Folger Prusa i3 Kit from ebay

Posted by Waltermixx

|

Re: Folger Prusa i3 Kit from ebay January 06, 2015 09:41AM |

Registered: 9 years ago Posts: 26 |

Quote

louspinuso

Quote

bengele

Quote

bengele

Hoping that someone who is better at electronics can verify what I am going to do. I am trying to follow Tom's Guide on setting up auto bed leveling

3D printing guides: Setting up auto bed tramming leveling tilt compensation!

I am going to just use the open terminals on the power supply to get 12v input and ground. It looks to me like the pin closest to the edge of the ramps board is where I need to hook up the output.

Does that look right? I would prefer not to fry anything.

In case anyone else finds is attempting to do the same thing wiring it up this way worked.

Does anyone have any tips on unloading the filament? I reverse the extruder but most of the time the melted end of the plastic gets caught in the gear and I have to take it apart to get it out.

I usually just cut the filament and force it through with new filament.

That's exactly what I do. Its a great feeling when the new color finally comes out.

|

Re: Folger Prusa i3 Kit from ebay January 06, 2015 09:57AM |

Registered: 9 years ago Posts: 23 |

|

Re: Folger Prusa i3 Kit from ebay January 06, 2015 12:42PM |

Registered: 9 years ago Posts: 6 |

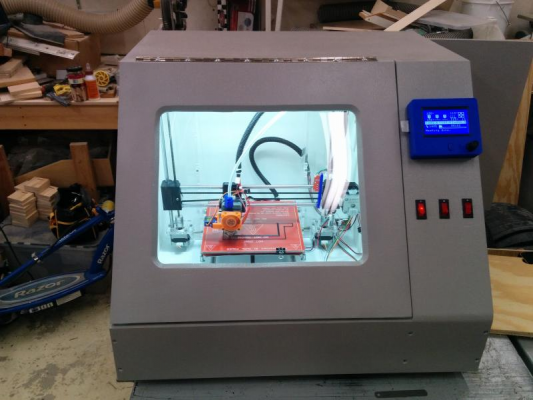

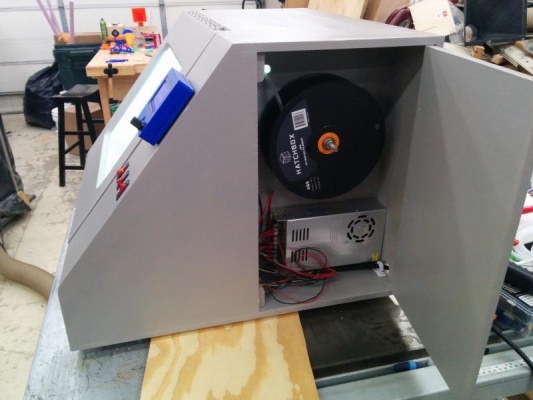

I finally got the enclosure done I have been working on for my Folger tech i3. Turned out pretty good I'd say!

Darren

Darren

|

Re: Folger Prusa i3 Kit from ebay January 06, 2015 01:51PM |

Registered: 9 years ago Posts: 58 |

DMAN120 That is an awesome enclosure. Very clean looking. Great job!

I am curious. Are you using the original PLA parts that came from Folger? If so how long have you been using them in an enclosure?

I used a box over my machine for awhile when I was doing a bunch of ABS prints on it and the PLA parts that were under any tension expanded and became unusable. (It was about 50c in the "enclosure" after warming up)

I reprinted them all in ABS from my other machine and I haven't had any issues since then.

-Zach

I am curious. Are you using the original PLA parts that came from Folger? If so how long have you been using them in an enclosure?

I used a box over my machine for awhile when I was doing a bunch of ABS prints on it and the PLA parts that were under any tension expanded and became unusable. (It was about 50c in the "enclosure" after warming up)

I reprinted them all in ABS from my other machine and I haven't had any issues since then.

-Zach

|

Re: Folger Prusa i3 Kit from ebay January 06, 2015 02:00PM |

Registered: 9 years ago Posts: 58 |

Quote

Newtoprinting

Can someone help please. My pla has been getting caught between the heat block and the filament drive. It would print fine for 10 minutes and then building up between heat block and fan/ filament drive.

It might help if you take a picture of you setup or if the problem is visible the problem itself. Is it the standard unmodified Folger extruder? Also post your basic print settings such as the extrusion temperature.

Off the top of my head a few possibilities....

- Wrong PLA Extrusion temp

- Clogged Extruder

- Inconsistent Filament Diameter or dirty filament (I had some recently that had globs in it so bad in some places it wouldn't even feed into the extruder)

- If you have cleaned your nozzle did your damage or accidentally remove the barrel liner by any chance?

- Nozzle not seated well to barrel/throat.

-Zach

|

Re: Folger Prusa i3 Kit from ebay January 06, 2015 03:14PM |

Registered: 9 years ago Posts: 23 |

Quote

czmorris

Quote

Newtoprinting

Can someone help please. My pla has been getting caught between the heat block and the filament drive. It would print fine for 10 minutes and then building up between heat block and fan/ filament drive.

It might help if you take a picture of you setup or if the problem is visible the problem itself. Is it the standard unmodified Folger extruder? Also post your basic print settings such as the extrusion temperature.

Off the top of my head a few possibilities....

- Wrong PLA Extrusion temp

- Clogged Extruder

- Inconsistent Filament Diameter or dirty filament (I had some recently that had globs in it so bad in some places it wouldn't even feed into the extruder)

- If you have cleaned your nozzle did your damage or accidentally remove the barrel liner by any chance?

- Nozzle not seated well to barrel/throat.

-Zach

My temperatures are 225 for 50mms and 240 for 70mms. I recently cleaned my extruder and the barrel liner came out but I putt back in. Also 3 of my fan blades from my extruder fan broke off and I need to get a new fan.

|

Re: Folger Prusa i3 Kit from ebay January 06, 2015 04:50PM |

Registered: 9 years ago Posts: 1,011 |

Nice enclosure Darren ! I like the side pannel very much. Are the switches for the light only ? Do you have an internal ventilation and do you manage fumes ?

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Folger Prusa i3 Kit from ebay January 06, 2015 06:49PM |

Registered: 9 years ago Posts: 12 |

Quote

Newtoprinting

Quote

czmorris

Quote

Newtoprinting

Can someone help please. My pla has been getting caught between the heat block and the filament drive. It would print fine for 10 minutes and then building up between heat block and fan/ filament drive.

It might help if you take a picture of you setup or if the problem is visible the problem itself. Is it the standard unmodified Folger extruder? Also post your basic print settings such as the extrusion temperature.

Off the top of my head a few possibilities....

- Wrong PLA Extrusion temp

- Clogged Extruder

- Inconsistent Filament Diameter or dirty filament (I had some recently that had globs in it so bad in some places it wouldn't even feed into the extruder)

- If you have cleaned your nozzle did your damage or accidentally remove the barrel liner by any chance?

- Nozzle not seated well to barrel/throat.

-Zach

My temperatures are 225 for 50mms and 240 for 70mms. I recently cleaned my extruder and the barrel liner came out but I putt back in. Also 3 of my fan blades from my extruder fan broke off and I need to get a new fan.

The temperatures that you mention are typical for ABS NOT PLA!!!!!!

Check the temperatures that the seller recommends for the PLA that you purchased! They usually are 160-180 degrees celcius!

|

Re: Folger Prusa i3 Kit from ebay January 06, 2015 06:56PM |

Registered: 9 years ago Posts: 5 |

Quote

Newtoprinting

Can I try your marlin zipQuote

jrcaster

Make sure you have all of the relevent files in the directory before you compile to arduino. Looks like you are missing the files that it is looking for.

I've been fighting with the Full Graphic Smart controller as well... I have several LCDs and RAMPS shields, I ruled out electronics, wiring etc... the only thing left is firmware issue or defective LCD board. I get stuff displayed in any other LCD that I plug in.

The LCD turns on, nothing displayed other than a one row of pixels (middle of screen) that are of different contrast than the rest of the screen (i.e. not fully on), That's it.

The folgertech configuration.h doesn't have the "FULL GRAPHIC" smart controller, so I tried adding it, also tried with stock marlin 1.01 to rule firmware out (Added the U8Glib.h library and include in configuration.h) still nothing on the screen.

As stated by other people, there's no pot on the board, and its not a inverted wiring issue else it wouldn't power up, I get no compile error.... using arduino 1.06, what's left?? thanks for any help!

Edited 1 time(s). Last edit at 01/06/2015 07:00PM by boboche.

|

Re: Folger Prusa i3 Kit from ebay January 06, 2015 07:53PM |

Registered: 9 years ago Posts: 6 |

Quote

czmorris

DMAN120 That is an awesome enclosure. Very clean looking. Great job!

I am curious. Are you using the original PLA parts that came from Folger? If so how long have you been using them in an enclosure?

I used a box over my machine for awhile when I was doing a bunch of ABS prints on it and the PLA parts that were under any tension expanded and became unusable. (It was about 50c in the "enclosure" after warming up)

I reprinted them all in ABS from my other machine and I haven't had any issues since then.

-Zach

I am using the PLA parts for now, I haven't had a chance to see if they would deform in a heated enclosure but I had planned to reprint them in ABS anyway.

Darren

Edited 1 time(s). Last edit at 01/06/2015 07:54PM by DMAN120.

|

Re: Folger Prusa i3 Kit from ebay January 06, 2015 07:59PM |

Registered: 9 years ago Posts: 12 |

Finally got everything set up and I'm trying to make sure everything is working for my first test print. Everything seems to be operating smoothly except the extruded stepper motor. I try to feed the filament and it feels/sounds like the stepper motor is in a bind. The stepper motor just kinda oscillates back and forth about 1mm. Anyone else had a problem like this?

|

Re: Folger Prusa i3 Kit from ebay January 06, 2015 08:02PM |

Registered: 9 years ago Posts: 6 |

Quote

Zavashier

Nice enclosure Darren ! I like the side panel very much. Are the switches for the light only ? Do you have an internal ventilation and do you manage fumes ?

Switches from the left are Main power, Lights and if needed a vent fan. I have never really noticed much of a smell when printing ABS but that may have been because it wasn't enclosed. If it needs a vent I can always add one..

As a side note I have started using Design Spark Mechanical to design my stl files for the printer, I was using Rhino 3D and still do for some things but Design Spark is much simpler after running through some of the tutorials and it is completely free!

Darren

|

Re: Folger Prusa i3 Kit from ebay January 06, 2015 09:33PM |

Registered: 9 years ago Posts: 10 |

Quote

czmorris

Quote

Newtoprinting

Can someone help please. My pla has been getting caught between the heat block and the filament drive. It would print fine for 10 minutes and then building up between heat block and fan/ filament drive.

It might help if you take a picture of you setup or if the problem is visible the problem itself. Is it the standard unmodified Folger extruder? Also post your basic print settings such as the extrusion temperature.

Off the top of my head a few possibilities....

- Wrong PLA Extrusion temp

- Clogged Extruder

- Inconsistent Filament Diameter or dirty filament (I had some recently that had globs in it so bad in some places it wouldn't even feed into the extruder)

- If you have cleaned your nozzle did your damage or accidentally remove the barrel liner by any chance?

- Nozzle not seated well to barrel/throat.

-Zach

I was having the exact same issue and the guy at folger suggested that I run the fan always on in the slicer settings so I did that and set the min. fan speed at 90 and the max at 100 and i havnt had any issues...... before I got this info I managed to wear the pinion gear. so I slid it out a bit. that helped also. if you have been trying for a while like I did for sure check that too

|

Re: Folger Prusa i3 Kit from ebay January 06, 2015 09:35PM |

Registered: 9 years ago Posts: 10 |

I agree with all the above. I was having the exact same issue and the guy at folger suggested that I run the fan always on in the slicer settings so I did that and set the min. fan speed at 90 and the max at 100 and i havnt had any issues...... before I got this info I managed to wear the pinion gear. so I slid it out a bit. that helped also. if you have been trying for a while like I did for sure check that tooQuote

czmorris

Quote

Newtoprinting

Can someone help please. My pla has been getting caught between the heat block and the filament drive. It would print fine for 10 minutes and then building up between heat block and fan/ filament drive.

It might help if you take a picture of you setup or if the problem is visible the problem itself. Is it the standard unmodified Folger extruder? Also post your basic print settings such as the extrusion temperature.

Off the top of my head a few possibilities....

- Wrong PLA Extrusion temp

- Clogged Extruder

- Inconsistent Filament Diameter or dirty filament (I had some recently that had globs in it so bad in some places it wouldn't even feed into the extruder)

- If you have cleaned your nozzle did your damage or accidentally remove the barrel liner by any chance?

- Nozzle not seated well to barrel/throat.

-Zach

Edited 1 time(s). Last edit at 01/06/2015 09:38PM by cliferton1.

|

Re: Folger Prusa i3 Kit from ebay January 06, 2015 10:01PM |

Registered: 9 years ago Posts: 58 |

Newtoprinting, As someone else mentioned your print temps are high for PLA. Personally I never go any higher than 210 for PLA and that is rare. Usually 180 or 190 for me.

As far the barrel liner goes I had something similar happen to mine awhile ago and it never worked properly for me again until I replaced the barrel. (Yours might be fine but in my case it would not). I would recommend lowering the temp and trying to print. If it works then great, If not you might think about replacing the barrel.

As for fans... I decided when I first wired my machine that I always wanted my fans on full so I have always had them wired straight to 12v.

Good luck!

-Zach

As far the barrel liner goes I had something similar happen to mine awhile ago and it never worked properly for me again until I replaced the barrel. (Yours might be fine but in my case it would not). I would recommend lowering the temp and trying to print. If it works then great, If not you might think about replacing the barrel.

As for fans... I decided when I first wired my machine that I always wanted my fans on full so I have always had them wired straight to 12v.

Good luck!

-Zach

|

Re: Folger Prusa i3 Kit from ebay January 06, 2015 10:12PM |

Registered: 9 years ago Posts: 12 |

I switched the y-axis and extruder stepper motors on the RAMPS board and the extruder stepper seemed to be working fine. So I guess the stepper motor is not the issue. The extruder stepper motor driver VREF is set to 0.35V. I don't know what the issue is.Quote

boy09

Finally got everything set up and I'm trying to make sure everything is working for my first test print. Everything seems to be operating smoothly except the extruded stepper motor. I try to feed the filament and it feels/sounds like the stepper motor is in a bind. The stepper motor just kinda oscillates back and forth about 1mm. Anyone else had a problem like this?

|

Re: Folger Prusa i3 Kit from ebay January 07, 2015 02:29AM |

Registered: 9 years ago Posts: 26 |

Quote

Newtoprinting

Can someone help please. My pla has been getting caught between the heat block and the filament drive. It would print fine for 10 minutes and then building up between heat block and fan/ filament drive.

I am having the same problem, I think its the PTFE sleeve inside the threated rod. Because it appears to be melting before it gets to the nozzle. To fix that I ordered another threaded rod with the PTFE sleeve in it. I will hopefully have it by the weekend.

|

Re: Folger Prusa i3 Kit from ebay January 07, 2015 10:15AM |

Registered: 9 years ago Posts: 2 |

|

Re: Folger Prusa i3 Kit from ebay January 07, 2015 10:31AM |

Registered: 9 years ago Posts: 26 |

Quote

boboche

Quote

Newtoprinting

Can I try your marlin zipQuote

jrcaster

Make sure you have all of the relevent files in the directory before you compile to arduino. Looks like you are missing the files that it is looking for.

I've been fighting with the Full Graphic Smart controller as well... I have several LCDs and RAMPS shields, I ruled out electronics, wiring etc... the only thing left is firmware issue or defective LCD board. I get stuff displayed in any other LCD that I plug in.

The LCD turns on, nothing displayed other than a one row of pixels (middle of screen) that are of different contrast than the rest of the screen (i.e. not fully on), That's it.

The folgertech configuration.h doesn't have the "FULL GRAPHIC" smart controller, so I tried adding it, also tried with stock marlin 1.01 to rule firmware out (Added the U8Glib.h library and include in configuration.h) still nothing on the screen.

As stated by other people, there's no pot on the board, and its not a inverted wiring issue else it wouldn't power up, I get no compile error.... using arduino 1.06, what's left?? thanks for any help!

Several of us have been there and done that wit the Full Graphic Smart controller. The consensus is, use the latest version of the Marlin firmware. Apparently the new version of the Full Graphic Smart controller, the one without the pot, does not work with the old version of Marlin. I too had the single line of pixels.

Make sure you install and import the U8Glib from https://code.google.com/p/u8glib/wiki/u8glib

I installed the new Marlin from https://github.com/MarlinFirmware/Marlin

Just configured my configuration.h and it worked.

|

Re: Folger Prusa i3 Kit from ebay January 07, 2015 04:32PM |

Registered: 9 years ago Posts: 13 |

Quote

bengele

Hoping that someone who is better at electronics can verify what I am going to do. I am trying to follow Tom's Guide on setting up auto bed leveling

3D printing guides: Setting up auto bed tramming leveling tilt compensation!

I am going to just use the open terminals on the power supply to get 12v input and ground. It looks to me like the pin closest to the edge of the ramps board is where I need to hook up the output.

Does that look right? I would prefer not to fry anything.

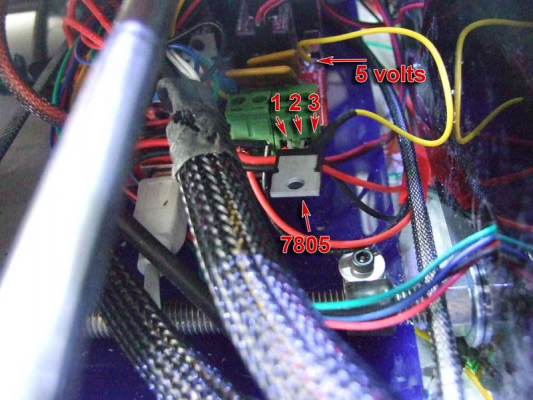

What I found is the Ramps board can not supply enough power (5V) to be able to run an LCD and a servo. I found a thread about problems with the 5V output .It's easy to take care of, what you need is a 7805 voltage regulator (got one from Radio Shack for around $2.00) hooked it up to 12V inputs then ran it to the 5V pin (the one you jump with the vcc pin to supply voltage to the servos). Now have plenty of power to run both.

|

Re: Folger Prusa i3 Kit from ebay January 07, 2015 04:51PM |

Registered: 9 years ago Posts: 13 |

Hey if you guys are looking for something to do with the 608 bearings that come with the kit.

[www.thingiverse.com] By by PristineSource

I built it but have not installed it yet Very well built just be careful when tightening the M8 bolt.

[www.thingiverse.com] By by PristineSource

I built it but have not installed it yet Very well built just be careful when tightening the M8 bolt.

|

Re: Folger Prusa i3 Kit from ebay January 07, 2015 07:12PM |

Registered: 9 years ago Posts: 5 |

Quote

KeyserSoze3d

Quote

boboche

Quote

Newtoprinting

Can I try your marlin zipQuote

jrcaster

Make sure you have all of the relevent files in the directory before you compile to arduino. Looks like you are missing the files that it is looking for.

I've been fighting with the Full Graphic Smart controller as well... I have several LCDs and RAMPS shields, I ruled out electronics, wiring etc... the only thing left is firmware issue or defective LCD board. I get stuff displayed in any other LCD that I plug in.

The LCD turns on, nothing displayed other than a one row of pixels (middle of screen) that are of different contrast than the rest of the screen (i.e. not fully on), That's it.

The folgertech configuration.h doesn't have the "FULL GRAPHIC" smart controller, so I tried adding it, also tried with stock marlin 1.01 to rule firmware out (Added the U8Glib.h library and include in configuration.h) still nothing on the screen.

As stated by other people, there's no pot on the board, and its not a inverted wiring issue else it wouldn't power up, I get no compile error.... using arduino 1.06, what's left?? thanks for any help!

Several of us have been there and done that wit the Full Graphic Smart controller. The consensus is, use the latest version of the Marlin firmware. Apparently the new version of the Full Graphic Smart controller, the one without the pot, does not work with the old version of Marlin. I too had the single line of pixels.

Make sure you install and import the U8Glib from https://code.google.com/p/u8glib/wiki/u8glib

I installed the new Marlin from https://github.com/MarlinFirmware/Marlin

Just configured my configuration.h and it worked.

Man....thanks a MILLION! I was downloading that 1.01 build with no results... just got it to display something.... so happy... Thank you so much!

|

Re: Folger Prusa i3 Kit from ebay January 07, 2015 08:29PM |

Registered: 9 years ago Posts: 12 |

Switched out stepper motor drivers and tha did the trick.Quote

rz90208

@boy09 - jittering stepper usually is a wiring issue. use a multimeter to find the pairs. Low or no resistance indicate a pair, open circuit indicates its not a pair. Pairs go next to each other in the 4 pin connector. Also try swapping the stepper drivers.

Now that that's fixed, I tried to run me first print (20mm calibration cube). I start the print and all the axes go to home (back right of build platform), then the extruder shoots over to the opposite side opposite side of the build platform (front left) and starts dumping filament in ~1second intervals. Repetier shows the cube filling in each layer (each 1second burst = 1 layer), then after about a minute it's done and the extruder never moved.

I'm using the Folger Tech configuration.h with the setting from MakerFront's setup guide. Should I ditch the folger tech configuration.h?

EDIT:

After looking at the G Code spit out by Slic3r, all of the G1 X & Y commands are around 300 like so:

G1 X313.964 Y290.000 E1.76864

G1 X313.964 Y310.000 E2.30323

G1 X313.569 Y311.725 E2.35053

G1 X312.463 Y313.106 E2.39783

G1 X310.000 Y313.964 E2.46755

G1 X290.000 Y313.964 E3.00214

G1 X288.275 Y313.569 E3.04944

G1 X286.894 Y312.463 E3.09674

Shouldn't all these values fall between 0 and 200, assuming a 200mm x 200mm build platform? Or no?

Edited 1 time(s). Last edit at 01/07/2015 10:57PM by boy09.

|

Re: Folger Prusa i3 Kit from ebay January 08, 2015 05:17PM |

Registered: 9 years ago Posts: 23 |

|

Re: Folger Prusa i3 Kit from ebay January 08, 2015 06:17PM |

Registered: 9 years ago Posts: 2 |

|

Re: Folger Prusa i3 Kit from ebay January 09, 2015 06:14AM |

Registered: 9 years ago Posts: 1,011 |

Your stepsticks output power is not properly set. I guess it's too high, your stepper motor should not be too hot, it should feel tepid to the touch. Maybe your printing speed is too low too. Measure the output power if you can, and lower it to a proper value. Your speed is low but the Folger's extruder do not allow high speeds anyways. PLA makes a lot of chips on the cold end gear. Be sure it's nice and clean. Mybe you can raise a bit the hotend temperature too, that will make the filament travel more fluent. But beware to raise it too high, because the Folger's extruder cloggs quicky when too hot.Quote

Newtoprinting

My extruder motor gets hot and then 20 minutes later it starts clicking and not feeding into hot end. Speed is 50mms 190 degrees with transparent pla

IMHO, the Folger's extruder uses a too small stepper motor. I suggest to upgrade that extruder for a Wade style as soon as possible. The reason is, direct drive extruders needs reasonable torque at low speed. With low torque motors, they won't have enough torque at very low speed to push the filament, especialy when it expands in the tube between the heastink and the heatblock, because of an unsufficient cooling system on Folger's. With a geared extruder, the motor will works faster. So it will be in an better operating range providing more torque. The gear itself increase the torque too. That will solve most of the problems. A good hotend will manage the remaining problems.

Edited 2 time(s). Last edit at 01/09/2015 06:29AM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Folger Prusa i3 Kit from ebay January 09, 2015 08:56AM |

Registered: 9 years ago Posts: 3 |

I've glanced through the thread and didn't see anything, but sorry if this is a repeat question. My Folger Tech printer runs great, but changing the filament has required me to take off the screws at the block above the hot end, feed filament through, and then insert the new filament in the block before putting it back into place and screwing it together (if that makes sense, like it is slightly off alignment). If I try to feed new filament without taking it apart, it always gets stuck at the entrance to the block and causes my stepper motor to click. Anyone have any tips or tricks for quickly changing out filaments now that I have multiple colors?

|

Re: Folger Prusa i3 Kit from ebay January 09, 2015 09:34AM |

Registered: 9 years ago Posts: 1,011 |

Well, you may try to bend (or unbend) your filament to help it passing thru. Maybe the heat block is missassembled. try to reverse it, there's multiple possible positions and some are close but not perfecly aligned.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Folger Prusa i3 Kit from ebay January 09, 2015 07:48PM |

Registered: 9 years ago Posts: 12 |

I downloaded the latest version of Marlin and Waltermixx's Configuration.h file. Is there an easy way to insert the configuration.h file into the latest version of Marlin? I'm guessing Waltermixx's config.h is from an older Marlin version so it returns some errors when you try to compile. Is there any way to make it work other than manually going through config.h and matching all of Waltermixx's values?

|

Re: Folger Prusa i3 Kit from ebay January 10, 2015 03:15AM |

Registered: 9 years ago Posts: 1,011 |

Use winmerge free software to compare the two versions

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Sorry, only registered users may post in this forum.