how do I put this extruder together?

Posted by 3D rob

|

how do I put this extruder together? April 08, 2015 03:05PM |

Registered: 10 years ago Posts: 202 |

I have this extruder:

[www.mijnalbum.nl]

[www.mijnalbum.nl]

how do I do it with that Teflon hose/tubing and that black clamp ring?

[www.mijnalbum.nl]

Look also a moment to the Attachment?

the top of the red plastic of the extruder is flat,

but the aluminum extruder with the teflon tube and the black clamp ring is not flat!

shall I cut on the green line? (Look to the Attachment please?)

if I do cut it

there be still remains a part of the black clamping ring behind in the extruder!

I hope the Google translate was successful?

Best regards from the Netherlands (Rotterdam)

Rob.

Edited 3 time(s). Last edit at 04/08/2015 03:11PM by 3D rob.

[www.mijnalbum.nl]

[www.mijnalbum.nl]

how do I do it with that Teflon hose/tubing and that black clamp ring?

[www.mijnalbum.nl]

Look also a moment to the Attachment?

the top of the red plastic of the extruder is flat,

but the aluminum extruder with the teflon tube and the black clamp ring is not flat!

shall I cut on the green line? (Look to the Attachment please?)

if I do cut it

there be still remains a part of the black clamping ring behind in the extruder!

I hope the Google translate was successful?

Best regards from the Netherlands (Rotterdam)

Rob.

Edited 3 time(s). Last edit at 04/08/2015 03:11PM by 3D rob.

|

Re: how do I put this extruder together? April 10, 2015 01:35PM |

Registered: 10 years ago Posts: 202 |

|

Re: how do I put this extruder together? April 10, 2015 04:30PM |

Registered: 9 years ago Posts: 977 |

That seems to be a standard Prusa i3 Rework extruder, but with an E3D hotend with a Bowden fitting i.e. wrong model. The teflon tube should not be used in this case. You can find more instructions for assembling the extruder itself in the wiki or online (search "i3 Rework assembly").

More help would require more specific questions and more pictures.

More help would require more specific questions and more pictures.

|

Re: how do I put this extruder together? April 10, 2015 05:42PM |

Registered: 10 years ago Posts: 202 |

Hello Andrew,

okay wrong model I understand!

.

but in order to fix it?

as I cut the teflon tube

tube equal to the top of the aluminum,

and then I slide it into the plastic slot?

cut at the height of the green line (look to the Attachment?)

[pic.sense3dprinter.com]

best regards

Rob.

okay wrong model I understand!

.

but in order to fix it?

as I cut the teflon tube

tube equal to the top of the aluminum,

and then I slide it into the plastic slot?

cut at the height of the green line (look to the Attachment?)

[pic.sense3dprinter.com]

best regards

Rob.

|

Re: how do I put this extruder together? April 10, 2015 08:47PM |

Registered: 9 years ago Posts: 977 |

|

Re: how do I put this extruder together? April 11, 2015 02:48AM |

Registered: 10 years ago Posts: 202 |

okay Andrew,

I know enough thank you!

it is actually not the way to do it like this i know

but I want to try it,

is important that the holes are centered (in-line)

and I think I should put the teflon tube in

and I must therefore ensure that the top of the holes are centered

( equally placed )

[reprapworld.com]

when I put the extruder in place

I look in through the plastic

then the holes are just right

So that looks good

Andrew thanks for now

best regards

Rob.

I know enough thank you!

it is actually not the way to do it like this i know

but I want to try it,

is important that the holes are centered (in-line)

and I think I should put the teflon tube in

and I must therefore ensure that the top of the holes are centered

( equally placed )

[reprapworld.com]

when I put the extruder in place

I look in through the plastic

then the holes are just right

So that looks good

Andrew thanks for now

best regards

Rob.

|

Re: how do I put this extruder together? April 11, 2015 05:24AM |

Registered: 11 years ago Posts: 469 |

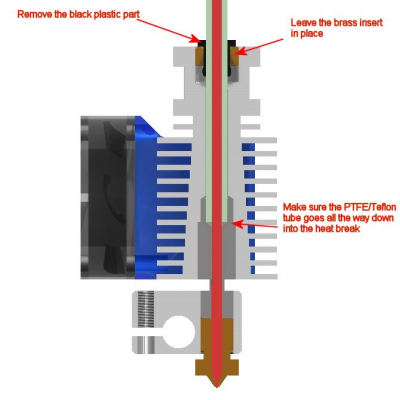

There's only 1 type of E3D 1.75 .....Universal

IF you insert the black part it will retain a PTFE tube for a remote extruder bowden set up

IF you remove it the hotend is suitable for direct drive

I wouldn't cut off the black part as the remaining bits may cause problems later . You can remove it with a bit of care & force. Easy to replace if you damage it.

Once removed insert the PTFE tube into the hotend and make sure it goes all the way into the heat break. I find turning it a bit while pushing it in helps to get it all the way down.

When its in place trim if flush with the top of the hotend with a sharp knife. USe a sharp knife so you dont deform the PTFE tube too much.

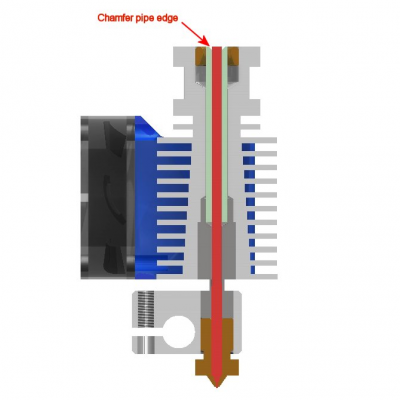

Its also a good idea to use a drill by hand and chamfer the hole of the pipe so its easy to feed in filament later.

Good luck

IF you insert the black part it will retain a PTFE tube for a remote extruder bowden set up

IF you remove it the hotend is suitable for direct drive

I wouldn't cut off the black part as the remaining bits may cause problems later . You can remove it with a bit of care & force. Easy to replace if you damage it.

Once removed insert the PTFE tube into the hotend and make sure it goes all the way into the heat break. I find turning it a bit while pushing it in helps to get it all the way down.

When its in place trim if flush with the top of the hotend with a sharp knife. USe a sharp knife so you dont deform the PTFE tube too much.

Its also a good idea to use a drill by hand and chamfer the hole of the pipe so its easy to feed in filament later.

Good luck

|

Re: how do I put this extruder together? April 11, 2015 07:28AM |

Registered: 10 years ago Posts: 202 |

.

Yesssssss

also thank you Bigfilsing!

you will not believe it,

but was also planning the top of the tube witha drill to make an angle (A forerunner, may I call it that?)

I even was thinking about a sharp cutter!

[webshop.bijoumoderne.nl]

.

[www.uploadarchief.net]

okay now I'm sure this is coming good!

(I was a little unsure!)

thank you so much Andrew and Bigfilsing

and Bigfilsing

friendly greetings from the Netherlands (Rotterdam)

Rob.

Edited 1 time(s). Last edit at 04/11/2015 07:32AM by 3D rob.

Yesssssss

also thank you Bigfilsing!

you will not believe it,

but was also planning the top of the tube witha drill to make an angle (A forerunner, may I call it that?)

I even was thinking about a sharp cutter!

[webshop.bijoumoderne.nl]

.

[www.uploadarchief.net]

okay now I'm sure this is coming good!

(I was a little unsure!)

thank you so much Andrew

and Bigfilsing

and Bigfilsing

friendly greetings from the Netherlands (Rotterdam)

Rob.

Edited 1 time(s). Last edit at 04/11/2015 07:32AM by 3D rob.

|

Re: how do I put this extruder together? April 11, 2015 10:01AM |

Registered: 11 years ago Posts: 469 |

Yeah that tool should work just dont go too deep and make the tube wall thickness to small ( wand dikkte te dun)

A good way to cut the PTFE pipe without crushing or deforming it is to put some filamant in it and cut around it if you see what i mean. then pull the filament out

No you cant call it a forerunner that doesnt translate from Dutch too well . There;s a few but probably a "lead in" would be best suited.

that doesnt translate from Dutch too well . There;s a few but probably a "lead in" would be best suited.

I used to live in Holland nearly 20 years ago and had a workshop in De VIerhavens straat In Rotterdam. Great place

If you get stuck with translation on this stuff just post again or PM me

Cheers

A good way to cut the PTFE pipe without crushing or deforming it is to put some filamant in it and cut around it if you see what i mean. then pull the filament out

No you cant call it a forerunner

that doesnt translate from Dutch too well . There;s a few but probably a "lead in" would be best suited.

that doesnt translate from Dutch too well . There;s a few but probably a "lead in" would be best suited.I used to live in Holland nearly 20 years ago and had a workshop in De VIerhavens straat In Rotterdam. Great place

If you get stuck with translation on this stuff just post again or PM me

Cheers

|

Re: how do I put this extruder together? April 11, 2015 10:44AM |

Registered: 10 years ago Posts: 202 |

Hello Bigfilsing,

Vierhavensstraat I'll come sometimes there

The euromast and the fair:

[www.google.nl]

.

And yes that was the word what I was looking for (lead in)

.

here are some foto's:

[www.mijnalbum.nl]

[www.mijnalbum.nl]

and A short video:

[www.youtube.com]

thanks for your advice, I will do so!

Kind regards Rob.

Vierhavensstraat I'll come sometimes there

The euromast and the fair:

[www.google.nl]

.

And yes that was the word what I was looking for (lead in)

.

here are some foto's:

[www.mijnalbum.nl]

[www.mijnalbum.nl]

and A short video:

[www.youtube.com]

thanks for your advice, I will do so!

Kind regards Rob.

|

Re: how do I put this extruder together? April 11, 2015 11:01AM |

Registered: 11 years ago Posts: 469 |

based on what i saw in the vid

Unless youre using a dual extruder take out the E1 stepper driver and keep it as a spare. Other wise its just using power ( not much ) for nothing. Better to take it off and keep it for later use.

try and keep the auto fuses ( the big yellow things next to the power connector) tidy. They are quite easy to break

Don't forget to loop power though to the other power connector for a heated bed. Many have fogotten this then wondered why the heated bed doesnt work later

Looks like a nice tidy build ...good stuff

Unless youre using a dual extruder take out the E1 stepper driver and keep it as a spare. Other wise its just using power ( not much ) for nothing. Better to take it off and keep it for later use.

try and keep the auto fuses ( the big yellow things next to the power connector) tidy. They are quite easy to break

Don't forget to loop power though to the other power connector for a heated bed. Many have fogotten this then wondered why the heated bed doesnt work later

Looks like a nice tidy build ...good stuff

|

Re: how do I put this extruder together? April 12, 2015 03:51AM |

Registered: 10 years ago Posts: 202 |

my first hobby electronics, so yes I know what I should do.

(but thanks good/fine that you point it out to me )

)

stepper driver:

yes I know, he is indeed too many!

I thought indeed that does not use many so put him there but just for temporary.

and also the fuse, I know what they are.(on the film one(1) fuse is skewed - the factory has done so)

also looping, I am indeed not done yet.

I was thinking to use a relay,

then goes the FET not so hot:

[www.youtube.com] (look on 0:38)

(FET switches the relay and relay switch the heat plate)

I will now and then show something here(photo/film)

or something to read.

I hope the translation still a little goes well ???

Bigfilsing, Andrew and everyone who read it

the friendly greetings from here!

Rob.

Edited 1 time(s). Last edit at 04/12/2015 03:55AM by 3D rob.

(but thanks good/fine that you point it out to me

)

)stepper driver:

yes I know, he is indeed too many!

I thought indeed that does not use many so put him there but just for temporary.

and also the fuse, I know what they are.(on the film one(1) fuse is skewed - the factory has done so)

also looping, I am indeed not done yet.

I was thinking to use a relay,

then goes the FET not so hot:

[www.youtube.com] (look on 0:38)

(FET switches the relay and relay switch the heat plate)

I will now and then show something here(photo/film)

or something to read.

I hope the translation still a little goes well ???

Bigfilsing, Andrew and everyone who read it

the friendly greetings from here!

Rob.

Edited 1 time(s). Last edit at 04/12/2015 03:55AM by 3D rob.

|

Re: how do I put this extruder together? April 12, 2015 04:16AM |

Registered: 11 years ago Posts: 469 |

The relay is a good idea as we all know the standard FET's aren't the best and most efficient.

I would recommend you look for an electronic relay rather than a standard automotive relay

Something like >> [www.ebay.com]

Good luck

I would recommend you look for an electronic relay rather than a standard automotive relay

Something like >> [www.ebay.com]

Good luck

|

Re: how do I put this extruder together? April 12, 2015 07:21AM |

Registered: 10 years ago Posts: 202 |

HAHAHAAaaaa look at (2:05) :

[www.youtube.com]

yes it is the best way to do it!

.

the rest of the video is also interesting!

I'm going to at one point later i think going to do

I will also make stability reinforcement brackets

for me it is very easy,

I am a professional metal worker.

.

but !!!

another question? (Software!)

what software can or can I use for the Prusa i3?

there is so much and I just stole my son's laptop

Marlin

Octoprint

Repetier

[www.3dprinter.nu]

[www.3dprinter.nu]

what is good, what is better, which is the best?

HELP!!!

[www.mijnalbum.nl]

[www.mijnalbum.nl]

[www.mijnalbum.nl]

Rob.

Edited 1 time(s). Last edit at 04/12/2015 07:47AM by 3D rob.

|

Re: how do I put this extruder together? April 12, 2015 08:03AM |

Registered: 11 years ago Posts: 469 |

Ok

Octoprint doesnt actually control the printer as such. It allows you to control it via a network web interface

Take a look at >> [www.youtube.com]

( nearly all of Toms video are worth a watch )

i have it installed on a Rasberry PI and its great for stand alone printing i,e, without a computer attached. You can also achieve stand alone operation with an LCD panel and memory card.

Marlin & Repetier are types of firmware that you load onto you control board.

Judging by your previous video you have already loaded the Marlin test program so id stick with Marlin if i were you. I find repetier a little bit trickier to set up but maybe thats just me.

I think the forum and internet support is better for Marlin so to start out go with Marlin . Its easy to change and try other things later when you have your machine up and running.

As for modeling software. Thats a big question with many answers

I would say that as a metal worker you'd want software that create's and edits solids( Autodesk Inventor, Catia, Solid works) rather than meshes. (Rhino.3Dmax, Blender Sketch up)

A great piece of free software for solid parametric modeling is Design Spark from RS components.

All of the above can export STL's to 3Dprint

Octoprint doesnt actually control the printer as such. It allows you to control it via a network web interface

Take a look at >> [www.youtube.com]

( nearly all of Toms video are worth a watch )

i have it installed on a Rasberry PI and its great for stand alone printing i,e, without a computer attached. You can also achieve stand alone operation with an LCD panel and memory card.

Marlin & Repetier are types of firmware that you load onto you control board.

Judging by your previous video you have already loaded the Marlin test program so id stick with Marlin if i were you. I find repetier a little bit trickier to set up but maybe thats just me.

I think the forum and internet support is better for Marlin so to start out go with Marlin . Its easy to change and try other things later when you have your machine up and running.

As for modeling software. Thats a big question with many answers

I would say that as a metal worker you'd want software that create's and edits solids( Autodesk Inventor, Catia, Solid works) rather than meshes. (Rhino.3Dmax, Blender Sketch up)

A great piece of free software for solid parametric modeling is Design Spark from RS components.

All of the above can export STL's to 3Dprint

|

Re: how do I put this extruder together? April 14, 2015 07:40PM |

Registered: 10 years ago Posts: 202 |

.

extruder not ready (not important for a moment)

.

I've been busy to make the printer work (software)

I did not do it! did not work

did not work

Now I asked in a another forum

and they wrote that I should connect the *Thermistors*

and that I had not done yet!

I hope tomorrow to do this here and I hope that it can be moved

.

Thermistors

there goes my next question,

it may be that there are two different types of sensors/Thermistors to be used?

that that of the bed is different from the extruder?

and if so,

maybe you can also fooled the ramps?

by, for example, by placing the resistors of 100K in place of the Sensoors?

Greetings to you all!

Rob.

Edited 3 time(s). Last edit at 04/14/2015 07:41PM by 3D rob.

extruder not ready (not important for a moment)

.

I've been busy to make the printer work (software)

I did not do it!

did not work

did not workNow I asked in a another forum

and they wrote that I should connect the *Thermistors*

and that I had not done yet!

I hope tomorrow to do this here and I hope that it can be moved

.

Thermistors

there goes my next question,

it may be that there are two different types of sensors/Thermistors to be used?

that that of the bed is different from the extruder?

and if so,

maybe you can also fooled the ramps?

by, for example, by placing the resistors of 100K in place of the Sensoors?

Greetings to you all!

Rob.

Edited 3 time(s). Last edit at 04/14/2015 07:41PM by 3D rob.

|

Re: how do I put this extruder together? April 14, 2015 09:33PM |

Registered: 9 years ago Posts: 977 |

|

Re: how do I put this extruder together? April 15, 2015 01:15AM |

Registered: 11 years ago Posts: 469 |

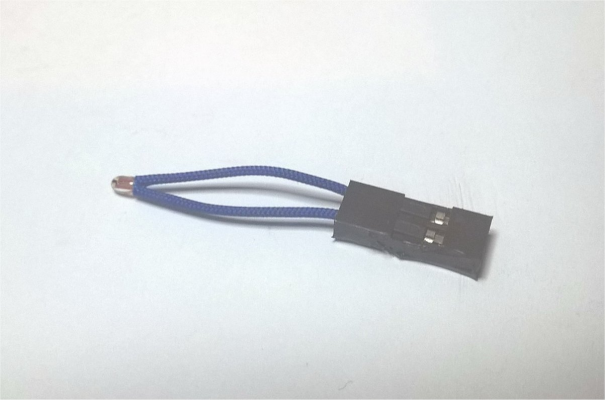

The issue is that the board protects itself when it cant read a temp for the hot end. So if its not reading a thermisistor on the hotend the firmware assumes cable break/defect thermisistor/ runaway temp.

IF you want to test the output for the heated bed its the same story.

You cant really use a fixed resistor as a substitute. It may work with a 100K potentionmeter where you could "set" the temperature reading and fool the ramps into thinking a thermisistor is attached but i think thats a lot

of work for little benifit.

you don't even need both to run tests on motors axis etc

just a single one for the end end will do

heres a pics of one that i made up to test ramps boards.

Edited 1 time(s). Last edit at 04/15/2015 01:21AM by bigfilsing.

IF you want to test the output for the heated bed its the same story.

You cant really use a fixed resistor as a substitute. It may work with a 100K potentionmeter where you could "set" the temperature reading and fool the ramps into thinking a thermisistor is attached but i think thats a lot

of work for little benifit.

you don't even need both to run tests on motors axis etc

just a single one for the end end will do

heres a pics of one that i made up to test ramps boards.

Edited 1 time(s). Last edit at 04/15/2015 01:21AM by bigfilsing.

|

Re: how do I put this extruder together? April 15, 2015 01:41AM |

Registered: 11 years ago Posts: 469 |

and dont forget you have to tell the ramps which type of thermistor you are using in your config.h file ...for both the hotend and the bed

>>>

//===========================================================================

//=============================Thermal Settings ============================

//===========================================================================

//

//--NORMAL IS 4.7kohm PULLUP!-- 1kohm pullup can be used on hotend sensor, using correct resistor and table

//

//// Temperature sensor settings:

// -2 is thermocouple with MAX6675 (only for sensor 0)

// -1 is thermocouple with AD595

// 0 is not used

// 1 is 100k thermistor - best choice for EPCOS 100k (4.7k pullup)

// 2 is 200k thermistor - ATC Semitec 204GT-2 (4.7k pullup)

// 3 is Mendel-parts thermistor (4.7k pullup)

// 4 is 10k thermistor !! do not use it for a hotend. It gives bad resolution at high temp. !!

// 5 is 100K thermistor - ATC Semitec 104GT-2 (Used in ParCan & J-Head) (4.7k pullup)

// 6 is 100k EPCOS - Not as accurate as table 1 (created using a fluke thermocouple) (4.7k pullup)

// 7 is 100k Honeywell thermistor 135-104LAG-J01 (4.7k pullup)

// 71 is 100k Honeywell thermistor 135-104LAF-J01 (4.7k pullup)

// 8 is 100k 0603 SMD Vishay NTCS0603E3104FXT (4.7k pullup)

// 9 is 100k GE Sensing AL03006-58.2K-97-G1 (4.7k pullup)

// 10 is 100k RS thermistor 198-961 (4.7k pullup)

// 11 is 100k beta 3950 1% thermistor (4.7k pullup)

// 12 is 100k 0603 SMD Vishay NTCS0603E3104FXT (4.7k pullup) (calibrated for Makibox hot bed)

// 13 is 100k Hisens 3950 1% up to 300°C for hotend "Simple ONE " & "Hotend "All In ONE"

// 20 is the PT100 circuit found in the Ultimainboard V2.x

// 60 is 100k Maker's Tool Works Kapton Bed Thermistor beta=3950

//

// 1k ohm pullup tables - This is not normal, you would have to have changed out your 4.7k for 1k

// (but gives greater accuracy and more stable PID)

// 51 is 100k thermistor - EPCOS (1k pullup)

// 52 is 200k thermistor - ATC Semitec 204GT-2 (1k pullup)

// 55 is 100k thermistor - ATC Semitec 104GT-2 (Used in ParCan & J-Head) (1k pullup)

//

// 1047 is Pt1000 with 4k7 pullup

// 1010 is Pt1000 with 1k pullup (non standard)

// 147 is Pt100 with 4k7 pullup

// 110 is Pt100 with 1k pullup (non standard)

#define TEMP_SENSOR_0 1 ( this is for the hotend type of sensor)

#define TEMP_SENSOR_1 0

#define TEMP_SENSOR_2 0

#define TEMP_SENSOR_BED 1 ( this is for the bed sensor)

>>>

//===========================================================================

//=============================Thermal Settings ============================

//===========================================================================

//

//--NORMAL IS 4.7kohm PULLUP!-- 1kohm pullup can be used on hotend sensor, using correct resistor and table

//

//// Temperature sensor settings:

// -2 is thermocouple with MAX6675 (only for sensor 0)

// -1 is thermocouple with AD595

// 0 is not used

// 1 is 100k thermistor - best choice for EPCOS 100k (4.7k pullup)

// 2 is 200k thermistor - ATC Semitec 204GT-2 (4.7k pullup)

// 3 is Mendel-parts thermistor (4.7k pullup)

// 4 is 10k thermistor !! do not use it for a hotend. It gives bad resolution at high temp. !!

// 5 is 100K thermistor - ATC Semitec 104GT-2 (Used in ParCan & J-Head) (4.7k pullup)

// 6 is 100k EPCOS - Not as accurate as table 1 (created using a fluke thermocouple) (4.7k pullup)

// 7 is 100k Honeywell thermistor 135-104LAG-J01 (4.7k pullup)

// 71 is 100k Honeywell thermistor 135-104LAF-J01 (4.7k pullup)

// 8 is 100k 0603 SMD Vishay NTCS0603E3104FXT (4.7k pullup)

// 9 is 100k GE Sensing AL03006-58.2K-97-G1 (4.7k pullup)

// 10 is 100k RS thermistor 198-961 (4.7k pullup)

// 11 is 100k beta 3950 1% thermistor (4.7k pullup)

// 12 is 100k 0603 SMD Vishay NTCS0603E3104FXT (4.7k pullup) (calibrated for Makibox hot bed)

// 13 is 100k Hisens 3950 1% up to 300°C for hotend "Simple ONE " & "Hotend "All In ONE"

// 20 is the PT100 circuit found in the Ultimainboard V2.x

// 60 is 100k Maker's Tool Works Kapton Bed Thermistor beta=3950

//

// 1k ohm pullup tables - This is not normal, you would have to have changed out your 4.7k for 1k

// (but gives greater accuracy and more stable PID)

// 51 is 100k thermistor - EPCOS (1k pullup)

// 52 is 200k thermistor - ATC Semitec 204GT-2 (1k pullup)

// 55 is 100k thermistor - ATC Semitec 104GT-2 (Used in ParCan & J-Head) (1k pullup)

//

// 1047 is Pt1000 with 4k7 pullup

// 1010 is Pt1000 with 1k pullup (non standard)

// 147 is Pt100 with 4k7 pullup

// 110 is Pt100 with 1k pullup (non standard)

#define TEMP_SENSOR_0 1 ( this is for the hotend type of sensor)

#define TEMP_SENSOR_1 0

#define TEMP_SENSOR_2 0

#define TEMP_SENSOR_BED 1 ( this is for the bed sensor)

|

Re: how do I put this extruder together? April 15, 2015 08:31AM |

Registered: 10 years ago Posts: 202 |

HOOOWwwww

I was afraid, it will not become easier with it!

I have this PCB:

[www.mijnalbum.nl]

here it is also, scroll down please?:

[reprap.org]

but I also I have this:

(coincidentally the PCB and additional temprature censoors bought!)

[www.mijnalbum.nl]

the heat plate I had, and the sensor for the E3D V6.

that are thus two(2) different types of censors.

I have two(2) of everything now.

who sits on the board is 100K

the sensor which is on the E3D V6 (approximately) 30ohm (30R)

.

thank you again Bigfilsing and Andrew!

the software,

I must admit it is not getting any easier

brains of mine have trouble with it!

friendly greetings from here again!

Rob.

Edited 2 time(s). Last edit at 04/15/2015 08:55AM by 3D rob.

I was afraid, it will not become easier with it!

I have this PCB:

[www.mijnalbum.nl]

here it is also, scroll down please?:

[reprap.org]

but I also I have this:

(coincidentally the PCB and additional temprature censoors bought!)

[www.mijnalbum.nl]

the heat plate I had, and the sensor for the E3D V6.

that are thus two(2) different types of censors.

I have two(2) of everything now.

who sits on the board is 100K

the sensor which is on the E3D V6 (approximately) 30ohm (30R)

.

thank you again Bigfilsing and Andrew!

the software,

I must admit it is not getting any easier

brains of mine have trouble with it!

friendly greetings from here again!

Rob.

Edited 2 time(s). Last edit at 04/15/2015 08:55AM by 3D rob.

|

Re: how do I put this extruder together? April 15, 2015 10:03AM |

Registered: 11 years ago Posts: 469 |

Je maakt het niet makelijk voor jezelf eh

I think you might be trying to run before you can walk

Right so put the thermo couples to one side and consider it an upgrade for later !!!!

Use the standard thermistor that came with the E3D for the hotend . They work perfectly fine !!! Only much later when you are really fine tuning your prints could you possible get any benifit from a thermo couple ( and they are more electronics that need setting up and could go wrong ...KIS = Keep it simple ( at least to start with) )

I think the E3D comes with a Semitec 100K ohm thermistor last time i checked.(so "5" in config.h)

Or if its an older type it could be a Epcos ( which is "1" in config.h)

I cant really tell what kind of temp sensor is fitted to the heated bed but im guessing its a thermistor as well. If you know the type it is then set it in config.h.

Config.h draws reference from thermisistor tables so its important you get it set correctly ( the tables are the known deviance's of the most popular thermistors because the errors for thermistors isnt linear i,e. if its 2 deg wrong at 100C doesnt mean it will be 2 deg at 150 etc)

When it doubt set it as "1" in config and see if it works.

If you then power up the ramps and connect to it with pronterface you should get a temp reading ( room temperature as long as you haven't switched on hotend or heated bed of course)

I think you might be trying to run before you can walk

Right so put the thermo couples to one side and consider it an upgrade for later !!!!

Use the standard thermistor that came with the E3D for the hotend . They work perfectly fine !!! Only much later when you are really fine tuning your prints could you possible get any benifit from a thermo couple ( and they are more electronics that need setting up and could go wrong ...KIS = Keep it simple ( at least to start with) )

I think the E3D comes with a Semitec 100K ohm thermistor last time i checked.(so "5" in config.h)

Or if its an older type it could be a Epcos ( which is "1" in config.h)

I cant really tell what kind of temp sensor is fitted to the heated bed but im guessing its a thermistor as well. If you know the type it is then set it in config.h.

Config.h draws reference from thermisistor tables so its important you get it set correctly ( the tables are the known deviance's of the most popular thermistors because the errors for thermistors isnt linear i,e. if its 2 deg wrong at 100C doesnt mean it will be 2 deg at 150 etc)

When it doubt set it as "1" in config and see if it works.

If you then power up the ramps and connect to it with pronterface you should get a temp reading ( room temperature as long as you haven't switched on hotend or heated bed of course)

|

Re: how do I put this extruder together? April 16, 2015 02:57AM |

Registered: 10 years ago Posts: 202 |

inderdaad ik maak het mij zelf niet makkelijk inderdaad!

indeed not make me easy.

that is because the seller he came with the PCB it themselves,

(he says) you've actually still need some PCB to convert the signal,

and I thought the seller will know it! (he is the man with the knowledge!)

but!

I've been busy with it again.

I got it still not running,

I have here two kinds of sensors I have also connected the sensor from the heated bed and the extruder.

there is now a friend withhe has visited who knows a lot more from software,

but he got no movement also!

I (we) have been looking and looking into the software.

I'll get moving if I only test the Arduino software is put on,

but repetier host I get (we) it still running.

so sensors are connected but equally no movement.

I've been thinking I'm going to look to the limit switches,

just check, you never know, maybe there is a mistake there?

I must honestly say: it is difficult, but still exciting!

Friendly greetings to you all again!

Rob.

Edited 2 time(s). Last edit at 04/16/2015 03:02AM by 3D rob.

indeed not make me easy.

that is because the seller he came with the PCB it themselves,

(he says) you've actually still need some PCB to convert the signal,

and I thought the seller will know it! (he is the man with the knowledge!)

but!

I've been busy with it again.

I got it still not running,

I have here two kinds of sensors I have also connected the sensor from the heated bed and the extruder.

there is now a friend withhe has visited who knows a lot more from software,

but he got no movement also!

I (we) have been looking and looking into the software.

I'll get moving if I only test the Arduino software is put on,

but repetier host I get (we) it still running.

so sensors are connected but equally no movement.

I've been thinking I'm going to look to the limit switches,

just check, you never know, maybe there is a mistake there?

I must honestly say: it is difficult, but still exciting!

Friendly greetings to you all again!

Rob.

Edited 2 time(s). Last edit at 04/16/2015 03:02AM by 3D rob.

|

Re: how do I put this extruder together? April 16, 2015 04:41AM |

Registered: 10 years ago Posts: 202 |

i believe that i found the mistake!!!

I dont dare hardly to write it down (I am ashamed of myself a bit)

i believe, attention BELIEVE......when I measure it well

(i hope that it is indeed that)

it seems that I have soldered the limit switches wrong,

and yet I have those INFO from the internet !?

shame...shame...shame....

if I have some time I go and work on it

Greetings everyone again!

Rob.

Edited 2 time(s). Last edit at 04/16/2015 05:11AM by 3D rob.

|

Re: how do I put this extruder together? April 16, 2015 09:11AM |

Registered: 10 years ago Posts: 202 |

|

Re: how do I put this extruder together? April 16, 2015 02:43PM |

Registered: 11 years ago Posts: 469 |

|

Re: how do I put this extruder together? April 16, 2015 05:50PM |

Registered: 10 years ago Posts: 202 |

.

YES YES YESSSSSsssssssss !!!!!!!!!!!!!!!!!!!!!!!!!

number five is alive !!!

number five is alive !!!

HO HO HOOOOOOOWWWWWwwwwwww hahahaaaa LOL

have been very happy, he moves!

still not 100% correct but I think that just yet problematic.

(the motors rotate only in one (1) direction)

and I believe that which can also come through the iend switches???

*with their pull-up / pull-down resistors*

I could be wrong! i do not know yet, but I have also discovered more INFO

So there I also need to get started to read.

(never too old to learn!)

Greetings all! (go to bed)

Rob.

HOOWWWwwww Bigfilsing

by exident I have downloaded : SPRINTER

that came through this video: [www.youtube.com]

That's because I just found out that my FIRMWARE

it just was not good on my PC.....in Arduino it was not in the Arduino software.

going down now ;-)

to my bed.

Edited 1 time(s). Last edit at 04/16/2015 06:04PM by 3D rob.

YES YES YESSSSSsssssssss !!!!!!!!!!!!!!!!!!!!!!!!!

number five is alive !!!

number five is alive !!!

HO HO HOOOOOOOWWWWWwwwwwww hahahaaaa LOL

have been very happy, he moves!

still not 100% correct but I think that just yet problematic.

(the motors rotate only in one (1) direction)

and I believe that which can also come through the iend switches???

*with their pull-up / pull-down resistors*

I could be wrong! i do not know yet, but I have also discovered more INFO

So there I also need to get started to read.

(never too old to learn!)

Greetings all! (go to bed)

Rob.

HOOWWWwwww Bigfilsing

by exident I have downloaded : SPRINTER

that came through this video: [www.youtube.com]

That's because I just found out that my FIRMWARE

it just was not good on my PC.....in Arduino it was not in the Arduino software.

going down now ;-)

to my bed.

Edited 1 time(s). Last edit at 04/16/2015 06:04PM by 3D rob.

|

Re: how do I put this extruder together? April 17, 2015 05:55AM |

Registered: 11 years ago Posts: 469 |

Not sure about sprinter or repetier but in Marlin you can only manually move the stepper axis away from the end stop until it has been homed for the first time since power on.

Which would explain why you can only move 1 way when you power on.

OK next step is to check end stops

Before powering on move you X and Y axis to mid point and your z to at least 50mm above the print bed . Then type a M119 command this should return your end stop status - Open if then are not touched & TRIGGERED if they are.

Hold them by hand one by one and issue the M119 command to check they are working

Which would explain why you can only move 1 way when you power on.

OK next step is to check end stops

Before powering on move you X and Y axis to mid point and your z to at least 50mm above the print bed . Then type a M119 command this should return your end stop status - Open if then are not touched & TRIGGERED if they are.

Hold them by hand one by one and issue the M119 command to check they are working

|

Re: how do I put this extruder together? April 17, 2015 06:04PM |

Registered: 10 years ago Posts: 202 |

Unfortunately, I understand your story not so good!

What I do notice,

is that all of the directions of rotation that do the motors in the direction of the end stops.

it is that I will not allow, otherwise the switch would be pressed.

shall I will allow it for once? or will I press the switch by hand?

.

now I will probably should be ashamed of myself???

where do I write that code M119?

I think somewhere in the Arduino language / code.

to remember I'm not a profesor, I'm just a simple soul! ;-)

.

I had to go to work today, so was just out of the picture for a moment

And Bigfilsing yet again thanks again!

Rob.

What I do notice,

is that all of the directions of rotation that do the motors in the direction of the end stops.

it is that I will not allow, otherwise the switch would be pressed.

shall I will allow it for once? or will I press the switch by hand?

.

now I will probably should be ashamed of myself???

where do I write that code M119?

I think somewhere in the Arduino language / code.

to remember I'm not a profesor, I'm just a simple soul! ;-)

.

I had to go to work today, so was just out of the picture for a moment

And Bigfilsing yet again thanks again!

Rob.

|

Re: how do I put this extruder together? April 18, 2015 09:05AM |

Registered: 11 years ago Posts: 469 |

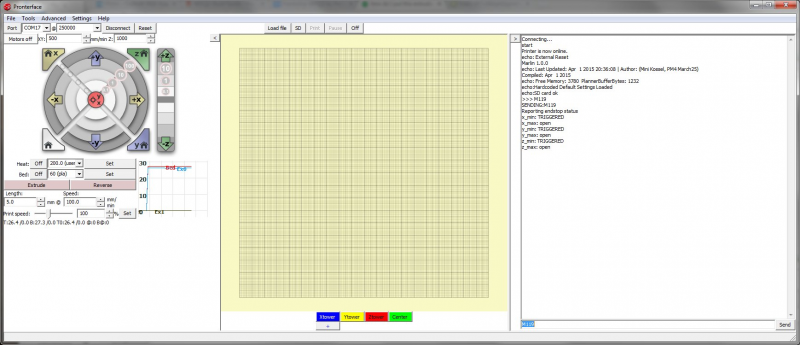

Ok first things first

M119 is gcode

Gcode is what controls the printer movements etc

Gcode is generated by slicer software ( like CUra for example) Cura takes your model ( an STL file) and together with settings you input like temprature layer height etc etc It generates Gcode to drive the printer.

The user can also type in gcode and send it to the printer in whats called a terminal window > this you can use to make adjustments to settings ...steps per mm for example but also "ask" the printer for status of things

M119 in effect request the current status of the endstops

The easiest way to start talking to your printer is with pronterface. A free download program that controls your printer for windows >>[koti.kapsi.fi]

Install that and then connect to your ramps board. Note you have to set the com port ( look in device manager which com port your printer is on) and the baud rate ( which is set in config.h)

when connected you will see the printer send back info in the terminal window of pronterface

at the bottom of that window is an input area where you can type in Gcode commands ( then hit enter or click "send" button on the left) and Marlin will report back

see pic below ( ignore what the text in the terminal window picture below says .... its from a different type of printer im building )

I think you need to do a lot more reading on the wiki pages and forums to understand all this stuff.

Unfortunately my written dutch isnt really good enough to write all this in dutch but im sure theres forums in NL for that.

So before you go any further stop messing around with Sprinter and repetier for the moment ( you can try them later ) get your printer running with standard Marlin and connect with pronterface.

That way you can easily test end stops /motor directions/ calibrate steps per mm etc etc. You know how to load Marlin test program so do the same with Marlin firmware.

Good luck

Edited 2 time(s). Last edit at 04/18/2015 09:09AM by bigfilsing.

M119 is gcode

Gcode is what controls the printer movements etc

Gcode is generated by slicer software ( like CUra for example) Cura takes your model ( an STL file) and together with settings you input like temprature layer height etc etc It generates Gcode to drive the printer.

The user can also type in gcode and send it to the printer in whats called a terminal window > this you can use to make adjustments to settings ...steps per mm for example but also "ask" the printer for status of things

M119 in effect request the current status of the endstops

The easiest way to start talking to your printer is with pronterface. A free download program that controls your printer for windows >>[koti.kapsi.fi]

Install that and then connect to your ramps board. Note you have to set the com port ( look in device manager which com port your printer is on) and the baud rate ( which is set in config.h)

when connected you will see the printer send back info in the terminal window of pronterface

at the bottom of that window is an input area where you can type in Gcode commands ( then hit enter or click "send" button on the left) and Marlin will report back

see pic below ( ignore what the text in the terminal window picture below says .... its from a different type of printer im building )

I think you need to do a lot more reading on the wiki pages and forums to understand all this stuff.

Unfortunately my written dutch isnt really good enough to write all this in dutch but im sure theres forums in NL for that.

So before you go any further stop messing around with Sprinter and repetier for the moment ( you can try them later ) get your printer running with standard Marlin and connect with pronterface.

That way you can easily test end stops /motor directions/ calibrate steps per mm etc etc. You know how to load Marlin test program so do the same with Marlin firmware.

Good luck

Edited 2 time(s). Last edit at 04/18/2015 09:09AM by bigfilsing.

|

Re: how do I put this extruder together? April 18, 2015 11:58AM |

Registered: 10 years ago Posts: 202 |

.

bigfilsing you do an excellent job!

and in the meantime I have done it.

everything goes up / down left / right, front / rear..... it works!

what I do is watch a lot of videos.

with search terms that I again read from people like you!

no professional videos but good enough for me:

[www.youtube.com]

the author of this video helped me to get the firmware in to the Arduino software (so now I can move everything!)

here a video with more clear explanation:

[www.youtube.com]

Yesssssss HAHAHA in German

.

I have several types of software on my PC now.

Repetier Host - Printrun - sprinter master.

I think also to take marlin on my PC, it seems to be good???

.

and yes I am reading also a lot!

VrGr Rob.

bigfilsing you do an excellent job!

and in the meantime I have done it.

everything goes up / down left / right, front / rear..... it works!

what I do is watch a lot of videos.

with search terms that I again read from people like you!

no professional videos but good enough for me:

[www.youtube.com]

the author of this video helped me to get the firmware in to the Arduino software (so now I can move everything!)

here a video with more clear explanation:

[www.youtube.com]

Yesssssss HAHAHA in German

.

I have several types of software on my PC now.

Repetier Host - Printrun - sprinter master.

I think also to take marlin on my PC, it seems to be good???

.

and yes I am reading also a lot!

VrGr Rob.

Sorry, only registered users may post in this forum.