I was being impatient, and parts curled off mid print and it just caused more problems. A fan blowing on your board (specifically the mosfet that is used to heat the bed) helps also so if you've got a small fan (even a small desk fan that you can point just on the board), that will allow the mosfet to stay on longer to heat the bed instead of powering itself off to prevent overheating (which is probably why it's taking so long).

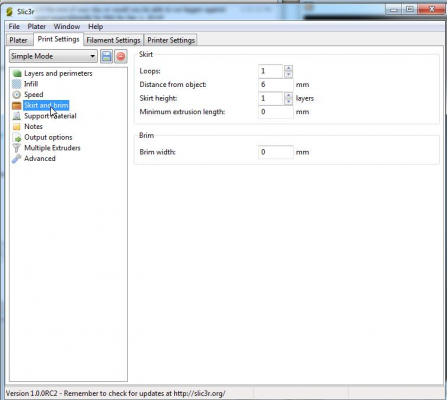

Also the skirt is (in Slic3r) in the "print settings" under "Skirt and Brim":

Another thing, that glass is SO CLEAN. Do you have any hairspray on it? Glue Stick? Anything to make it sticky? if not, the plastic isn't going to stick to it.

And I agree with zorg when he says that the nozzle seems to be too high. Here's a video of my printer printing a calibration box. You can see that my glass is not very clear because of the hairspray I'm using on it. My wife has some super extra hold that she insists I spray in the garage because "that stuff is sticky and it's hard to clean off". True story. I cleaned my glass off in the kitchen sink this morning and I had to wash it like 4 times with dish soap and a sponge to get it clean.

[youtu.be]

I agree that the bed takes forever to get to temp, which is why I made a blanket fort for my printer, that helped a lot, but it also softened some parts so I'll have to make sure it doesn't stay hot in the enclosure. Trust me, you want that 100 or higher temp on your bed for ABS. I tried getting away with 90 because I was being impatient, and parts curled off mid print and it just caused more problems. A fan blowing on your board (specifically the mosfet that is used to heat the bed) helps also so if you've got a small fan (even a small desk fan that you can point just on the board), that will allow the mosfet to stay on longer to heat the bed instead of powering itself off to prevent overheating (which is probably why it's taking so long).

Also the skirt is (in Slic3r) in the "print settings" under "Skirt and Brim":

Another thing, that glass is SO CLEAN. Do you have any hairspray on it? Glue Stick? Anything to make it sticky? if not, the plastic isn't going to stick to it.

And I agree with zorg when he says that the nozzle seems to be too high. Here's a video of my printer printing a calibration box. You can see that my glass is not very clear because of the hairspray I'm using on it. My wife has some super extra hold that she insists I spray in the garage because "that stuff is sticky and it's hard to clean off". True story. I cleaned my glass off in the kitchen sink this morning and I had to wash it like 4 times with dish soap and a sponge to get it clean.

[youtu.be]

|

Re: Folger Prusa i3 Kit from ebay November 22, 2014 08:30AM |

Registered: 9 years ago Posts: 134 |

Thanks guys. I'm not sure why it looks like it is too high, because it literally is one papers thickness off the glass. I can get a piece of paper under the nozzle at 0,0,0 and still have some drag. In all four corners.

It just seems like the material isn't coming out melty enough, or quick enough as well. I'm going to the store today to buy some of that Garnier Fructis max hold and try that.

I run the hot end at 235...so I know it's getting hot enough. As for the bed, I plan on building a box for it out of melamine, but my concern is that the plexiglass frame etc will melt and warp in there.

It just seems like the material isn't coming out melty enough, or quick enough as well. I'm going to the store today to buy some of that Garnier Fructis max hold and try that.

I run the hot end at 235...so I know it's getting hot enough. As for the bed, I plan on building a box for it out of melamine, but my concern is that the plexiglass frame etc will melt and warp in there.

|

Re: Folger Prusa i3 Kit from ebay November 22, 2014 08:39AM |

Registered: 9 years ago Posts: 12 |

Hello guys,

I also had an issue with the heatbed, when it reached 95 degrees it would take 5 minutes to increase by one degree!!!

So I used a sheet of the foamy stuff that you wrap fragile things to insulate the bottom of the bed and when I heat the bed for a print I cover the top with a piece of cardboard!!!

I remove it when it reaches temperature just before the print.

It really helps and it does not heats up the rest of the printer!

Hope it helps!

I also had an issue with the heatbed, when it reached 95 degrees it would take 5 minutes to increase by one degree!!!

So I used a sheet of the foamy stuff that you wrap fragile things to insulate the bottom of the bed and when I heat the bed for a print I cover the top with a piece of cardboard!!!

I remove it when it reaches temperature just before the print.

It really helps and it does not heats up the rest of the printer!

Hope it helps!

|

Re: Folger Prusa i3 Kit from ebay November 22, 2014 09:33AM |

Registered: 9 years ago Posts: 208 |

Oddly enough i find that the heated bed heats quicker and consistently when the bed is pushed forward all the way on the Y axis (away from the frame).

Not sure why, but it seems to work better... give it a try and see if you have better heating results for your bed...

give it a try and see if you have better heating results for your bed...

my Y-axis min. endstop is at the front of my Prusa, so it starts off in that position.... i just noticed that if i manually start to heat the bed,

it does the same thing you discribe, unless the bed is all the way forward... odd but true with me.

Edited 1 time(s). Last edit at 11/22/2014 09:38AM by Waltermixx.

Not sure why, but it seems to work better...

give it a try and see if you have better heating results for your bed...

give it a try and see if you have better heating results for your bed...my Y-axis min. endstop is at the front of my Prusa, so it starts off in that position.... i just noticed that if i manually start to heat the bed,

it does the same thing you discribe, unless the bed is all the way forward... odd but true with me.

Edited 1 time(s). Last edit at 11/22/2014 09:38AM by Waltermixx.

|

Re: Folger Prusa i3 Kit from ebay November 22, 2014 11:00AM |

Registered: 9 years ago Posts: 45 |

Quote

Waltermixx

Oddly enough i find that the heated bed heats quicker and consistently when the bed is pushed forward all the way on the Y axis (away from the frame).

Not sure why, but it seems to work better...give it a try and see if you have better heating results for your bed...

my Y-axis min. endstop is at the front of my Prusa, so it starts off in that position.... i just noticed that if i manually start to heat the bed,

it does the same thing you discribe, unless the bed is all the way forward... odd but true with me.

I am wondering if the wire from the thermistor is picking up interference. That may be why it behaves differently when the bed is in a different position. You might be able to test it by grabbing the wire that leads fronm the thermistor to the control board and see if that changes anything. If it does, the wire may need some shielding to the control board ground.

If the thermistor wire is bundled with other wires, it may help to run the thermistor wire separate from other wires, and away from stepper motors, sensors, etc...

Edited 1 time(s). Last edit at 11/22/2014 11:04AM by Easy.

|

Re: Folger Prusa i3 Kit from ebay November 22, 2014 12:16PM |

Registered: 10 years ago Posts: 136 |

if your bed can only get to around 90 degrees celcius comfortably, that's good enough to get an ABS print sticking with additional bed adhesives. I find little difference between 90 to 100 tbh. If you're having trouble getting a part to stick, try putting down blue painters tape on the bed and rubbing a glue stick on the top of the blue tape, dont need much glue.

|

Re: Folger Prusa i3 Kit from ebay November 22, 2014 01:02PM |

Registered: 9 years ago Posts: 110 |

Quote

konto89

Hello guys,

I also had an issue with the heatbed, when it reached 95 degrees it would take 5 minutes to increase by one degree!!!

So I used a sheet of the foamy stuff that you wrap fragile things to insulate the bottom of the bed and when I heat the bed for a print I cover the top with a piece of cardboard!!!

I remove it when it reaches temperature just before the print.

It really helps and it does not heats up the rest of the printer!

Hope it helps!

OMG, this was probably the best thing I've tried by far. While I was washing some coffee mugs this morning and making a fresh cup of coffee (probably 15 minutes total) I watched the graph in pronter face break 100 and then keep rising. By the time I had my coffee done and drinking it was almost at 110. This works so much better than covering the whole printer to keep the bed warm. Thank you so much!!

|

Re: Folger Prusa i3 Kit from ebay November 22, 2014 03:04PM |

Registered: 9 years ago Posts: 110 |

Ok, so been printing for a few days and last night I had my first airprint and I assumed it was related to the filament getting too soft in my "enclosure" and didn't investigate too much more (especially since after I noticed I put some pressure on the filament and it started extruding). This afternoon I printed some clips to screw my printer down to a board and they printed beautifully, then I started printing the same part I was printing last night when I airprinted and I got the airprint again, on the first layer. I tried pushing it through while the extruder was running but it just wouldn't go so I stopped everything and ran the extruder in reverse and found an airbubble in the section of filament that was in the tip.

I cut it off and started feeding it again and again heard clicking when it was in the tip, but it was extruding plastic so I kept extruding 20 mm at a time until the clicking stopped and the filament started feeding smoothly. I'm going to try this print again, in the hopes that it will go all 7 hours and give me what I asked for, but I'm starting to think I may need new filament.

I cut it off and started feeding it again and again heard clicking when it was in the tip, but it was extruding plastic so I kept extruding 20 mm at a time until the clicking stopped and the filament started feeding smoothly. I'm going to try this print again, in the hopes that it will go all 7 hours and give me what I asked for, but I'm starting to think I may need new filament.

Sorry, only registered users may post in this forum.