|

Re: Migbot Prusa i3 Unofficial Support Thread December 02, 2016 06:04PM |

Registered: 8 years ago Posts: 26 |

Quote

Wes78

An alternative to the factory sensor, especially for those that want to print on glass. I have this sensor on my other printers and it works Flawlessly.

It's a plug and play. The only thing will probably have to do is invert the in endstop signal.

[www.dropbox.com]

[www.filastruder.com]

Thanks Wes. I found a local company that supplies a similar sensor based off that one. Going to give it a go.

|

Re: Migbot Prusa i3 Unofficial Support Thread December 08, 2016 08:58PM |

Registered: 8 years ago Posts: 23 |

Hi, I had a filament jam that I cleared up, but ever since clearing it I get melted filament oozing UP over the hot end where the threaded tube enters the hot end block.

If it were a water pipe I would just wrap it in silicone tape. I worry though that the stuff from the hardware store might not be rated for the temps here.

Anyone have any ideas / recommendations for a quick fix that doesn't require an online order and shipping delays?

Or... am I screwed and need to buy a new hotend/threaded tube?

Thanks in advance,

Jason.

If it were a water pipe I would just wrap it in silicone tape. I worry though that the stuff from the hardware store might not be rated for the temps here.

Anyone have any ideas / recommendations for a quick fix that doesn't require an online order and shipping delays?

Or... am I screwed and need to buy a new hotend/threaded tube?

Thanks in advance,

Jason.

|

Re: Migbot Prusa i3 Unofficial Support Thread December 08, 2016 09:18PM |

Registered: 8 years ago Posts: 11 |

|

Re: Migbot Prusa i3 Unofficial Support Thread December 08, 2016 10:32PM |

Registered: 8 years ago Posts: 23 |

Quote

jazzbassNick

When this happened to me, I found that some of the threads of the heater block had actually disintegrated and fell out. I think I ended up getting a set of 5 heater blocks on Amazon.

Thanks... don't suppose you still have the links to the blocks you bought?

Also... did you replace the threaded tube as well or just the block?

Thanks,

J

|

Re: Migbot Prusa i3 Unofficial Support Thread December 09, 2016 01:37PM |

Registered: 8 years ago Posts: 103 |

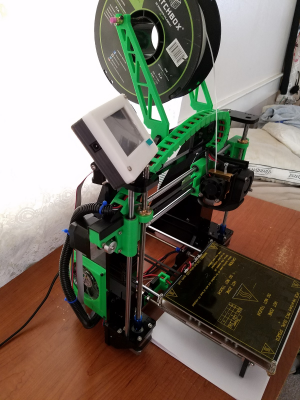

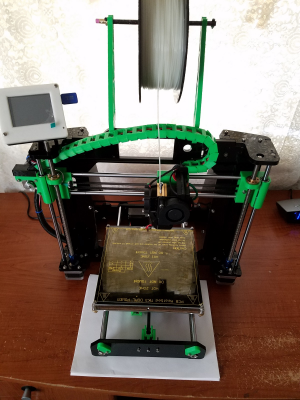

Here she is up and running on marlin 1.1.0-RC7 "Jittery Jedi"

Edited 1 time(s). Last edit at 12/09/2016 01:38PM by Wes78.

Edited 1 time(s). Last edit at 12/09/2016 01:38PM by Wes78.

|

Re: Migbot Prusa i3 Unofficial Support Thread December 09, 2016 02:39PM |

Registered: 8 years ago Posts: 11 |

Quote

uberjay

Thanks... don't suppose you still have the links to the blocks you bought?

Also... did you replace the threaded tube as well or just the block?

Thanks,

J

I had replaced the threaded tube prior.

The heater blocks I ordered aren't available - I'm not sure I'd recommend anyway since it didn't have a grub screw to hold the thermistor in, had to use kapton tape.

Here's the links to both the tubes and the blocks:

[www.amazon.com]

[www.amazon.com]

Oh, I think I did use some teflon tape (the really thin white stuff) on the threads of the tube, if that's the tape you were asking about.

Looks like there's some similar available though.

Edited 1 time(s). Last edit at 12/09/2016 02:45PM by jazzbassNick.

|

Re: Migbot Prusa i3 Unofficial Support Thread December 09, 2016 02:42PM |

Registered: 8 years ago Posts: 23 |

Quote

jazzbassNick

I had replaced the threaded tube prior.

The heater blocks I ordered aren't available - I'm not sure I'd recommend anyway since it didn't have a grub screw to hold the thermistor in, had to use kapton tape.

Here's the links to both the tubes and the blocks:

[www.amazon.com]

[www.amazon.com]

Looks like there's some similar available though.

Thanks, that helped me find something available on the Canadian Amazon site:

[www.amazon.ca]

|

Re: Migbot Prusa i3 Unofficial Support Thread December 09, 2016 02:49PM |

Registered: 8 years ago Posts: 103 |

for whats its worth, im using a heater block from a e3d clone, had extra parts laying around

I like it a lot better cause its smaller and the way it clamps on to the heater cartage is much much better then the stock one it came with

i allso moded the heat brake so that i can run the inner from the tip all the way to the gear from the motor

I like it a lot better cause its smaller and the way it clamps on to the heater cartage is much much better then the stock one it came with

i allso moded the heat brake so that i can run the inner from the tip all the way to the gear from the motor

|

Re: Migbot Prusa i3 Unofficial Support Thread December 12, 2016 11:13AM |

Registered: 8 years ago Posts: 23 |

Hey, this is going to sound like a dumb question, but in the attached picture the vendor lines up the gap in threads closer to the nozzle end. I thought the gap was for the set-screw in the extruder block?

Just wondering if this could be why my hot-end / threaded feed tube are leaking - if I have it upside down? I thought the thread looked about the same - maybe it is not??

Thanks,

Jason.

Just wondering if this could be why my hot-end / threaded feed tube are leaking - if I have it upside down? I thought the thread looked about the same - maybe it is not??

Thanks,

Jason.

|

Re: Migbot Prusa i3 Unofficial Support Thread December 12, 2016 11:18AM |

Registered: 8 years ago Posts: 103 |

|

Re: Migbot Prusa i3 Unofficial Support Thread December 12, 2016 11:18AM |

Registered: 8 years ago Posts: 11 |

|

Re: Migbot Prusa i3 Unofficial Support Thread December 12, 2016 11:25AM |

Registered: 8 years ago Posts: 23 |

Thanks guys.

As I think about it now, I did have the gap down (toward the hot end) before I had a jam. After the jam I switched it thinking it was for the set-screw. DOH!

Going to flip it and get back to the way it should be. As a side note, the gap-up orientation really made it hard to get my bed sensor aligned right ;-).

Cheers,

J.

As I think about it now, I did have the gap down (toward the hot end) before I had a jam. After the jam I switched it thinking it was for the set-screw. DOH!

Going to flip it and get back to the way it should be. As a side note, the gap-up orientation really made it hard to get my bed sensor aligned right ;-).

Cheers,

J.

|

Re: Migbot Prusa i3 Unofficial Support Thread December 12, 2016 11:44AM |

Registered: 8 years ago Posts: 103 |

....actually let me get straight to the point, when you have leaking heater block . More often then not means you nozzle isn't fully seated against the heat brake. There should not ever be a gap between the nozzle and the heat brake. This will not only cause a leaking heater block but also increase your chances of a jam.

My suggested procedure would be screwing in the tip to the heater block once at bottom back it off roughly half of turn then screw in the heat break until it bottoms out on top of the nozzle.

Then putting a wrench on the heater block and one on the nozzle tighten them firmly just be careful not to over tightened and stripped the heater block.

My suggested procedure would be screwing in the tip to the heater block once at bottom back it off roughly half of turn then screw in the heat break until it bottoms out on top of the nozzle.

Then putting a wrench on the heater block and one on the nozzle tighten them firmly just be careful not to over tightened and stripped the heater block.

|

Re: Migbot Prusa i3 Unofficial Support Thread December 12, 2016 11:58AM |

Registered: 8 years ago Posts: 23 |

Quote

Wes78

....actually let me get straight to the point, when you have leaking heater block . More often then not means you nozzle isn't fully seated against the heat brake. There should not ever be a gap between the nozzle and the heat brake. This will not only cause a leaking heater block but also increase your chances of a jam.

My suggested procedure would be screwing in the tip to the heater block once at bottom back it off roughly half of turn then screw in the heat break until it bottoms out on top of the nozzle.

Then putting a wrench on the heater block and one on the nozzle tighten them firmly just be careful not to over tightened and stripped the heater block.

Thanks for that. What I had done was close, but without the backing off of the nozzle and retightening. I'll give that a whirl.

Thanks,

J

|

Re: Migbot Prusa i3 Unofficial Support Thread December 12, 2016 12:03PM |

Registered: 8 years ago Posts: 103 |

|

Re: Migbot Prusa i3 Unofficial Support Thread December 16, 2016 05:19AM |

Registered: 8 years ago Posts: 111 |

Quick Q-

Anyone have any experience with a BLTouch Sensor (Like this one)? Looks like it would be ideal for people with non-metallic build plates.

Anyone have any experience with a BLTouch Sensor (Like this one)? Looks like it would be ideal for people with non-metallic build plates.

|

Re: Migbot Prusa i3 Unofficial Support Thread January 01, 2017 10:05PM |

Registered: 8 years ago Posts: 26 |

Quote

IBaz

Quote

Wes78

An alternative to the factory sensor, especially for those that want to print on glass. I have this sensor on my other printers and it works Flawlessly.

It's a plug and play. The only thing will probably have to do is invert the in endstop signal.

[www.dropbox.com]

[www.filastruder.com]

Thanks Wes. I found a local company that supplies a similar sensor based off that one. Going to give it a go.

OK, I have finally gotten around to installing this sensor but it isn't plug and play. I have wired it in to what I believe to be the correct manner but when homing the z-axis will not move down. I can make the LED come on by manually moving towards the bed or any object to make it sense something but it just won't do it automatically. Do I have to invert the endstop signal as Wes suggested? If so how do I go about it?

|

Re: Migbot Prusa i3 Unofficial Support Thread January 01, 2017 10:23PM |

Registered: 8 years ago Posts: 103 |

It is plug and play. There is not any special you have to do to get the sensor to work,

- goes to - , + gose + and Signal goes to Signal , when wiring up to your bored. Simple as that.

Just like the stock sensor.

However....

The very first thing you need to do once you have the sensor operational on your printer is to type in m119 in a command line and verify rather or not the Z end stop has been triggered. You might even hold something under the sensor to have the light come on and running m119 to see if it's untriggered

If the Z end stop has been triggered it will not allowed to home z, because it thinks it's already there

If it shows that it has been triggered you will need to invert the signal within the Marlin firmware and reflash it to your board.

Easy peasy

Edited 1 time(s). Last edit at 01/01/2017 10:25PM by Wes78.

- goes to - , + gose + and Signal goes to Signal , when wiring up to your bored. Simple as that.

Just like the stock sensor.

However....

The very first thing you need to do once you have the sensor operational on your printer is to type in m119 in a command line and verify rather or not the Z end stop has been triggered. You might even hold something under the sensor to have the light come on and running m119 to see if it's untriggered

If the Z end stop has been triggered it will not allowed to home z, because it thinks it's already there

If it shows that it has been triggered you will need to invert the signal within the Marlin firmware and reflash it to your board.

Easy peasy

Edited 1 time(s). Last edit at 01/01/2017 10:25PM by Wes78.

|

Re: Migbot Prusa i3 Unofficial Support Thread January 01, 2017 10:50PM |

Registered: 8 years ago Posts: 103 |

what your going to be looking for is this here:

// Mechanical endstop with COM to ground and NC to Signal uses "false" here (most common setup).

#define X_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define Y_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define Z_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define X_MAX_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define Y_MAX_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define Z_MAX_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define Z_MIN_PROBE_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

change this one from--> #define Z_MIN_PROBE_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

to this---> #define Z_MIN_PROBE_ENDSTOP_INVERTING false // set to true to invert the logic of the endstop,

save and reflash.

once flashed send an M119 to make sure that the Z is now un-triggered

Edited 1 time(s). Last edit at 01/01/2017 10:51PM by Wes78.

// Mechanical endstop with COM to ground and NC to Signal uses "false" here (most common setup).

#define X_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define Y_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define Z_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define X_MAX_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define Y_MAX_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define Z_MAX_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

#define Z_MIN_PROBE_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

change this one from--> #define Z_MIN_PROBE_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

to this---> #define Z_MIN_PROBE_ENDSTOP_INVERTING false // set to true to invert the logic of the endstop,

save and reflash.

once flashed send an M119 to make sure that the Z is now un-triggered

Edited 1 time(s). Last edit at 01/01/2017 10:51PM by Wes78.

|

Re: Migbot Prusa i3 Unofficial Support Thread January 01, 2017 11:00PM |

Registered: 8 years ago Posts: 26 |

Thanks Wes, I did manage to work that out and inverted the endstop as above. It now seems to be probing as before but it is very inconsistent. Some probes it smashes the nozzle into the bed while others it will stop several millimeters above it. I just don't think it reads the PEI sheet correctly. I have this adhered directly to the aluminium bed.

|

Re: Migbot Prusa i3 Unofficial Support Thread January 01, 2017 11:14PM |

Registered: 8 years ago Posts: 103 |

|

Re: Migbot Prusa i3 Unofficial Support Thread January 01, 2017 11:20PM |

Registered: 8 years ago Posts: 26 |

No glass. Just the heatbed under the aluminium build plate as per the OEM setup. I've just added a PEI sheet to the top of this originally thinking the original probe would have enough distance to read through the PEI but it didn't. This is why I went for this probe but it just doesn't seem to sense correctly.

|

Re: Migbot Prusa i3 Unofficial Support Thread January 01, 2017 11:23PM |

Registered: 8 years ago Posts: 103 |

Quote

IBaz

No glass. Just the heatbed under the aluminium build plate as per the OEM setup. I've just added a PEI sheet to the top of this originally thinking the original probe would have enough distance to read through the PEI but it didn't. This is why I went for this probe but it just doesn't seem to sense correctly.

For best results, the sensor needs to sense the reflection from the top surface of the bed. There is a potential problem when the sensor is used with a transparent bed material that reflects infrared light weakly and there is a surface below the transparent material that reflects IR much more strongly. Here is a guide to using the sensor with different print surfaces:

Glass (with or without coatings such as hairspray, PVA or Kapton tape): works as-is if placed directly on a PCB bed heater or other surface that does not reflect strongly. If there is an aluminium heat spreader or bed plate underneath the glass, then either paint the aluminium surface matt black (see below), or put a sheet of matt black paper between the glass and the aluminium.

PEI: this is highly transparent to IR. Paint the underside matt black before using adhesive sheet to attach it to the bed plate.

BuildTak: the dark grey variant works well with the sensor. I have not tested the white variant.

PrintBite: works well with the sensor.

Bright aluminium: not suitable unless the sensor is modified to reduce its sensitivity, because the strong reflection will saturate the sensor.

If you need to paint the top of an aluminium heat spreader or the underside of a PEI sheet matt black, then I recommend using spray-on barbecue & stove paint. It needs to be cured at an elevated temperature to harden. I have found 2 hours at 170C in a domestic electric fan oven works well.

I personally use a sheet of black construction paper between the glass and the aluminum. I had issues untill I did that

Edited 1 time(s). Last edit at 01/01/2017 11:28PM by Wes78.

|

Re: Migbot Prusa i3 Unofficial Support Thread January 02, 2017 04:43AM |

Registered: 8 years ago Posts: 26 |

Bugger, that's a pain. I managed to scrape the PEI off the aluminium bed in one piece. Now just have to find a way to remove this stubborn 3M adhesive. I have some flat black muffler paint here so it's high temp and should do the trick.

Will report back once this is done, hopefully solves the problem.

Will report back once this is done, hopefully solves the problem.

|

Re: Migbot Prusa i3 Unofficial Support Thread February 21, 2017 04:42PM |

Registered: 8 years ago Posts: 111 |

So my printer had a massive failure of a print. Wife woke up to a big smoldering plastic mass being pushed around the print bed. Anyway, I am using it as an excuse to upgrade from a Lite6 to a v6 hotend  . I want to do the thermocouple upgrade ( which uses this adpater board ) but don't know how to hook up/configure the adapter board to the MKS Base 1.3 board. All online references are for RAMPS and Megatronics. I want to get all my ducks in a row before I order it. Any help would be appreciated. thanx in advance.

. I want to do the thermocouple upgrade ( which uses this adpater board ) but don't know how to hook up/configure the adapter board to the MKS Base 1.3 board. All online references are for RAMPS and Megatronics. I want to get all my ducks in a row before I order it. Any help would be appreciated. thanx in advance.

. I want to do the thermocouple upgrade ( which uses this adpater board ) but don't know how to hook up/configure the adapter board to the MKS Base 1.3 board. All online references are for RAMPS and Megatronics. I want to get all my ducks in a row before I order it. Any help would be appreciated. thanx in advance.

. I want to do the thermocouple upgrade ( which uses this adpater board ) but don't know how to hook up/configure the adapter board to the MKS Base 1.3 board. All online references are for RAMPS and Megatronics. I want to get all my ducks in a row before I order it. Any help would be appreciated. thanx in advance.

|

Re: Migbot Prusa i3 Unofficial Support Thread April 27, 2017 05:16PM |

Registered: 7 years ago Posts: 1 |

Does anyone know what the proper name for the connectors that plug the end stop wiring in to the board? I'd like to replace the wiring on my y axis end stop. I was able to identify a compatible switch for the end stop but am still trying to figure out what the compatible part would be for the wiring connector.

|

Re: Migbot Prusa i3 Unofficial Support Thread April 27, 2017 06:05PM |

Registered: 8 years ago Posts: 269 |

Quote

sdw_nj

Does anyone know what the proper name for the connectors that plug the end stop wiring in to the board? I'd like to replace the wiring on my y axis end stop. I was able to identify a compatible switch for the end stop but am still trying to figure out what the compatible part would be for the wiring connector.

They're JST Balance charger LiPo connectors

Edited 1 time(s). Last edit at 04/27/2017 06:06PM by Ax.

|

Re: Migbot Prusa i3 Unofficial Support Thread April 14, 2018 01:17PM |

Registered: 8 years ago Posts: 17 |

|

Re: Migbot Prusa i3 Unofficial Support Thread July 19, 2018 02:01PM |

Registered: 8 years ago Posts: 6 |

Perhaps a bit late for the last poster, but in case anyone else needs it -- I recently upgraded my Migbot i3 by installing a Z-probe and while I was at it, I also upgraded to the latest Marlin firmware (1.1.8). The configuration file changed quite a bit from the original version so if you need something to start with, here are my final config files.

Make sure you adjust your travel limits etc.! My printer is slightly modified in some aspects so it probably does not match the original.

Make sure you adjust your travel limits etc.! My printer is slightly modified in some aspects so it probably does not match the original.

|

Re: Migbot Prusa i3 Unofficial Support Thread October 11, 2018 07:04AM |

Registered: 8 years ago Posts: 9 |

Not sure if anyone still checks this thread, but i just recently started to get my Migbot Prusa i3 back up and running. I had the frame break on me during a move, and just never got around to fixing it. So last night i finally got it calibrated, and ready to print a test cube, when during the homing process, and binder clip slipped off the build plate, and got stuck between the "y"carriage, and the rear frame of the printer. It made that horrible vibrating noise, which i can only assume was the teeth of the pulley slipping on the teeth of the belt. Well after i corrected this my "y" axis no longer works. I switched some wiring around to see if it was the motor, but the motor works when it is connected to the "x" axis and i home it. Thinking something happened to the board,(MKS Base v1.3) but i am unsure of how to troubleshoot it. What should be my next step? I have a new board that i ordered a few years ago when i thought the original board had gone bad, but actually had not. The new one is a "MKS Base v1.4" if i need to install this new board how do i go about getting the correct firmware on it? I have the arduino program, but have never used it. Is it possible to hook up the old board, copy what is on it, then hook up the new one, and upload? Sorry for the rambling, and hopefully someone can give me some advice.

Sorry, only registered users may post in this forum.