Folger Prusa i3 Kit from ebay

Posted by Waltermixx

|

Re: Folger Prusa i3 Kit from ebay April 17, 2015 06:35PM |

Registered: 9 years ago Posts: 6 |

Quote

Vanbot

Quote

flippydip

So i got my printer printing, just an issue with the extruder. It seems like it can't fully catch the filament, it misses it thus making a loud noise as if it is skipping. Because of this the filament doesn't come out smoothly.

Could someone please help!

Thank You

I took my extruder apart to see how the filament is supposed to feed into the drive wheels.First are you feeding it into the hole on the top that is directly over the hot end? On mine, looking at the top of the extruder its the hole on the right.

When I feed filament into mine, I hold the filament so that it is curling down and the lower tip ends up pointing to the right. That seems to make sure it goes between the drive wheel and idler. It took a while for mine to feed in properly and it was sort of clicking until it did.

Yes i am feeding it to the one on the right. I also took it apart to see how it works. Best way i can describe it is that the motor isn't catching the filament consistently, like it slips so the filament doesn't come out right. It is also coming out very thick .

|

Re: Folger Prusa i3 Kit from ebay April 17, 2015 06:40PM |

Registered: 9 years ago Posts: 20 |

Well, my machine is up and running - I'm not sure if I had a bad batch of steppers or what... but the extruder one was also bad. Swapped it for the steppers (known working and already dialed in) from my other machine and it prints. If the extruder you have is "clicking" that is a sign you have insufficent current or the far more likely - improper filament feeding. Since the kit does not come with a spool holder this could be a problem.

My calibration cube came out all right - having wired up the heated bed yet for reasons previously known, but I got 19.78mm (plus or minus .03mm due to tool) on a hollow 20mm calibration cube. Warping and bed adhesion issues were expected. The filament I have needs to be dialed in because it failed the 20mm bridge test with supporting .5 mm walls. Blegh. Calibration time now.

My calibration cube came out all right - having wired up the heated bed yet for reasons previously known, but I got 19.78mm (plus or minus .03mm due to tool) on a hollow 20mm calibration cube. Warping and bed adhesion issues were expected. The filament I have needs to be dialed in because it failed the 20mm bridge test with supporting .5 mm walls. Blegh. Calibration time now.

|

Re: Folger Prusa i3 Kit from ebay April 17, 2015 07:10PM |

Registered: 9 years ago Posts: 156 |

Now that I have the correct Printer Shape settings for mine it at least doesn't try to print 100 mm off the edge of my bed. I've tried printing a dental floss holder which is sort of fork shaped. It prints upside down so it starts by printing the two "tines" of the holder. When I attempt this print it starts printing the tip of one tine just fine but the other one it tries printing in mid air. I guess I should try printing a cube to see what needs adjusting.

|

Re: Folger Prusa i3 Kit from ebay April 18, 2015 09:11AM |

Registered: 9 years ago Posts: 116 |

Another thing.

When I got my kit the fan on the extruder was loose because the screws were bottomed in the motor casing. I put some stainless washers between the aluminium block and the motor housing to reduce the thermal contact area as well as adding the extra thickness for the screw problem. I would have used fiberglass if I had them. I also filed a notch in the heatsink to clear the setscrew that secured the extruder screw/shaft/nozzle holder and I put some CPU thermal paste in between the block and the heatsink the fan blows onto to allow better heat transfer.

When I got my kit the fan on the extruder was loose because the screws were bottomed in the motor casing. I put some stainless washers between the aluminium block and the motor housing to reduce the thermal contact area as well as adding the extra thickness for the screw problem. I would have used fiberglass if I had them. I also filed a notch in the heatsink to clear the setscrew that secured the extruder screw/shaft/nozzle holder and I put some CPU thermal paste in between the block and the heatsink the fan blows onto to allow better heat transfer.

|

Re: Folger Prusa i3 Kit from ebay April 18, 2015 12:46PM |

Registered: 9 years ago Posts: 6 |

|

Re: Folger Prusa i3 Kit from ebay April 18, 2015 01:33PM |

Registered: 9 years ago Posts: 20 |

With the heated bed the calibration cube is now at 19.92 or 19.95 out of 20 mm. The bridge still is not being done properly from a .5 thickness wall, but it is sticking. So its time to calibrate that part of it. My PLA is actually printing well at 193 C instead of the 200C I originally had it set at. Got about 10 mins left on my Folger Tech endstops and they look sweet.

Preparing for more calibration before getting to the larger and more complex prints... more dialing it in to come. This kit has already beat an older I2 kit that cost me 2.5x as much... so I'm happy with the end result.

Preparing for more calibration before getting to the larger and more complex prints... more dialing it in to come. This kit has already beat an older I2 kit that cost me 2.5x as much... so I'm happy with the end result.

|

Re: Folger Prusa i3 Kit from ebay April 18, 2015 05:12PM |

Registered: 9 years ago Posts: 6 |

|

Re: Folger Prusa i3 Kit from ebay April 18, 2015 10:19PM |

Registered: 9 years ago Posts: 52 |

Quote

flippydip

Yes i am feeding it to the one on the right. I also took it apart to see how it works. Best way i can describe it is that the motor isn't catching the filament consistently, like it slips so the filament doesn't come out right. It is also coming out very thick .

I ran into terrible skipping as well. My solution was to turn the extruder temp up until the skipping stopped. Still occasionally get a skip and will replace this extruder soon.

Speaking of replacements, what have people printed that has improved their Folger Tech? I have been looking for an x carrage that runs on 4 bearings instead of the 3. I also need a new extruder. I've only found one option that uses the same v bearing. Just needs a spring. Printing it now along with new Z & X endstop mounts.

Edited 1 time(s). Last edit at 04/18/2015 10:20PM by DriftyDave.

|

Re: Folger Prusa i3 Kit from ebay April 19, 2015 01:12PM |

Registered: 9 years ago Posts: 156 |

Quote

DriftyDave

Quote

flippydip

Yes i am feeding it to the one on the right. I also took it apart to see how it works. Best way i can describe it is that the motor isn't catching the filament consistently, like it slips so the filament doesn't come out right. It is also coming out very thick .

I ran into terrible skipping as well. My solution was to turn the extruder temp up until the skipping stopped. Still occasionally get a skip and will replace this extruder soon.

Speaking of replacements, what have people printed that has improved their Folger Tech? I have been looking for an x carrage that runs on 4 bearings instead of the 3. I also need a new extruder. I've only found one option that uses the same v bearing. Just needs a spring. Printing it now along with new Z & X endstop mounts.

There's a thread on improvements people have made to their Folger i3's. I don't know that the 4 bearing carriage will improve things. I have read that it makes it more difficult to get the linear bearings to all line up just right. What was your reasoning behind adding another bearing?

The one instant improvement I'd like to make it to the extruder. It's a pain to thread in new filament. Does anyone know of a design that works with the existing hot end to allow easier filament changes?

|

Re: Folger Prusa i3 Kit from ebay April 19, 2015 01:23PM |

Registered: 9 years ago Posts: 98 |

Quote

Vanbot

The one instant improvement I'd like to make it to the extruder. It's a pain to thread in new filament. Does anyone know of a design that works with the existing hot end to allow easier filament changes?

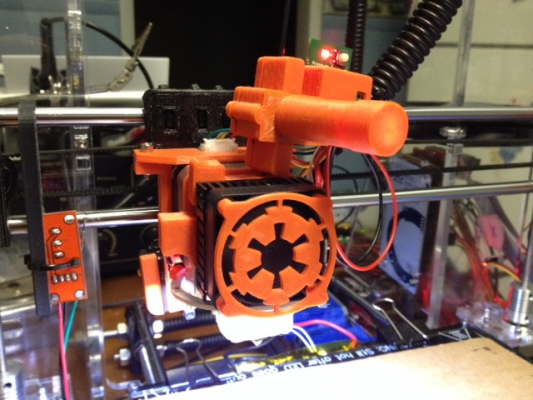

This one is great. Have had zero problems since installing it. Love it actually.

Extruder for FolgerTech Prusa i3 (v-groove bearing and flat feeder)

Here is mine installed:

I also used this tape 10M 13mm Width PTFE Coated Fiberglass Fabric With Silicone Adhesive Tape to wrap the hot end block which also helped a great deal.

|

Re: Folger Prusa i3 Kit from ebay April 19, 2015 02:20PM |

Registered: 9 years ago Posts: 156 |

Quote

krwynn

Quote

Vanbot

The one instant improvement I'd like to make it to the extruder. It's a pain to thread in new filament. Does anyone know of a design that works with the existing hot end to allow easier filament changes?

This one is great. Have had zero problems since installing it. Love it actually.

Extruder for FolgerTech Prusa i3 (v-groove bearing and flat feeder)

Here is mine installed:

I also used this tape 10M 13mm Width PTFE Coated Fiberglass Fabric With Silicone Adhesive Tape to wrap the hot end block which also helped a great deal.

I had seen that design on Thingiverse. If you think it works well I'll print one up!

How do you find that tape helps?

|

Re: Folger Prusa i3 Kit from ebay April 19, 2015 02:28PM |

Registered: 9 years ago Posts: 98 |

|

Re: Folger Prusa i3 Kit from ebay April 19, 2015 02:32PM |

Registered: 9 years ago Posts: 156 |

Quote

krwynn

Quote

Vanbot

How do you find that tape helps?

Keeps the heat concentrated on the heat end block. Also seems to keep heat from migrating up and also keeps the fan from blowing on the heat block.

How does that manifest itself in the printing? I've just started getting mine to print so I'm not at the point yet where I'm able to diagnose problems.

|

Re: Folger Prusa i3 Kit from ebay April 19, 2015 02:36PM |

Registered: 9 years ago Posts: 98 |

Most/all jams are from the filament getting too hot before it reaches the heat block and jams the tube. Tape keeps the heat on the block and lets the fan cool the filament and the top section of the tube where the filament enters.

Quote

Vanbot

Quote

krwynn

Quote

Vanbot

How do you find that tape helps?

Keeps the heat concentrated on the heat end block. Also seems to keep heat from migrating up and also keeps the fan from blowing on the heat block.

How does that manifest itself in the printing? I've just started getting mine to print so I'm not at the point yet where I'm able to diagnose problems.

|

Re: Folger Prusa i3 Kit from ebay April 19, 2015 11:32PM |

Registered: 8 years ago Posts: 6 |

Hi all, New to the printing game.

I wanted to add my thoughts on the Folger Tech kit. I live local to them so it was an easy choice for me to pick it up from them. I have been working with it for about a month. It does have some issues but nothing you can't work through if you are willing. The mods that I have made so far:

- Extruder was reversed for me off the bat, fixed in firmware.

- I had lots of skips once I fixed the direction of the extruder. Replaced the stock parts with thingiverse : 650957. Spring tension feeder. Works great, no more skips. Helps with filament variations.

- Found parts where coming out mirror image, Y direction fixed in firmware.

-Would get a good print and then a fail, then good. Bed level was my issue. I ditched the acrylic y sled for more rigid aluminum. I ended up fighting through auto bed level with and induction sensor and an aluminum bed. Bed and sled were custom made ( I am a CNC machinist) After hacking through Marlin I got it to work. And so far its worth all the pain. Sensor I bought from Folger. Bracket I printed from thingiverse : 671600

- I have been successful with PLA and ABS. Although I have not picked a preferred yet.

I am happy with the kit, but I am willing to tinker. If you think its going to work out of the box I don't think its going to happen. This forum is awesome and I got a lot from this thread alone. I am happy to share want I have learned and help anyone who wants to learn or needs some direction. Keep up the great work, Thanks for all that have helped me. Good luck.

-Tom

I wanted to add my thoughts on the Folger Tech kit. I live local to them so it was an easy choice for me to pick it up from them. I have been working with it for about a month. It does have some issues but nothing you can't work through if you are willing. The mods that I have made so far:

- Extruder was reversed for me off the bat, fixed in firmware.

- I had lots of skips once I fixed the direction of the extruder. Replaced the stock parts with thingiverse : 650957. Spring tension feeder. Works great, no more skips. Helps with filament variations.

- Found parts where coming out mirror image, Y direction fixed in firmware.

-Would get a good print and then a fail, then good. Bed level was my issue. I ditched the acrylic y sled for more rigid aluminum. I ended up fighting through auto bed level with and induction sensor and an aluminum bed. Bed and sled were custom made ( I am a CNC machinist) After hacking through Marlin I got it to work. And so far its worth all the pain. Sensor I bought from Folger. Bracket I printed from thingiverse : 671600

- I have been successful with PLA and ABS. Although I have not picked a preferred yet.

I am happy with the kit, but I am willing to tinker. If you think its going to work out of the box I don't think its going to happen. This forum is awesome and I got a lot from this thread alone. I am happy to share want I have learned and help anyone who wants to learn or needs some direction. Keep up the great work, Thanks for all that have helped me. Good luck.

-Tom

|

Re: Folger Prusa i3 Kit from ebay April 19, 2015 11:53PM |

Registered: 9 years ago Posts: 156 |

Hey Tom. Welcome.

We've had some very similar issues. I'm printing the spring loaded extruder as we speak in fact so I'm glad to hear it works well for you. Otherwise yes lots of second guessing the settings in the manual and firmware. I e-mailed Dan at Folger tonight to suggest they get their documentation updated.

I've replaced the Folger Y and Z end stops with adjustable types that make life much easier. I'm hoping to add a prox sensor as well for auto leveling and wasn't sure how well it worked with aluminum. Would you mind discussing what it was like getting that to work?

We've had some very similar issues. I'm printing the spring loaded extruder as we speak in fact so I'm glad to hear it works well for you. Otherwise yes lots of second guessing the settings in the manual and firmware. I e-mailed Dan at Folger tonight to suggest they get their documentation updated.

I've replaced the Folger Y and Z end stops with adjustable types that make life much easier. I'm hoping to add a prox sensor as well for auto leveling and wasn't sure how well it worked with aluminum. Would you mind discussing what it was like getting that to work?

|

Re: Folger Prusa i3 Kit from ebay April 20, 2015 12:30AM |

Registered: 8 years ago Posts: 6 |

My prox sensor is working well with the aluminum bed. I had to build a voltage divider to get the 12v down to 5v for the ramps to work and not fry, the output sensor wire goes to your current Z endstop connector on the ramps board, and the +,- need to go to 12 volts. My big hurdle was getting the Marlin firmware with auto bed level that would even compile. I found Github sucks the version information. I am using 1.0.2 that I got from [codeload.github.com]. Other versions that I got would not compile. I will attached my config.h so you can look at what I had to do compared to yours. I used the settings from Folger mins the ones I had to change to get X and Y and Extruder to go the right way. Only other file modified other than config.h was config_adv and confirmed that line 89 #define ENDSTOPS_ONLY_FOR_HOMING was uncommeted, which it was in my copy.

Setting the hotend and working out the probe offsets is really the hardest part to get right. I got it so that I don't have to put a Z offset in my slicer and my first layer is coming out great. I got the bed as level as I could before tweaking the probe. I am currently getting a total correction of .06 mm according to the G29 autolevel data. And you can see that the Z steppers are moving while its printing each layer not just when it moves to the next.

I would be happy to get into details if anyone needs further help.

-Tom

Setting the hotend and working out the probe offsets is really the hardest part to get right. I got it so that I don't have to put a Z offset in my slicer and my first layer is coming out great. I got the bed as level as I could before tweaking the probe. I am currently getting a total correction of .06 mm according to the G29 autolevel data. And you can see that the Z steppers are moving while its printing each layer not just when it moves to the next.

I would be happy to get into details if anyone needs further help.

-Tom

|

Re: Folger Prusa i3 Kit from ebay April 20, 2015 12:45AM |

Registered: 8 years ago Posts: 6 |

I just thought of a little more detail if you are looking at my config.h from my other post. My X endstop is on the LEFT, Y endstop on on the REAR near y stepper, and the prox prob in on the RIGHT side of the Extruder. My filament goes into the Right hole and the thumb grips are on the Left to change filament. I can post some pics if it helps too.

I did change the Y belt bracket as well to a clamping one, no zip ties, so munch nicer.

-Tom

I did change the Y belt bracket as well to a clamping one, no zip ties, so munch nicer.

-Tom

|

Re: Folger Prusa i3 Kit from ebay April 20, 2015 07:33PM |

Registered: 9 years ago Posts: 52 |

The whole carriage vibrates more then I'd like it too, especially when i put a belt tensioner on. Was thinking a fourth bearing might help it run smoother.Quote

Vanbot

What was your reasoning behind adding another bearing?

Do you have a link? This sounds like something I could use!Quote

thanks78

I did change the Y belt bracket as well to a clamping one, no zip ties, so munch nicer.

|

Re: Folger Prusa i3 Kit from ebay April 20, 2015 07:59PM |

Registered: 9 years ago Posts: 156 |

Quote

DriftyDave

The whole carriage vibrates more then I'd like it too, especially when i put a belt tensioner on. Was thinking a fourth bearing might help it run smoother.Quote

Vanbot

What was your reasoning behind adding another bearing?

Do you have a link? This sounds like something I could use!Quote

thanks78

I did change the Y belt bracket as well to a clamping one, no zip ties, so munch nicer.

Mine vibrates badly too. Sounds like a buckets of screws rattling around. But it seems to move nice and smoothly. I have heard differing opinions on whether the linear bearings require grease. Some say no and some say to pack them with grease.

I wonder if printed bearings would be quieter.

|

Re: Folger Prusa i3 Kit from ebay April 20, 2015 09:04PM |

Registered: 9 years ago Posts: 21 |

Quote

Vanbot

Quote

DriftyDave

The whole carriage vibrates more then I'd like it too, especially when i put a belt tensioner on. Was thinking a fourth bearing might help it run smoother.Quote

Vanbot

What was your reasoning behind adding another bearing?

Do you have a link? This sounds like something I could use!Quote

thanks78

I did change the Y belt bracket as well to a clamping one, no zip ties, so munch nicer.

Mine vibrates badly too. Sounds like a buckets of screws rattling around. But it seems to move nice and smoothly. I have heard differing opinions on whether the linear bearings require grease. Some say no and some say to pack them with grease.

I wonder if printed bearings would be quieter.

Just got my set of these in today Poly Linear Bearings, and can't wait to try them out. They are linear bearings that have a frelon (some sort of delrin derivative) lining in them. They are self lubricating and have no moving parts. I'm hoping these should all but eliminate the noise! I'll let you guys know tomorrow how they work!

|

Re: Folger Prusa i3 Kit from ebay April 20, 2015 11:08PM |

Registered: 9 years ago Posts: 156 |

Quote

enzo1027

Quote

Vanbot

Quote

DriftyDave

The whole carriage vibrates more then I'd like it too, especially when i put a belt tensioner on. Was thinking a fourth bearing might help it run smoother.Quote

Vanbot

What was your reasoning behind adding another bearing?

Do you have a link? This sounds like something I could use!Quote

thanks78

I did change the Y belt bracket as well to a clamping one, no zip ties, so munch nicer.

Mine vibrates badly too. Sounds like a buckets of screws rattling around. But it seems to move nice and smoothly. I have heard differing opinions on whether the linear bearings require grease. Some say no and some say to pack them with grease.

I wonder if printed bearings would be quieter.

Just got my set of these in today Poly Linear Bearings, and can't wait to try them out. They are linear bearings that have a frelon (some sort of delrin derivative) lining in them. They are self lubricating and have no moving parts. I'm hoping these should all but eliminate the noise! I'll let you guys know tomorrow how they work!

Nice! Can't wait to hear how they work.

|

Re: Folger Prusa i3 Kit from ebay April 21, 2015 01:18AM |

Registered: 10 years ago Posts: 477 |

Quote

enzo1027

Just got my set of these in today Poly Linear Bearings, and can't wait to try them out. They are linear bearings that have a frelon (some sort of delrin derivative) lining in them. They are self lubricating and have no moving parts. I'm hoping these should all but eliminate the noise! I'll let you guys know tomorrow how they work!

What was the cost of them??

Steve

My updated Instructable on our Prusa i3 Build

[www.instructables.com]

|

Re: Folger Prusa i3 Kit from ebay April 21, 2015 01:29AM |

Registered: 8 years ago Posts: 6 |

This is the Y belt holder I used. I did not use the captive nut, just the standard with lock nuts. [www.thingiverse.com]. Belt is still nice and tight after lots of printing.

Are there any advantages to using a geared extruder? Like the wades and alike. My stepper gets quite warm on long prints. I was thinking not having it attached right to the hotend would help. Anyone have thoughts either way. Thanks.

-Tom

Are there any advantages to using a geared extruder? Like the wades and alike. My stepper gets quite warm on long prints. I was thinking not having it attached right to the hotend would help. Anyone have thoughts either way. Thanks.

-Tom

|

Re: Folger Prusa i3 Kit from ebay April 21, 2015 02:01AM |

Registered: 9 years ago Posts: 156 |

Quote

thanks78

This is the Y belt holder I used. I did not use the captive nut, just the standard with lock nuts. [www.thingiverse.com]. Belt is still nice and tight after lots of printing.

Are there any advantages to using a geared extruder? Like the wades and alike. My stepper gets quite warm on long prints. I was thinking not having it attached right to the hotend would help. Anyone have thoughts either way. Thanks.

-Tom

I'd like to convert mine to a Wade's. Especially when I see how tricked out Steve's is. But I don't think they work with MK8 do they?

|

Re: Folger Prusa i3 Kit from ebay April 21, 2015 02:08AM |

Registered: 8 years ago Posts: 6 |

|

Re: Folger Prusa i3 Kit from ebay April 21, 2015 08:28AM |

Registered: 9 years ago Posts: 41 |

Here is a cruddy video of my attempt at using a wades extruder. I had very few problems with the original folger tech hot end, but I want to print higher temperature materials in the future and decided to upgrade.

Most wade extruders have a jhead type mount for the hot end that the current Folger extruder does not use. It would take some CAD model work to get it to mount properly and I am not 100% sure how to attach the cooling heatsink and fan to get the proper amount of cooling required to run reliably.

Then there is the task of getting all the extra hardware needed. I actually found this to be the most difficult part. Most opensource .stl files are using metric hardware. All my local hardware stores carry a bare minimum of anything metric. I ended purchasing a hardware kit online and I still had to dremel out holes for the proper size.

Now that I have it running, I couldn't be happier with how well the filament flows. It is very smooth and consistent. Those hobbed bolts really grip the filament hard. The new problem I have now is my fan shroud hits the binder clips holding my glass to the bed.

Most wade extruders have a jhead type mount for the hot end that the current Folger extruder does not use. It would take some CAD model work to get it to mount properly and I am not 100% sure how to attach the cooling heatsink and fan to get the proper amount of cooling required to run reliably.

Then there is the task of getting all the extra hardware needed. I actually found this to be the most difficult part. Most opensource .stl files are using metric hardware. All my local hardware stores carry a bare minimum of anything metric. I ended purchasing a hardware kit online and I still had to dremel out holes for the proper size.

Now that I have it running, I couldn't be happier with how well the filament flows. It is very smooth and consistent. Those hobbed bolts really grip the filament hard. The new problem I have now is my fan shroud hits the binder clips holding my glass to the bed.

|

Re: Folger Prusa i3 Kit from ebay April 21, 2015 09:39AM |

Registered: 8 years ago Posts: 6 |

For me the hot end is not an issue. I have access to CNC swiss lathes and a few mills. I plan on making a one piece heat sink that mounts my existing heater block / nozzle using the threaded tube.

I am currently testing with ABS and getting it to stick. I am going to make the parts the a wades and let you know how it ends up.

I am currently testing with ABS and getting it to stick. I am going to make the parts the a wades and let you know how it ends up.

|

Re: Folger Prusa i3 Kit from ebay April 21, 2015 02:05PM |

Registered: 9 years ago Posts: 21 |

Quote

Vanbot

Quote

enzo1027

Quote

Vanbot

Quote

DriftyDave

The whole carriage vibrates more then I'd like it too, especially when i put a belt tensioner on. Was thinking a fourth bearing might help it run smoother.Quote

Vanbot

What was your reasoning behind adding another bearing?

Do you have a link? This sounds like something I could use!Quote

thanks78

I did change the Y belt bracket as well to a clamping one, no zip ties, so munch nicer.

Mine vibrates badly too. Sounds like a buckets of screws rattling around. But it seems to move nice and smoothly. I have heard differing opinions on whether the linear bearings require grease. Some say no and some say to pack them with grease.

I wonder if printed bearings would be quieter.

Just got my set of these in today Poly Linear Bearings, and can't wait to try them out. They are linear bearings that have a frelon (some sort of delrin derivative) lining in them. They are self lubricating and have no moving parts. I'm hoping these should all but eliminate the noise! I'll let you guys know tomorrow how they work!

Nice! Can't wait to hear how they work.

They are INCREDIBLY quiet! I made a short Youtube video so you could take a listen for yourself. Poly Bushing Video Clip

I hit a bit of a snag unfortunately. Like an ass, I failed to look at the dimensions for the bearings. These are slightly larger than an LM8UU. However, they will work fine for my bed, and I'm in the process as we speak of designing a new extruder carriage to fit them. It will also have a better belt gripping system. I should have the carriage done today and printed out tonight.

Quote

Steveroy

What was the cost of them??

Steve

They were $16 a pop through McMaster. A little pricey, but well worth it when compared to the junk ones we get with the kit, imho.

|

Re: Folger Prusa i3 Kit from ebay April 21, 2015 02:24PM |

Registered: 9 years ago Posts: 156 |

Quote

enzo1027

Quote

Vanbot

Quote

enzo1027

Quote

Vanbot

Quote

DriftyDave

The whole carriage vibrates more then I'd like it too, especially when i put a belt tensioner on. Was thinking a fourth bearing might help it run smoother.Quote

Vanbot

What was your reasoning behind adding another bearing?

Do you have a link? This sounds like something I could use!Quote

thanks78

I did change the Y belt bracket as well to a clamping one, no zip ties, so munch nicer.

Mine vibrates badly too. Sounds like a buckets of screws rattling around. But it seems to move nice and smoothly. I have heard differing opinions on whether the linear bearings require grease. Some say no and some say to pack them with grease.

I wonder if printed bearings would be quieter.

Just got my set of these in today Poly Linear Bearings, and can't wait to try them out. They are linear bearings that have a frelon (some sort of delrin derivative) lining in them. They are self lubricating and have no moving parts. I'm hoping these should all but eliminate the noise! I'll let you guys know tomorrow how they work!

Nice! Can't wait to hear how they work.

They are INCREDIBLY quiet! I made a short Youtube video so you could take a listen for yourself. Poly Bushing Video Clip

I hit a bit of a snag unfortunately. Like an ass, I failed to look at the dimensions for the bearings. These are slightly larger than an LM8UU. However, they will work fine for my bed, and I'm in the process as we speak of designing a new extruder carriage to fit them. It will also have a better belt gripping system. I should have the carriage done today and printed out tonight.

Quote

Steveroy

What was the cost of them??

Steve

They were $16 a pop through McMaster. A little pricey, but well worth it when compared to the junk ones we get with the kit, imho.

Wow those are beautiful. So quiet. Not sure I'm ready to buck up $48 for my X carriage but nice to know the option is there.

Has anyone tried or heard of anyone trying 3d printed linear bearings? I'm curious how well they work. Maybe printed in nylon they'd be a good replacement.

Edited 1 time(s). Last edit at 04/21/2015 02:24PM by Vanbot.

Sorry, only registered users may post in this forum.