Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2015 02:10PM |

Registered: 9 years ago Posts: 251 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2015 03:58PM |

Registered: 8 years ago Posts: 135 |

Read through the entire thread, some interesting developments/problems so far! I have been following RepRap and 3D printers for a couple years now trying to decide what I wanted to do. Eventually settled on this one and ordered from their site today! I live in NH so the idea of supporting a 3D printer company that is local(or at least within the same state) seemed like a good idea and its hard to argue with their prices/feedback. Well be joining the conversation once my build is under way!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2015 05:04PM |

Registered: 8 years ago Posts: 367 |

Quote

Devil Inc

Quote

markts

After witnessing some "play" in the Y belt, I installed a spring tensioner. It seems much better, so I started a 2 hour print. About 20 minutes in I heard a strange sound and found the bed had shifted. I thought the belt slipped because it started printing basically off the bed (on the side away from the endstop). Something must have bound up, so I tried removing the tensioner, but now the belt is stretched so that's not an option.

I'll have to do a smaller print to see what's going on. I'm hoping it's something simple.

I'm having the same trouble with mine now that I've added the adjustable tensioner to the X-Axis. Not sure if it's a 'that's too tight' condition or what. I'm going to work on troubleshooting it tonight, ran out of time to mess with it last night. I have to get it working smoothly, my E3D V6 hot end should be waiting for me when I get home from work. Still need to get an extruder mount, etc. printed for it.

I added both tensioners (the spring sort) on Saturday, and have done about 3 hours printing since then with no problems. It would be great to get some feedback from Dan about what "tight but not too tight" for the belts means, and when to use them. I've not noticed any difference in quality either one way or the other, though I think the movement in the X and Y direction may be a little noisier than before.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2015 05:08PM |

Registered: 8 years ago Posts: 28 |

Quote

widespreaddeadhead

Can you post a picture?Quote

Tenny

So I'm thinking about purchasing the E3D-V6 Lite for this now, but I have one major concern.

Most of my prints have more zig-zag lines on them...

Here's one that's a tad worse than most: [lh3.googleusercontent.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2015 09:19PM |

Registered: 8 years ago Posts: 171 |

Quote

Devil Inc

Quote

markts

After witnessing some "play" in the Y belt, I installed a spring tensioner. It seems much better, so I started a 2 hour print. About 20 minutes in I heard a strange sound and found the bed had shifted. I thought the belt slipped because it started printing basically off the bed (on the side away from the endstop). Something must have bound up, so I tried removing the tensioner, but now the belt is stretched so that's not an option.

I'll have to do a smaller print to see what's going on. I'm hoping it's something simple.

I'm having the same trouble with mine now that I've added the adjustable tensioner to the X-Axis. Not sure if it's a 'that's too tight' condition or what. I'm going to work on troubleshooting it tonight, ran out of time to mess with it last night. I have to get it working smoothly, my E3D V6 hot end should be waiting for me when I get home from work. Still need to get an extruder mount, etc. printed for it.

I'm going ot have to back up. Remove the Y belt and lose the tensioner, and go back to PLA for a while.

I'm not having much luck with ABS, and now I have the belt slipping or something. Darn!

I'm not having much luck with ABS, and now I have the belt slipping or something. Darn!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2015 09:29PM |

Registered: 8 years ago Posts: 45 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2015 10:23PM |

Registered: 8 years ago Posts: 34 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2015 10:31PM |

Registered: 8 years ago Posts: 367 |

Quote

DMPurdy

How did you put the tensioner on? I didn't see anything on how to do that in the instructions.I am having trouble with my bed not heating. It is the first time I have started it and tried anything so not sure what I am missing.

Here's how I fitted my tensioner spring - spring against the flat side like this [goo.gl]. For the X belt, I just prised it one. This was hard, just a matter of holding one end on and then maneuvering the other. For the Y belt, I tried this but couldn't get it (and put one end of the metal tip through the belt in trying), so I ended up taking the pulley off the frame, fitting the spring and then reattaching the pulley. Also hard to do.

For the bed heating, all I can suggest is check the wiring. If you put a voltmeter across the screw terminals on the ramps board with everything turned off, you should measure 3.6 ohms. Zero means you have a short circuit, infinity means you have an open one.

Edited 1 time(s). Last edit at 06/22/2015 10:32PM by animoose.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2015 10:39PM |

Registered: 8 years ago Posts: 45 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2015 10:44PM |

Registered: 8 years ago Posts: 367 |

What is the right thing for lubricating the bearings and rods? I've heard people say white lithium grease. Would 3-in-1 oil do (I ask this only because I have some)? And do you have to take the bearings off the rods to apply it, or can you just put some on the rods and then works the mechanism back and forth a few times?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2015 10:50PM |

Registered: 8 years ago Posts: 171 |

Quote

Uncertainty

Also FYI I'm having the best print so far with ABS (black from FolgerTech) @ 215cExtruder 95cBed using skirt/brim with elmer's purple school glue on a clean glass plate

You give me hope! I kept cranking up the heat when it didn't seem to be working - I was up to 245. Maybe I should have been going lower.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2015 11:02PM |

Registered: 8 years ago Posts: 34 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2015 11:06PM |

Registered: 8 years ago Posts: 45 |

Quote

DMPurdy

Thanks I will give it a try...Also, is the the glass piece supposed to be secured down to the heat bed or just loose? It seems like it may slide around.

I use bulldog clips (2 in front, 2 in back) to secure the glass to the heater. I apply my glue when glass is cold, then I heat up bed to 110c with cardboard on top to retain heat, and remove when bed is at 100c then I start extruder and start print, which brings bed back to 100, and I manually bring bed to 95 after a layer or two. But I will try bed at 110-115, it may improve things

Edited 1 time(s). Last edit at 06/22/2015 11:08PM by Uncertainty.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2015 11:06PM |

Registered: 8 years ago Posts: 45 |

Quote

markts

Quote

Uncertainty

Also FYI I'm having the best print so far with ABS (black from FolgerTech) @ 215cExtruder 95cBed using skirt/brim with elmer's purple school glue on a clean glass plate

You give me hope! I kept cranking up the heat when it didn't seem to be working - I was up to 245. Maybe I should have been going lower.

I found that at 230-245c that the extruder was clicking, probably because it was oozing out faster than it could extrude or something?

Edited 1 time(s). Last edit at 06/22/2015 11:07PM by Uncertainty.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2015 11:10PM |

Registered: 8 years ago Posts: 66 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2015 11:18PM |

Registered: 8 years ago Posts: 171 |

Quote

Uncertainty

Quote

markts

Quote

Uncertainty

Also FYI I'm having the best print so far with ABS (black from FolgerTech) @ 215cExtruder 95cBed using skirt/brim with elmer's purple school glue on a clean glass plate

You give me hope! I kept cranking up the heat when it didn't seem to be working - I was up to 245. Maybe I should have been going lower.

I found that at 230-245c that the extruder was clicking, probably because it was oozing out faster than it could extrude or something?

I'll be darned - the clicking made me think the stuff wasn't melting/extruding so I thought it needed to be hotter. I'm also using glue stick on glass, 105 degrees to start. Haven't had an issue with it sticking yet.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2015 11:49PM |

Registered: 8 years ago Posts: 45 |

Quote

markts

Quote

Uncertainty

Quote

markts

Quote

Uncertainty

Also FYI I'm having the best print so far with ABS (black from FolgerTech) @ 215cExtruder 95cBed using skirt/brim with elmer's purple school glue on a clean glass plate

You give me hope! I kept cranking up the heat when it didn't seem to be working - I was up to 245. Maybe I should have been going lower.

I found that at 230-245c that the extruder was clicking, probably because it was oozing out faster than it could extrude or something?

I'll be darned - the clicking made me think the stuff wasn't melting/extruding so I thought it needed to be hotter. I'm also using glue stick on glass, 105 degrees to start. Haven't had an issue with it sticking yet.

Let me know if it works out for you.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 23, 2015 12:23AM |

Registered: 8 years ago Posts: 45 |

Quote

animoose

What is the right thing for lubricating the bearings and rods? I've heard people say white lithium grease. Would 3-in-1 oil do (I ask this only because I have some)? And do you have to take the bearings off the rods to apply it, or can you just put some on the rods and then works the mechanism back and forth a few times?

I used 3-in-1, I figure if it's good enough for a sewing machine, why not the printer... I just applied it with a rag and then moved the printer around in x,y,z. If only I could get rid of my z threaded rods to stop squealing (only does it on the way down -- I think the nut may be at fault, not sure yet...)

Edited 2 time(s). Last edit at 06/23/2015 12:24AM by Uncertainty.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 23, 2015 12:27AM |

Registered: 8 years ago Posts: 367 |

Quote

Uncertainty

Quote

animoose

What is the right thing for lubricating the bearings and rods? I've heard people say white lithium grease. Would 3-in-1 oil do (I ask this only because I have some)? And do you have to take the bearings off the rods to apply it, or can you just put some on the rods and then works the mechanism back and forth a few times?

I used 3-in-1, I figure if it's good enough for a sewing machine, why not the printer... I just applied it with a rag and then moved the printer around in x,y,z. If only I could get rid of my z threaded rods to stop squealing (only does it on the way down -- I think the nut may be at fault, not sure yet...)

I had squealing Z rods as well. Squeaking, screeching might be other words for it, and it was also only on the way down. I listened carefully and worked out it came from just one side. Then I saw that the motor was just slightly off true with respect to the threaded rod. Undid the screws on the motors bracket, moved it a fraction, and all was good after that.

Edited 1 time(s). Last edit at 06/23/2015 12:33AM by animoose.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 23, 2015 01:17AM |

Registered: 8 years ago Posts: 45 |

Quote

animoose

Quote

Uncertainty

Quote

animoose

What is the right thing for lubricating the bearings and rods? I've heard people say white lithium grease. Would 3-in-1 oil do (I ask this only because I have some)? And do you have to take the bearings off the rods to apply it, or can you just put some on the rods and then works the mechanism back and forth a few times?

I used 3-in-1, I figure if it's good enough for a sewing machine, why not the printer... I just applied it with a rag and then moved the printer around in x,y,z. If only I could get rid of my z threaded rods to stop squealing (only does it on the way down -- I think the nut may be at fault, not sure yet...)

I had squealing Z rods as well. Squeaking, screeching might be other words for it, and it was also only on the way down. I listened carefully and worked out it came from just one side. Then I saw that the motor was just slightly off true with respect to the threaded rod. Undid the screws on the motors bracket, moved it a fraction, and all was good after that.

Awesome! I'll give that a try tomorrow. Thx

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 23, 2015 05:36PM |

Registered: 8 years ago Posts: 19 |

Got my kit a few days ago!...

Just started on assembling the base frame. I noticed that some of the hardware is mixed up. I've got all normal bolts instead of the specified pan heads.

The normal bolts don't have too much surface area under the heads to properly grip stuff.

Not sure how much this will affect the rigidity of the system.

Any body else have the same problem?

Just started on assembling the base frame. I noticed that some of the hardware is mixed up. I've got all normal bolts instead of the specified pan heads.

The normal bolts don't have too much surface area under the heads to properly grip stuff.

Not sure how much this will affect the rigidity of the system.

Any body else have the same problem?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 23, 2015 07:05PM |

Registered: 8 years ago Posts: 19 |

Hi guys, I was out camping so I didn't get a chance to work on the printer.

I rewired the extruder to the D8 output, and swapped the configuration in pins.h for extruder 0 and extruder 1. It's heating up right now, which is nice.

I'm showing 225C on the extruder and 97C on the heated bed and I can manually extrude orange goop.

I've loaded the test cube and it's printing right now. Okay, cube is coming out. I'll let you know how it goes, but so far it's promising!

Thanks again!

---

Unshockable Engineering

www.unshockable.ca

I rewired the extruder to the D8 output, and swapped the configuration in pins.h for extruder 0 and extruder 1. It's heating up right now, which is nice.

I'm showing 225C on the extruder and 97C on the heated bed and I can manually extrude orange goop.

I've loaded the test cube and it's printing right now. Okay, cube is coming out. I'll let you know how it goes, but so far it's promising!

Thanks again!

---

Unshockable Engineering

www.unshockable.ca

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 23, 2015 07:15PM |

Registered: 8 years ago Posts: 19 |

Heh, the part fell off the bed. Trying again with tape.

It worked, but it looks like the ceramic bed isn't going to work. (Or maybe I have to use adhesive?) The temperature dropped to 200C, so it was losing cohesion at the end. (This is how it was programmed in the config files.)

But hey, now I have an unlimited supply of plastic stuff!

Edited 2 time(s). Last edit at 06/23/2015 08:30PM by Unshockable.

It worked, but it looks like the ceramic bed isn't going to work. (Or maybe I have to use adhesive?) The temperature dropped to 200C, so it was losing cohesion at the end. (This is how it was programmed in the config files.)

But hey, now I have an unlimited supply of plastic stuff!

Edited 2 time(s). Last edit at 06/23/2015 08:30PM by Unshockable.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 24, 2015 07:58PM |

Registered: 8 years ago Posts: 19 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2015 12:25AM |

Registered: 8 years ago Posts: 45 |

Quote

go_gn

Any tips for tightening those nylock nuts in step 6: 3 ?

I'm guessing a nut driver should do the trick, but I don't have one handy and even so, the nut simply locks on the seal after going in a few threads.

Thanks in advance!

I hold the nut with some pliers and then turn the bolt usings the hex/allen key. You don't need more force than that IMO.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2015 03:56AM |

Registered: 8 years ago Posts: 13 |

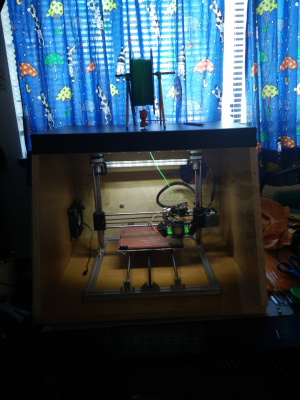

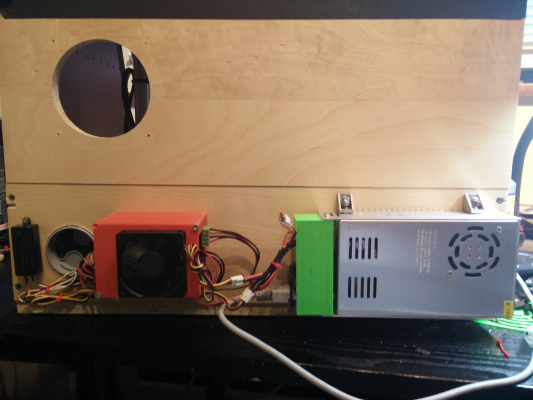

Almost finished with my enclosure. Still dialing down the settings though. Extruder clicks if I go below 210C with PLA at default speeds... print quality sucks at that high of a temp. Any ideas?

Edited 1 time(s). Last edit at 06/25/2015 04:06AM by Agedashi.

Edited 1 time(s). Last edit at 06/25/2015 04:06AM by Agedashi.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2015 04:05AM |

Registered: 8 years ago Posts: 13 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2015 09:06AM |

Registered: 8 years ago Posts: 13 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2015 10:07AM |

Registered: 8 years ago Posts: 27 |

Has anyone compiled like a go-to list of all the problems/solutions found for this printer yet?

I'm about to finish up the mechanical assembly, and i've skimmed this thread a few times and there seems to be the most problems with the electronics. I guess my plan was to just go through the configuration guide as is and if I come to problems I could scour this thread to see if my problems matched any of yours, but if there was a compiled list of things, it would be easier to act preventative-ly instead of reactive-ly. would be more efficient i'd imagine as well. I know this forum kind of serves as the list, but it gets a little tricky connecting the right solution to each problem when all the posts aren't chained together very well. (it'd be nice if there was a hierarchical reply structure kinda like reddit or something).

Anyways, I'm a noob, i know, and any pre-warnings or advice before starting the electronics would be helpful.

Thanks,

I'm about to finish up the mechanical assembly, and i've skimmed this thread a few times and there seems to be the most problems with the electronics. I guess my plan was to just go through the configuration guide as is and if I come to problems I could scour this thread to see if my problems matched any of yours, but if there was a compiled list of things, it would be easier to act preventative-ly instead of reactive-ly. would be more efficient i'd imagine as well. I know this forum kind of serves as the list, but it gets a little tricky connecting the right solution to each problem when all the posts aren't chained together very well. (it'd be nice if there was a hierarchical reply structure kinda like reddit or something).

Anyways, I'm a noob, i know, and any pre-warnings or advice before starting the electronics would be helpful.

Thanks,

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2015 12:27PM |

Registered: 8 years ago Posts: 367 |

Quote

Agedashi

Almost finished with my enclosure. Still dialing down the settings though. Extruder clicks if I go below 210C with PLA at default speeds... print quality sucks at that high of a temp. Any ideas?

Adjust the current (lower Vref), maybe? I posted a link some while back to a blog post with a video illustrating two kinds of clicks, one for too much power to the extruder, and one for too little.

Sorry, only registered users may post in this forum.