Folger Prusa i3 Kit from ebay

Posted by Waltermixx

|

Re: Folger Prusa i3 Kit from ebay March 27, 2015 12:36AM |

Registered: 9 years ago Posts: 705 |

|

Re: Folger Prusa i3 Kit from ebay March 27, 2015 06:04AM |

Registered: 9 years ago Posts: 27 |

Quote

elwood127

Hey Hathalud, this is all that holds in the x axis rods if yours is the same as my printer. See Pic.

Yeah. I have one (it's shaped differently... it's the cast off from the motor mount, but it's effective) I'm just missing one of them at the moment... I know it arrived, it's just not present atm.

Anyways, I got it working... Just having trouble with the software right now... but I'll take all that to another discussion or forum where it's more appropriate. Thanks for the help folks!

|

Re: Folger Prusa i3 Kit from ebay March 27, 2015 12:17PM |

Registered: 11 years ago Posts: 18 |

|

Re: Folger Prusa i3 Kit from ebay March 27, 2015 07:33PM |

Registered: 9 years ago Posts: 116 |

|

Re: Folger Prusa i3 Kit from ebay March 28, 2015 02:08AM |

Registered: 10 years ago Posts: 4 |

I was hoping I could be pointed in the right direct. I bought this kit back in october or november, and I am still having issues getting it built and working. Well, the build was easy, but the wiring... Well, not good. Two weeks ago, after finally wiring my PSU, rampsw, motors, etc, I said a little prayer and connected my Arduino(while connected to the ramps, with power on) to my laptop to begin programming(at the time, I thought the arduino had to be mounted to the Ramps in order to function whatsoever -_-). (It might be important to note that at this point, everything is heating up, but not moving--Heated bed and hotend are... hot.) When I did, the laptop immediately shut off. Reset the laptop, plugged in the arduino, reset once more. Upon some research, found that this can happen with USB ports that aren't powered well. This made some sense, so I figured I'd try a newer Asus that I knew worked and worked well. No reset, but my cursor began going mad, and randomly clicking. Confused and defeated, I unplugged the arduino, did more research, and found out that the arduino could be programmed on its own, using usb power(Duh). I attempted to program, but the led would slowly fade out after 30 seconds on the board, and my PC would not recognize. Lo and behold, several chips on the board seem to be fried. Resolving that somewhere, somehow, I've read or watched a poor instruction, I purchased a new ramps, arduino mega, and step sticks.

Today, I review my wiring, findi9ng what I believed to be the issue. My PSU's power cable's Live and Neutral cables were crossed. I also possibly had my endstop switches on incorrectly. I correct the PSU(wich never gave me issues in the first place), rewire the new ramps, hook up and program the new Arduino(Worked!) connect the new arduino, power it all on. Unlike my first boot, nothing really happens. The PSU lights up and the fan spins, the arduinpo lights up, but the ramps doesn't. Unlike the first time, the heated bed does not heat, and the hotend is not... well, hot. Thinking this is due to settings in the programming somehow(At this point I'm truly lost) I connect the arduino to my Asus. I get the same error as before, the cursor jumping wildly, and nothing working. BUT, the arduino hasn't fried itself, so I'm happy there. At this point, I'm beaten. I'd hoped I could come here and beg for some assistance.

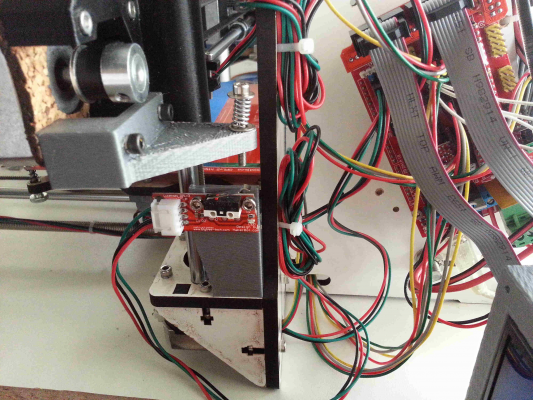

At this point, I know only a couple things. First, I'm positive there must be feedback coming from the arduino into the laptop. This seems like a very bad thing. Second, my wiring matched every diagram I've seen. I've attached a couple picks of the new ramps for evidence. I can't figure the beast out. I've built pcs for 15 years, and have never had an ounce of difficulty with electronics in general, but this thing, the entire 3D printer, makes me feel like a dunce, and I can't seem to learn my way out of it. Thanks for any, and all, assistance guys. (Also, this post may be in the wrong place--I just figured this seemed right, since this is the kit I'm using)

Today, I review my wiring, findi9ng what I believed to be the issue. My PSU's power cable's Live and Neutral cables were crossed. I also possibly had my endstop switches on incorrectly. I correct the PSU(wich never gave me issues in the first place), rewire the new ramps, hook up and program the new Arduino(Worked!) connect the new arduino, power it all on. Unlike my first boot, nothing really happens. The PSU lights up and the fan spins, the arduinpo lights up, but the ramps doesn't. Unlike the first time, the heated bed does not heat, and the hotend is not... well, hot. Thinking this is due to settings in the programming somehow(At this point I'm truly lost) I connect the arduino to my Asus. I get the same error as before, the cursor jumping wildly, and nothing working. BUT, the arduino hasn't fried itself, so I'm happy there. At this point, I'm beaten. I'd hoped I could come here and beg for some assistance.

At this point, I know only a couple things. First, I'm positive there must be feedback coming from the arduino into the laptop. This seems like a very bad thing. Second, my wiring matched every diagram I've seen. I've attached a couple picks of the new ramps for evidence. I can't figure the beast out. I've built pcs for 15 years, and have never had an ounce of difficulty with electronics in general, but this thing, the entire 3D printer, makes me feel like a dunce, and I can't seem to learn my way out of it. Thanks for any, and all, assistance guys. (Also, this post may be in the wrong place--I just figured this seemed right, since this is the kit I'm using)

|

Re: Folger Prusa i3 Kit from ebay March 28, 2015 03:05AM |

Registered: 9 years ago Posts: 98 |

I don't see a black wire in the very bottom connection (green power in block, wires that come from your power supply). Your themistor connections look weird too but I can't tell for sure because of the picture. Looks like awfully thick wires for that.

Edited 1 time(s). Last edit at 03/28/2015 03:05AM by krwynn.

Edited 1 time(s). Last edit at 03/28/2015 03:05AM by krwynn.

|

Re: Folger Prusa i3 Kit from ebay March 28, 2015 03:33AM |

Registered: 10 years ago Posts: 4 |

I panicked when I looked at the picture hah, but no, the cables are plugged into the block, just got twisted when I took the picture. As for the thickness, I'm unsure, but I'm fairly certain I have everything ran properly. Its an aweful rats nest, but I think the thermistors are in right.

|

Re: Folger Prusa i3 Kit from ebay March 28, 2015 10:51PM |

Registered: 9 years ago Posts: 116 |

Hello All:

I would like to know how you installed the couplings on the motors and the Z threaded rods into the couplings. The install I see in the instruction has the motor shafts going up almost all of the length of the coupling and I feel this compromises the coupling. So I installed the coupling so the motor shaft only goes into the solid part of the coupling. But then I installed the threaded rod so it touches the motor shaft. But by the same logic as before this would also compromise the coupling. If I pull up the threaded rod and install it into the upper solid portion of the coupling then the coupling carries the vertical loads and since it is compressible the Z axis accuracy will suffer.

One way would be to put in a wobble pin that would carry the vertical loads thru the coupling and onto the motor shaft. Or a stack of 5mm steel balls that would support the vertical loads. The ideal solution for the Prusa I3 type printers is a thrust bearing and support for the threaded rod to decouple the load of the X carriage and extruder from the coupling and motor bearings and feed it directly into the vertical frame.

You thoughts please.

Ecky, 3d printing newb

Canada, J6? ???

I would like to know how you installed the couplings on the motors and the Z threaded rods into the couplings. The install I see in the instruction has the motor shafts going up almost all of the length of the coupling and I feel this compromises the coupling. So I installed the coupling so the motor shaft only goes into the solid part of the coupling. But then I installed the threaded rod so it touches the motor shaft. But by the same logic as before this would also compromise the coupling. If I pull up the threaded rod and install it into the upper solid portion of the coupling then the coupling carries the vertical loads and since it is compressible the Z axis accuracy will suffer.

One way would be to put in a wobble pin that would carry the vertical loads thru the coupling and onto the motor shaft. Or a stack of 5mm steel balls that would support the vertical loads. The ideal solution for the Prusa I3 type printers is a thrust bearing and support for the threaded rod to decouple the load of the X carriage and extruder from the coupling and motor bearings and feed it directly into the vertical frame.

You thoughts please.

Ecky, 3d printing newb

Canada, J6? ???

|

Re: Folger Prusa i3 Kit from ebay March 30, 2015 10:45AM |

Registered: 9 years ago Posts: 41 |

I was getting frustrated with finding the proper hardware for a wade's extruder for a E3D V6 to install on my Folger Tech I3. My local Lowes and Menards keep a minimal stock of anything in metric. Either I found a model I liked on thingiverse but it didn't work well with the hardware I could find or I found a model I didn't like that had the hardware I could use. I decided to create my own extruder from scratch using NX 8.0. I have attached the.stl and an image of the model I created. I saw a couple of others using E3D's on this forum and thought I would share this here. I printed one already, but I didn't like how the M3 and M4 nut cut outs fit even though I used my Machiner's Handbook. I took direct measurements from a couple of the spare nuts I had lying around and gave them a little clearance allowing for a snug fit. I also opened up the the hole to the hotend so that the PTFE tubing can go all the way to the hobbed bolt. Most of the model uses M3 nuts and screws, but I had a hard time finding a long enough M3 screw for the idler and went with M4. I used an old Tippmann A5 velocity adjustment spring and cut it to size. It might be a little stiff but it seems like it will work nicely. I still am working on the hot end clamp and idler, but just about anything of the Rework designs should work with it. This does use the Rework X-carriage. Please let me know what you guys think or what you used to install your V6.

|

Re: Folger Prusa i3 Kit from ebay March 31, 2015 07:14AM |

Registered: 9 years ago Posts: 116 |

I can't find any metric hardware in the regular stores either and I live in Canada, a metric country. The rest of the world has gone metric even the people that invented the Imperial system. I guess we need to face facts and also go down that road one day. Till then it is a struggle to find what we need to support our hobby.

|

Re: Folger Prusa i3 Kit from ebay March 31, 2015 12:43PM |

Registered: 9 years ago Posts: 27 |

I found two issues with my printer and I'm hoping you guys can help.

1. The prints are mirrored. Most of what I've been printing is kinda universal, but on the first print where it had to be precise, I found it printed mirrored... the new endstop holder I printed was upside down. And since then I've noticed that it's printing mirrored from what is set up in Cura for slicing...

2. I printed out a calibration print that's suppose to fit a nickel through it, and the print is too small. I assume that's a stepper motor calibration issue, correct?

1. The prints are mirrored. Most of what I've been printing is kinda universal, but on the first print where it had to be precise, I found it printed mirrored... the new endstop holder I printed was upside down. And since then I've noticed that it's printing mirrored from what is set up in Cura for slicing...

2. I printed out a calibration print that's suppose to fit a nickel through it, and the print is too small. I assume that's a stepper motor calibration issue, correct?

|

Re: Folger Prusa i3 Kit from ebay March 31, 2015 01:23PM |

Registered: 9 years ago Posts: 29 |

Quote

hathalud

I found two issues with my printer and I'm hoping you guys can help.

1. The prints are mirrored. Most of what I've been printing is kinda universal, but on the first print where it had to be precise, I found it printed mirrored... the new endstop holder I printed was upside down. And since then I've noticed that it's printing mirrored from what is set up in Cura for slicing...

2. I printed out a calibration print that's suppose to fit a nickel through it, and the print is too small. I assume that's a stepper motor calibration issue, correct?

Yeah, on my folger the y axis is mirrored. Until I fix the hardware side if that, I just always flip the y in cura.

As for your calibration print, do you currently have a fan shroud to cool the extruded plastic? If you don't, I found one for the Folgertech i3 on thingiverse: Thingiverse

I don't know which calibration quarter slot you are printing, but if the slot is on the bottom, the first layer is always going to be smashed in a little, so all you have to do is clan up the slot. I don't think that it is a motor calibration issue, but you may want to try and adjust your stepper pots.

|

Re: Folger Prusa i3 Kit from ebay March 31, 2015 02:01PM |

Registered: 9 years ago Posts: 27 |

Quote

cheaptrick2

Yeah, on my folger the y axis is mirrored. Until I fix the hardware side if that, I just always flip the y in cura.

As for your calibration print, do you currently have a fan shroud to cool the extruded plastic? If you don't, I found one for the Folgertech i3 on thingiverse: Thingiverse

I don't know which calibration quarter slot you are printing, but if the slot is on the bottom, the first layer is always going to be smashed in a little, so all you have to do is clan up the slot. I don't think that it is a motor calibration issue, but you may want to try and adjust your stepper pots.

Correcting for the mirroring issue in Cura is obvious, but in my book that's a work-around, not a fix.

As for the calibration, I'm using this print. [www.thingiverse.com] and it's small uniformly in both the X and the Y.

*** P.S. Thanks for the fan shroud. That'll be my next print. I'll probably have to print it twice, increasing the size to account for my printer's misalignment the second time.

Edited 1 time(s). Last edit at 03/31/2015 02:19PM by hathalud.

|

Re: Folger Prusa i3 Kit from ebay April 01, 2015 10:01PM |

Registered: 9 years ago Posts: 6 |

I finally have been printing for about 1 week now. No enclosure,bed is at 121 although it doesn't really go past 90,extruder is at 230. flawless prints. making parts for improvements. You must keep the extruder clean.......Everything..amd I mean mostly everything the folger guys had on there build file were wrong. I had to pick my brain alot.

|

Re: Folger Prusa i3 Kit from ebay April 01, 2015 11:22PM |

Registered: 9 years ago Posts: 27 |

Quote

Billygeorge

I finally have been printing for about 1 week now. No enclosure,bed is at 121 although it doesn't really go past 90,extruder is at 230. flawless prints. making parts for improvements. You must keep the extruder clean.......Everything..amd I mean mostly everything the folger guys had on there build file were wrong. I had to pick my brain alot.

My bed refuses to go past 70! lol

|

Re: Folger Prusa i3 Kit from ebay April 02, 2015 05:00AM |

Registered: 9 years ago Posts: 116 |

Quote

Billygeorge

I finally have been printing for about 1 week now. No enclosure,bed is at 121 although it doesn't really go past 90,extruder is at 230. flawless prints. making parts for improvements. You must keep the extruder clean.......Everything..amd I mean mostly everything the folger guys had on there build file were wrong. I had to pick my brain alot.

Would you care to share your good files with the community??

|

Re: Folger Prusa i3 Kit from ebay April 02, 2015 03:27PM |

Registered: 9 years ago Posts: 52 |

I am about 4-5 hours into the build and have completed the mechanical part of the build. I am going to start on the electronics tonight. So far the build has gone great! I did run into a few issues.

1. There were no Y bearing holders in my kit. Turns out they got rid of these in RevB. I had an old build document. Now uses zip ties. I think I'll print the Y bearing holders and rebuild my bed at some point in the future. No matter how tight the zip ties are the bearings feel a tad loose.

2. X assembly was completely upside down. Make sure your stepper is on the right hand side when attaching the X assembly to the acrylic frame.

3. Y belt block wasn't tight enough to hold belt in place. There was no pressing the belt into the block as it loosely slipped in. Any movement would just pull the belt out of the belt block. I fixed this by pressing a short piece(length of the belt block) of spare belt to wedge in alongside the Y belt where it is inside the block.

4. Not enough zip-ties. Fixed by grabbing some mini zip ties I had lying around.

I hope this info helps someone! Excited to get back at it tonight.

1. There were no Y bearing holders in my kit. Turns out they got rid of these in RevB. I had an old build document. Now uses zip ties. I think I'll print the Y bearing holders and rebuild my bed at some point in the future. No matter how tight the zip ties are the bearings feel a tad loose.

2. X assembly was completely upside down. Make sure your stepper is on the right hand side when attaching the X assembly to the acrylic frame.

3. Y belt block wasn't tight enough to hold belt in place. There was no pressing the belt into the block as it loosely slipped in. Any movement would just pull the belt out of the belt block. I fixed this by pressing a short piece(length of the belt block) of spare belt to wedge in alongside the Y belt where it is inside the block.

4. Not enough zip-ties. Fixed by grabbing some mini zip ties I had lying around.

I hope this info helps someone! Excited to get back at it tonight.

|

Re: Folger Prusa i3 Kit from ebay April 02, 2015 07:35PM |

Registered: 9 years ago Posts: 14 |

@DriftyDave For the Y and X axis carriage belts you should do it how they picture in the Prusa i3 rework build pics, which is wrap it completely around the inner block and ziptie it back onto itself on the outside. Other wise it will eventually come off or just cause you issues.

I did it as described in the folger build manual then had to order new belts to do it properly later....don't be me.

See

X-axis belt secure method

Edited 1 time(s). Last edit at 04/02/2015 07:36PM by donkahones.

I did it as described in the folger build manual then had to order new belts to do it properly later....don't be me.

See

X-axis belt secure method

Edited 1 time(s). Last edit at 04/02/2015 07:36PM by donkahones.

|

Re: Folger Prusa i3 Kit from ebay April 03, 2015 01:53PM |

Registered: 9 years ago Posts: 52 |

@donkahones: Crud. I'll need to order new belts too then. Tanks for the picture! That looks soooo much better then what I've got going on! Is there some new documentation other then whats on the Folger google drive?

I got most the electronics installed last night. Power supply, Ramps, Arduino, Heated bed, Hot end, and hot end fan installed. Tonight I'll work on Thermistors, stepper motors, and end stops. Having a great time building this thing!

I got most the electronics installed last night. Power supply, Ramps, Arduino, Heated bed, Hot end, and hot end fan installed. Tonight I'll work on Thermistors, stepper motors, and end stops. Having a great time building this thing!

|

Re: Folger Prusa i3 Kit from ebay April 03, 2015 03:24PM |

Registered: 9 years ago Posts: 14 |

@DriftyDave The Prusa i3 Rework section on this site has some pretty good build documentation of which most is applicable. There are some serious holes in folgers build manual. (differing bolt sizes, unclear directions etc.).

Once you get it up and running you will see that there are a number of better ways to do things.

First thing you'll probably want to print is this fan duct Mk7 head Fan Duct It will help a lot with PLA cooling until you can get a dedicated fan hooked up.

After that you'll realize the Z-axis endstop design is horrible. I've yet to find a good solution that works really well for me. I have to recalibrate bed leveling almost every print. Get used to doing this. I bought some different, longer, springs and bolts to mount the bed on to give me more adjustability.

Once you get it up and running you will see that there are a number of better ways to do things.

First thing you'll probably want to print is this fan duct Mk7 head Fan Duct It will help a lot with PLA cooling until you can get a dedicated fan hooked up.

After that you'll realize the Z-axis endstop design is horrible. I've yet to find a good solution that works really well for me. I have to recalibrate bed leveling almost every print. Get used to doing this. I bought some different, longer, springs and bolts to mount the bed on to give me more adjustability.

|

Re: Folger Prusa i3 Kit from ebay April 03, 2015 07:45PM |

Registered: 9 years ago Posts: 27 |

Quote

donkahones

After that you'll realize the Z-axis endstop design is horrible. I've yet to find a good solution that works really well for me. I have to recalibrate bed leveling almost every print. Get used to doing this. I bought some different, longer, springs and bolts to mount the bed on to give me more adjustability.

I found these prints the other day that should help with that:

With this print you'll still have to calibrate after each print more than likely, but fine tuning the Z-endstop ought to be a lot easier... http://www.thingiverse.com/thing:313694

On the other hand this print requires a few new parts to be had, but it automates leveling the build plate in the firmware so that prints come out a whole lot better... http://www.thingiverse.com/thing:545911 Here is an extreme example of it as a proof of concept. https://www.youtube.com/watch?v=x8eqSQNAyro

At the moment I don't have either of these implemented on my printer, but I'm sharing what I found that hopefully will help others out a lot.

|

Re: Folger Prusa i3 Kit from ebay April 03, 2015 08:16PM |

Registered: 9 years ago Posts: 53 |

Quote

donkahones

After that you'll realize the Z-axis endstop design is horrible. I've yet to find a good solution that works really well for me. I have to recalibrate bed leveling almost every print. Get used to doing this. I bought some different, longer, springs and bolts to mount the bed on to give me more adjustability.

I made these specifically for the Folger Tech--losely based apon what I could find on thingiverse....

Edited 1 time(s). Last edit at 04/03/2015 08:25PM by 55rebel.

|

Re: Folger Prusa i3 Kit from ebay April 03, 2015 11:02PM |

Registered: 9 years ago Posts: 6 |

the ONLY things I have changed in the original Ardunio firmware was the # 33 board and the Extruder steps per min(from 90 to 225). that finally got it to move. I also added a LCD which I #defined as Reprap smart controller. I had originally set the VREFS on the motors to 0.35V except the y which is 0.55V. Id post the entire conf H but it won't help if you've changed other things. I was going back and forth for the past 2 months. I read some forums and figured it out LOL..........One thing for sure is that you MUST home ALL axes before you can move it. That I finally stumbled upon too.

Edited 1 time(s). Last edit at 04/03/2015 11:04PM by Billygeorge.

Edited 1 time(s). Last edit at 04/03/2015 11:04PM by Billygeorge.

|

Re: Folger Prusa i3 Kit from ebay April 04, 2015 12:02AM |

Registered: 9 years ago Posts: 116 |

|

Re: Folger Prusa i3 Kit from ebay April 04, 2015 12:07AM |

Registered: 9 years ago Posts: 15 |

Hello all i have been using my folgertech since january i am now getting pretty good qulity prints my the only problem i have yet to work out is when my extruder stops then moves to another area to start there is a fraction of a second were not enough plastic is being laid down leaving very small blank areas its not to bad most prints come out well but every area it stops and starts at is a little light. I have adjusted all of the axis steps per mm as well as extruder they are all verry close in tolerance. I am using the stock configuration h file from folger tech only change i have made is steps per mm . Any suggestions greatly appreciated.

|

Re: Folger Prusa i3 Kit from ebay April 04, 2015 02:23AM |

Registered: 9 years ago Posts: 27 |

Quote

downinit

Hello all i have been using my folgertech since january i am now getting pretty good qulity prints my the only problem i have yet to work out is when my extruder stops then moves to another area to start there is a fraction of a second were not enough plastic is being laid down leaving very small blank areas its not to bad most prints come out well but every area it stops and starts at is a little light. I have adjusted all of the axis steps per mm as well as extruder they are all verry close in tolerance. I am using the stock configuration h file from folger tech only change i have made is steps per mm . Any suggestions greatly appreciated.

There's a setting in the configuration file that tells the extruder to reverse the filament by X amount before it lifts up and moves to another spot on the print. Lowering this value will probably help you. In a prior post, one of the suggestions Mudjunkie made was to set DEFAULT_RETRACT_ACCELERATION to 500.

|

Re: Folger Prusa i3 Kit from ebay April 04, 2015 05:41PM |

Registered: 9 years ago Posts: 8 |

Ok, my Folger I3 printer is built. Everything work good, except a few things.... When I test my motors, x,y and z they move only one way, the other way it tell me that I'm at the stop but I'm not.

For example, I move x axix (-x) and it move left and if I move left(+x) it give me code:

''echo:endstops hit: Y:-1.40

echo:endstops hit: X:-1.56

echo:endstops hit: X:-1.55''

but I'm not at the endstop...

It's the same on the Y and Z

Any idea what is wrong?

For example, I move x axix (-x) and it move left and if I move left(+x) it give me code:

''echo:endstops hit: Y:-1.40

echo:endstops hit: X:-1.56

echo:endstops hit: X:-1.55''

but I'm not at the endstop...

It's the same on the Y and Z

Any idea what is wrong?

|

Re: Folger Prusa i3 Kit from ebay April 04, 2015 11:12PM |

Registered: 9 years ago Posts: 52 |

donkahones: Thanks for the info! Got the whole thing together today! All the motors move correctly, everything heats up and I was able to level the bed for the first, of many, times.

Only issue so far is the extruder just clicks when trying to fed filament... Gonna have to search around on that one. Any advice would be appreciated. ;D

Only issue so far is the extruder just clicks when trying to fed filament... Gonna have to search around on that one. Any advice would be appreciated. ;D

|

Re: Folger Prusa i3 Kit from ebay April 05, 2015 12:47AM |

Registered: 9 years ago Posts: 27 |

Quote

DriftyDave

Only issue so far is the extruder just clicks when trying to fed filament... Gonna have to search around on that one. Any advice would be appreciated. ;D

If it's a soft click (not very loud) the filament isn't fed through the extruder motor housing. If it's a loud clicking-popping sound then the filament is properly fed into the extruder motor housing but not moving down and the motor is skipping steps. I found that initially I had to disassemble the hot end and watch the filament go in until I got a feel for when it was acting right and what pressures were needed on my part.

|

Re: Folger Prusa i3 Kit from ebay April 05, 2015 01:10AM |

Registered: 9 years ago Posts: 8 |

Quote

choopi

Ok, my Folger I3 printer is built. Everything work good, except a few things.... When I test my motors, x,y and z they move only one way, the other way it tell me that I'm at the stop but I'm not.

For example, I move x axix (-x) and it move left and if I move left(+x) it give me code:

''echo:endstops hit: Y:-1.40

echo:endstops hit: X:-1.56

echo:endstops hit: X:-1.55''

but I'm not at the endstop...

It's the same on the Y and Z

Any idea what is wrong?

Ok, now my x and z are working good! Now my new snag! My Y only move one way... If I move y+ it goes towards the front and if I hit the -y it goes towards the front also.

Sorry, only registered users may post in this forum.