Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 10:04AM |

Registered: 8 years ago Posts: 27 |

@mel0n were you planning on wiring the fan to the D9 pins on the ramps 1.4? (that is just what i've found other people doing online)

and another questions, I haven't quite had time to work out why my LCD won't work when my machine isn't connected via usb to my computer, so i need to do that, but in case my voltage regulator or something else is broken could I just head down the Octoprint route instead and use my computer as the defacto LCD? This would let me print without a USB connection as well right?

and another questions, I haven't quite had time to work out why my LCD won't work when my machine isn't connected via usb to my computer, so i need to do that, but in case my voltage regulator or something else is broken could I just head down the Octoprint route instead and use my computer as the defacto LCD? This would let me print without a USB connection as well right?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 11:33AM |

Registered: 8 years ago Posts: 25 |

Quote

ejnelson

Has anyone added a 2nd fan to be used as a PLA print cooling fan? I know someone designed a fan diverter to divert some of the air that blows on the heat sink for the hot end, but would it be possible to just add another fan so that you don't have to take off the diverter every time you want to print ABS?

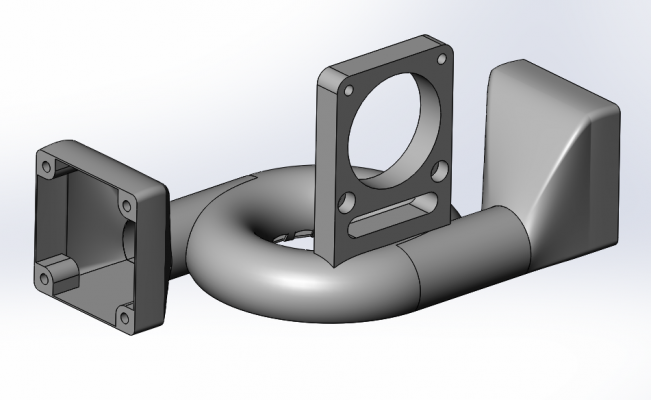

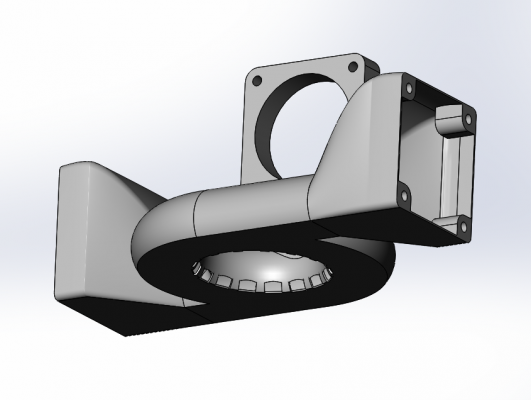

I've been working on a dual fan design based on this, that blows air 360 degrees around the nozzle. I tried printing a section of the donut to see if its possible, but it was not successful. I almost gave up on it and redesigned it as a triangle donut. But after mel0ns comment about bridging with ABS, I may give that a try. The design is not finalized yet, but this is what I have so far. It will probably be printed in 3 parts... the donut, and the 2 fan reducers. It will mount between the extruder fan and the heat sink. It will use 2 x 40mm fans that will be powered by a fan extender. I wanted to keep D9 open in case I convert to dual extruders, but D9 will work otherwise. I will probalby run the fans through a switch so I can easily turn them off.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 12:53PM |

Registered: 8 years ago Posts: 430 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 01:31PM |

Registered: 8 years ago Posts: 367 |

Quote

msaeger

Quote

animoose

Today's tweak. Now I can see things as I print (brightness adjustment to follow).

Yes tell me more about the light. I was just thinking I would buy a led book light and clamp it on there someplace.

It's three white LEDs and a 220 ohm resistor, wired directly to the 12V on the power supply. So that gives about 10mA (very approximately) which makes for plenty of brightness. Too much sometimes, so I'll probably add a 10k pot at the power supply end to dim it down. It just a cylinder, closed at one end with three 5mm holes for the LEDs in that end. There is a clip which attaches to the cylinder and an exposed part of the screw holding the fan (or fan mount) to the extruder. This allows you to rotate it a bit to change the angle, and it is short enough that it sits higher than the tip of the nozzle so it won't hit the print. It's also very light (in the weight sense). I'll post some more details and the model files in the next days, when I have a little more time.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 02:03PM |

Registered: 8 years ago Posts: 135 |

@ejnelson Yeah I was just going to wire it to the fan pins for control, if that doesnt work I was just going to include a hardware switch to the power supply.

@JoeH Cool Design! Yeah I think you would have a lot better luck printing something like that in ABS.

Some Filament information as well:

I have tried out 3 brand of filament so far. Folger Tech PLA (decent tolerances +- 0.03mm) , SainSmart PLA + ABS , and Hatchbox PLA+ABS

Folger Tech PLA - Works ok, seems to like higher temps.

SainSmart PLA - At 205C this stuff has been the best so far. Once dialed in it sticks to glass at 55C perfectly, comes out great, was exposed to high humidity for a long time and had minimal popping. My Favorite material I have worked with so far. Consistent filament diameter 1.72mm

SainSmart ABS - At 225C this stuff is also great. I have been printing really nice overhangs/bridges and it sticks to purple glue stick like you wouldn't believe. Consistent Filament diameter 1.74mm

Hatchbox ABS - I am still fighting with it to find a good temp. There seems to be a large ammount of variance in Filament diameter +- .06mm and it swtched from oval to round throughout the roll. In general there is a lot of inconsistancies and the color of the green is not that great. It also does not want to stick to glue stick/glass/hairspray.

Hatchbox PLA - Have yet to try this roll, but I hope it is better than their ABS. I have read nothing but good stuff about hatchbox but I am not seeing it yet.

Overall I would have to say I am VERY satisfied with SainSmart Filaments and would not hesitate to place a large order. Their filaments have exceeded my expectations and they are one of the best brands available on amazon IMHO. If I had any complaint about SainSmart it would be their spools and packaging. They are made out of cardboard so they deform easily/just arent as sturdy as the plastic rolls. The packaging is allso really crappy. They include a silica gel packet inside the plastic bag with the spool but this seems pointless as both spools I have were in seperate orders and both had holes in the bag and it was not vaccum sealed like the Hatchbox. So Hatchbox has much nicer packaging and spools, but SainSmart has the better Filament and thats the only thing that counts.

Edited 1 time(s). Last edit at 07/10/2015 02:06PM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

@JoeH Cool Design! Yeah I think you would have a lot better luck printing something like that in ABS.

Some Filament information as well:

I have tried out 3 brand of filament so far. Folger Tech PLA (decent tolerances +- 0.03mm) , SainSmart PLA + ABS , and Hatchbox PLA+ABS

Folger Tech PLA - Works ok, seems to like higher temps.

SainSmart PLA - At 205C this stuff has been the best so far. Once dialed in it sticks to glass at 55C perfectly, comes out great, was exposed to high humidity for a long time and had minimal popping. My Favorite material I have worked with so far. Consistent filament diameter 1.72mm

SainSmart ABS - At 225C this stuff is also great. I have been printing really nice overhangs/bridges and it sticks to purple glue stick like you wouldn't believe. Consistent Filament diameter 1.74mm

Hatchbox ABS - I am still fighting with it to find a good temp. There seems to be a large ammount of variance in Filament diameter +- .06mm and it swtched from oval to round throughout the roll. In general there is a lot of inconsistancies and the color of the green is not that great. It also does not want to stick to glue stick/glass/hairspray.

Hatchbox PLA - Have yet to try this roll, but I hope it is better than their ABS. I have read nothing but good stuff about hatchbox but I am not seeing it yet.

Overall I would have to say I am VERY satisfied with SainSmart Filaments and would not hesitate to place a large order. Their filaments have exceeded my expectations and they are one of the best brands available on amazon IMHO. If I had any complaint about SainSmart it would be their spools and packaging. They are made out of cardboard so they deform easily/just arent as sturdy as the plastic rolls. The packaging is allso really crappy. They include a silica gel packet inside the plastic bag with the spool but this seems pointless as both spools I have were in seperate orders and both had holes in the bag and it was not vaccum sealed like the Hatchbox. So Hatchbox has much nicer packaging and spools, but SainSmart has the better Filament and thats the only thing that counts.

Edited 1 time(s). Last edit at 07/10/2015 02:06PM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 02:22PM |

Registered: 8 years ago Posts: 25 |

I've been printing PLA on glass with purple glue stick without the heat bed. I cut my startup time by 5 to 7 minutes since I don't have to wait on the heat bed to warm up. And the prints stick very well.

I've only tried Folger Tech PLA so far. I do have Folger Tech ABS, and Hatchbox PLA and ABS to try. I may try the Folger Tech ABS tonight. What bed temp do you think I should start with for the Folger Tech ABS?

P.S. If I'm able to print the fan shroud and it works good, I'll post the files on Thingiverse.

Edited 1 time(s). Last edit at 07/10/2015 02:24PM by JoeH.

I've only tried Folger Tech PLA so far. I do have Folger Tech ABS, and Hatchbox PLA and ABS to try. I may try the Folger Tech ABS tonight. What bed temp do you think I should start with for the Folger Tech ABS?

P.S. If I'm able to print the fan shroud and it works good, I'll post the files on Thingiverse.

Edited 1 time(s). Last edit at 07/10/2015 02:24PM by JoeH.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 02:29PM |

Registered: 8 years ago Posts: 171 |

Quote

JoeH

I've been printing PLA on glass with purple glue stick without the heat bed. I cut my startup time by 5 to 7 minutes since I don't have to wait on the heat bed to warm up. And the prints stick very well.

I've only tried Folger Tech PLA so far. I do have Folger Tech ABS, and Hatchbox PLA and ABS to try. I may try the Folger Tech ABS tonight. What bed temp do you think I should start with for the Folger Tech ABS?

P.S. If I'm able to print the fan shroud and it works good, I'll post the files on Thingiverse.

I've used a bed temp of about 100 degrees with FolgerTech ABS and it stuck ok with with glue stick on glass. I'll have to try the PLA with glue stick - I went back to blue painter's tape and 60 degrees for PLA.

Edited 1 time(s). Last edit at 07/10/2015 02:30PM by markts.

|

Re: Non-warping, no smell, PET filament: July 10, 2015 02:39PM |

Registered: 9 years ago Posts: 13 |

Thanks RRuser for referring us  . Some quick info to share.

. Some quick info to share.

The new eSUN PETG colors: opaque black/white and semi-trans green/orange are available on Amazon (Prime eligible) and our site too. (Orange/Green will be on Amazon in 3 days).

http://www.amazon.com/dp/B00ZAUR6M0

http://www.amazon.com/dp/B00ZAUQZTA

http://www.intservo.com

The next color will be Solid Red and should be here in early September. If you have any suggestions on future colors please let me know. you can email to admin@intservo.com

/William at INTSERVO

eSUN distributor in USA: [www.intservo.com]

Amazon Storefront: [amzn.to]

PETG available!

. Some quick info to share.

. Some quick info to share.The new eSUN PETG colors: opaque black/white and semi-trans green/orange are available on Amazon (Prime eligible) and our site too. (Orange/Green will be on Amazon in 3 days).

http://www.amazon.com/dp/B00ZAUR6M0

http://www.amazon.com/dp/B00ZAUQZTA

http://www.intservo.com

The next color will be Solid Red and should be here in early September. If you have any suggestions on future colors please let me know. you can email to admin@intservo.com

/William at INTSERVO

eSUN distributor in USA: [www.intservo.com]

Amazon Storefront: [amzn.to]

PETG available!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 02:44PM |

Registered: 8 years ago Posts: 135 |

I found that PLA direct on glass works great for me with the heated bed. Since PLA is such lower temp on the bed, I am just leaving the bed on between prints since 55C wont burn me and cuts down the time for heating. I just had to cancel a print from work because the Hatchbox currently in my printer keeps comming unstuck. I am going to scrape off all the glue stick and apply a fresh layer, and turn the bed temp up to 110C to see if that helps it stick.

So far SainSmart and Folger Tech have been plug and play(or at least as plug and play as filament can be) for me so far. I would like to go ahead and coin the term "Hatchbox Headaches" as I am getting a lot of them.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

So far SainSmart and Folger Tech have been plug and play(or at least as plug and play as filament can be) for me so far. I would like to go ahead and coin the term "Hatchbox Headaches" as I am getting a lot of them.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Non-warping, no smell, PET filament: July 10, 2015 02:50PM |

Registered: 8 years ago Posts: 367 |

I've been using JET PLA exclusively so far, and it seems good to me, clean prints, no bubble etc. Here's an Amazon link: [www.amazon.com]. I am using blue tape on glass at either 60 or 70C. I tried wiping the blue tape with isopropyl alcohol, and it makes a HUGE difference. The first few prints after I did this were stuck down so hard I thought I would never be able to remove them. Even now, with the tape really worn and scratched up, it's still working well.

I wonder how much the filaments that work well depends on the climate where you live. I am in Southern California in an area where the temperature this time of year is always 70-80F and the humidity is neither desert arid nor East Coast steamy.

See my blog at [moosteria.blogspot.com].

I wonder how much the filaments that work well depends on the climate where you live. I am in Southern California in an area where the temperature this time of year is always 70-80F and the humidity is neither desert arid nor East Coast steamy.

See my blog at [moosteria.blogspot.com].

|

Re: Non-warping, no smell, PET filament: July 10, 2015 03:12PM |

Registered: 8 years ago Posts: 135 |

Quote

animoose

The first few prints after I did this were stuck down so hard I thought I would never be able to remove them. Even now, with the tape really worn and scratched up, it's still working well.

I had the same feeling with my first ABS print on Glue Stick haha.

PLA however I get it to stick to glass really well, and it takes a good amount of force to remove it from the glass if the bed is still hot. But If I let the bed cool it removes itself as it cools. Same with ABS and glue stick, only removing ABS from glue stick while the bed is still hot is close to impossible and I almost rip the bed off the printer every time so now I just let my ABS prints cool first and they slide right off like they were never stuck in the first place.

Quote

animoose

I wonder how much the filaments that work well depends on the climate where you live. I am in Southern California in an area where the temperature this time of year is always 70-80F and the humidity is neither desert arid nor East Coast steamy.

Steamy east coast here. Humidity has been >90% for over a week and all my windows are open. Its been ~80F during the day and ~50-60F during night

My Y carriage cable chain is almost done and I will be uploading the stl's soon.

Edited 1 time(s). Last edit at 07/10/2015 03:14PM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 04:06PM |

Registered: 8 years ago Posts: 81 |

Quote

mel0n

This is exactly what people should NOT be doing. Yes it will work, but your also putting your printer out there on the default port for websites, so when that guy in china hits your ip when he is running a long term scan on his server array, youve now become a target. And believe me China WILL ATTACK YOU if you put anything on port 80 ever. We had a guy from china break into VM's set up to teach some basic linux courses, which he then used toattack everything on the schools network. Once they are into your network, they will attack everything on it. Everything is being attacked by China 100% of the time and I am not exadurating. The raspberry pi by default has no security measures AT ALL. Theres no firewall (iptables), your passwords are default, packages are not 100% up to date. There are a LOT of security vulnerabilities that need to be taken care of before you put it on the WWW

and Hobbes, like already said, check the soldering on the board, those fets are fine, mine were bent exactly like that. So were the fuses, I just bent them back up.

Errr, It may not have come across clear enough, but im not suggesting to open up port 80 on your router. It's to forward any port of your choice e.g 65534 to your raspberrypi's IP:80.

So basically, you're not opening port 80. This china guy will need to have the additional task of scanning all of your public IP's open ports before he can figure out that your running a website on port 65534.

But then again, it is still not secure.. And as i have mentioned, if security is a concern, go encrypted.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 04:09PM |

Registered: 8 years ago Posts: 10 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 04:23PM |

Registered: 8 years ago Posts: 135 |

Quote

wderoxas

Errr, It may not have come across clear enough, but im not suggesting to open up port 80 on your router.

That's how I interpreted what you said. thanks for clarifying haha.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 05:47PM |

Registered: 8 years ago Posts: 25 |

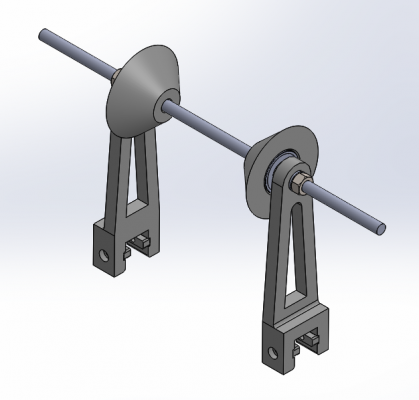

I just posted a top mount spool holder on Thingiverse. If anyone needs cone for a different size bearing, just let me know and I careate a new one for it. More info about the holder on Thingiverse.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 06:09PM |

Registered: 8 years ago Posts: 135 |

Cool, I made this one : [www.thingiverse.com]

It fits the bearings tightly and I found that replacing spools is kinda a pain without removing one of the mounts from the printer. I see yours locks into the rails, let me know how your spool changing process goes! I havent cut my threaded rod shorter yet as I am still debating weather or not I want it to hold 2 spools.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

It fits the bearings tightly and I found that replacing spools is kinda a pain without removing one of the mounts from the printer. I see yours locks into the rails, let me know how your spool changing process goes! I havent cut my threaded rod shorter yet as I am still debating weather or not I want it to hold 2 spools.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 06:54PM |

Registered: 8 years ago Posts: 25 |

The nice thing about this setup is that the arms slide on the rail without coming off. The shims prevent them from tilting side to side and front to back, and you can't pull them up. So all I have to do is undo one nut, slide the arm a bit, then pull the rod out enough to get the cone out, then the spool is out. Then reverse to install the new spool... not too bad IMO!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 07:43PM |

Registered: 8 years ago Posts: 135 |

Yeah mine is setup to work the same way in theory. But the printed spacers were a bit tight and I had to work them all up and down the threaded rod a few times to get them to slide on and off, but with 6 spacers total plus the bearings, its impossible to slide the rod through without ripping the stands off the frame, so I just take 1 stand off, then slide everything off 1 side of the rod to change the spool.

I also couldnt get any metric threaded rod at Lowes, all they carry is imperial sizes in everything which I absolutely hate but thats what is available to me so the rod is a pretty tight fit on the old skateboard bearings I used which just adds to the difficulty of sliding the rod out. I think If I shorten the rod by a considerable amount it might be easier.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

I also couldnt get any metric threaded rod at Lowes, all they carry is imperial sizes in everything which I absolutely hate but thats what is available to me so the rod is a pretty tight fit on the old skateboard bearings I used which just adds to the difficulty of sliding the rod out. I think If I shorten the rod by a considerable amount it might be easier.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 07:46PM |

Registered: 8 years ago Posts: 7 |

Anyone having extruder issues? Mine was working fine for the first few prints, but now it's making a slow (1-2 a second) rhythmic clicking sound where the filament "skips". If I hold the filament feeding into the extruder and push down, it gets a lot better but still skips occasionally (when it skips, I can feel the filament jump back up at me). The extruder is definitely not laying down all the plastic it is supposed to, I haven't had a print come out good enough to use since this started - layers aren't adhereing, walls aren't thick enough, and the print gains height slower than the z-axis rises, so i'm eventually printing in air if I let this run long enough.

On a possibly related note, I'm seeing a puddle of melted PLA forming on the top of the hot end block, as if some of the plastic is melting and bubbling upwards rather than being extruded properly. Is this normal?

On a possibly related note, I'm seeing a puddle of melted PLA forming on the top of the hot end block, as if some of the plastic is melting and bubbling upwards rather than being extruded properly. Is this normal?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 07:49PM |

Registered: 8 years ago Posts: 171 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 08:30PM |

Registered: 8 years ago Posts: 430 |

Quote

nonfish

Anyone having extruder issues? Mine was working fine for the first few prints, but now it's making a slow (1-2 a second) rhythmic clicking sound where the filament "skips". If I hold the filament feeding into the extruder and push down, it gets a lot better but still skips occasionally (when it skips, I can feel the filament jump back up at me). The extruder is definitely not laying down all the plastic it is supposed to, I haven't had a print come out good enough to use since this started - layers aren't adhereing, walls aren't thick enough, and the print gains height slower than the z-axis rises, so i'm eventually printing in air if I let this run long enough.

On a possibly related note, I'm seeing a puddle of melted PLA forming on the top of the hot end block, as if some of the plastic is melting and bubbling upwards rather than being extruded properly. Is this normal?

Maybe there is a clog and the top is the path of least resistance now.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 09:04PM |

Registered: 8 years ago Posts: 135 |

Quote

nonfish

Anyone having extruder issues? Mine was working fine for the first few prints, but now it's making a slow (1-2 a second) rhythmic clicking sound where the filament "skips". If I hold the filament feeding into the extruder and push down, it gets a lot better but still skips occasionally (when it skips, I can feel the filament jump back up at me). The extruder is definitely not laying down all the plastic it is supposed to, I haven't had a print come out good enough to use since this started - layers aren't adhereing, walls aren't thick enough, and the print gains height slower than the z-axis rises, so i'm eventually printing in air if I let this run long enough.

On a possibly related note, I'm seeing a puddle of melted PLA forming on the top of the hot end block, as if some of the plastic is melting and bubbling upwards rather than being extruded properly. Is this normal?

Probably clog, though the seeping is probably from you pushing on the filament. I would check your stepper driver voltage for the extruder. Maybe try adjusting it and see if it goes away. if jacking up the voltage on the driver doesnt fix it, then its time to pull it apart. Good luck! Also if you pull it apart don't do what I did and rip the PTFE tubing off. Basically the hot end will have a white tube sticking out of it, I knew this was there but I thought it was a separate peice from the nossle, so I tried to pull it out and it just ripped off at the nossle. Everything still works fine with it in 2 pieces but thats probably why I have oozing around the heat block now. so dont pull on the white tube!

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 09:54PM |

Registered: 8 years ago Posts: 21 |

I stayed up till 4 am yesterday building my 2020. I'm on page 24, at the power supply installation. Up to this point, there is no mention to how or when to tighten down all the frame screws. At the beginning it mentions that we will later, but i'm coming up to the electronics and Dan seemed to have omitted this step. When I installed the X&Z assembly, it became clear that it won't fit if i keep the frame squared off (as in, all brackets are flush with each other).

Shown in the picture

I can center out the sides and the Y belt, but I need information on where the vertical frame should be bolted down in reference to the front or the back of the base frame.

Shown in the picture

I can center out the sides and the Y belt, but I need information on where the vertical frame should be bolted down in reference to the front or the back of the base frame.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 10:13PM |

Registered: 8 years ago Posts: 430 |

Quote

hobbes

I stayed up till 4 am yesterday building my 2020. I'm on page 24, at the power supply installation. Up to this point, there is no mention to how or when to tighten down all the frame screws. At the beginning it mentions that we will later, but i'm coming up to the electronics and Dan seemed to have omitted this step. When I installed the X&Z assembly, it became clear that it won't fit if i keep the frame squared off (as in, all brackets are flush with each other).

Shown in the picture

I can center out the sides and the Y belt, but I need information on where the vertical frame should be bolted down in reference to the front or the back of the base frame.

Page 6 says the rear of the vertical beam should be 90mm (edit should have been 90 not 900) from the rear of the printer.

I made all the corners like you have in the picture flush. Did you make sure the blocks on the X assembly are 300mm apart? or maybe they cut the extrusions the wrong length?

Edited 2 time(s). Last edit at 07/10/2015 10:38PM by msaeger.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 10:23PM |

Registered: 8 years ago Posts: 21 |

Quote

msaeger

Page 6 says the rear of the vertical beam should be 900mm from the rear of the printer.

I made all the corners like you have in the picture flush. Did you make sure the blocks on the X assembly are 300mm apart? or maybe they cut the extrusions the wrong length?

thank you for pointing that out. Page 6 does in fact say 90mm from the rear. I somehow missed that.

As for the x assembly, it was, but I guess it got pulled inward when assembling the belt.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 10:25PM |

Registered: 8 years ago Posts: 430 |

Quote

SainSmart PLA - At 205C this stuff has been the best so far. Once dialed in it sticks to glass at 55C perfectly, comes out great, was exposed to high humidity for a long time and had minimal popping. My Favorite material I have worked with so far. Consistent filament diameter 1.72mm

Got a link to exactly which pla from them? Amazon seems to have more than one. Any other pla recommendations? I would just get more from Folger but they seem to be out.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 11:09PM |

Registered: 8 years ago Posts: 10 |

I was wondering if fire hazards need to be considered on this printer? I'm just worried that a thermistor failure on the hot end might cause thermal runaway and cause the printed extruder parts to catch fire. Do you think a thermal fuse wired inline with the hot end and then placed physically close enough would do the trick? It would cut off the current to the hot end and possibly prevent a fire.

Edit: I just noticed Marlin has a built in thermal runaway protection period that you can set. Perhaps this is sufficient to prevent a major catastrophe?

Edited 2 time(s). Last edit at 07/10/2015 11:14PM by arxidon.

Edit: I just noticed Marlin has a built in thermal runaway protection period that you can set. Perhaps this is sufficient to prevent a major catastrophe?

Edited 2 time(s). Last edit at 07/10/2015 11:14PM by arxidon.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 11:21PM |

Registered: 9 years ago Posts: 251 |

There is a thread on the solidoodle forum about this happening to someone and the subsequent fire. Bottom line and common sense are that you shouldn't run your printer unattended.Quote

arxidon

I was wondering if fire hazards need to be considered on this printer? I'm just worried that a thermistor failure on the hot end might cause thermal runaway and cause the printed extruder parts to catch fire.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 10, 2015 11:25PM |

Registered: 8 years ago Posts: 430 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 12:04AM |

Registered: 8 years ago Posts: 135 |

Quote

hobbes

Quote

msaeger

Page 6 says the rear of the vertical beam should be 900mm from the rear of the printer.

I made all the corners like you have in the picture flush. Did you make sure the blocks on the X assembly are 300mm apart? or maybe they cut the extrusions the wrong length?

thank you for pointing that out. Page 6 does in fact say 90mm from the rear. I somehow missed that.

As for the x assembly, it was, but I guess it got pulled inward when assembling the belt.

!! I had the same problem and never found a measurement. I just adjusted everything until it was exactly even on all sides and I had movement of the bed and head that covered the whole print area with an equal margin on all sides. Basically the length of the PSU from the rear beam.

Quote

msaeger

Quote

SainSmart PLA - At 205C this stuff has been the best so far. Once dialed in it sticks to glass at 55C perfectly, comes out great, was exposed to high humidity for a long time and had minimal popping. My Favorite material I have worked with so far. Consistent filament diameter 1.72mm

Got a link to exactly which pla from them? Amazon seems to have more than one. Any other pla recommendations? I would just get more from Folger but they seem to be out.

[www.amazon.com]

Quote

widespreaddeadhead

There is a thread on the solidoodle forum about this happening to someone and the subsequent fire. Bottom line and common sense are that you shouldn't run your printer unattended.Quote

arxidon

I was wondering if fire hazards need to be considered on this printer? I'm just worried that a thermistor failure on the hot end might cause thermal runaway and cause the printed extruder parts to catch fire.

This is why I run a print server with webcam. I can watch it and stop if there's a problem and make fine adjustments. Something that has become more useful is I used to wake up in the morning and download/slice/start a print before getting ready for work, which took a lot of time. Now I just get up, turn on the heated bed, and slice/start my print from work! Plus on top of seeing a fire via webcam, I can See the temps on a real time graph to prevent a fire from ever starting!

Pics from my original build. [imgur.com] She looks much better now! [i.imgur.com] (the green spool holder is Sainsmart green PLA i linked above. Not the hatchbox green ABS thats on the spool, the hatchbox is a lot lightert in color and looks nowhere near as good!) and I just finished printing the last peice of my custom cable chain. I will be tearing my Y axis apart tomorrow and installing a cable chain. Stay tuned for a thingiverse upload of my stl files!Quote

msaeger

Anyone have some pictures of how they tidied their wires? I still have mine hanging all over because I don't want to stop printing stuff and take the time to do it but I should probably do it before I start damaging wires.

Edited 4 time(s). Last edit at 07/11/2015 12:16AM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

Sorry, only registered users may post in this forum.