Migbot Prusa i3 Unofficial Support Thread

Posted by jcabrer

|

Re: Migbot Prusa i3 Unofficial Support Thread April 17, 2016 09:34PM |

Registered: 8 years ago Posts: 5 |

Quote

Ax

Quote

Adam304

Quote

jazzbassNick

My guess would be you've got your limit switches in the "+" instead of the "-" slots. If you look closely at the board, they're labeled.

I don't remember more than one driver, but it's been awhile. I'm sure one of the experts will chime in.

Appreciated the quick reply, thank you. I checked and even reversed the endstop connections, still the same. The bed crashes front, x to the right, z straight up.

The driver i was was questioning is ftdiport from CDM v2.08.

Doesn't hurt to install both. It can only help if you're getting com errors. If you take a look at my Marlin 1.1 firmware, and can get it uploaded it should work. Sounds like the directions are set wrong in the firmware and should be as follows:

// Invert the stepper direction. Change (or reverse the motor connector) if an axis goes the wrong way. #define INVERT_X_DIR true #define INVERT_Y_DIR true #define INVERT_Z_DIR true

Thanks for your time in replying, again its truly appreciated. I took a guess installed the ftdiport driver to the COM3 device under device manager. I was able to upload the firmware through the arduino console, albiet with some red text in the logs. I still can't get any software to play nice though.

The motors still rotate in the wrong direction when homing. The extruder seems fine. Should I try to rewire the stepper motors? How? Link to your firmware?

|

Re: Migbot Prusa i3 Unofficial Support Thread April 24, 2016 12:55AM |

Registered: 8 years ago Posts: 26 |

Has anyone tried this PEI/Ultem as a build surface yet?

I have only seen good reviews on it and am considering giving it a go. The only problem I see is that I'm using the proximity sensor for bed leveling and wondering if this will still sense through the PEI sheet. I believe the sensor only has a 2mm range so with a 1mm PEI sheet and approximately another 1mm in 3M adhesive this could contact the build plate before sensing.

I have searched and found a plethora of similar sensors on eBay up to 5mm range which in theory should work. However they list all different specs that I'm not entirely familiar with.

My question is, what 5mm proximity sensor would be compatible with the Migbot and would it just be plug and play, only requiring level adjustment to dial in the nozzle height or would one also need to adjust something in the firmware?

I have only seen good reviews on it and am considering giving it a go. The only problem I see is that I'm using the proximity sensor for bed leveling and wondering if this will still sense through the PEI sheet. I believe the sensor only has a 2mm range so with a 1mm PEI sheet and approximately another 1mm in 3M adhesive this could contact the build plate before sensing.

I have searched and found a plethora of similar sensors on eBay up to 5mm range which in theory should work. However they list all different specs that I'm not entirely familiar with.

My question is, what 5mm proximity sensor would be compatible with the Migbot and would it just be plug and play, only requiring level adjustment to dial in the nozzle height or would one also need to adjust something in the firmware?

|

Re: Migbot Prusa i3 Unofficial Support Thread April 24, 2016 03:57PM |

Registered: 13 years ago Posts: 50 |

|

Re: Migbot Prusa i3 Unofficial Support Thread April 25, 2016 12:27PM |

Registered: 8 years ago Posts: 269 |

Quote

Adam304

Quote

Ax

Quote

Adam304

Quote

jazzbassNick

My guess would be you've got your limit switches in the "+" instead of the "-" slots. If you look closely at the board, they're labeled.

I don't remember more than one driver, but it's been awhile. I'm sure one of the experts will chime in.

Appreciated the quick reply, thank you. I checked and even reversed the endstop connections, still the same. The bed crashes front, x to the right, z straight up.

The driver i was was questioning is ftdiport from CDM v2.08.

Doesn't hurt to install both. It can only help if you're getting com errors. If you take a look at my Marlin 1.1 firmware, and can get it uploaded it should work. Sounds like the directions are set wrong in the firmware and should be as follows:

// Invert the stepper direction. Change (or reverse the motor connector) if an axis goes the wrong way. #define INVERT_X_DIR true #define INVERT_Y_DIR true #define INVERT_Z_DIR true

Thanks for your time in replying, again its truly appreciated. I took a guess installed the ftdiport driver to the COM3 device under device manager. I was able to upload the firmware through the arduino console, albiet with some red text in the logs. I still can't get any software to play nice though.

The motors still rotate in the wrong direction when homing. The extruder seems fine. Should I try to rewire the stepper motors? How? Link to your firmware?

Apologies, been a little on the busy side - Firmware's on github at [github.com]

Take the 1.1 firmware, it works a hell of a lot better. I'm currently testing the 1.1 RC5 build on my home Migbot, I'll have it converted over to all the configs soon.

For the rest of you all, I did a quick knock up of an overhead spool holder, that doubles as a LCD screen stand-off. It's basically a remix of my filament guide and an overhead spool holder I used to use. It'll happily hold 2 spools and just works. Find it here

|

Re: Migbot Prusa i3 Unofficial Support Thread April 26, 2016 02:34AM |

Registered: 9 years ago Posts: 112 |

|

Re: Migbot Prusa i3 Unofficial Support Thread May 02, 2016 09:03AM |

Registered: 7 years ago Posts: 11 |

Hello everyone,

I have a problem with the Z axis of my Migbot Prusa I3 (the 3D Electron sold by 3D Printers Online Store).

I opened a new thread : [forums.reprap.org]

Any help would greatly appreciated. Thank you in advance

I have a problem with the Z axis of my Migbot Prusa I3 (the 3D Electron sold by 3D Printers Online Store).

I opened a new thread : [forums.reprap.org]

Any help would greatly appreciated. Thank you in advance

|

Re: Migbot Prusa i3 Unofficial Support Thread May 05, 2016 11:22AM |

Registered: 8 years ago Posts: 5 |

Could anyone tell me how to increase the extruder motor torque by increasing voltage/amperage through Marlin? Is it possible? Kinda lost since there isn't a physical driver attached. The motor isn't holding and is skipping some. Or could someone tell me a good replacement for the motor? Thanks to everyone for the assistance.

|

Re: Migbot Prusa i3 Unofficial Support Thread May 05, 2016 07:39PM |

Registered: 8 years ago Posts: 269 |

Quote

Adam304

Could anyone tell me how to increase the extruder motor torque by increasing voltage/amperage through Marlin? Is it possible? Kinda lost since there isn't a physical driver attached. The motor isn't holding and is skipping some. Or could someone tell me a good replacement for the motor? Thanks to everyone for the assistance.

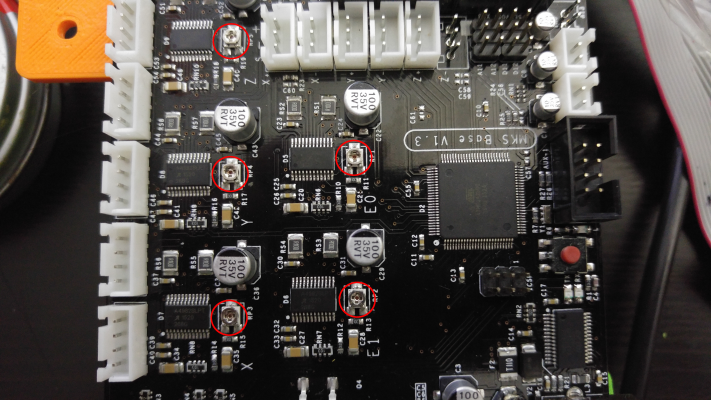

It's not done through Marlin, there's small potentiometers near the stepper drivers.

|

Re: Migbot Prusa i3 Unofficial Support Thread May 05, 2016 08:06PM |

Registered: 9 years ago Posts: 112 |

|

Re: Migbot Prusa i3 Unofficial Support Thread May 05, 2016 08:12PM |

Registered: 9 years ago Posts: 112 |

|

Re: Migbot Prusa i3 Unofficial Support Thread May 05, 2016 09:19PM |

Registered: 9 years ago Posts: 112 |

it's been an hour for this upload to google drive as this is the hardship of these 1 year collection not complete as there is no complete stuff, 3d is learn and play and never ending, i don't like to lost promise but this uploading really take time: [drive.google.com]

|

Re: Migbot Prusa i3 Unofficial Support Thread May 05, 2016 11:20PM |

Registered: 8 years ago Posts: 5 |

Quote

Ax

Quote

Adam304

Could anyone tell me how to increase the extruder motor torque by increasing voltage/amperage through Marlin? Is it possible? Kinda lost since there isn't a physical driver attached. The motor isn't holding and is skipping some. Or could someone tell me a good replacement for the motor? Thanks to everyone for the assistance.

It's not done through Marlin, there's small potentiometers near the stepper drivers.

Appreciate the pic so much, thank you. Originally when looking at it, I thought it some weird capacitor or led. You rock.

|

Re: Migbot Prusa i3 Unofficial Support Thread May 09, 2016 01:24AM |

Registered: 8 years ago Posts: 111 |

|

Re: Migbot Prusa i3 Unofficial Support Thread May 09, 2016 03:40AM |

Registered: 8 years ago Posts: 269 |

Quote

veaceonee

If you adjust those pots, make sure you use a NON-CONDUCTIVE screwdriver. Otherwise it makes interesting noises, probably not to good for it.

Just make sure the Steppers are off by sending an M18 via the console of your preferred software, you can then use a standard screwdriver.

|

Re: Migbot Prusa i3 Unofficial Support Thread May 09, 2016 09:43PM |

Registered: 8 years ago Posts: 22 |

Hello all,

I am under the Marlin Version 1.1.0-RC3. (https://github.com/AxMod3DPrint/Migbot-Firmware)

I installed the sensor LJC18A3 H Z / BX for auto leveling.

But I have a little problem. When I run printing, the G28 is going very well (the Z is detected), he moved to G29 and there, it is as if the sensor is not triggered, continuous nozzle right into the tray.

The weird thing, I unplug the power supply, reconnect and recovery printing, and then everything works. I did the test with 3 differents impressions and every time I got the same result.

Any idea what's happening?

I am under the Marlin Version 1.1.0-RC3. (https://github.com/AxMod3DPrint/Migbot-Firmware)

I installed the sensor LJC18A3 H Z / BX for auto leveling.

But I have a little problem. When I run printing, the G28 is going very well (the Z is detected), he moved to G29 and there, it is as if the sensor is not triggered, continuous nozzle right into the tray.

The weird thing, I unplug the power supply, reconnect and recovery printing, and then everything works. I did the test with 3 differents impressions and every time I got the same result.

Any idea what's happening?

|

Re: Migbot Prusa i3 Unofficial Support Thread May 09, 2016 11:40PM |

Registered: 8 years ago Posts: 269 |

Sounds like the wiring. That sensor needs a Voltage divider circuit as per the circuit in Tom's Video, it's sounding like it's not reliably getting a signal, which would suggest the output voltage is too high.

|

Re: Migbot Prusa i3 Unofficial Support Thread May 10, 2016 12:04AM |

Registered: 8 years ago Posts: 22 |

I tried with the voltage divider, but in this case, the sensor no longer goes into "TRIGGERED" it remains "OPEN" even after detecting the bed.

But I do not understand why detection is well with the G28 and the G29 not to.

I'll try to compile with Arduino 1.0.5, currently I use Arduino 1.5.8

And also can be put more distance on Z_RAISE_BEFORE_PROBING and Z_RAISE_BETWEEN_PROBINGS

Maybe this will change anything.

Edited 1 time(s). Last edit at 05/10/2016 12:56AM by Ceax.

But I do not understand why detection is well with the G28 and the G29 not to.

I'll try to compile with Arduino 1.0.5, currently I use Arduino 1.5.8

And also can be put more distance on Z_RAISE_BEFORE_PROBING and Z_RAISE_BETWEEN_PROBINGS

Maybe this will change anything.

Edited 1 time(s). Last edit at 05/10/2016 12:56AM by Ceax.

|

Re: Migbot Prusa i3 Unofficial Support Thread May 10, 2016 04:21AM |

Registered: 8 years ago Posts: 22 |

|

Re: Migbot Prusa i3 Unofficial Support Thread May 10, 2016 02:01PM |

Registered: 8 years ago Posts: 269 |

Good to know it's sorted. Sounds more like the Arduino version. Marin 1.1-RC3 worked better with the old version, however, shortly, I'm going to be pushing RC6 to the github, auto levelling has been totally overhauled, Get your probe at the right height and you don't need to set an offset. I have it running on my home Migbot now and it's working fine.

|

Re: Migbot Prusa i3 Unofficial Support Thread May 10, 2016 04:17PM |

Registered: 8 years ago Posts: 22 |

|

Re: Migbot Prusa i3 Unofficial Support Thread May 26, 2016 08:56PM |

Registered: 8 years ago Posts: 111 |

|

Re: Migbot Prusa i3 Unofficial Support Thread May 26, 2016 10:14PM |

Registered: 9 years ago Posts: 112 |

|

Re: Migbot Prusa i3 Unofficial Support Thread May 26, 2016 10:59PM |

Registered: 8 years ago Posts: 111 |

|

Re: Migbot Prusa i3 Unofficial Support Thread May 26, 2016 11:23PM |

Registered: 9 years ago Posts: 112 |

|

Re: Migbot Prusa i3 Unofficial Support Thread May 27, 2016 03:04AM |

Registered: 8 years ago Posts: 111 |

i will upload a pic when I get it tore down and swapped out. I use 3D Solutech, Hatchbox, Foxsmart, Esun brands. I do have a spool of wood, but I use it very rarely. i don not have any glow in the dark or metal filaments. Could the throat be sticking out to far, thereby not getting cooled down enough?

|

Re: Migbot Prusa i3 Unofficial Support Thread May 27, 2016 11:34AM |

Registered: 9 years ago Posts: 112 |

veaceonee, one things about wood filament it very easy to get stuck on the tube and whenever i print using wood i would use ABS filament and heat the nozzle up to 245 to clean the throat before print (spent a little time and you may save the future trouble) and nozzle. as attach is the throat should be 0.8-2mm distance the max. please upload the picture so will be easier for me to guide you!

|

Re: Migbot Prusa i3 Unofficial Support Thread May 27, 2016 11:52AM |

Registered: 9 years ago Posts: 112 |

|

Re: Migbot Prusa i3 Unofficial Support Thread May 27, 2016 07:42PM |

Registered: 8 years ago Posts: 111 |

Took the printer apart, filament all jammed in the throat. Went into Cura, and noticed my retract was set to 4.5mm at 40 mm/sec. Changed it to 1.0mm at 40 mm/sec (as I read somewhere that I cant remember), gonna see if that helps. I havent done any wood in well over a couple weeks.

Did you want a picture of the extruder setup or the old throat?

*edit: I read on a Geeetech website (here) that a guy had good results when he drilled a hole in the heatsink that is right in front of the feeder, hence blowing cool air inside that area. Gave that a try.

Edited 1 time(s). Last edit at 05/27/2016 07:46PM by veaceonee.

Did you want a picture of the extruder setup or the old throat?

*edit: I read on a Geeetech website (here) that a guy had good results when he drilled a hole in the heatsink that is right in front of the feeder, hence blowing cool air inside that area. Gave that a try.

Edited 1 time(s). Last edit at 05/27/2016 07:46PM by veaceonee.

|

Re: Migbot Prusa i3 Unofficial Support Thread May 28, 2016 04:56AM |

Registered: 9 years ago Posts: 112 |

veaceonee , the retract only can be max at 2.5mm-3.5mm why i don't go lower or hight because if i lower the print will have alot of spider web which i don't like. if too much it's will jam at throat as for the retraction speed, please only 20-30 not more as it will cause too much issue, let have an example if the heat up the filament will be soft and when you put in too fast it will jam. this is important and please please don't let the screw too tight, it will break the filament which is not a good things. hot melt, tight break. remember this.

|

Re: Migbot Prusa i3 Unofficial Support Thread May 28, 2016 06:32AM |

Registered: 8 years ago Posts: 269 |

Gonna stick my nose in here. Frankly, with the amount you'll be ending up spending on new throats to find one that actually works, you're better off getting an E3D and being done with it. The MK8 design is old and inherently flawed due to the way it transfers heat. I've had Lite6's on all my Migbots and regularly run 4-6mm retractions on them all and the same for the v6s on the 2 FB2020s I have. I've not had a full blockage in a very long time and the partials were my fault for not getting the PTFE tubing correcly into the Lite6'.

A Lite6 is £25.80 ($31.80, no Tax to the US) + postage direct from E3D and is about the same equivalent price in the US. There is absolutely NO reason to be using a crappy hot end assembly like the MK8 that comes on the Migbots as standard when you can get a well designed one cheaply like the Lite6. You will save yourself a lot of blood, sweat, tears, frustration, research and blockages if you print a mount and get an E3D. I'm speaking from experience here. I've had 4 Migbots, 1 has been converted into a FB2020+, but all my printers run either an E3D v6 or Lite6. I've not had an issue since I made the switch.

A Lite6 is £25.80 ($31.80, no Tax to the US) + postage direct from E3D and is about the same equivalent price in the US. There is absolutely NO reason to be using a crappy hot end assembly like the MK8 that comes on the Migbots as standard when you can get a well designed one cheaply like the Lite6. You will save yourself a lot of blood, sweat, tears, frustration, research and blockages if you print a mount and get an E3D. I'm speaking from experience here. I've had 4 Migbots, 1 has been converted into a FB2020+, but all my printers run either an E3D v6 or Lite6. I've not had an issue since I made the switch.

Sorry, only registered users may post in this forum.