Replacing Solidoodle 2 with Prusa i3 - worth it?

Posted by roli

|

Replacing Solidoodle 2 with Prusa i3 - worth it? January 12, 2015 03:46PM |

Registered: 9 years ago Posts: 17 |

Hi!

I have a bit of a dilemma and I am hoping that you can help me with it.

I currently have a Solidoodle 2 3D printer. I've had it for slightly over two years now. But I feel like it's time for an upgrade. I think it's showing signs of wear. It seems that I keep upgrading the thing all the time instead of actually using it.

It's been half a year since I upgraded to E3D v6 hot end because the original kept clogging. Recently the heater cartridge broke so I had to replace that as well. The original power supply that has been underpowered from the start is really struggling too. And the most important thing - print quality has gone totally downhill. I've tried calibrating everything from the extruder, stepper drivers, pid temperatures, belt tension, ... This are the results:

Left is the original print (my second print ever on that printer) .3mm, right is .3mm print made recently. I seems like some sort of oscillation on the x-y axis. And I am having huge z banding issues as well (as with most solidoodle users with pretty much stock configuration).

And to be honest, I am sick of constantly fixing everything and not getting the results.

So I've been looking around the internet for an alternative (first that came to mind was Solidoodle Press) but then I came across this Prusa i3 kit: [www.3dprintersonlinestore.com]

It seems reasonably priced. It includes an LCD, a bigger build platform (15x15x15cm is just a bit too small for me) and it seems a lot more maintainable than mine.

My question for you is simple - can the Prusa i3 be easily calibrated (I am willing to spend a few hours calibrating it) to get the results like my original solidoodle print? And is it worth the upgrade?

I have a bit of a dilemma and I am hoping that you can help me with it.

I currently have a Solidoodle 2 3D printer. I've had it for slightly over two years now. But I feel like it's time for an upgrade. I think it's showing signs of wear. It seems that I keep upgrading the thing all the time instead of actually using it.

It's been half a year since I upgraded to E3D v6 hot end because the original kept clogging. Recently the heater cartridge broke so I had to replace that as well. The original power supply that has been underpowered from the start is really struggling too. And the most important thing - print quality has gone totally downhill. I've tried calibrating everything from the extruder, stepper drivers, pid temperatures, belt tension, ... This are the results:

Left is the original print (my second print ever on that printer) .3mm, right is .3mm print made recently. I seems like some sort of oscillation on the x-y axis. And I am having huge z banding issues as well (as with most solidoodle users with pretty much stock configuration).

And to be honest, I am sick of constantly fixing everything and not getting the results.

So I've been looking around the internet for an alternative (first that came to mind was Solidoodle Press) but then I came across this Prusa i3 kit: [www.3dprintersonlinestore.com]

It seems reasonably priced. It includes an LCD, a bigger build platform (15x15x15cm is just a bit too small for me) and it seems a lot more maintainable than mine.

My question for you is simple - can the Prusa i3 be easily calibrated (I am willing to spend a few hours calibrating it) to get the results like my original solidoodle print? And is it worth the upgrade?

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? January 12, 2015 11:20PM |

Registered: 9 years ago Posts: 120 |

Before dropping everything and running for the RepRap hills, can you check if the hotend is wobbly at all on your Solidoodle? Just wiggle it around a bit to see if it is tight.

I have a hunch that your problem has to do with that- reading this when assuming that the E3D hotend is the issue seems to match up pretty well with when your quality troubles started to appear:

OK, on to the RepRap question.

Really, expecting 'low maintenance' from a RepRap depends on:

Most RepRaps today are a bit behind the on-market technology (auto bed-level, etc) in terms of the stock designs and kits. With tweaking, you can get a more skilled (read: easier) printer (#2 above).

However, that means *more tweaking and more calibrating* to get those new features.

I can tell you that it took me about 3 weeks (probably 30 hours) to get my Prusa i3 Rework to print acceptably. And it still didn't print as well as your second print for another 2 weeks. So don't expect the calibration to be simple.

If I were you, then I would stay with the Solidoodle and repair it. Eventually it will stop being "bad" once you replace all of the parts with issues- as long as you aren't putting "bad" parts in, or your spares are getting damaged, then hold on and wait for your repairs to shine through. If you do end up giving up on it, though, then expect a lot of work for a RepRap. Not nearly as simple as your Solidoodle was.

So let me know if the extruder is wiggly- and tell me about what you think about RepRaps as an option

Edited 1 time(s). Last edit at 01/12/2015 11:21PM by Blue Ice.

Blue Ice

blog at [contemporarymaker.com]

I have a hunch that your problem has to do with that- reading this when assuming that the E3D hotend is the issue seems to match up pretty well with when your quality troubles started to appear:

Quote

roli

It's been half a year since I upgraded to E3D v6 hot end because the original kept clogging. Recently the heater cartridge broke so I had to replace that as well. The original power supply that has been underpowered from the start is really struggling too. And the most important thing - print quality has gone totally downhill. I've tried calibrating everything from the extruder, stepper drivers, pid temperatures, belt tension,

OK, on to the RepRap question.

Really, expecting 'low maintenance' from a RepRap depends on:

- Your skill at diagnosing and fixing problems.

- Your printer's skill at making 3D printing simple.

Most RepRaps today are a bit behind the on-market technology (auto bed-level, etc) in terms of the stock designs and kits. With tweaking, you can get a more skilled (read: easier) printer (#2 above).

However, that means *more tweaking and more calibrating* to get those new features.

I can tell you that it took me about 3 weeks (probably 30 hours) to get my Prusa i3 Rework to print acceptably. And it still didn't print as well as your second print for another 2 weeks. So don't expect the calibration to be simple.

If I were you, then I would stay with the Solidoodle and repair it. Eventually it will stop being "bad" once you replace all of the parts with issues- as long as you aren't putting "bad" parts in, or your spares are getting damaged, then hold on and wait for your repairs to shine through. If you do end up giving up on it, though, then expect a lot of work for a RepRap. Not nearly as simple as your Solidoodle was.

So let me know if the extruder is wiggly- and tell me about what you think about RepRaps as an option

Edited 1 time(s). Last edit at 01/12/2015 11:21PM by Blue Ice.

Blue Ice

blog at [contemporarymaker.com]

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? January 13, 2015 04:52AM |

Registered: 9 years ago Posts: 17 |

Thanks for the reply! Somebody already suggested that the extruder may be wobbly. But I checked and it seems pretty solid to me. I specifically used an extruder mount with a nice clamp to prevent exactly this problem. And I am not actually sure when these problems started. It could very much be before I replaced the hot end - prints back then were horrific because of constant clogging.

Here is another picture. This time while printing PLA. Especially important here is that jagged edge. It's not really jagged. It's smooth. It looks like a sine wave or something. It can be clearly seen on every first layer and it can be seen (because the object doesn't look smooth) on other layers as well.

The other important thing is the fact that while printing it will often ruin what it's printing. For instance on the above picture it basically knocked the old layers out when trying to print new ones. And I can't print multiple objects anymore. Because it keeps hitting the already printed stuff and then it eventually just knocks it off. I can hear it (and see it because the bed vibrates violently) scraping across the layers whenever it makes a transition from one side to the other.

------------------------

As for reprap. To be honest I like the design of prusa i3. It does seem much easier to maintain then what I currently have. And I like how the bed stays on the same height. And of course I like the increased build size and autonomous printing (which could be added to mine but I would need to replace the electronics) . Oh, and I've seen an easy to add auto bed leveling system as well. That increased my interest too.

I am willing to spend a few hours (even 30) to get my printer calibrated. But I need to actually get it calibrated eventually. With Solidoodle I have no idea what's wrong and I've spent countless weekends trying to fix it without any success.

Edited 1 time(s). Last edit at 01/13/2015 06:24AM by roli.

Here is another picture. This time while printing PLA. Especially important here is that jagged edge. It's not really jagged. It's smooth. It looks like a sine wave or something. It can be clearly seen on every first layer and it can be seen (because the object doesn't look smooth) on other layers as well.

The other important thing is the fact that while printing it will often ruin what it's printing. For instance on the above picture it basically knocked the old layers out when trying to print new ones. And I can't print multiple objects anymore. Because it keeps hitting the already printed stuff and then it eventually just knocks it off. I can hear it (and see it because the bed vibrates violently) scraping across the layers whenever it makes a transition from one side to the other.

------------------------

As for reprap. To be honest I like the design of prusa i3. It does seem much easier to maintain then what I currently have. And I like how the bed stays on the same height. And of course I like the increased build size and autonomous printing (which could be added to mine but I would need to replace the electronics) . Oh, and I've seen an easy to add auto bed leveling system as well. That increased my interest too.

I am willing to spend a few hours (even 30) to get my printer calibrated. But I need to actually get it calibrated eventually. With Solidoodle I have no idea what's wrong and I've spent countless weekends trying to fix it without any success.

Edited 1 time(s). Last edit at 01/13/2015 06:24AM by roli.

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? January 13, 2015 11:59AM |

Registered: 9 years ago Posts: 120 |

All right, then a RepRap it is!

I have a Prusa i3 Rework that I made. Most parts are from a kit. I would strongly recommend getting a kit instead of sourcing parts if you want to save your time searching. Also, some places have very reasonable prices for the whole thing. (This usually does not include consumables.)

The Prusa i3 Rework is similar to the Prusa i3, but it has a couple additions and always has a metal frame. The only thing that I don't like about my Prusa i3 Rework is that the whole frame can wobble if the securing nuts on the bottom are not tight enough. But that's not really an issue if you get 'em really well when you assemble the whole thing.

Otherwise, it is very repeatable and usually consistently good as well. It's just the tuning and poking that takes a while to figure out. So once you get the whole thing built and calibrated, you are nearly there. The auto-bed leveler I've seen as well, and I'm thinking about putting one on mine. However, it's working OK without it- adding it means more tweaking of the printer.

So I would recommend the Prusa i3 Rework- it has its quirks, but you have a good solid community here to help you figure them out. It's pretty modular, so you should be able to just swap stuff that doesn't work. Again, it'll take a while to get it set up correctly. But that's part of what makes it satisfying

Blue Ice

blog at [contemporarymaker.com]

Quote

roli

As for reprap. To be honest I like the design of prusa i3. It does seem much easier to maintain then what I currently have. And I like how the bed stays on the same height. And of course I like the increased build size and autonomous printing (which could be added to mine but I would need to replace the electronics) . Oh, and I've seen an easy to add auto bed leveling system as well. That increased my interest too.

I am willing to spend a few hours (even 30) to get my printer calibrated. But I need to actually get it calibrated eventually. With Solidoodle I have no idea what's wrong and I've spent countless weekends trying to fix it without any success.

I have a Prusa i3 Rework that I made. Most parts are from a kit. I would strongly recommend getting a kit instead of sourcing parts if you want to save your time searching. Also, some places have very reasonable prices for the whole thing. (This usually does not include consumables.)

The Prusa i3 Rework is similar to the Prusa i3, but it has a couple additions and always has a metal frame. The only thing that I don't like about my Prusa i3 Rework is that the whole frame can wobble if the securing nuts on the bottom are not tight enough. But that's not really an issue if you get 'em really well when you assemble the whole thing.

Otherwise, it is very repeatable and usually consistently good as well. It's just the tuning and poking that takes a while to figure out. So once you get the whole thing built and calibrated, you are nearly there. The auto-bed leveler I've seen as well, and I'm thinking about putting one on mine. However, it's working OK without it- adding it means more tweaking of the printer.

So I would recommend the Prusa i3 Rework- it has its quirks, but you have a good solid community here to help you figure them out. It's pretty modular, so you should be able to just swap stuff that doesn't work. Again, it'll take a while to get it set up correctly. But that's part of what makes it satisfying

Blue Ice

blog at [contemporarymaker.com]

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? January 13, 2015 03:04PM |

Registered: 9 years ago Posts: 17 |

I actually posted the link to the kit that I've been thinking about in my first post: [www.3dprintersonlinestore.com]

It seems to include everything and it is a bit cheaper than most. I am not completely sure about the Acrylic frame though. It seems to work but I can imagine it causing some problems.

To be honest this whole thing just randomly popped into my head when I saw some pretty cheap Prusa i3 kit somewhere. Then I looked on the net some more and found this one. I had plans to go for a new 3D printer somewhere around the years end and actually getting something newer from Solidoodle or a delta. Though deltas seem to be a bit harder to calibrate so I quickly decided against that idea. I am now in a bit of a dilemma. Go with my original plan or go with the Prusa i3 now and be done with it. The i3 seems to have a lot of potential for further upgrade as well - dual extruders for instance.

It seems to include everything and it is a bit cheaper than most. I am not completely sure about the Acrylic frame though. It seems to work but I can imagine it causing some problems.

To be honest this whole thing just randomly popped into my head when I saw some pretty cheap Prusa i3 kit somewhere. Then I looked on the net some more and found this one. I had plans to go for a new 3D printer somewhere around the years end and actually getting something newer from Solidoodle or a delta. Though deltas seem to be a bit harder to calibrate so I quickly decided against that idea. I am now in a bit of a dilemma. Go with my original plan or go with the Prusa i3 now and be done with it. The i3 seems to have a lot of potential for further upgrade as well - dual extruders for instance.

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? January 13, 2015 05:23PM |

Registered: 9 years ago Posts: 120 |

Yeah, they look OK. I wouldn't necessarily go for the cheapest printer available, though. I bought my kit from Replikeo, and although they made some questionable design choices (such as a fibreglass build plate instead of a glass one), their customer service is pretty good and they shipped me replacements for damaged parts (twice). Keep in mind that shipping will probably set you back quite a bit. I also purchased a glass plate and a display.

Overall, I would recommend a metal frame over the acrylic ones because they are sturdier and will hold up to more printer vibrations. Most people I know got the Aluminum kit from Replikeo.

The Prusa i3 Rework also has lots of benefits over the Prusa i3- it's sturdier, has thicker threaded rods, and it has plastic parts together that were separated in the Prusa i3. Both models have lots of upgrade possibilities.

Blue Ice

blog at [contemporarymaker.com]

Overall, I would recommend a metal frame over the acrylic ones because they are sturdier and will hold up to more printer vibrations. Most people I know got the Aluminum kit from Replikeo.

The Prusa i3 Rework also has lots of benefits over the Prusa i3- it's sturdier, has thicker threaded rods, and it has plastic parts together that were separated in the Prusa i3. Both models have lots of upgrade possibilities.

Blue Ice

blog at [contemporarymaker.com]

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? January 13, 2015 05:42PM |

Registered: 9 years ago Posts: 17 |

From the checks that I did the he3d kit seems to be the cheapest one (when including shipping). Some other kits include free shipping but not to my country so they end up being more expensive in the end.

I will consider the metal frame though. I'll see if I can find a metal one somewhere for a reasonable price. Though one of the reasons why I actually began looking into this was the price. So I am not willing to go much higher when it comes to that. But I would have no problem paying a bit more.

I will consider the metal frame though. I'll see if I can find a metal one somewhere for a reasonable price. Though one of the reasons why I actually began looking into this was the price. So I am not willing to go much higher when it comes to that. But I would have no problem paying a bit more.

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? January 14, 2015 05:24PM |

Registered: 9 years ago Posts: 376 |

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? January 17, 2015 09:29AM |

Registered: 9 years ago Posts: 17 |

Sorry for a late reply. I wasn't at home to actually check.

The heat sink doesn't rotate (it can't since it is mounted). But the heater block does. I tightened it down a bit. But the assembly instructions for e3d say that this part should only be hand tight.

One maybe important thing as well - the e3d fan doesn't sit nicely on the heatsink and vibrates. This vibrations are then transfered throughout the frame and the whole thing vibrates loudly. I tried removing the fan and printing a few layers. The problem didn't go away. But I am just pointing this out even if I don't think that it is that important.

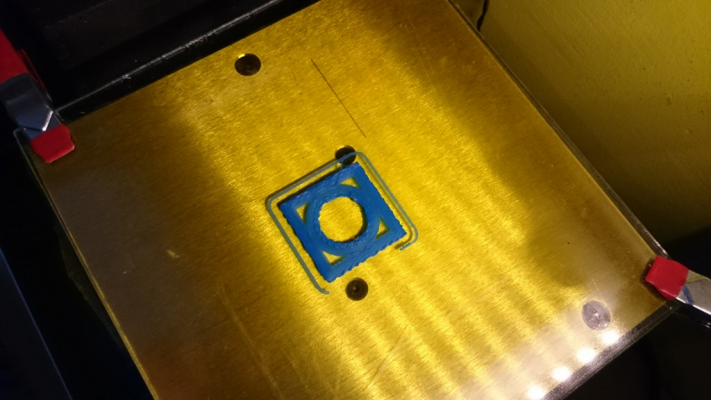

EDIT: Here is a better image of what the problem is:

This is the first layer. The outside edges should be straight. But they are not. Interestingly though the skirt is perfectly fine.

Edited 1 time(s). Last edit at 01/17/2015 09:51AM by roli.

The heat sink doesn't rotate (it can't since it is mounted). But the heater block does. I tightened it down a bit. But the assembly instructions for e3d say that this part should only be hand tight.

One maybe important thing as well - the e3d fan doesn't sit nicely on the heatsink and vibrates. This vibrations are then transfered throughout the frame and the whole thing vibrates loudly. I tried removing the fan and printing a few layers. The problem didn't go away. But I am just pointing this out even if I don't think that it is that important.

EDIT: Here is a better image of what the problem is:

This is the first layer. The outside edges should be straight. But they are not. Interestingly though the skirt is perfectly fine.

Edited 1 time(s). Last edit at 01/17/2015 09:51AM by roli.

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? January 17, 2015 05:51PM |

Registered: 9 years ago Posts: 17 |

I managed to partially solve the problem. Basically - I had to lover the print temperature. I used 220°C before to print ABS. Lowering the temperature to 195°C has greatly improved the final look of the print. Still not as good as that original print though. You can still see some small "sine waves" on the actual surface but it isn't as bad as before.

I am thinking that the problem is still there. And the actual higher temperature was just exaggerating it. Because 195°C is a bit low for ABS (gives me adhesion problems without a brim).

Speaking of temperatures... How long does a heated print bed on Prusa i3 take to heat up to 90°C? Because my Solidoodle is still using a heater resistor below the bed instead of a PCB heated bed. And that takes forever to reach 90°C and is struggling to reach 100°C and stay there. Shoddy power supply probably doesn't help with this.

Edited 2 time(s). Last edit at 01/17/2015 05:56PM by roli.

I am thinking that the problem is still there. And the actual higher temperature was just exaggerating it. Because 195°C is a bit low for ABS (gives me adhesion problems without a brim).

Speaking of temperatures... How long does a heated print bed on Prusa i3 take to heat up to 90°C? Because my Solidoodle is still using a heater resistor below the bed instead of a PCB heated bed. And that takes forever to reach 90°C and is struggling to reach 100°C and stay there. Shoddy power supply probably doesn't help with this.

Edited 2 time(s). Last edit at 01/17/2015 05:56PM by roli.

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? January 17, 2015 11:29PM |

Registered: 12 years ago Posts: 132 |

The wavy edges look like typical Solidoodle moire. The steps/mm of the extruder are low enough that the stepping shows up in the print as pulsing in the extrusion. It usually becomes more pronounced after installing an E3D because that hotend is precise enough to show that effect more than the stock hot end. You can dial it down by adjusting the vref. There are plenty of threads on that at Soliforum if you search E3D Vref and Moire. It won't go away completely however unless you do something to increase the steps/mm (basically resolution) of the extruder. You can do that by replacing the extruder driver with an 8825 and changing from 1/16 to 1/32 microstepping. An alternative is replacing the extruder motor with a .9 degree stepper that has 400 steps/revolution rather than 200.

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? January 18, 2015 12:16AM |

Registered: 11 years ago Posts: 661 |

Quote

Blue Ice

Most RepRaps today are a bit behind the on-market technology (auto bed-level, etc) in terms of the stock designs and kits. With tweaking, you can get a more skilled (read: easier) printer (#2 above).

You'll find pretty much all of the technology employed in lower end consumer printers, sub US$2k range, uses technology derivied from Repraps or Repstraps. There might be something that was designed and implemented by one of those machines but every major advancement has been based on a community or open design. Including bed compensation. The term bed leveling is a misnomer. It's not leveling the bed, the bed is still not level. I's having the machine adjust to compensate for that and it was first on an open machine. The builders have taken those elements and implemented them differently and most of the commercial machines do have what most general consumers would consider a more esthetic design but the premise of the machines and the way the technology is used is directly derivied from the various Repraps.

Where a lot of those companies add value is in the integration of the various parts and the assembly. As noted it can be a chore for a new builder to assemble and configure the machine and implement the software toolchain. When you get a built package that's generally done for you but at an added cost with less flexibility than a Reprap/Repstrap.

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? January 18, 2015 03:45AM |

Registered: 9 years ago Posts: 376 |

Yeah, the heater block should not rotate at all. If you think about it, it's attached on a screw thread. If it can rotate a bit during printing it will lower or raise the nozzle by a bit.

The fans are a bit of a nightmare. I super glue two thin strips of felt just inside the grip part of the fan holder which cancels out all the rattling. If you can disconnect the fan and hold it while it is running and there is significant vibration it would be worth getting a replacement fan.

It could also be a stepper driver problem. I don't know what electronics are used on the solidooodle, if that is even fixable or configurable.I had similar issues which went away when I replaced the driver unit on the extruder. But before you go there you need to sort out these hot end issues.

The fans are a bit of a nightmare. I super glue two thin strips of felt just inside the grip part of the fan holder which cancels out all the rattling. If you can disconnect the fan and hold it while it is running and there is significant vibration it would be worth getting a replacement fan.

It could also be a stepper driver problem. I don't know what electronics are used on the solidooodle, if that is even fixable or configurable.I had similar issues which went away when I replaced the driver unit on the extruder. But before you go there you need to sort out these hot end issues.

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? January 18, 2015 08:09AM |

Registered: 9 years ago Posts: 17 |

Well I tightened the block so it doesn't rotate by hand anymore. That should be solved.

My Solidoodle is using standard Sanguinololu rev. 1.3a. Nothing fancy really. They later replaced those with something else if I can remember correctly.

@IanJohnson: Thanks! I will check it in more detail. But it seems like it. Strangely nobody on Soliforum has mentioned this to me before.

I think I'll still go for the Reprap. And then sell the one with worse results. Or just keep them both - one for the backup and simultaneous printing.

My Solidoodle is using standard Sanguinololu rev. 1.3a. Nothing fancy really. They later replaced those with something else if I can remember correctly.

@IanJohnson: Thanks! I will check it in more detail. But it seems like it. Strangely nobody on Soliforum has mentioned this to me before.

I think I'll still go for the Reprap. And then sell the one with worse results. Or just keep them both - one for the backup and simultaneous printing.

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? January 19, 2015 06:36AM |

Registered: 9 years ago Posts: 17 |

Well, I have ordered my Prusa i3 kit. This one to be specific:

[www.iniciativas3d.com]

285€ without tax with LCD and 1kgb of ABS. Then I also ordered a aluminum frame so I will actually have an aluminum printer - still 50€ cheaper than it would cost me to get an aluminum kit from them. They had some special offer yesterday - todays prices are much different.

[www.iniciativas3d.com]

285€ without tax with LCD and 1kgb of ABS. Then I also ordered a aluminum frame so I will actually have an aluminum printer - still 50€ cheaper than it would cost me to get an aluminum kit from them. They had some special offer yesterday - todays prices are much different.

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? January 19, 2015 11:37AM |

Registered: 9 years ago Posts: 120 |

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? February 28, 2015 09:45PM |

Registered: 9 years ago Posts: 17 |

Here's an update. I have received my Prusa i3 kit last week. And I finally got it assembled (more or less) today. I will explain everything in a later post. But right now I am having some issues with the steppers.

Namely I can't seem to move any of them at all. I installed Marlin and hopefully configured it correctly. The LCD panel seems to work as well. But whenever I try to move any of the axes by 1mm it just doesn't move. Steppers seem to just move left-right a bit and make a horrible noise. And if I keep doing that the stepper drivers become hot (really hot).I measured the voltage between the trimmer and GND and it is reading 0,93V (as it should according to some calibration guide that I found). So it should work. But it doesn't. Any ideas?

Electronics are standard Ramps 1.4 with what seem to be Polulu A4988 drivers (at least if I can read that small print correctly). I've installed all three jumpers for all stepper drivers.

Edited 2 time(s). Last edit at 02/28/2015 10:02PM by roli.

Namely I can't seem to move any of them at all. I installed Marlin and hopefully configured it correctly. The LCD panel seems to work as well. But whenever I try to move any of the axes by 1mm it just doesn't move. Steppers seem to just move left-right a bit and make a horrible noise. And if I keep doing that the stepper drivers become hot (really hot).I measured the voltage between the trimmer and GND and it is reading 0,93V (as it should according to some calibration guide that I found). So it should work. But it doesn't. Any ideas?

Electronics are standard Ramps 1.4 with what seem to be Polulu A4988 drivers (at least if I can read that small print correctly). I've installed all three jumpers for all stepper drivers.

Edited 2 time(s). Last edit at 02/28/2015 10:02PM by roli.

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? March 01, 2015 09:08AM |

Registered: 9 years ago Posts: 17 |

Sometimes I am such an idiot. I didn't know that stepper coil pair wires should be together. I changed all the wires and now the X, Y and extruder axis work perfectly.

What doesn't run perfectly is the Z axis. It moves in the desired direction a bit then all you can hear from the motors is some noise. Something that sounds like they are trying to turn but they can't. Problem is that I can't quite figure out why. I can move the axis by hand (by turning the motor shafts) without too much resistance. Too much resistance is of course a very relative term. It's nowhere near smooth but it doesn't require much force.

I tried disconnecting one stepper and then that side moves perfectly. So it apparently has some issues driving both steppers. I increased the voltage on that driver to 1.18V (as stated in that before mentioned calibration guide) so the steppers should have enough power.

I can move the thing if I just use 0.1mm steps. A bit more than that and the above mentioned thing happens.

Edited 1 time(s). Last edit at 03/01/2015 09:35AM by roli.

What doesn't run perfectly is the Z axis. It moves in the desired direction a bit then all you can hear from the motors is some noise. Something that sounds like they are trying to turn but they can't. Problem is that I can't quite figure out why. I can move the axis by hand (by turning the motor shafts) without too much resistance. Too much resistance is of course a very relative term. It's nowhere near smooth but it doesn't require much force.

I tried disconnecting one stepper and then that side moves perfectly. So it apparently has some issues driving both steppers. I increased the voltage on that driver to 1.18V (as stated in that before mentioned calibration guide) so the steppers should have enough power.

I can move the thing if I just use 0.1mm steps. A bit more than that and the above mentioned thing happens.

Edited 1 time(s). Last edit at 03/01/2015 09:35AM by roli.

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? March 02, 2015 08:11AM |

Registered: 10 years ago Posts: 553 |

Quote

roli

I managed to partially solve the problem. Basically - I had to lover the print temperature. I used 220°C before to print ABS. Lowering the temperature to 195°C has greatly improved the final look of the print. Still not as good as that original print though. You can still see some small "sine waves" on the actual surface but it isn't as bad as before.

I am thinking that the problem is still there. And the actual higher temperature was just exaggerating it. Because 195°C is a bit low for ABS (gives me adhesion problems without a brim).

Speaking of temperatures... How long does a heated print bed on Prusa i3 take to heat up to 90°C? Because my Solidoodle is still using a heater resistor below the bed instead of a PCB heated bed. And that takes forever to reach 90°C and is struggling to reach 100°C and stay there. Shoddy power supply probably doesn't help with this.

I guess you have bought a new printer already but that looks like your printing too close to the bed. Also an E3D isn't the best choice for printing PLA, should not be recommended to people new to printing since it can jam easily and have extrusion issues with PLA.

Quote

IanJohnson

The wavy edges look like typical Solidoodle moire. The steps/mm of the extruder are low enough that the stepping shows up in the print as pulsing in the extrusion. It usually becomes more pronounced after installing an E3D because that hotend is precise enough to show that effect more than the stock hot end. You can dial it down by adjusting the vref. There are plenty of threads on that at Soliforum if you search E3D Vref and Moire. It won't go away completely however unless you do something to increase the steps/mm (basically resolution) of the extruder. You can do that by replacing the extruder driver with an 8825 and changing from 1/16 to 1/32 microstepping. An alternative is replacing the extruder motor with a .9 degree stepper that has 400 steps/revolution rather than 200.

How is this an extruder issue? The Solidoodle looks like nearly every direct drive that uses MK7/MK8 drive gears and many people run those without issue on 200 step motors with 16x. Also I think nearly every Printrbot uses a similar drive gear or one with a very close effective diameter. Motors with 400 steps usually have less torque which is undesirable in extruder use and also can not run as fast which may cause issues if running them in a Wades extruder at higher printing speeds.

Please add your printer design to [reprap.org]

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? March 02, 2015 01:24PM |

Registered: 12 years ago Posts: 132 |

It may be an extruder/hot end combo issue. My Solidoodle 1 had a geared stepper, and didn't have the moire. SD2 and above came with a direct motor with no gearing, and you can see the moire in almost any Solidoodle print. Switching to 1/32 microstepping, 400 step motor, or a geared extruder like the Bulldog is guaranteed to make it go away. It's possible that it might have something to do with the quality of the driver or motor.

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? March 11, 2015 06:33PM |

Registered: 9 years ago Posts: 17 |

Well I have finally managed to put everything together into a working condition.

I've had the most issues with actually putting the mechanical parts together. Mostly because of the plastic parts that came with the kit. One part was missing completely and two parts (the Z axis motor mounts) broke when installing. I had to print those myself. They have also sent me 628zz bearings instead of 608zz so I couldn't assemble the extruder. I tried dremeling it out to fit the bigger bearings but abandoned the idea later. So I printed myself a new extruder on my solidoodle. A different design actually. And I printed it in PLA - it came out horrible. The belt on the X axis was also a pain in the ass to install - mostly because it doesn't have any real way to adjust the tension.

I had to wait a bit longer for the kit to arrive because the store where I bought it apparently had issues producing plastic parts. So they have sent me an all metal hot-end instead of a standard one. It looks almost exactly like my e3d so I am guessing that it is some knockoff thing or something. But I am not complaining.

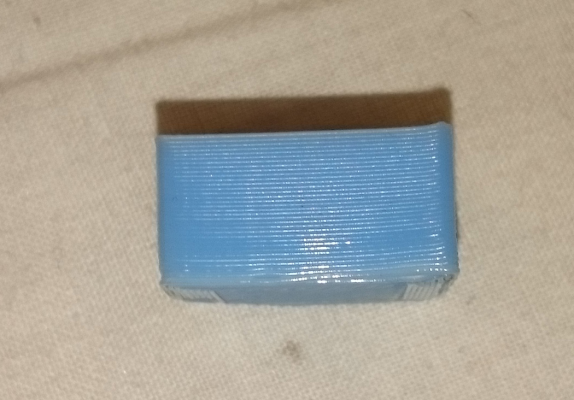

After I solved all the weird motor problems the thing was practically finished and I got my first print on the new printer:

The only thing wrong with that was basically the thing unsticking from the bed a bit during print. Otherwise it's pretty much what I wanted in a first print.

I then did some basic calibration - steps per mm for all axis. X, Y and Z only needed some very minor adjustment.

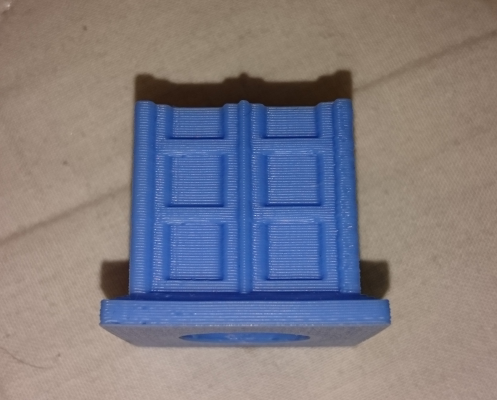

Then I went for my classic benchmark test:

As you can see - that's really what I wanted.

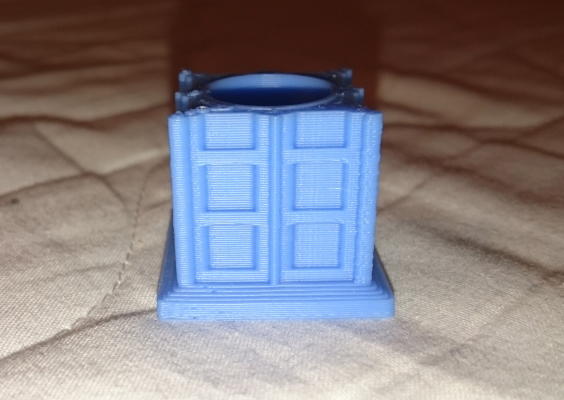

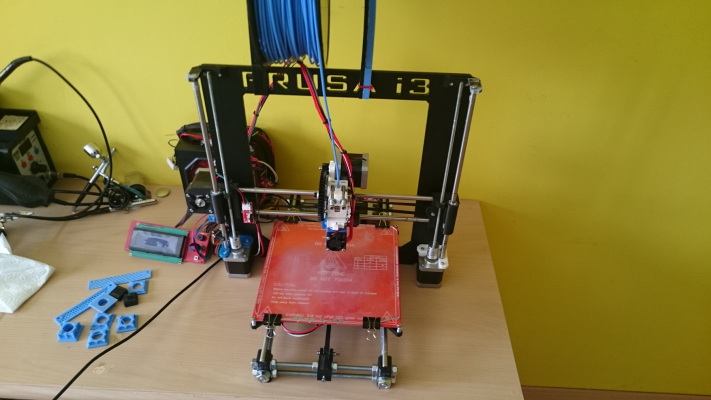

And here is the picture of the happy printer. It still needs a bit of cable management though.

I am having only one issue now - I can't get the prints to stick to the bed. I am using ABS with the classic glass + hairspray method. I am using the same glass and hairspray as on solidoodle so I would expect everything to work. But it doesn't. First layer seems to stick fine at the beginning but then just suddenly pops off during the print. The bed temperature is 90°C as I am used to on the solidoodle. And the prusa is much better at keeping that temperature constant (though it does take longer to reach it than solidoodle). I've tried increasing the bed temperature to 100°C and it helps quite a bit. But it still isn't good. I've had to actually squish the first layer much more than I would normally do, to get anything to stick to the bed. And I've had to lower the first layer height to 0.1mm because of that.

I've had the most issues with actually putting the mechanical parts together. Mostly because of the plastic parts that came with the kit. One part was missing completely and two parts (the Z axis motor mounts) broke when installing. I had to print those myself. They have also sent me 628zz bearings instead of 608zz so I couldn't assemble the extruder. I tried dremeling it out to fit the bigger bearings but abandoned the idea later. So I printed myself a new extruder on my solidoodle. A different design actually. And I printed it in PLA - it came out horrible. The belt on the X axis was also a pain in the ass to install - mostly because it doesn't have any real way to adjust the tension.

I had to wait a bit longer for the kit to arrive because the store where I bought it apparently had issues producing plastic parts. So they have sent me an all metal hot-end instead of a standard one. It looks almost exactly like my e3d so I am guessing that it is some knockoff thing or something. But I am not complaining.

After I solved all the weird motor problems the thing was practically finished and I got my first print on the new printer:

The only thing wrong with that was basically the thing unsticking from the bed a bit during print. Otherwise it's pretty much what I wanted in a first print.

I then did some basic calibration - steps per mm for all axis. X, Y and Z only needed some very minor adjustment.

Then I went for my classic benchmark test:

As you can see - that's really what I wanted.

And here is the picture of the happy printer. It still needs a bit of cable management though.

I am having only one issue now - I can't get the prints to stick to the bed. I am using ABS with the classic glass + hairspray method. I am using the same glass and hairspray as on solidoodle so I would expect everything to work. But it doesn't. First layer seems to stick fine at the beginning but then just suddenly pops off during the print. The bed temperature is 90°C as I am used to on the solidoodle. And the prusa is much better at keeping that temperature constant (though it does take longer to reach it than solidoodle). I've tried increasing the bed temperature to 100°C and it helps quite a bit. But it still isn't good. I've had to actually squish the first layer much more than I would normally do, to get anything to stick to the bed. And I've had to lower the first layer height to 0.1mm because of that.

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? March 16, 2015 10:21PM |

Registered: 9 years ago Posts: 182 |

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? March 18, 2015 06:08PM |

Registered: 9 years ago Posts: 17 |

245°C? Isn't that a bit too much? I have it set to 200 for upper layers and 215°C for first layer. And it starts extruding nicely at a bit above 180°C (at least free air extrusion).

I'll try the skirt. But I somehow dobut that it will help. Because it's not that the prints warp. They just pop off. I've increased the bed temperature to 110°C and that keeps the print stable so it doesn't unstick everytime. It still does sometimes. But not as much. Before at 90°C it would just pop off by itself. And even at 110°C when the print is finished I can pull the print off the bed with no real resistance. I remember on solidoodle I had to wait for the bed to cool down before I could even try to unstick the thing. Because it was impossible to pull it off when the bed was hot.

I'll try the skirt. But I somehow dobut that it will help. Because it's not that the prints warp. They just pop off. I've increased the bed temperature to 110°C and that keeps the print stable so it doesn't unstick everytime. It still does sometimes. But not as much. Before at 90°C it would just pop off by itself. And even at 110°C when the print is finished I can pull the print off the bed with no real resistance. I remember on solidoodle I had to wait for the bed to cool down before I could even try to unstick the thing. Because it was impossible to pull it off when the bed was hot.

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? February 23, 2016 04:32PM |

Registered: 8 years ago Posts: 3 |

No, not too much. Actually I print ABS at 265 with an all metal E3D V6 to avoid layer delamination and it works great. (And before anyone points out about the ABS becoming brittle, etc etc... nonsense. Please do your research)

Also, for the sticking issues you mentioned get a PEI plate at Amazon ($17), The right adhesive (3M), stick on top of the glass and forget about it. Don't even consider Kapton, Blue Tape, ABS sludge, Hair spray, etc.. You may have issues with sticking too much. If it happens, no sweat. Just put some drops of alcohol inside/around the part,wait 10 min and the parts pop out like magic. Don't get my word for it. Search google for PEI and you won't be disappointed.

BTW... I have had a Prusa Graber that I put together and absolutely love it. I just bought an SD4 very very cheap but without even powering on I can say I am really disappointed with the overall hardware. Not to say it can't be fixed with the upgrades but I am amazed how this thing sold for more than 1K at a point. When consider how accurate and reliable my Prusa I3 Graber is, plus Auto Bed Leveling, Part Fan, and other open source upgrades I have to say the SD4 is a rip off at that price point.

Also, for the sticking issues you mentioned get a PEI plate at Amazon ($17), The right adhesive (3M), stick on top of the glass and forget about it. Don't even consider Kapton, Blue Tape, ABS sludge, Hair spray, etc.. You may have issues with sticking too much. If it happens, no sweat. Just put some drops of alcohol inside/around the part,wait 10 min and the parts pop out like magic. Don't get my word for it. Search google for PEI and you won't be disappointed.

BTW... I have had a Prusa Graber that I put together and absolutely love it. I just bought an SD4 very very cheap but without even powering on I can say I am really disappointed with the overall hardware. Not to say it can't be fixed with the upgrades but I am amazed how this thing sold for more than 1K at a point. When consider how accurate and reliable my Prusa I3 Graber is, plus Auto Bed Leveling, Part Fan, and other open source upgrades I have to say the SD4 is a rip off at that price point.

|

Re: Replacing Solidoodle 2 with Prusa i3 - worth it? February 24, 2016 09:23AM |

Registered: 9 years ago Posts: 251 |

Sorry, only registered users may post in this forum.