Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2015 12:28PM |

Registered: 8 years ago Posts: 367 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2015 12:32PM |

Registered: 8 years ago Posts: 367 |

Quote

ejnelson

Has anyone compiled like a go-to list of all the problems/solutions found for this printer yet?

I'm about to finish up the mechanical assembly, and i've skimmed this thread a few times and there seems to be the most problems with the electronics. I guess my plan was to just go through the configuration guide as is and if I come to problems I could scour this thread to see if my problems matched any of yours, but if there was a compiled list of things, it would be easier to act preventative-ly instead of reactive-ly. would be more efficient i'd imagine as well. I know this forum kind of serves as the list, but it gets a little tricky connecting the right solution to each problem when all the posts aren't chained together very well. (it'd be nice if there was a hierarchical reply structure kinda like reddit or something).

Anyways, I'm a noob, i know, and any pre-warnings or advice before starting the electronics would be helpful.

Thanks,

A goto list would be a great idea. I kept a record of some issues I came up against during construction on my blog, as [moosteria.blogspot.com]. Mostly it's a reminder to myself in case I ever need to rebuild part of it, but take a look and see if it helps. I am planning to add some information on what I've done since I had it working; maybe Dan will look through it and see if he thinks there is anything worth adjusting in the construction guide.

On the electronics: check before turning the power on. Twice :-) And if you adjust the Vrefs on the stepper drivers, be very very careful not to touch anything else while you do it. I shorted something (I don't know what) and damaged the Arduino board.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2015 01:52PM |

Registered: 8 years ago Posts: 27 |

Thanks Animoose!

Actually, your blog has been one of my main resources I've been using to help me with the build. The forum is so disjointed with people at various stages popping in with problems, so your blog being nice and chronological is perfect. I saw that you blew up your board (sorry about that) and it seems that you ran into a few other problems with the electronics, most notably the with the endstops I believe. You outlined the configuration changes that you made, would you say that those changes should be applicable to everyone? or just people who have your same problem of the x movement jumping? Should I just anticipate having similar problems?

Actually, your blog has been one of my main resources I've been using to help me with the build. The forum is so disjointed with people at various stages popping in with problems, so your blog being nice and chronological is perfect. I saw that you blew up your board (sorry about that) and it seems that you ran into a few other problems with the electronics, most notably the with the endstops I believe. You outlined the configuration changes that you made, would you say that those changes should be applicable to everyone? or just people who have your same problem of the x movement jumping? Should I just anticipate having similar problems?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2015 04:02PM |

Registered: 8 years ago Posts: 367 |

I don't recall whether the change was for the X axis jumping, or for it not working at all (which might have manifested as jumping, if Repetier was confused about where the print head was). I can't say for sure that the changes are needed for everyone, as there do seem to have been a few different versions that have been reported here. I guess that comes down to differences in construction (e.g. some people put the end stop on the left) and in whether the the motor cable is reversed, as shown in the build guide. I don't think anything harmful will happen if you have it set wrong, it just means the printer won't work. The thing that makes it confusing is that the physical construction, the configuration.h and pins.h settings, and the home position settings in Repetier all need to agree. I think I worked through two or three combinations before I got to the one that worked for me, but it didn't take long to do this. Part 9 of my blog says what worked for me, and could start with that and see how it goes. Just make yourself familiar with the position of the emergency stop button in Repetier before clicking home.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2015 07:17PM |

Registered: 8 years ago Posts: 27 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2015 08:06PM |

Registered: 8 years ago Posts: 367 |

You definitely need that jumper. They control to rate at which the motor runs. Without this, it will run at twice the rate it should. It's missing from the X motor control, so you can steal one from the second extruder control.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2015 11:22PM |

Registered: 8 years ago Posts: 27 |

Ok thanks, i stole one from the second extruder control like you mentioned. So, i ended up running into problems like I was worried about. I was adjusting the Vrefs and heard the pop and got the smoke.  Next step is to buy a new ramps 1.4 correct? The one on amazon that animoose linked on his blog is out of stock, I found this one: link, should work right?

Next step is to buy a new ramps 1.4 correct? The one on amazon that animoose linked on his blog is out of stock, I found this one: link, should work right?

Next step is to buy a new ramps 1.4 correct? The one on amazon that animoose linked on his blog is out of stock, I found this one: link, should work right?

Next step is to buy a new ramps 1.4 correct? The one on amazon that animoose linked on his blog is out of stock, I found this one: link, should work right?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2015 11:40PM |

Registered: 8 years ago Posts: 367 |

Quote

ejnelson

Ok thanks, i stole one from the second extruder control like you mentioned. So, i ended up running into problems like I was worried about. I was adjusting the Vrefs and heard the pop and got the smoke.Next step is to buy a new ramps 1.4 correct? The one on amazon that animoose linked on his blog is out of stock, I found this one: link, should work right?

Sorry to hear about that. The RAMPS board you linked to could be fine, but there is some variation in how well made they are. I picked that one off Amazon because I could see some good reviews for it.

Before you get this, may I suggest a couple of other things. Did you see where the smoke came from? I ask this in case you replace the RAMPS board only to find the problem was somewhere else. It could also be the stepper driver or the Arduino. You can test the first by using the spare stepper board that was in the kit, or using one that you know to be good (one of mine was non functional right out of the pack). In my case I know that it was the Arduino that I had damaged, and it was working except that the USB connection was blown. The way I tested this was rather convoluted, but I think you could see if this is the case by taking disconnecting the Arduino from the RAMPS and trying reflashing the firmware. If you get an error from the Arduino IDE along the lines of communication timeout, then it's likely that the Arduino is the problem. Or you could do what I did and buy one of each, just in case. Anything left over can be used for your next printer

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 26, 2015 01:20AM |

Registered: 8 years ago Posts: 45 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 26, 2015 07:52AM |

Registered: 8 years ago Posts: 19 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 26, 2015 08:39AM |

Registered: 8 years ago Posts: 27 |

Thanks Animoose, the only symptom I noticed in my limited testing last night was that before the pop and smoke the z axis was moving both directions, x and y would move but only one direction. After the pop and smoke nothing was responsive. I will test the arduino like you mentioned tonight.

@uncertainty I was adjusting the Vrefs with both the power supply connected to the wall and usb connected to my computer. where were you before last night?!

@uncertainty I was adjusting the Vrefs with both the power supply connected to the wall and usb connected to my computer. where were you before last night?!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 26, 2015 10:50AM |

Registered: 11 years ago Posts: 335 |

Quote

stanger2k

Do you guys have any tips with making sure that my two Y rods are properly alligned?

There is a standard procedure used for aligning parallel shafts and its super easy: [www.pbclinear.com]

Basically you designate one rail as the master and align it however you want (I like parallel to the frame). Then you lock the master rail in place and leave the second rail loose.

Slide the table to one end and tighten that end of the second rail. Slide the table to the other end and tighten the rest of the second rail.

Since the second rails position has been dictated by the table there is no chance of binding.

Unless you have a few grand in measuring equipment or highly accurate reference surfaces for both rails you don't want to align them independently. If the table is rigid it would be guaranteed to bind. If it doesn't bind, something is bending.. The master/follower alignment procedure is used for most machines.

Edited 1 time(s). Last edit at 06/26/2015 10:53AM by 691175002.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 26, 2015 12:03PM |

Registered: 8 years ago Posts: 45 |

Quote

go_gn

A quick question : I may not have access to a soldering iron until next week. Is it possible to skip the heated bed soldering step and continue further?

I know that PLA doesn't require a heated bed. Can I do the soldering later without needing to disassemble too much?

It can wait. It just sits on top so it can be installed later.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 26, 2015 12:04PM |

Registered: 8 years ago Posts: 45 |

Quote

ejnelson

Thanks Animoose, the only symptom I noticed in my limited testing last night was that before the pop and smoke the z axis was moving both directions, x and y would move but only one direction. After the pop and smoke nothing was responsive. I will test the arduino like you mentioned tonight.

@uncertainty I was adjusting the Vrefs with both the power supply connected to the wall and usb connected to my computer. where were you before last night?!

Not sure if it would have prevented the magic smoke from escaping. But its one less thing to worry about.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 26, 2015 05:53PM |

Registered: 11 years ago Posts: 335 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 26, 2015 07:05PM |

Registered: 8 years ago Posts: 27 |

OK, so here I am trying to figure out what blew up. I uploaded the blink sketch to the arduino after disconnecting the ramps board. The arduino did indeed blink. i was then able to reupload marlin, connect the ramps board and connect to the arduino with repetier. I cannot get the machine to do anything through repetier though. I tried replacing the driver on which i was fiddling with the Vref when I heard the pop.

also, the endstop's LEDs will light up when I trigger them. and the error message i get in repetier when trying to move the carriage manually is that an endstop is hit. ( no endstops are hit)

I'm gunna go ahead and assume my ramps is fried unless someone else has other input...

Edited 1 time(s). Last edit at 06/26/2015 07:08PM by ejnelson.

also, the endstop's LEDs will light up when I trigger them. and the error message i get in repetier when trying to move the carriage manually is that an endstop is hit. ( no endstops are hit)

I'm gunna go ahead and assume my ramps is fried unless someone else has other input...

Edited 1 time(s). Last edit at 06/26/2015 07:08PM by ejnelson.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 26, 2015 07:31PM |

Registered: 8 years ago Posts: 27 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 26, 2015 09:33PM |

Registered: 8 years ago Posts: 5 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 27, 2015 01:31AM |

Registered: 8 years ago Posts: 2 |

Hello everyone I am new here and just received my kit, 9 days from ordering so not to bad.

I was looking at the parts in the kit just to see what was all included and noticed a small issue which may not be an issue at all.

I was looking at the RAMPS board in the anti static bag an a few of the components are bent. There are 2 tall flat items next to the green connector and 2 more next to the blue terminal block that are also bent over a little. They are probably bent over at about a 30 degree angle from shipping. Should I just carefully straighten them when I open the bag when I get to that part of the build, or should I contact FolgerTech ?

Thank

Bill

I was looking at the parts in the kit just to see what was all included and noticed a small issue which may not be an issue at all.

I was looking at the RAMPS board in the anti static bag an a few of the components are bent. There are 2 tall flat items next to the green connector and 2 more next to the blue terminal block that are also bent over a little. They are probably bent over at about a 30 degree angle from shipping. Should I just carefully straighten them when I open the bag when I get to that part of the build, or should I contact FolgerTech ?

Thank

Bill

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 27, 2015 01:56AM |

Registered: 8 years ago Posts: 606 |

It matters not . . . straighten them up if it makes you feel better, just don't break anything off. The only thing that could be an issue is the MOSFETS (black, with three leads and a metal tab, near the D8/D9/D10 connectors) and on those, you don't want the tabs touching each other.

- Tim

- Tim

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 27, 2015 03:45AM |

Registered: 8 years ago Posts: 45 |

Quote

ejnelson

oh frick, just kidding, duh moment. I didn't have the power supply plugged back in. I plugged the power supply in and now I can move the z axis in both directions and the y and x is one direction (but not the other).

I'm curious. Can you look at the voltage regulator on the arduino? Does it look cracked? It is very likely this is what went if it is still functional?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 27, 2015 09:26PM |

Registered: 8 years ago Posts: 45 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 27, 2015 10:07PM |

Registered: 11 years ago Posts: 335 |

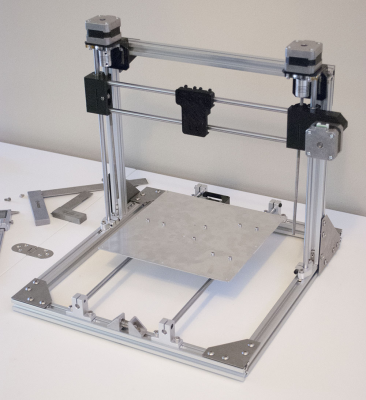

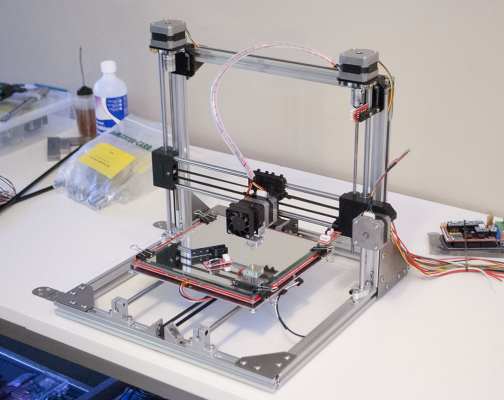

Mine arrived a few days ago and I've finished the assembly - still need to get the electronics set up.

I've kind of been doing my own thing but the only dramatic alteration is the corner brackets.

So far the kit has been pretty good, the only complaint I've got is that the Z linear bearing holders were shitty prints and I had to carve them out with a knife.

I've kind of been doing my own thing but the only dramatic alteration is the corner brackets.

So far the kit has been pretty good, the only complaint I've got is that the Z linear bearing holders were shitty prints and I had to carve them out with a knife.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 27, 2015 10:50PM |

Registered: 8 years ago Posts: 171 |

Quote

Uncertainty

I'm back to printing at 230c (abs)/ bed 110->105c with great results. Extruder motor gets hella hot though, I'm worried it will warp the carriage. My Vref is at 0.38 but I fear going any lower due to skipping.

Interesting! I was having problems with the extruder clicking and I figured the temperature wasn't high enough (also ABS). Someone suggested LOWERING the temp and yep, it works much better. I think my last print was at 205? I'm not crazy about the stringiness of the ABS though (some of my stuff looks like Mini Wheats) so I'm still getting it dialed in. Last two prints at the lower temp had no skipping or clicking though,.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 28, 2015 08:06AM |

Registered: 8 years ago Posts: 27 |

Quote

Uncertainty

Quote

ejnelson

oh frick, just kidding, duh moment. I didn't have the power supply plugged back in. I plugged the power supply in and now I can move the z axis in both directions and the y and x is one direction (but not the other).

I'm curious. Can you look at the voltage regulator on the arduino? Does it look cracked? It is very likely this is what went if it is still functional?

On Vacaton right now. I'll do a post when I get back with an image and also the Marlin code that worked for me.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 28, 2015 04:58PM |

Registered: 8 years ago Posts: 45 |

Quote

markts

Quote

Uncertainty

I'm back to printing at 230c (abs)/ bed 110->105c with great results. Extruder motor gets hella hot though, I'm worried it will warp the carriage. My Vref is at 0.38 but I fear going any lower due to skipping.

Interesting! I was having problems with the extruder clicking and I figured the temperature wasn't high enough (also ABS). Someone suggested LOWERING the temp and yep, it works much better. I think my last print was at 205? I'm not crazy about the stringiness of the ABS though (some of my stuff looks like Mini Wheats) so I'm still getting it dialed in. Last two prints at the lower temp had no skipping or clicking though,.

lol that was me who recommended bringing temp down

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 28, 2015 07:54PM |

Registered: 8 years ago Posts: 430 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 28, 2015 09:05PM |

Registered: 8 years ago Posts: 367 |

I had my first try at printing Benchy today. There's pictures from during the print and the finished result at [goo.gl]. I aim to write up a detailed account on my blog in the next few days (it's probably more information that most people here are interested in). I printed in 0.3mm before realizing that the recommended layer size is 0.2mm, and when I have time I'll do another run. Most of the problems are due to the filament not cooling quickly enough. That's why there are problems with the gunwhale overhang at the back, the sides of the bow and the loops in the wheelhouse openings. I might see if a cooling fan will help in the next run. I am pretty happy with it.

Edited 1 time(s). Last edit at 06/28/2015 09:05PM by animoose.

See my blog at [moosteria.blogspot.com].

Edited 1 time(s). Last edit at 06/28/2015 09:05PM by animoose.

See my blog at [moosteria.blogspot.com].

|

Non-warping, no smell, PET filament: June 29, 2015 08:14AM |

Registered: 10 years ago Posts: 444 |

I see everyone using PLA; maybe nobody knows about PET:

Non-warping, no smell, PET filament:

No shrinking or warping.

No smell.

No enclosure required.

Build plate can be heated or not.

Does not absorb water or moisture from air.

Clear color is the most transparent of all filament materials.

Is much "tougher" that PLA or ABS; will bend before breaking.

Uses about the same extruder temps as ABS.

Does not need a print cooling fan like PLA does.

Also known as Polyester, PETG, PETT, PET+

Is what most soda pop bottles are made of.

Does not degrade in water.

FDA approved in the USA for for food contact.

Not brittle.

Is the most recycled plastic.

Current places carrying PET:

eSun - from Intservo, in North Carolina USA:

[intservo.com]

Made Solid - from California USA:

[shop.madesolid.com]

Made Solid - from Matter Hackers, in California USA:

[www.matterhackers.com]

Made Solid - from Design Box, in Ohio USA:

[designbox3d.com]

Made Solid - From Australia:

[thinglab.com.au]

Colorfabb XT - from Netherlands:

[colorfabb.com]

Colorfabb XT - from Printed Solid, in Delaware USA:

[www.printedsolid.com]

Taulman T-Glase - from Matter Hackers, in California USA:

[www.matterhackers.com]

Taulman T-Glase - from MakerGeeks, in Missouri USA:

[www.makergeeks.com]

Taulman T-Glase - from Imprinte 3D, in France:

[www.imprimante3dfrance.com]

Eco PETG - from China (must email to order):

[www.ecoreprap.com]

Reprap PET - from Denmark:

[reprap.me]

Gizmo Dorks - in Los Angeles, USA:

[gizmodorks.com]

Non-warping, no smell, PET filament:

No shrinking or warping.

No smell.

No enclosure required.

Build plate can be heated or not.

Does not absorb water or moisture from air.

Clear color is the most transparent of all filament materials.

Is much "tougher" that PLA or ABS; will bend before breaking.

Uses about the same extruder temps as ABS.

Does not need a print cooling fan like PLA does.

Also known as Polyester, PETG, PETT, PET+

Is what most soda pop bottles are made of.

Does not degrade in water.

FDA approved in the USA for for food contact.

Not brittle.

Is the most recycled plastic.

Current places carrying PET:

eSun - from Intservo, in North Carolina USA:

[intservo.com]

Made Solid - from California USA:

[shop.madesolid.com]

Made Solid - from Matter Hackers, in California USA:

[www.matterhackers.com]

Made Solid - from Design Box, in Ohio USA:

[designbox3d.com]

Made Solid - From Australia:

[thinglab.com.au]

Colorfabb XT - from Netherlands:

[colorfabb.com]

Colorfabb XT - from Printed Solid, in Delaware USA:

[www.printedsolid.com]

Taulman T-Glase - from Matter Hackers, in California USA:

[www.matterhackers.com]

Taulman T-Glase - from MakerGeeks, in Missouri USA:

[www.makergeeks.com]

Taulman T-Glase - from Imprinte 3D, in France:

[www.imprimante3dfrance.com]

Eco PETG - from China (must email to order):

[www.ecoreprap.com]

Reprap PET - from Denmark:

[reprap.me]

Gizmo Dorks - in Los Angeles, USA:

[gizmodorks.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 29, 2015 10:34AM |

Registered: 11 years ago Posts: 335 |

I got some sheet metal from Home Depot and used a shear/drill press. You could probably print a set of usable corner brackets but you kind of need tools to work with sheet metal.Quote

msaeger

How did you make the corner brackets? I am just starting but I am imagining there should be something like those in the corners.

Sorry, only registered users may post in this forum.