Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 05:02AM |

Registered: 8 years ago Posts: 21 |

ok i got my extruder to work (manually) and everything seems to work, such as homing xyz. I can't for the life of me figure out how to start a print through repetier. I sliced a file and pressed print, and even though it says "heating extruder" the temperature was going down instead.

Oh, also, in the manual control doesn't display a heating bed icon (where the temp and fan icons are). Everything seems wired correctly and i followed the config instructions to a T, so not sure how to enable that.

Is there a way i can use cura with this thing? Is there a specific setup?

Also, i can't find information on how to install the lcd screen + card reader. I plugged them into the printer, but other than lighting up, it doesn't display anything.

Edited 4 time(s). Last edit at 07/11/2015 01:41PM by hobbes.

Oh, also, in the manual control doesn't display a heating bed icon (where the temp and fan icons are). Everything seems wired correctly and i followed the config instructions to a T, so not sure how to enable that.

Is there a way i can use cura with this thing? Is there a specific setup?

Also, i can't find information on how to install the lcd screen + card reader. I plugged them into the printer, but other than lighting up, it doesn't display anything.

Edited 4 time(s). Last edit at 07/11/2015 01:41PM by hobbes.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 08:33AM |

Registered: 8 years ago Posts: 430 |

Quote

hobbes

ok i got my extruder to work (manually) and everything seems to work, such as homing xyz. I can't for the life of me figure out how to start a print through repetier. I sliced a file and pressed print, and even though it says "heating extruder" the temperature was going down instead.

I get that sometimes too and to get it to work I need to unplug main power and USB on the printer, then connect USB then the main power the start repetier. I have also sometimes needed to reboot the PC to get it to work.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 08:40AM |

Registered: 8 years ago Posts: 430 |

Quote

Pics from my original build. [imgur.com] She looks much better now! [i.imgur.com] (the green spool holder is Sainsmart green PLA i linked above. Not the hatchbox green ABS thats on the spool, the hatchbox is a lot lightert in color and looks nowhere near as good!) and I just finished printing the last peice of my custom cable chain. I will be tearing my Y axis apart tomorrow and installing a cable chain. Stay tuned for a thingiverse upload of my stl files!

I am printing the second upright of the spool holder you put together maybe after that I will do something with the wires. I will be waiting to see the cable chain.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 12:11PM |

Registered: 8 years ago Posts: 20 |

Hey all-

Ordered my 2020 kit on Friday and am anxiously awaiting delivery this Monday! I've been reading through this thread trying to learn what I can before the build starts. My biggest concern was the quality of the RAMPS board, but decided not to order an extra from Amazon as of now, due to Dan mentioning that they switched suppliers. Can any report as to the quality of the RAMPS board that is currently shipping?

Thanks!

Ordered my 2020 kit on Friday and am anxiously awaiting delivery this Monday! I've been reading through this thread trying to learn what I can before the build starts. My biggest concern was the quality of the RAMPS board, but decided not to order an extra from Amazon as of now, due to Dan mentioning that they switched suppliers. Can any report as to the quality of the RAMPS board that is currently shipping?

Thanks!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 12:23PM |

Registered: 8 years ago Posts: 10 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 01:27PM |

Registered: 8 years ago Posts: 135 |

Cable Chain is done! Had to drill a hole in the aluminum bed for the wires, but anything is better than the way they were hanging off the back of the bed before.

[www.thingiverse.com]

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

[www.thingiverse.com]

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 01:46PM |

Registered: 8 years ago Posts: 21 |

Quote

msaeger

Quote

Pics from my original build. [imgur.com] She looks much better now! [i.imgur.com] (the green spool holder is Sainsmart green PLA i linked above. Not the hatchbox green ABS thats on the spool, the hatchbox is a lot lightert in color and looks nowhere near as good!) and I just finished printing the last peice of my custom cable chain. I will be tearing my Y axis apart tomorrow and installing a cable chain. Stay tuned for a thingiverse upload of my stl files!

I am printing the second upright of the spool holder you put together maybe after that I will do something with the wires. I will be waiting to see the cable chain.

did not work for me.

can still move things around manually homeing xyz etc, can heat extruder manually and i do see my pla filament come out of it, canNOT seem to heat the bed at all, and no matter what i do, i can't get this damn thing to print!

I'd put a file on the sd card but again, i can't find any guides on how that works either

this is getting pretty frustrating. As of now, i have a 300$ paperweight on my desk.

Edited 4 time(s). Last edit at 07/11/2015 02:33PM by hobbes.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 02:43PM |

Registered: 8 years ago Posts: 276 |

Quote

hobbes

Quote

msaeger

Quote

Pics from my original build. [imgur.com] She looks much better now! [i.imgur.com] (the green spool holder is Sainsmart green PLA i linked above. Not the hatchbox green ABS thats on the spool, the hatchbox is a lot lightert in color and looks nowhere near as good!) and I just finished printing the last peice of my custom cable chain. I will be tearing my Y axis apart tomorrow and installing a cable chain. Stay tuned for a thingiverse upload of my stl files!

I am printing the second upright of the spool holder you put together maybe after that I will do something with the wires. I will be waiting to see the cable chain.

did not work for me.

can still move things around manually homeing xyz etc, can heat extruder manually and i do see my pla filament come out of it, canNOT seem to heat the bed at all, and no matter what i do, i can't get this damn thing to print!

I'd put a file on the sd card but again, i can't find any guides on how that works either

this is getting pretty frustrating. As of now, i have a 300$ paperweight on my desk.

I think you're having two separate problems...

1. Something is wrong with your heatbed or with the connections you've made to it. Triple check everything. Maybe post a picture of the solder joints you did.

2. If you have slic3r configured to heat the print bed before printing, and your heatbed is not working, the print will not start. If you're printing PLA, try generating some gcode that does not turn on the heat bed, and see if the print starts.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 02:51PM |

Registered: 11 years ago Posts: 335 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 04:24PM |

Registered: 8 years ago Posts: 21 |

Quote

therippa

I think you're having two separate problems...

1. Something is wrong with your heatbed or with the connections you've made to it. Triple check everything. Maybe post a picture of the solder joints you did.

2. If you have slic3r configured to heat the print bed before printing, and your heatbed is not working, the print will not start. If you're printing PLA, try generating some gcode that does not turn on the heat bed, and see if the print starts.

I love you

Is that wrong?

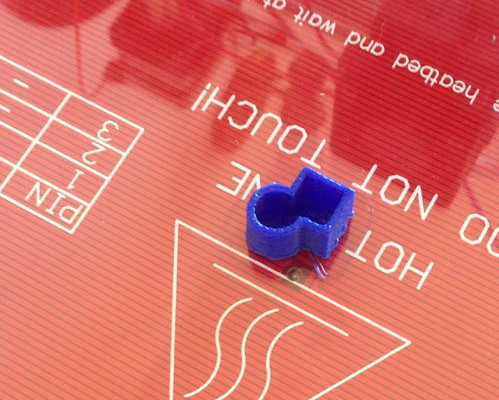

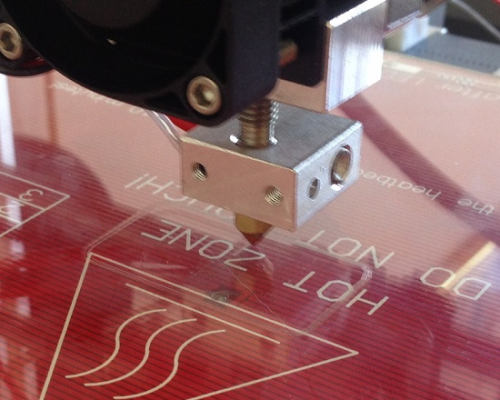

Is that wrong?First print!

First layer was practically non existent, however I have it set to 0.4 on repetier. It was very well pressed on the glass. Was afraid i was going to break the glass trying to remove it. Is it a calibration issue or setup in repetier? When i calibrated the bed, i used a sheet of paper between the nozzle and the bed.

Is that thing in the middle of the heating bed supposed to light up, or is it just a temperature gauge? My electronics knowledge extends to winding motors, that's it..

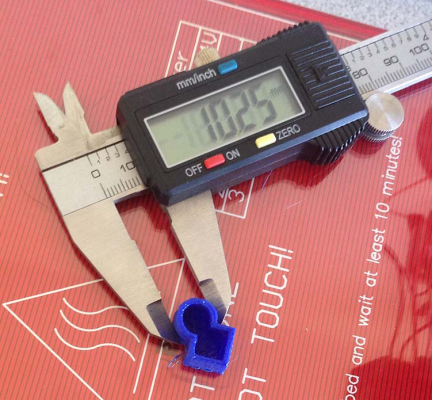

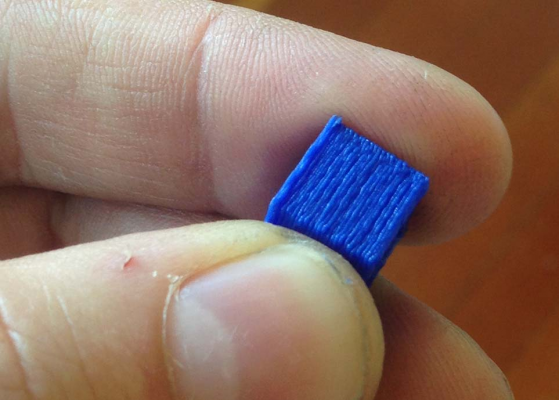

Supposed to be 10mm, but close enough.

Same here.

And here, although this may be due to the first layer not being correct.

Supposedly 0.1 layer height? On calipers, they seem more like 0.2 thick.

Layer detail.

Bed temp 70, extruder 219.

Thoughts and suggestions are encouraged and appreciated.

Would still like some info on getting the lcd screen to work and using cura.

..oh, and the first layer height thing as well, of course.

Edited 2 time(s). Last edit at 07/11/2015 04:58PM by hobbes.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 05:09PM |

Registered: 8 years ago Posts: 367 |

@hobbes - well done! Looks like a good start.

The think in the middle of the bed won't light up. I'm not sure what problem you are seeing on the first layer. Some things you can do are: print a skirt, to allow the extruder to really get flowing. Mine doesn't start immediately without this. Also: print the first layer at a slower speed. I use 30% of normal speed, and an extrusion width of 200%. 0.4 is OK as a first layer height. I usually use 115% of the first layer height which works provided the first layer height is less than 0.35mm.

See my blog at [moosteria.blogspot.com].

The think in the middle of the bed won't light up. I'm not sure what problem you are seeing on the first layer. Some things you can do are: print a skirt, to allow the extruder to really get flowing. Mine doesn't start immediately without this. Also: print the first layer at a slower speed. I use 30% of normal speed, and an extrusion width of 200%. 0.4 is OK as a first layer height. I usually use 115% of the first layer height which works provided the first layer height is less than 0.35mm.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 05:09PM |

Registered: 8 years ago Posts: 276 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 05:42PM |

Registered: 8 years ago Posts: 14 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 07:33PM |

Registered: 8 years ago Posts: 21 |

That's a bummer. Good luck getting your parts in asap, man.Quote

awmyhr

Was looking forward to putting this kit together w/my boy today, but alas it was not to be. I got M3 T-nuts instead of M4, meaning we couldn't even do the first step. Oh well, fired off an e-mail to support, hope to get the right parts soon...

Every now and then i thought i had missing parts, but it was all there. Some stuff just didn't match, like getting phillips screws instead of pan head hexagonal (which i didn't mind since i prefer phillips). I couldn't find the bag with the jumpers for the board, then i examined the config guide's pictures and realized that all my jumpers were pre-installed. I was lucky enough to have all the necessary components.

Quote

theRippa

hobbes - it's not supposed to light up, it's just the thermistor. Did you get the bed heating up, or did you just print with the bed turned off?

I got the bed heating up because i wanted to make sure it worked. I did turn it off after, since i'm currently working with PLA for now (got some nice purple ABS on the way).

It turns out one of the wires connecting to the board was a little loose so it didn't recognize the heatbed. This was actually one of the preinstalled components mentioned above that appear unassembled in the assembly guide.

Ok, so i learned a lot since my last post. Bear with me: i got a few more pictures.

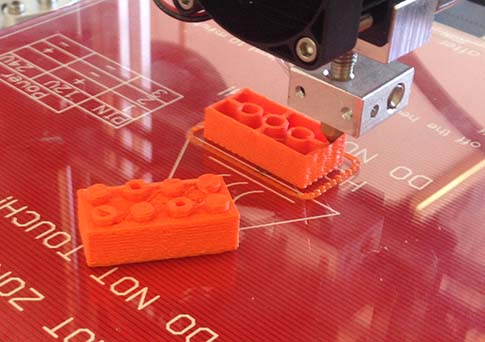

Print 3 under way with print 2 next to it. My nozzle was just too darn close on the first run, which is why it wasn't laying down any filament on the previous prints. I moved my endstop just a hair and it seemed to help.

i have absolutely NO IDEA why, but my lcd decided to start working on the third print. I'm going to be fidgeting around with that next.

I realized why my layer height was so thick on the first and second prints: i didn't have the right PRINT setting selected. I didn't realize there was a PRINT setting and PRINTER setting. Now i know..and the more you know...!

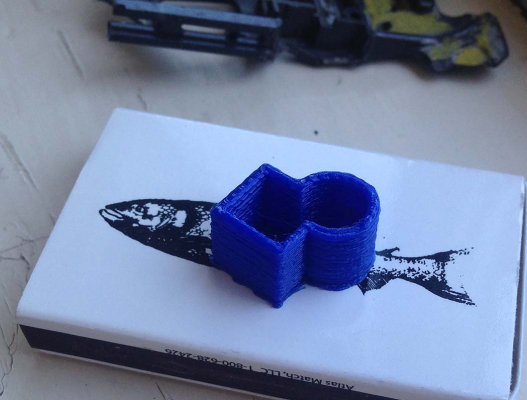

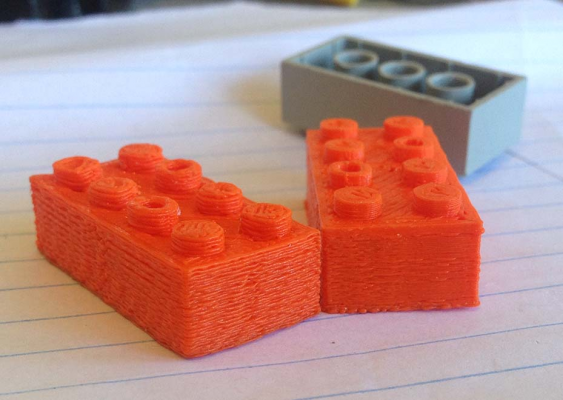

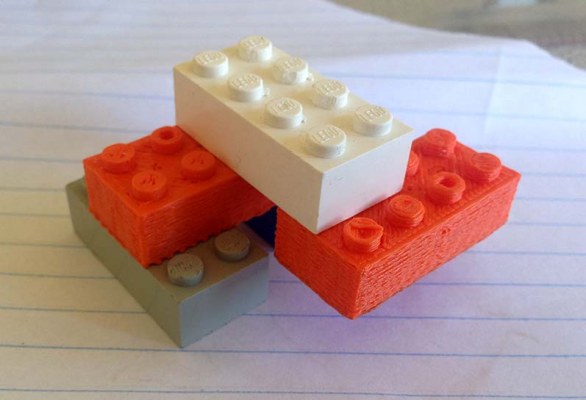

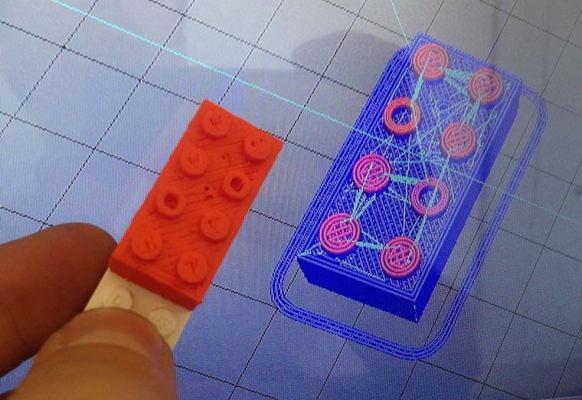

This is a Lego brick i designed specifically with different knobs to test resolution and mechanical properties. I'm used to printing at 16 micron resolution at work, so it became quickly clear that i can forget about 2 degree drafts

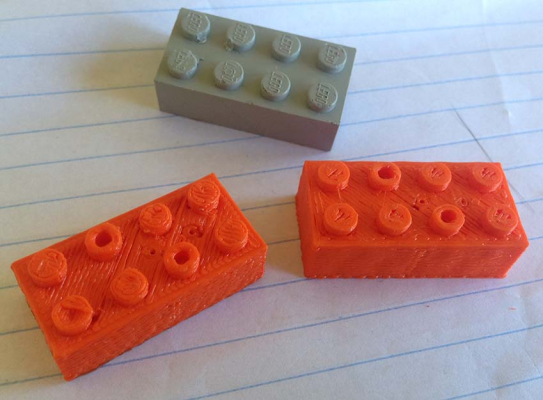

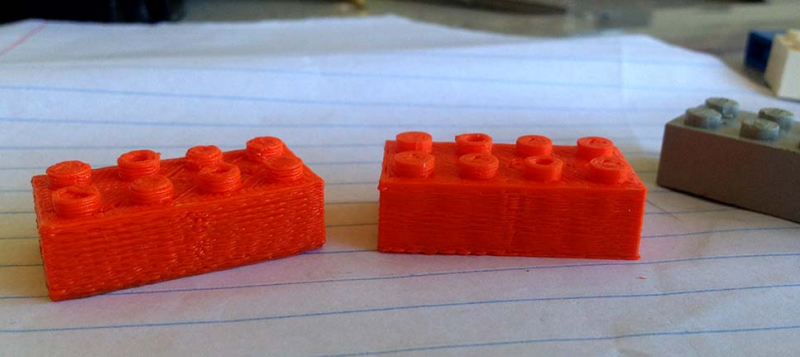

0.4mm vs 0.2mm height. I'd love to test 0.1, but that would take an hour. These two took 16 and 31 minutes respectively.

Detail closeup. Very noticeable in the knobs. Oh by the way, it looks like the printer has some difficulty making TRUE circles. So far, all my circular rounds have been sort of...ovally.

They work!

Here's something weird: my part printed mirrored. Not really sure how it happened. My first print matched my CAD just fine. Repetier shows the model as appears in Solidworks, however the bricks were printed mirrored. Thoughts?

One concerning issue i'm having right now is that my X-axis motor is overheating like crazy after just a few minutes. I noticed this while calibrating the printer last night for leveling. It's the only one that gets really hot. I saw posts from Devil inc in the first pages having the same symptoms, but i didn't quite understand his solution. Some help, please?

Edited 1 time(s). Last edit at 07/11/2015 07:34PM by hobbes.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 07:41PM |

Registered: 8 years ago Posts: 135 |

My x-axis motor gets super hot too. I haven't done anything about it. Seems to work and its not melting the ABS part its attached to!

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 09:31PM |

Registered: 8 years ago Posts: 430 |

Quote

mel0n

Cool, I made this one : [www.thingiverse.com]

It fits the bearings tightly and I found that replacing spools is kinda a pain without removing one of the mounts from the printer. I see yours locks into the rails, let me know how your spool changing process goes! I havent cut my threaded rod shorter yet as I am still debating weather or not I want it to hold 2 spools.

Did you print the cone bearing supports larger? They appear to be about 50mm in repetier host and I am thinking the center of the spool is larger than that.

So far I have the uprights printed and they fit really good!

Edit:

I made one of the cones and they are way smaller than the inside of the spool so either I did something wrong or I don't understand how this works.

Edited 1 time(s). Last edit at 07/11/2015 11:20PM by msaeger.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 11, 2015 10:02PM |

Registered: 8 years ago Posts: 430 |

Quote

One concerning issue i'm having right now is that my X-axis motor is overheating like crazy after just a few minutes. I noticed this while calibrating the printer last night for leveling. It's the only one that gets really hot. I saw posts from Devil inc in the first pages having the same symptoms, but i didn't quite understand his solution. Some help, please?

Mine gets really hot too but the Y motor which I would think it working just as hard doesn't even get warm. I am thinking the x motor is just under sized. I have also read people saying to adjust the stepper driver current for that too but I am more afraid of screwing up something doing that than the motor being hot.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 12:45AM |

Registered: 8 years ago Posts: 135 |

Got my first bad jam :[ I got the dreaded heat creep up the heat break, and roasted the PLA I was printing with. Got a failed print, very badly jammed heat break, and the teflon/ptfe tubing in the heat break bsaically turned to ash. I have done some researching on it and this hot end is very prone to this sort of thing happening. I will probably upgrade to an e3d after I get this repaired so I can print a mount for an e3d.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 01:59AM |

Registered: 8 years ago Posts: 606 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 02:28AM |

Registered: 8 years ago Posts: 135 |

I have been switching between PLA and ABS. I just spent 30 mins and got the clog cleared. The ptfe is actually fine looking, it was just caked/burnt black ABS that came out of it I think. Ran about 800mm of PLA through it once I got it cleared and I saw little black chunks for at least the first 500mm and it smelled of horrible burnt plastic. I think it will be ok for a print again. Annoying that I just cleared the whole thing with PLA because now I have to switch back to ABS so I can print a new extruder because after the research I did and the fact that this is the 3rd time I have had a bad jam like this, I am buying an E3D. I was going to anyways, but I was holding off for a bit, but I dont feel like dealing with this extruder/hot end anymore. I have yet to successfully pull a filament out of it from the top. Thats how I got my first jam actually. Everything I have read about switching filaments suggests that pulling it out the top at ~100C is the best method to get a clean switch to the new filament. Every time I have tried it just gets stuck really bad and I have figured out that the oozing around the heating block is due to extremely poor tolerances between the nossel and the heat break.

That plus I have been trying to find a way to increase my Z height and center the weight on the print head a little better. I think it would really help to quiet down those bearings. I am probably going to go with this setup [www.thingiverse.com]

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

That plus I have been trying to find a way to increase my Z height and center the weight on the print head a little better. I think it would really help to quiet down those bearings. I am probably going to go with this setup [www.thingiverse.com]

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 03:03AM |

Registered: 8 years ago Posts: 21 |

so i'm realizing that all my prints are mirrored. Even the first one, though i didn't think so at first. I'm not mirroring them in repetier, they actually appear normal on the preview. The printer simply prints a mirrored version of what's displaying. Something to do with the config?

Also, my extruder is doing this thing now on the first layer where i hear a clicking/skipping noise and the filament won't extrude. If i pull lightly on the filament, then it will start extruding just fine. After the first layer, it works fine. Thoughts?

Also, my extruder is doing this thing now on the first layer where i hear a clicking/skipping noise and the filament won't extrude. If i pull lightly on the filament, then it will start extruding just fine. After the first layer, it works fine. Thoughts?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 04:20AM |

Registered: 8 years ago Posts: 606 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 09:37AM |

Registered: 8 years ago Posts: 4 |

Quote

awmyhr

Was looking forward to putting this kit together w/my boy today, but alas it was not to be. I got M3 T-nuts instead of M4, meaning we couldn't even do the first step. Oh well, fired off an e-mail to support, hope to get the right parts soon...

Got mine Friday and had the same issue. Total bummer.

Here's a question hopefully someone can answer: on step 5, attaching the upper frame, are the two vertical pieces of 2020 supposed to be 90 mm from the very back outside edge of the printer or from the inside back edge? The photos in the guide make it look like it's from the inside back edge, or 110 mm from the very back outside edge.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 11:06AM |

Registered: 11 years ago Posts: 335 |

Quote

matteatschicken

Here's a question hopefully someone can answer: on step 5, attaching the upper frame, are the two vertical pieces of 2020 supposed to be 90 mm from the very back outside edge of the printer or from the inside back edge? The photos in the guide make it look like it's from the inside back edge, or 110 mm from the very back outside edge.

It doesn't actually matter since there is enough Y travel to cover the full heated bed regardless. I did aproximately 90mm inside, 110mm outside.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 11:14AM |

Registered: 8 years ago Posts: 4 |

Quote

691175002

Quote

matteatschicken

Here's a question hopefully someone can answer: on step 5, attaching the upper frame, are the two vertical pieces of 2020 supposed to be 90 mm from the very back outside edge of the printer or from the inside back edge? The photos in the guide make it look like it's from the inside back edge, or 110 mm from the very back outside edge.

It doesn't actually matter since there is enough Y travel to cover the full heated bed regardless. I did aproximately 90mm inside, 110mm outside.

Thanks, you answered that perfectly. I was worried about losing build volume.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 12:25PM |

Registered: 8 years ago Posts: 606 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 12:48PM |

Registered: 11 years ago Posts: 335 |

I'm getting kind of pissed off at the number of corners cut on this kit.

The Y-bearing holder prints I received were extremely inconsistent. The shortest was 17.6mm and the tallest was 18.7mm which made bed leveling impossible. I shimmed the bearing holders to fix this issue.

Now one of the linear bearings has completely seized and a second one has somehow become extremely loose (0.5mm+ of play). This is after less than 10 hours of printing. This printer was assembled carefully. There was no binding and every axis used to slide smoothly over its travel.

I'm confused because I have purchased plenty of bargain linear motion on eBay before and it has always been smooth and reliable. I'm genuinely considering just drilling holes in a block of plastic instead of using this trash.

The Y-bearing holder prints I received were extremely inconsistent. The shortest was 17.6mm and the tallest was 18.7mm which made bed leveling impossible. I shimmed the bearing holders to fix this issue.

Now one of the linear bearings has completely seized and a second one has somehow become extremely loose (0.5mm+ of play). This is after less than 10 hours of printing. This printer was assembled carefully. There was no binding and every axis used to slide smoothly over its travel.

I'm confused because I have purchased plenty of bargain linear motion on eBay before and it has always been smooth and reliable. I'm genuinely considering just drilling holes in a block of plastic instead of using this trash.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 12:53PM |

Registered: 8 years ago Posts: 4 |

Quote

tadawson

Hey, would either of you guys that got M3 T Nuts like to part with them? Folger used M3 in the Kossel, and I need a few more for ongoing changes/improvements, and all that I have found for sale are bags of 100 . . .

- Tim

Sorry buddy, I already redrilled and retapped them because I didn't want to wait on shipping.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 12:57PM |

Registered: 8 years ago Posts: 367 |

I really hope someone from Folger reads this forum from time to time. It seems like those of us who received kits early after the release got reasonable quality - a few issues, but usually fixable. But now there's more and more reports of missing or poor quality parts. In this blog post (http://moosteria.blogspot.com/2015/07/3d-printer-project-part-14-folgertech.html) I commented that poor attention to quality and detail was the weak spot for Folger. I really want them to succeed, but this is something they need to tackle head on if they are going to do so.

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 01:01PM |

Registered: 8 years ago Posts: 606 |

Quote

matteatschicken

Quote

tadawson

Hey, would either of you guys that got M3 T Nuts like to part with them? Folger used M3 in the Kossel, and I need a few more for ongoing changes/improvements, and all that I have found for sale are bags of 100 . . .

- Tim

Sorry buddy, I already redrilled and retapped them because I didn't want to wait on shipping.

No problem, and thanks for the reply!

- Tim

Sorry, only registered users may post in this forum.