Folger Prusa i3 Kit from ebay

Posted by Waltermixx

|

Re: Folger Prusa i3 Kit from ebay October 11, 2014 10:18PM |

Registered: 12 years ago Posts: 76 |

I got my first recognizable print!!!!!!!!!!!!!!!!!!!!!!!!!!

I dug around a bit in gcode and thought perhaps since the line to move the extruder 15mm was a G1 and the rest of the z axis lines seemed to be a G0 that maybe it was something with that command so I changed it to G0 and tried it, and failed

Then I just removed the line completely and let the z axis home normally rather than me forcing it to hover and let the print go. Other than it not sticking completely at one corner it was able to finish the print so now I have a hollow cube with a crushed bottom corner!!!!!!!!!!!!

Then I just removed the line completely and let the z axis home normally rather than me forcing it to hover and let the print go. Other than it not sticking completely at one corner it was able to finish the print so now I have a hollow cube with a crushed bottom corner!!!!!!!!!!!!Now I KNOW I wont get to sleep for a while, gotta try some more printing.........

|

Re: Folger Prusa i3 Kit from ebay October 11, 2014 11:31PM |

Registered: 9 years ago Posts: 28 |

umm am I doing something wrong here??? My current config is the one posted in this forum topic, I checked my vref's and they are as follows z: .34, y:.56,x:.34,e:.32. But when i load up repetier-host and try to jog with any axis with the manual control it makes a high pitched noise using 10m jog, and if i use 0.1m jog it jumps a little then stops. Would could be the problem, I have tried the Ramps 1.4 test file and everything runs smoothly going back and fourth. Someone even recommend sending command g1 x10 f300, and that works too. Anyone one have an idea what could be the problem?

|

Re: Folger Prusa i3 Kit from ebay October 11, 2014 11:36PM |

Registered: 9 years ago Posts: 208 |

Quote

dooms101

Quote

Waltermixx

Dooms101 good to see you online again

love to see a post of your printer in action printing the skull, and of course once it's done

Cheers.

Well things still didn't work out. I started getting an air print about 2 hours in... Seems like the issue is still there. I'm starting to suspect it has something to do with the cold end getting too hot. That would somewhat explain why the filament keeps getting flattened. I'm taking the extruder apart now to try and see what the issue is. I might also try removing the two nuts. They don't really seem to have any functionality other than adding a little bit of mass.

I think you should try what I did. The NUTS allow a tighter connection to the cooling block. The heat will rise right up tube and keep the filament warm if the heat is not allowed to dissipate via the cooling block.. The nuts hold the tube tighter to the cooling block allowing it to dissipate heat. If you remove the nuts entirely the only thing keeping the tube in contact with the cooling block is the little set screw.... (I edited this, i realized i was using the word bolts instead of nuts so I corrected this... hope it makes better sense now...)

The nuts should be used to keep the tube tight against the cooling block. And the small heat break (narrowing of the tube) should be above the hot end.

Hope it helps....

Edited 2 time(s). Last edit at 10/12/2014 07:38AM by Waltermixx.

|

Re: Folger Prusa i3 Kit from ebay October 11, 2014 11:43PM |

Registered: 9 years ago Posts: 208 |

|

Re: Folger Prusa i3 Kit from ebay October 11, 2014 11:55PM |

Registered: 9 years ago Posts: 208 |

Quote

coldfront

umm am I doing something wrong here??? My current config is the one posted in this forum topic, I checked my vref's and they are as follows z: .34, y:.56,x:.34,e:.32. But when i load up repetier-host and try to jog with any axis with the manual control it makes a high pitched noise using 10m jog, and if i use 0.1m jog it jumps a little then stops. Would could be the problem, I have tried the Ramps 1.4 test file and everything runs smoothly going back and fourth. Someone even recommend sending command g1 x10 f300, and that works too. Anyone one have an idea what could be the problem?

Try homing everything first. I don't think you get control until it knows where home is....

|

Re: Folger Prusa i3 Kit from ebay October 12, 2014 12:54AM |

Registered: 9 years ago Posts: 54 |

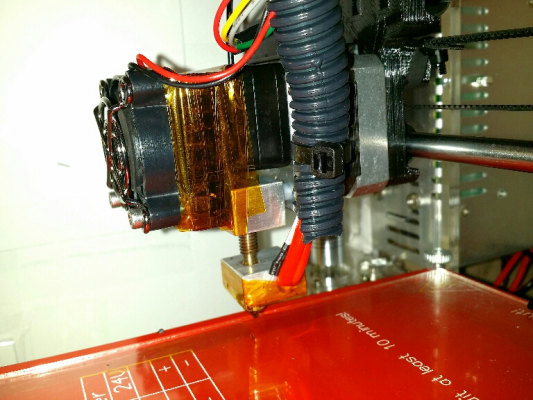

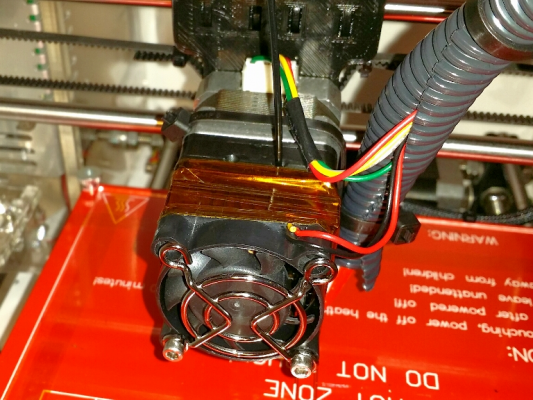

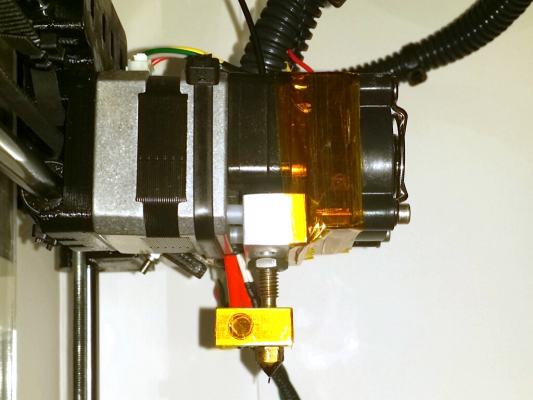

Okay, so I took my extruder apart and adjusted it similarly to what Waltermixx did. I removed one of the nuts and moved the other one to the top against the cold end block. I also turned the cold block 180 degrees so that my hot end goes into the other hole which is actually threaded and doesn't have a set screw. I also didn't put the threaded piece in as far but I'm not sure if that's beneficial or not.

Since I turned the cold block around it offset everything by 4mm, so I cut some nylon spacers to compensate. The benefit of this is that the cold end block does not touch the motor. Which is great because that was probably a major heat transfer area. I then used the thin kapton tape to make the heatsink and fan connection air tight. This forces the air to go through the hole in the back of the heatsink and into the extruder drive gear and back over the cold block.

I'll be trying another long print tomorrow to test the new setup. Hopefully it fixes this for good.

|

Re: Folger Prusa i3 Kit from ebay October 12, 2014 04:07PM |

Registered: 9 years ago Posts: 208 |

Eager to see how you make out Dooms101.

looking forward to some good news... interesting, i was looking at the threaded hole in the cooling block and thought, that would be a better way to go, certainly more contact with the metal of the tube.

and said to myself, i would go that route if this did not work... so very eager to see how you make out

cheers.

looking forward to some good news... interesting, i was looking at the threaded hole in the cooling block and thought, that would be a better way to go, certainly more contact with the metal of the tube.

and said to myself, i would go that route if this did not work... so very eager to see how you make out

cheers.

|

Re: Folger Prusa i3 Kit from ebay October 12, 2014 09:32PM |

Registered: 9 years ago Posts: 208 |

Well I did a 90 minute print, and wouldn't you know it, at about 75 minutes I got air printing again. Unfortunately I forgot to feel the stepper and cooling block to see if they were super warm. I will try another print and see if it does it again... If it does I may look into a spring loaded extruder.... Or try the threaded hole on the cold end... :0)

Cheers!

Cheers!

|

Re: Folger Prusa i3 Kit from ebay October 12, 2014 09:57PM |

Registered: 9 years ago Posts: 36 |

I received this kit on Thursday, and am about finished with the build. I hit a couple of snags, and this thread, and the photos, were enormously helpful.

Some of the issues I dealt with:

1) The central belt clamp on the Y-bed needed an extra hole drilled in the bed, for fitting.

2) The power supply needed holes drilled: I ended up drilling three new holes in order to use the threaded mounting holes in the PSU.

3) The PSU needed to be switched to 110V (it was set to 220V) as received.

4) The Z-axis plastic end pieces needed some fettling with the Dremel so that the pulley wheel spun freely and the smooth rods could be inserted fully.

5) The extruder mount plastic piece also needed some fettling so that the bearings fitted in it squarely

And a couple of things that weren't obvious to me:

6) The RAMPS shield needs a) the two-pin jumpers provided installed on the pin pairs under all the speed controllers, b) the speed controller heatsinks need to be stuck to the chips, being careful not to short out the adjacent pins

7) The Vrefs for the motors (small pots on the speed controller boards) needed tweaking (with the ceramic tool) to match the recommended values from Folger (elsewhere in this thread).

8) Quite a bit of fiddling in Configuration.h ... e.g. disabling the max endstop setting.

Some things are still not right on my machine:

a) One of the extruder thermistor leads arrived in the package detached (I've asked Folger for help), so I cannot hope to print yet. To make tests, I added a 100kOhm pot across the thermistor pins on the RAMPS board, which allows me to simulate any temperature I like (and also allows the printer to work - it wont work without a resistance between these pins, apparently).

b) I can't see where or how to place the Y-axis/bed endstop switch, using the provided plastic mount. Help (e.g. photos) would be very welcome!

c) Should there have been a second thermistor, for the heated bed, included in the kit? Mine didn't include one,if so.

Edited 1 time(s). Last edit at 10/12/2014 10:06PM by jjbunn.

Some of the issues I dealt with:

1) The central belt clamp on the Y-bed needed an extra hole drilled in the bed, for fitting.

2) The power supply needed holes drilled: I ended up drilling three new holes in order to use the threaded mounting holes in the PSU.

3) The PSU needed to be switched to 110V (it was set to 220V) as received.

4) The Z-axis plastic end pieces needed some fettling with the Dremel so that the pulley wheel spun freely and the smooth rods could be inserted fully.

5) The extruder mount plastic piece also needed some fettling so that the bearings fitted in it squarely

And a couple of things that weren't obvious to me:

6) The RAMPS shield needs a) the two-pin jumpers provided installed on the pin pairs under all the speed controllers, b) the speed controller heatsinks need to be stuck to the chips, being careful not to short out the adjacent pins

7) The Vrefs for the motors (small pots on the speed controller boards) needed tweaking (with the ceramic tool) to match the recommended values from Folger (elsewhere in this thread).

8) Quite a bit of fiddling in Configuration.h ... e.g. disabling the max endstop setting.

Some things are still not right on my machine:

a) One of the extruder thermistor leads arrived in the package detached (I've asked Folger for help), so I cannot hope to print yet. To make tests, I added a 100kOhm pot across the thermistor pins on the RAMPS board, which allows me to simulate any temperature I like (and also allows the printer to work - it wont work without a resistance between these pins, apparently).

b) I can't see where or how to place the Y-axis/bed endstop switch, using the provided plastic mount. Help (e.g. photos) would be very welcome!

c) Should there have been a second thermistor, for the heated bed, included in the kit? Mine didn't include one,if so.

Edited 1 time(s). Last edit at 10/12/2014 10:06PM by jjbunn.

|

Re: Folger Prusa i3 Kit from ebay October 12, 2014 10:31PM |

Registered: 9 years ago Posts: 208 |

Good notes...

the thermister for the heat bed, is actually soldered to the heat bed.

if you got a PCB Heatbed R1 Dual Power, it has the thermistor soldered to the center of the board, so all you have to do is solder leads to the edge of the pcboard, they are beside the 1,2,3 connectors for the heat bed. they should be labeled, mine are facing down, or I would tell you how they were labeled... i think i posted a picture of it earlier... found it and attached it.

found it and attached it.

I have my y-end stop at the front of my Prusa i3 mounted beside the y-idler. I'm using a different kind of mount... i posted the stl file for it in the thread above somewhere...

i found it on thingiverse.

Edited 4 time(s). Last edit at 10/12/2014 10:40PM by Waltermixx.

the thermister for the heat bed, is actually soldered to the heat bed.

if you got a PCB Heatbed R1 Dual Power, it has the thermistor soldered to the center of the board, so all you have to do is solder leads to the edge of the pcboard, they are beside the 1,2,3 connectors for the heat bed. they should be labeled, mine are facing down, or I would tell you how they were labeled... i think i posted a picture of it earlier...

found it and attached it.

found it and attached it.I have my y-end stop at the front of my Prusa i3 mounted beside the y-idler. I'm using a different kind of mount... i posted the stl file for it in the thread above somewhere...

i found it on thingiverse.

Edited 4 time(s). Last edit at 10/12/2014 10:40PM by Waltermixx.

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 12:02AM |

Registered: 9 years ago Posts: 36 |

Quote

Waltermixx

Good notes...

the thermister for the heat bed, is actually soldered to the heat bed.

if you got a PCB Heatbed R1 Dual Power, it has the thermistor soldered to the center of the board, so all you have to do is solder leads to the edge of the pcboard, they are beside the 1,2,3 connectors for the heat bed. they should be labeled, mine are facing down, or I would tell you how they were labeled... i think i posted a picture of it earlier...found it and attached it.

I have my y-end stop at the front of my Prusa i3 mounted beside the y-idler. I'm using a different kind of mount... i posted the stl file for it in the thread above somewhere...

i found it on thingiverse.

I wondered about that - the thermistor being already on the hotbed, but I couldn't see it - to check, I just measured 77kOhm resistance between the pads, so obviously you're correct

Fabricating a new mount is a Catch-22 for me. Perhaps I can do without the Y endstop until I get printing ....

Many thanks!

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 12:24AM |

Registered: 9 years ago Posts: 208 |

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 01:46AM |

Registered: 9 years ago Posts: 36 |

Quote

Waltermixx

The printer likes to home before printing. You could wire it, and press the button when the carriage gets close to the mounting spot.

The end stops are not used during printing. Only just before so it knows where 0,0,0 is.

P.s. I am 1 hour into a 2 hour vase print... So far so good.

Good info ... I may give it a try. I detached the thermistor, and found there was just enough of the broken lead to solder a wire to, so now I am able to heat the extruder. The PID control looked good: the nozzle quickly went up to the set 200C and sat there nicely. I was tempted to feed a bit of PLA in, but I think I'll quit for today while the going is good

How did you wire in your extruder fan? I didn't see any suitable wires or connector in the kit.

Good luck with the vase!

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 08:30AM |

Registered: 9 years ago Posts: 54 |

Quote

Waltermixx

Well I did a 90 minute print, and wouldn't you know it, at about 75 minutes I got air printing again. Unfortunately I forgot to feel the stepper and cooling block to see if they were super warm. I will try another print and see if it does it again... If it does I may look into a spring loaded extruder.... Or try the threaded hole on the cold end... :0)

Cheers!

I know your pain! It was very frustrating to have this happen over and over again... so much wasted filament and time.

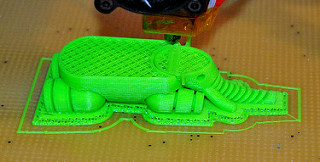

Since I rearranged the cold end and made a duct with the kapton tape I've had two successful long prints. It seems to have fixed the issue so far.

This guy took about 3.5 hours to print.

I'm going to design and print a better fan mount/duct so that other people here can use it. I think spacing the cold end block away from the motor is the biggest reason its working better, but also the air being directed into the extruder gear itself.

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 08:39AM |

Registered: 9 years ago Posts: 208 |

The kit came with long grey and red wires. I used that wire for the extruder fan and the heat bed thermistor.

There should have been:

Heavy gage red and black paired wire for power leads

Heay gage white wire for the heat bed

Thinner gage red wire very long

Thinner gage gey wire very long

5 motor wiring harnesses ( red, grey, yellow green)

I used what was left of the grey and red wire for the ramps cooling fan leads. ( I ordered another fan from the folder guys...)

The vase came out good. Smooth and extruded all the way through its construction....

So the retract setting may also be a factor with the jamming....

Perhaps a screen cap of where to find that setting?

Edited 3 time(s). Last edit at 10/13/2014 09:22AM by Waltermixx.

There should have been:

Heavy gage red and black paired wire for power leads

Heay gage white wire for the heat bed

Thinner gage red wire very long

Thinner gage gey wire very long

5 motor wiring harnesses ( red, grey, yellow green)

I used what was left of the grey and red wire for the ramps cooling fan leads. ( I ordered another fan from the folder guys...)

The vase came out good. Smooth and extruded all the way through its construction....

So the retract setting may also be a factor with the jamming....

Perhaps a screen cap of where to find that setting?

Edited 3 time(s). Last edit at 10/13/2014 09:22AM by Waltermixx.

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 08:50AM |

Registered: 9 years ago Posts: 208 |

Dooms101 that is a great looking print! Very nice...smooth!

I was wondering if you could raise your x carriage high enough to get a better picture of the bottom of the cooling block and hot end area.

It looks like you have no nut between the cool end and hot end, and just one on the top side of the cooling block, that is what the earlier post said.

I think your setup appears to be the best, so I would like to match it as close as possible.

That is one great print!

Edited 2 time(s). Last edit at 10/13/2014 09:17AM by Waltermixx.

I was wondering if you could raise your x carriage high enough to get a better picture of the bottom of the cooling block and hot end area.

It looks like you have no nut between the cool end and hot end, and just one on the top side of the cooling block, that is what the earlier post said.

I think your setup appears to be the best, so I would like to match it as close as possible.

That is one great print!

Edited 2 time(s). Last edit at 10/13/2014 09:17AM by Waltermixx.

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 09:27AM |

Registered: 9 years ago Posts: 12 |

Hello guys, I ordered mine on thursday and since then I am reading and watching as much I can so I will be ready for the build.

I was very happy to find this thread as there is not much available documentation for the specific kit!

It is my first 3d printer and I am very excited!!!!

I would like to ask you how many days after you placed your order was the kit shipped? Until now mine is not marked as shipped.

P.S.: Sorry for my english, I am from Greece and it's not my native language!

I was very happy to find this thread as there is not much available documentation for the specific kit!

It is my first 3d printer and I am very excited!!!!

I would like to ask you how many days after you placed your order was the kit shipped? Until now mine is not marked as shipped.

P.S.: Sorry for my english, I am from Greece and it's not my native language!

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 09:30AM |

Registered: 9 years ago Posts: 54 |

Quote

Waltermixx

Dooms101 that is a great looking print! Very nice...smooth!

I was wondering if you could raise your x carriage high enough to get a better picture of the bottom of the cooling block and hot end area.

It looks like you have no nut between the cool end and hot end, and just one on the top side of the cooling block, that is what the earlier post said.

I think your setup appears to be the best, so I would like to match it as close as possible.

That is one great print!

I'll take a picture when I get home later. But yes, I only used one nut to cinch the hot end tube into the threaded cold end hole. I also didn't thread it in all the way, maybe just about halfway. I also put some thermal interface compound on the thread and between the heatsink and cold block.

I think wrapping the heatsink in tape is also important as it forces air into the hole in the middle of the heatsink which is over the extruder gear.

Edited 1 time(s). Last edit at 10/13/2014 09:31AM by dooms101.

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 09:37AM |

Registered: 9 years ago Posts: 208 |

Thanks Dooms I think a few pictures will help, it sounds as if the nut you are using is up against the bottom of the cooling block, and not at the top.

it also sounds like you threaded the hot end tube only half way up the cooling block. ( so the nut could not be on the top of the cooling block. ).

Today is Thanksgiving in Canada so I am off all day, so this may be a good time to rebuild it again, and apply the Kapton tape around the heatsink

to direct cooling to the extruder gear...

going to give it a shot.

it also sounds like you threaded the hot end tube only half way up the cooling block. ( so the nut could not be on the top of the cooling block. ).

Today is Thanksgiving in Canada so I am off all day, so this may be a good time to rebuild it again, and apply the Kapton tape around the heatsink

to direct cooling to the extruder gear...

going to give it a shot.

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 11:32AM |

Registered: 12 years ago Posts: 76 |

Quote

konto89

Hello guys, I ordered mine on thursday and since then I am reading and watching as much I can so I will be ready for the build.

I was very happy to find this thread as there is not much available documentation for the specific kit!

It is my first 3d printer and I am very excited!!!!

I would like to ask you how many days after you placed your order was the kit shipped? Until now mine is not marked as shipped.

P.S.: Sorry for my english, I am from Greece and it's not my native language!

On the ebay item he has it marked as 10 day handling, considering he sold 193 from the beginning of September he must be swamped. I ordered mine on Sept 22nd and I think UPS showed that it had info on the item Sept 29th, not actually shipped just that they had been informed electronically that a package was to be shipped. It actually shipped out Oct 6th and I got it Oct 8th.

I think the estimated time to get it when I bought it was dead on the first day of the estimate.

It seems very popular, I think that from the time I ordered it until when I got it he sold another 70 more.

In my case I was looking to build one from scratch but after I decided on a Prusa i3 and used his list to spec out the costs I was up in the low 300 dollar range without a hot end yet and that was indvidual purchases over ebay. Seemed like a no brainer since I'd get everything at once and not have to deal with dozens of suppliers.

One thing I'd highly recommend is get either the standard LCD or the graphic LCD it really is nice to be able to remove the PC from the mix when I was having issues at the beginning and now that I'm printing I like that I can turn off the shop PC or use it for something else and not worry about a crash ruining a print. He has those as well, 18.99 and 23.99 dollars.

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 12:39PM |

Registered: 9 years ago Posts: 54 |

Quote

Waltermixx

Thanks Dooms I think a few pictures will help, it sounds as if the nut you are using is up against the bottom of the cooling block, and not at the top.

it also sounds like you threaded the hot end tube only half way up the cooling block. ( so the nut could not be on the top of the cooling block. ).

Today is Thanksgiving in Canada so I am off all day, so this may be a good time to rebuild it again, and apply the Kapton tape around the heatsink

to direct cooling to the extruder gear...

going to give it a shot.

Yeah, I should have been more clear. There is only one nut and it is on the underside of the cold block.

In order to use the threaded hole on the cold end, you need to rotate the cold block 180degrees which ends up offsetting the hole 4mm inwards in relation to the hole on the extruder drive. This is actually desirable as it allows you to use 4mm nylon spacers (or something similar) on the two long screws that hold the cold end, heatsink, and fan assembly to the motor. What you end up with is a 4mm gap between the cold block and the motor which air will vent through (assuming you tape things up like I did). This thermally isolates the motor, which as you know we don't want to get hot as it will soften the filament that it is trying to drive. It also allows more surface area of the cold block to be exposed to the air.

I hope I explained that well enough, it's hard to describe without pictures. If you don't have 4mm nylon spacers then you can always print some. It wont get hot enough to melt ABS spacers, but PLA wont do.

If you wait a little bit, I should have time tonight to design a fan mount/shroud that would have the 4mm spacers. That way you don't have to make your own or use tape.

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 12:57PM |

Registered: 9 years ago Posts: 208 |

That would be very helpful  I think everyone with this printer may wish to adopt that way to go.

I think everyone with this printer may wish to adopt that way to go.

on the bad news front,

while tightening up the two long M3 bolts, my screwdriver slipped and went into my fan blades... (yup the fan was running) and I lost a blade... and now the fan buzzes...

i may remove the fan i bought to cool the ramps board for now, and replace that fan later... i put heat sinks on the heat bed and extruder mosfets.

and they are not too bad... i may but the noisy fan on the ramps board for now, but it may drive me nuts.

Ok, for those of you who thought, Hey I dont have to turn the cold block around, all i have to do is, use the threaded hole, move the pully to the other side of the extruder, and reverse the direction of the extruder motor ( in configuration.h file) to false from true, and bobs your uncle, no spacer required and all should be well with the possible exception that the cooling block is still up against the extruder stepper motor... Well I tried that, and did not have very good luck... it seemed logical, but when I did this... i found that the stepper motor would only click when trying to feed the filament down into the hot extruder... there did not appear to be a straight path from the whole to feed the filament, down past the gear, and then into the tube that goes into the hot end... I could manually push filament through when taken appart and hot end heated, but it does not appear to all line up.... so turning the cooling block 180 degrees sounds like a better option...

So i will be holding off until i see Dooms' plans for the fan and spacer.

well at least no one else may try that and fail as I did... learn from my experience, and check out Doom's instructions above. if it was not a holiday in canada, i would head to home depot right now and get a bunch of nylon spacers and attack this now....

if it was not a holiday in canada, i would head to home depot right now and get a bunch of nylon spacers and attack this now....

Edited 3 time(s). Last edit at 10/13/2014 01:13PM by Waltermixx.

I think everyone with this printer may wish to adopt that way to go.

I think everyone with this printer may wish to adopt that way to go.

on the bad news front,

while tightening up the two long M3 bolts, my screwdriver slipped and went into my fan blades... (yup the fan was running) and I lost a blade... and now the fan buzzes...

i may remove the fan i bought to cool the ramps board for now, and replace that fan later... i put heat sinks on the heat bed and extruder mosfets.

and they are not too bad... i may but the noisy fan on the ramps board for now, but it may drive me nuts.

Ok, for those of you who thought, Hey I dont have to turn the cold block around, all i have to do is, use the threaded hole, move the pully to the other side of the extruder, and reverse the direction of the extruder motor ( in configuration.h file) to false from true, and bobs your uncle, no spacer required and all should be well with the possible exception that the cooling block is still up against the extruder stepper motor... Well I tried that, and did not have very good luck... it seemed logical, but when I did this... i found that the stepper motor would only click when trying to feed the filament down into the hot extruder... there did not appear to be a straight path from the whole to feed the filament, down past the gear, and then into the tube that goes into the hot end... I could manually push filament through when taken appart and hot end heated, but it does not appear to all line up.... so turning the cooling block 180 degrees sounds like a better option...

So i will be holding off until i see Dooms' plans for the fan and spacer.

well at least no one else may try that and fail as I did... learn from my experience, and check out Doom's instructions above.

if it was not a holiday in canada, i would head to home depot right now and get a bunch of nylon spacers and attack this now....

if it was not a holiday in canada, i would head to home depot right now and get a bunch of nylon spacers and attack this now....Edited 3 time(s). Last edit at 10/13/2014 01:13PM by Waltermixx.

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 02:13PM |

Registered: 9 years ago Posts: 58 |

Still no extrusion issues with my setup. Thankfully.

I did add some tape around the extruder for insulation but that wasn't prompted by any issues yet.

A few example prints can be found here. The skull box had some issues but that was due to running without supports.

A short video of the moving fish print can be found here.

That elephant looks nice. I printed it awhile ago on my UP printer but I should try it again on the current setup and compare. Picture here

Edited 1 time(s). Last edit at 10/13/2014 02:23PM by czmorris.

I did add some tape around the extruder for insulation but that wasn't prompted by any issues yet.

A few example prints can be found here. The skull box had some issues but that was due to running without supports.

A short video of the moving fish print can be found here.

That elephant looks nice. I printed it awhile ago on my UP printer but I should try it again on the current setup and compare. Picture here

Edited 1 time(s). Last edit at 10/13/2014 02:23PM by czmorris.

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 04:36PM |

Registered: 10 years ago Posts: 3 |

Hey all,

So I've been a long time lurker here. I have had the bug to get/make/build a 3D printer for awhile now. I have gone back and forth with kits vs parts myself etc. This kit however seems to fit the bill, especially due to its cost.

I'm curious how those of you who have done this would feel about this kit for the first time builder? I have zero experience in the 3D printer world. I am good at building stuff. I build furniture, fly RC planes/helis etc so I'm used to building things large and small. I'm ok with electronics (I own a multimeter and actually use it sometimes).

It seems overall to me this is still a good deal. It seems other more expensive kits have had reviews with similar issues as this one, so any kits seems to need a fair amount of twiddling regardless of their cost.

Thanks in advance.

So I've been a long time lurker here. I have had the bug to get/make/build a 3D printer for awhile now. I have gone back and forth with kits vs parts myself etc. This kit however seems to fit the bill, especially due to its cost.

I'm curious how those of you who have done this would feel about this kit for the first time builder? I have zero experience in the 3D printer world. I am good at building stuff. I build furniture, fly RC planes/helis etc so I'm used to building things large and small. I'm ok with electronics (I own a multimeter and actually use it sometimes).

It seems overall to me this is still a good deal. It seems other more expensive kits have had reviews with similar issues as this one, so any kits seems to need a fair amount of twiddling regardless of their cost.

Thanks in advance.

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 05:46PM |

Registered: 9 years ago Posts: 58 |

goldenPSP,

This kit is fairly easy to assemble but in my opinion there are a few issues to consider. As long as you are patient (from your project list seems like it) you likely won't have any issues. You don't seem to be but if you are more of the type that says "I just want it to work" I wouldn't suggest getting a kit at all. Otherwise this is a fairly nice kit to get for a beginner as it will teach you a good deal but not break the bank.

Cons First

- There are no instructions. If you are looking for an "IKEA" style kit this isn't it.

- You will likely have to drill out some extra holes in places they are missing.

- You should do some research on RAMPS and Marlin (or firmware of your choice). Don't just plug it in and assume it will work.

- If you wire something wrong it is possible to cause damage. Do your homework on the electronics before trying to power up and print.

Pros.

- The components in the kit are fairly cheap and easily to replace if you break something.

- It works with well known firmware and software so there is lots of information and help available.

- The specs on this kit in my opinion are really good for the price point.

- You only need basic tools.

- There are several people who have purchased this kit. Many of them are on this forum so there is plenty of help.

- The rods now come pre-cut. This is really good news if you live in an apartment or something and don't have access to tools or a workshop.

- Due to the open nature the kit is easy to add onto and upgrade.

Edited 1 time(s). Last edit at 10/13/2014 05:48PM by czmorris.

This kit is fairly easy to assemble but in my opinion there are a few issues to consider. As long as you are patient (from your project list seems like it) you likely won't have any issues. You don't seem to be but if you are more of the type that says "I just want it to work" I wouldn't suggest getting a kit at all. Otherwise this is a fairly nice kit to get for a beginner as it will teach you a good deal but not break the bank.

Cons First

- There are no instructions. If you are looking for an "IKEA" style kit this isn't it.

- You will likely have to drill out some extra holes in places they are missing.

- You should do some research on RAMPS and Marlin (or firmware of your choice). Don't just plug it in and assume it will work.

- If you wire something wrong it is possible to cause damage. Do your homework on the electronics before trying to power up and print.

Pros.

- The components in the kit are fairly cheap and easily to replace if you break something.

- It works with well known firmware and software so there is lots of information and help available.

- The specs on this kit in my opinion are really good for the price point.

- You only need basic tools.

- There are several people who have purchased this kit. Many of them are on this forum so there is plenty of help.

- The rods now come pre-cut. This is really good news if you live in an apartment or something and don't have access to tools or a workshop.

- Due to the open nature the kit is easy to add onto and upgrade.

Edited 1 time(s). Last edit at 10/13/2014 05:48PM by czmorris.

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 06:14PM |

Registered: 10 years ago Posts: 3 |

Quote

czmorris

goldenPSP,

This kit is fairly easy to assemble but in my opinion there are a few issues to consider. As long as you are patient (from your project list seems like it) you likely won't have any issues. You don't seem to be but if you are more of the type that says "I just want it to work" I wouldn't suggest getting a kit at all. Otherwise this is a fairly nice kit to get for a beginner as it will teach you a good deal but not break the bank.

Cons First

- There are no instructions. If you are looking for an "IKEA" style kit this isn't it.

- You will likely have to drill out some extra holes in places they are missing.

- You should do some research on RAMPS and Marlin (or firmware of your choice). Don't just plug it in and assume it will work.

- If you wire something wrong it is possible to cause damage. Do your homework on the electronics before trying to power up and print.

Pros.

- The components in the kit are fairly cheap and easily to replace if you break something.

- It works with well known firmware and software so there is lots of information and help available.

- The specs on this kit in my opinion are really good for the price point.

- You only need basic tools.

- There are several people who have purchased this kit. Many of them are on this forum so there is plenty of help.

- The rods now come pre-cut. This is really good news if you live in an apartment or something and don't have access to tools or a workshop.

- Due to the open nature the kit is easy to add onto and upgrade.

Yes I like to tinker. I also like things to work sometimes. But in this case the kit route is beneficial both due to learning (it helps to maintain your device when you have built it) and budget (a commercial printers cost will likely cause my wife to make me sleep with the printer on the couch).

I have plenty of workspace. I have a full woodworking shop as well as a place in the basement dedicated for my RC planes and stuff.

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 10:19PM |

Registered: 9 years ago Posts: 54 |

Quote

goldenPSP

Quote

czmorris

goldenPSP,

This kit is fairly easy to assemble but in my opinion there are a few issues to consider. As long as you are patient (from your project list seems like it) you likely won't have any issues. You don't seem to be but if you are more of the type that says "I just want it to work" I wouldn't suggest getting a kit at all. Otherwise this is a fairly nice kit to get for a beginner as it will teach you a good deal but not break the bank.

Cons First

- There are no instructions. If you are looking for an "IKEA" style kit this isn't it.

- You will likely have to drill out some extra holes in places they are missing.

- You should do some research on RAMPS and Marlin (or firmware of your choice). Don't just plug it in and assume it will work.

- If you wire something wrong it is possible to cause damage. Do your homework on the electronics before trying to power up and print.

Pros.

- The components in the kit are fairly cheap and easily to replace if you break something.

- It works with well known firmware and software so there is lots of information and help available.

- The specs on this kit in my opinion are really good for the price point.

- You only need basic tools.

- There are several people who have purchased this kit. Many of them are on this forum so there is plenty of help.

- The rods now come pre-cut. This is really good news if you live in an apartment or something and don't have access to tools or a workshop.

- Due to the open nature the kit is easy to add onto and upgrade.

Yes I like to tinker. I also like things to work sometimes. But in this case the kit route is beneficial both due to learning (it helps to maintain your device when you have built it) and budget (a commercial printers cost will likely cause my wife to make me sleep with the printer on the couch).

I have plenty of workspace. I have a full woodworking shop as well as a place in the basement dedicated for my RC planes and stuff.

You sound like me, I think you'd really enjoy this kit. It's satisfying how inexpensive it is (relative to other kits) and as long as you take care when assembling and do a little research it'll work great. It certainly takes a lot of patience, research, and ingenuity to get it dialed in but thats the fun part!

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 10:30PM |

Registered: 9 years ago Posts: 58 |

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 10:31PM |

Registered: 9 years ago Posts: 54 |

Here's an update on my adjustments to the extruder. Looks like it fixed the problem, I just got done with a perfect 3 hour print of a really tricky T-Rex skull that failed several times before I made the adjustments. I also sped up the max_feed_rate in marlin to 150, 150, 3, 25 which made the print crazy fast. I'm also using a 0.152mm layer height which is giving really really smooth prints.

Now that I'm convinced that it works I'm going to design a shroud that will replace the nylon spacers I used as well as avoiding the need to tape everything. I'll also redirect the vented air as right now it blows down on the print and causes a little bit of warping.

Here's a better angle of the extruder that shows how things are now spaced out:

Now that I'm convinced that it works I'm going to design a shroud that will replace the nylon spacers I used as well as avoiding the need to tape everything. I'll also redirect the vented air as right now it blows down on the print and causes a little bit of warping.

Here's a better angle of the extruder that shows how things are now spaced out:

|

Re: Folger Prusa i3 Kit from ebay October 13, 2014 10:36PM |

Registered: 9 years ago Posts: 54 |

Quote

czmorris

goldenPSP, Don't get me wrong the machine works well. and it is certainly fun to tinker with.

I did a reprint of the elephant. Unfortunately I couldn't find my previous one to do a side by side comparison.

Looks good! I see you used a raft. I've never used one, I do use a brim on most prints. How hard is it to get the raft off?

Sorry, only registered users may post in this forum.