Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 01:19PM |

Registered: 8 years ago Posts: 135 |

Quote

matteatschicken

Quote

tadawson

Hey, would either of you guys that got M3 T Nuts like to part with them? Folger used M3 in the Kossel, and I need a few more for ongoing changes/improvements, and all that I have found for sale are bags of 100 . . .

- Tim

Sorry buddy, I already redrilled and retapped them because I didn't want to wait on shipping.

HAHAHA thats amazing. I would totally have gone to the store and bought a tap to do that too. I have noticed my ends of my X carriage that ride on the Z rods are seeing quite a bit of wear. I will probably jump on printing my own set of spare parts soon, as I had an Oh-Shit moment last night and luckily have the printer still going but a new set of parts is high on my list. The tops of those carriages where the bearings snap in had broken on the top of both sides and the bearings are not in alignment with the printed piece very well. They broke at the bridge right at the top of the groove that goes up the side of the bearing holder. That and my extruder problems posted about above. got a new E3D on order.

Edited 1 time(s). Last edit at 07/12/2015 03:48PM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 02:55PM |

Registered: 8 years ago Posts: 4 |

Quote

mel0n

Quote

matteatschicken

Quote

tadawson

Hey, would either of you guys that got M3 T Nuts like to part with them? Folger used M3 in the Kossel, and I need a few more for ongoing changes/improvements, and all that I have found for sale are bags of 100 . . .

- Tim

Sorry buddy, I already redrilled and retapped them because I didn't want to wait on shipping.

HAHAHA thats amazing. I would totally have gone to the store and bought a tap to do that too. I have noticed my ends of my X carriage that ride on the Z rods are seeing quite a bit of wear. I will probably jump on printing my own set of spare parts soon, as I had an Oh-Shit moment last night and luckily have the printer still going but a new set of parts is high on my list. The rtops of those carriages where the brarings snap in had broken on the top of both sides and the bearings are not in alignment with the printed piece very well. They broke at the bridge right at the top of the groove that goes up the side of the bearing holder. That and my extruder problems posted about above. got a new E3D on order.

I mean when I can walk out of harbor freight with a multimeter and a 40 piece metric tap and die set for 13 bucks, how could I not do it?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 03:03PM |

Registered: 8 years ago Posts: 276 |

For those upgrading to the e3d bowden setup, I think this is the ultimate Z-axis adapter [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 04:54PM |

Registered: 11 years ago Posts: 335 |

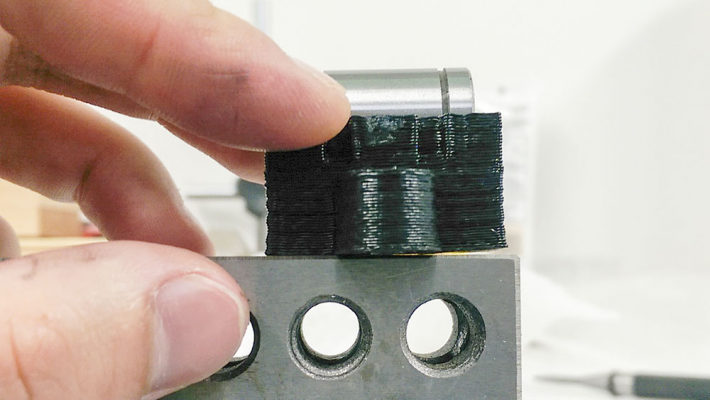

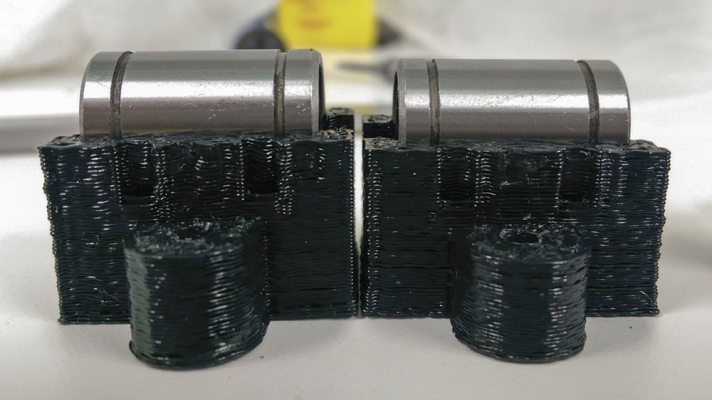

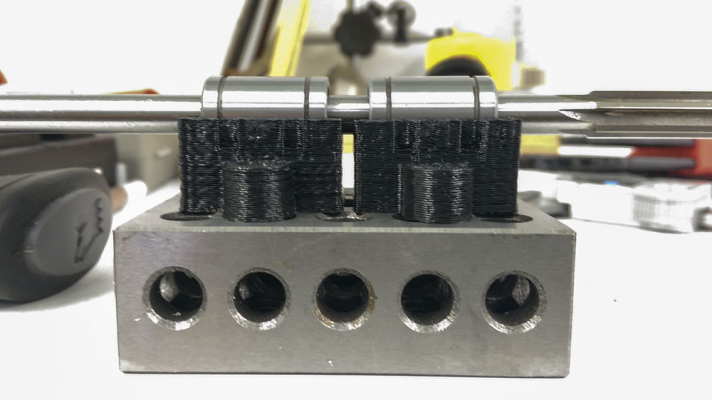

Here is my second attempt at the Y axis. To start here are the parts supplied by folger:

Warped:

Not even close to the same height:

Together these problems made it impossible to tighten screws without bending the bed, and the heated bed was mounted at such a wacky angle that it was impossible to level without shims.

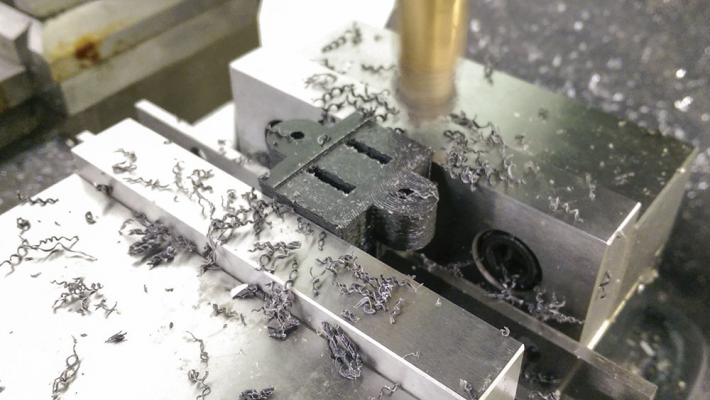

I fixed them with a setup on the mill:

One print was so much taller than the others the entire bottom had to be removed.

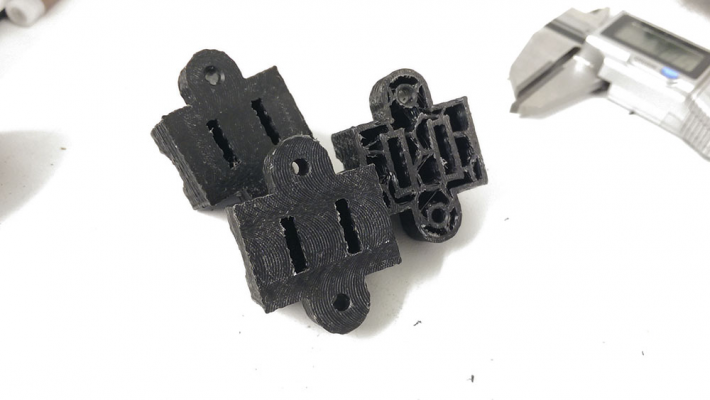

Finally flat and the same height:

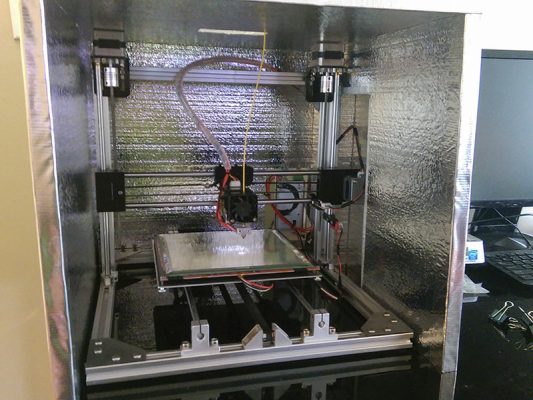

And a few pictures of the foam enclosure I am using:

It felt okay before but is much smoother now. I don't like relying on shims or loose fits in my projects since they are always masking shoddy work.

And a bonus picture of fiber insulation on the bottom of my heated bed:

The heated bed can hit 110c pretty quickly now but the tape is only rated to 105c. The enclosure maintains 50-60c depending on the bed temperature.

Edited 1 time(s). Last edit at 07/12/2015 04:56PM by 691175002.

Warped:

Not even close to the same height:

Together these problems made it impossible to tighten screws without bending the bed, and the heated bed was mounted at such a wacky angle that it was impossible to level without shims.

I fixed them with a setup on the mill:

One print was so much taller than the others the entire bottom had to be removed.

Finally flat and the same height:

And a few pictures of the foam enclosure I am using:

It felt okay before but is much smoother now. I don't like relying on shims or loose fits in my projects since they are always masking shoddy work.

And a bonus picture of fiber insulation on the bottom of my heated bed:

The heated bed can hit 110c pretty quickly now but the tape is only rated to 105c. The enclosure maintains 50-60c depending on the bed temperature.

Edited 1 time(s). Last edit at 07/12/2015 04:56PM by 691175002.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 05:49PM |

Registered: 8 years ago Posts: 606 |

If you want, drop Folger ane-mail . . . I'm sure they will replace the bad parts. It seems that they have a printer making this stuff that isn't cutting it . . . on my Kossel kkt, most parts were good, but there was a carriage with a warp that made yours look flat . . . and I can't help but wonder who (or what) had the bright idea that it was OK to ship . . .

- Tim

- Tim

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 06:50PM |

Registered: 8 years ago Posts: 21 |

Quote

tadawson

Likely a motor direction/endstop issue . . . did you have any issues when you first built it regarding getting it to home properly?

- Tim

yes, the x axis would not go to home and it was acting bizarre when manually moving it through repetier. I found a solution in the early pages of the thread where i had to correct a value in the h.configuration of the arduino marlin-ramps script thing.

I added a negative (-) to a 1 in the endstop settings. So X_HOME was 1 and i changed it to -1 and that fixed the issue.

Do you believe that might have reversed the direction in which it prints?

This is what it looks like:

Quote

// ENDSTOP SETTINGS:

// Sets direction of endstops when homing; 1=MAX, -1=MIN

#define X_HOME_DIR -1

#define Y_HOME_DIR -1

#define Z_HOME_DIR -1

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 07:53PM |

Registered: 8 years ago Posts: 10 |

Hobbes I think your x axis is flipped. You can either flip your x-axis motor connector around (when powered off), or you can change "#define INVERT_X_DIR" in your configuration.h. You'll probably have to change the X_HOME back to 1 from -1 in your configuration.h as well once you've done one of the above.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 09:18PM |

Registered: 8 years ago Posts: 81 |

Currently printing a 4-bearing x carriage with ABS. I have placed massive circles on the four corners but i guess it isn't enough to hold it down and keep it from lifting.

Looks like the corners at the front already lifted slightly..

[zangetsu.asuscomm.com]

Looks like the corners at the front already lifted slightly..

[zangetsu.asuscomm.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 09:24PM |

Registered: 8 years ago Posts: 171 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 09:35PM |

Registered: 8 years ago Posts: 81 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 09:49PM |

Registered: 8 years ago Posts: 121 |

I have started reading and rereading the guide now. Could you direct me to a good how to forum or guide for beginners? In addition to the printer I grabbed 4 rolls pla (black, white, blue, pink), some 3mm drill bits for cleaning, and 3 optical stops (my first upgrade all ready planned). I need to figure out what type of 8x8 glass to get was thinking I might just ask for oven door glass? And does anyone know how much to take off the corners I see some printers with square glass and others with beveled corners. to look at the pictures square glass should work fine. I hope to print on it with pla using hairspray any advise? I have no clue how to flash the firmware or anything yet. This is my first 3d printer and I am completely clueless. I have 4 days till it gets here so I am trying to make sure I have everything ready Should I pick up some screws just in case saw posts about some kits shipping missing screws. I'm almost scared enough to get an extra board just in case i run into solder/flux issues. I did add on the LCD and did I read correctly I need to pick the right firmware to enable it? It seems like axis direction seems to be the biggest problems people run into. Sorry just acting like a kid waiting for Christmas who is also afraid of frying his gift LOL

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 09:53PM |

Registered: 8 years ago Posts: 81 |

The back portion seems fine. But generally, when printing with a big square object with ABS, i noticed that the back corners are also lifted slightly when looking at the object's base.

Right now, im thinking of merging at least a quarter of those circles with my object. Im gonna have to finish this one first and see if it is reasonably usable. Otherwise, im gonna try merging them.

Any pro-tips out there? I have already tried setting up the skirt to be as tall as the object, but most of the time, it creates more problems specially when it decided not to stick to the bed anymore. It gets messy when it does that.

Right now, im thinking of merging at least a quarter of those circles with my object. Im gonna have to finish this one first and see if it is reasonably usable. Otherwise, im gonna try merging them.

Any pro-tips out there? I have already tried setting up the skirt to be as tall as the object, but most of the time, it creates more problems specially when it decided not to stick to the bed anymore. It gets messy when it does that.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 10:11PM |

Registered: 8 years ago Posts: 367 |

@wderoxas - try printing the first layer slower. I used 30% speed in Slic3r. Also set the first layer extrusion width in the advanced settings to 200%. These helped a lot with avoiding corners warping. And the last thing is try the same temperature for all layers, that is no special temperature for the first layer. I think that matters more with PLA as it doesn't have the elasticity of ABS. It can prevent the second and later layers putting a stress on the first layer as a result of cooling at different rates.

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 10:13PM |

Registered: 8 years ago Posts: 7 |

Is anyone else having problems with the extruder oozing where it shouldn't - out the top and around the nozzle? Pictures Here. This is after only a few minutes running; every 15 minutes of printing or so I need to manually clean the nozzle to not get massive deposits in my print.

Edited 1 time(s). Last edit at 07/12/2015 10:13PM by nonfish.

Edited 1 time(s). Last edit at 07/12/2015 10:13PM by nonfish.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 10:18PM |

Registered: 8 years ago Posts: 81 |

Quote

[email protected]

I have started reading and rereading the guide now. Could you direct me to a good how to forum or guide for beginners? In addition to the printer I grabbed 4 rolls pla (black, white, blue, pink), some 3mm drill bits for cleaning, and 3 optical stops (my first upgrade all ready planned). I need to figure out what type of 8x8 glass to get was thinking I might just ask for oven door glass? And does anyone know how much to take off the corners I see some printers with square glass and others with beveled corners. to look at the pictures square glass should work fine. I hope to print on it with pla using hairspray any advise? I have no clue how to flash the firmware or anything yet. This is my first 3d printer and I am completely clueless. I have 4 days till it gets here so I am trying to make sure I have everything ready Should I pick up some screws just in case saw posts about some kits shipping missing screws. I'm almost scared enough to get an extra board just in case i run into solder/flux issues. I did add on the LCD and did I read correctly I need to pick the right firmware to enable it? It seems like axis direction seems to be the biggest problems people run into. Sorry just acting like a kid waiting for Christmas who is also afraid of frying his gift LOL

The build and config guide on folfertech's google drive as fine as it is. You can check out animoose's blog as well for additional tips.

glass - im using an ordinary 3.5 mm glass and it seems to be fine. Just make sure both sides are flat. It doesnt matter if the corners are bevelled or not as long as the edges are. You wouldn't want your fingers to get cut buy sharp edges i assume. And for the dimension, just make sure the glass can sit nicely on the heated bed. Too long or too wide, then youll risk any of its corners sitting on top of the bolt's head.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 10:23PM |

Registered: 8 years ago Posts: 3 |

Quote

nonfish

Is anyone else having problems with the extruder oozing where it shouldn't - out the top and around the nozzle? Pictures Here. This is after only a few minutes running; every 15 minutes of printing or so I need to manually clean the nozzle to not get massive deposits in my print.

I had the same issue, The nozzle is either coming unscrewed, or the heatbreak is not seated against the nozzle properly.

I had to completely disassemble and clean the hot-end (while hot) to get the plastic out and get all of the parts re-seated against themselves properly.

It took me a few hours and bad prints to figure it out.

Edited 1 time(s). Last edit at 07/12/2015 10:27PM by Aridad.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 10:25PM |

Registered: 8 years ago Posts: 81 |

Thanks animoose. I think the config bundle from folger is set to 50%. Ill try to bring it down to 30%. And also try that width setting.Quote

animoose

@wderoxas - try printing the first layer slower. I used 30% speed in Slic3r. Also set the first layer extrusion width in the advanced settings to 200%. These helped a lot with avoiding corners warping. And the last thing is try the same temperature for all layers, that is no special temperature for the first layer. I think that matters more with PLA as it doesn't have the elasticity of ABS. It can prevent the second and later layers putting a stress on the first layer as a result of cooling at different rates.

As for the temp, its already set uniformly, however, im on 90 degrees only. Was previously running on 100 but recently, i just can't get the bed reach that temp so i brought it down.

Edit: i realized your referring to hot-end temp here. Gonna try that out too.

Edited 1 time(s). Last edit at 07/12/2015 10:47PM by wderoxas.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 10:27PM |

Registered: 8 years ago Posts: 7 |

Quote

Aridad

I had the same issue, The nozzle is either coming unscrewed, or the heatbreak is not seated against the nozzle properly.

I had to completely disassemble and clean the hot-end (while hot) to get the plastic out and get all of the parts re-seated against themselves properly.

It took me a few hours and bad prints to figure it out.

That was my next plan of action anyways. Probably don't have time today, but I'll try tomorrow and see how it goes. Thanks!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 10:31PM |

Registered: 8 years ago Posts: 81 |

Aside from tightening them (which could probably get loose again overtime due to vibrations), will an rtv silicone on the threads can get it sealed for good? Its usually rated for 350 degrees and up since its used to seal engine blocks.

Edited 1 time(s). Last edit at 07/12/2015 10:32PM by wderoxas.

Edited 1 time(s). Last edit at 07/12/2015 10:32PM by wderoxas.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 10:35PM |

Registered: 8 years ago Posts: 3 |

Quote

wderoxas

Aside from tightening them (which could probably get loose again overtime due to vibrations), will an rtv silicone on the threads can get it sealed for good? Its usually rated for 350 degrees and up since its used to seal engine blocks.

350 degrees Fahrenheit is not good enough... 200 Celsius is 392 Fahrenheit. I regularly use 230c for the first layer... I'm pretty sure that most RTV, except maybe copper, will not withstand these temperatures.

Edited 1 time(s). Last edit at 07/12/2015 10:40PM by Aridad.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 10:41PM |

Registered: 8 years ago Posts: 81 |

What i meant was 350 degree celsius. I see them on motor shops used to seal the engine head to the block. Perhaps, youd need to be certain that it has temperature limits well above the temp we used to run our hot ends.Quote

Aridad

Quote

wderoxas

Aside from tightening them (which could probably get loose again overtime due to vibrations), will an rtv silicone on the threads can get it sealed for good? Its usually rated for 350 degrees and up since its used to seal engine blocks.

350 degrees Fahrenheit is not good enough... 200 Celsius is 424 Fahrenheit. I regularly use 230c for the first layer... I'm pretty sure that most RTV, except maybe copper, will not withstand these temperatures.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 12, 2015 11:22PM |

Registered: 8 years ago Posts: 430 |

Quote

[email protected]

I have started reading and rereading the guide now. Could you direct me to a good how to forum or guide for beginners? In addition to the printer I grabbed 4 rolls pla (black, white, blue, pink), some 3mm drill bits for cleaning, and 3 optical stops (my first upgrade all ready planned). I need to figure out what type of 8x8 glass to get was thinking I might just ask for oven door glass? And does anyone know how much to take off the corners I see some printers with square glass and others with beveled corners. to look at the pictures square glass should work fine. I hope to print on it with pla using hairspray any advise? I have no clue how to flash the firmware or anything yet. This is my first 3d printer and I am completely clueless. I have 4 days till it gets here so I am trying to make sure I have everything ready Should I pick up some screws just in case saw posts about some kits shipping missing screws. I'm almost scared enough to get an extra board just in case i run into solder/flux issues. I did add on the LCD and did I read correctly I need to pick the right firmware to enable it? It seems like axis direction seems to be the biggest problems people run into. Sorry just acting like a kid waiting for Christmas who is also afraid of frying his gift LOL

This is the best forum I found and this is my first printer too. If you don't already you should listen to the 3d printing today podcast. They have some good info on there and are entertaining.

I just used the glass from a picture frame out of the closet. I tried to buy a piece but the hardware store I went to didn't sell glass so bought a glass cutter and cut down an 8x10. It's cut really crooked but it still works

I wouldn't bother buying screws until you see what's missing. The T nuts would be the only thing they might not have at the hardware store.

I wouldn't bother buying screws until you see what's missing. The T nuts would be the only thing they might not have at the hardware store. I almost think people are finding issues because they are really knowledgeable and are analyzing everything really close. Me being clueless I just put it together and aside from the Y axis alignment issue I had (which is in this thread) and have been happily printing stuff. I could probably get the quality better but I am still having fun when I get bored I will start getting it dialed in better.

While you wait for it to come I would try and come up with some kind of spool holder. I think one of the first things people make when they get the printer working is a spool holder but what do you use for a spool holder while you print one? You will be like me and need to babysit it because that thing on the side is worthless.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 13, 2015 01:10AM |

Registered: 8 years ago Posts: 135 |

Is anybody else having issues opening the stl files? I downloaded them to print out a new x-end-motor mount, but I cant get any of the files to open... I am not sure what the issue is. It just keeps saying they don't exist.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 13, 2015 04:25AM |

Registered: 8 years ago Posts: 276 |

Quote

mel0n

Is anybody else having issues opening the stl files? I downloaded them to print out a new x-end-motor mount, but I cant get any of the files to open... I am not sure what the issue is. It just keeps saying they don't exist.

I can add them just fine to Repetier. I added my files to dropbox, try using them - [db.tt]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 13, 2015 08:25AM |

Registered: 8 years ago Posts: 171 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 13, 2015 08:26AM |

Registered: 8 years ago Posts: 121 |

I got to work today was going to print out a hard copy of the guide and now the link is not working for me. Will I need to download it at home since it's working on the computer i bought the printer on and just flash stick them?Or is maintenance/new guide coming? Also can people suggest what tools or supplies I should have on hand when it gets here (I mean other then common hand tools, soldering iron, and calipers?) I have 4 rolls of pla and 3mm drill bits just in case all ready.

Edited 1 time(s). Last edit at 07/13/2015 11:11AM by jasonsaffle13@gmail.com.

Edited 1 time(s). Last edit at 07/13/2015 11:11AM by jasonsaffle13@gmail.com.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 13, 2015 09:28AM |

Registered: 8 years ago Posts: 135 |

Quote

markts

What's wrong with the spool holder? One more thing I need to upgrade that I didn't know I needed to.. Lol..

Nothing is necessarily "wrong" with it. It works, just not very good. This explains a lot of the problems associated with filament feeding resistance/path:

[www.youtube.com]

So first, having the round spool on a square bar already adds some resistance. Putting it on proper bearings allows it to spin freely, therefor reducing the amount of force needed to pull it from the reel. Add to that the angle that the filament is comming to the extruder, and the fact that it has to travel through a bracket, adds more friction and a weird angle. So that just exadurates the effect of the extruter tugging on the filament as it moves left and right.

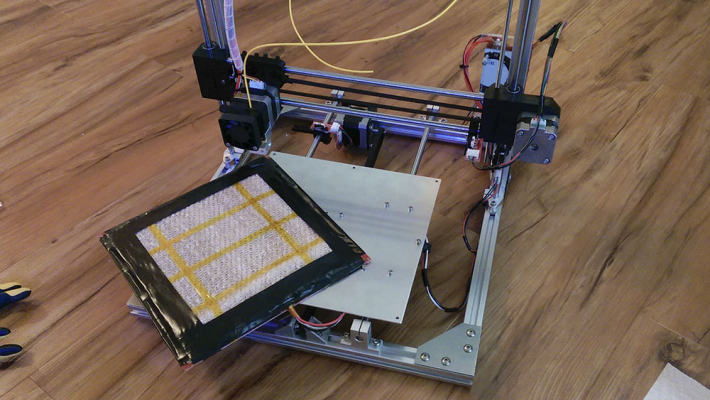

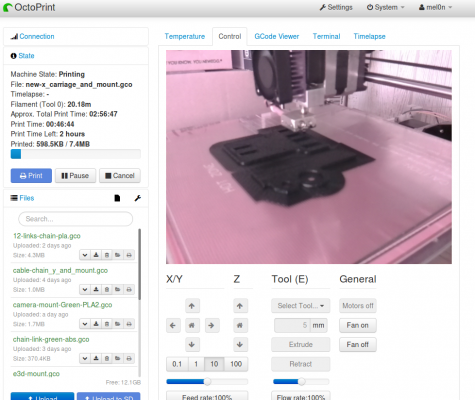

So here is a link to some pictures that shows my spool setup, camera setup, and the kind of print quality you can expect from a setup like mine:

(those are parts for the E3D direct drive extruder, they turned out really good and I really like printing ABS with a brim on purple glue stick)

[imgur.com]

Here's a little Octoprint action for you all (using Raspberry Pi NoIR camera) what my printer is doing RIGHT NOW :

Quote

therippa

Quote

mel0n

Is anybody else having issues opening the stl files? I downloaded them to print out a new x-end-motor mount, but I cant get any of the files to open... I am not sure what the issue is. It just keeps saying they don't exist.

I can add them just fine to Repetier. I added my files to dropbox, try using them - [db.tt]

Thanks for the upload by the way. I downloaded them all as a zip, and it had errors every time I unzipped, but I got the files to load finally and thats whats printing in the pic above^ So thanks a lot !

Edited 3 time(s). Last edit at 07/13/2015 10:51AM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 13, 2015 11:35AM |

Registered: 9 years ago Posts: 251 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 13, 2015 12:18PM |

Registered: 8 years ago Posts: 27 |

Any suggestions for getting this bad boy to work with octoprint?

It's a cheap inland brand camera

[www.microcenter.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 13, 2015 01:54PM |

Registered: 8 years ago Posts: 20 |

Decided to reprint some of the included black PLA parts to fix the quality issue, as I have access to a Dimension Elite ABS printer. Upon opening the STL's in Solidworks 2014, I was getting measurements of 50+ *meters* in length on some small parts like the carriage mounts. Anyone else attempt to work with the STLs on the drive and have this issue? Massively scaled up. Could just be Solidworks? I've used Solidworks to generate STLs but rarely open them up with the program.

Sorry, only registered users may post in this forum.