Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 05:12AM |

Registered: 8 years ago Posts: 81 |

Quote

CheopisIV

I was almost able to put a sheet of paper in there so 2mm should do the trick

Got some free time..

Here's how long from the original:

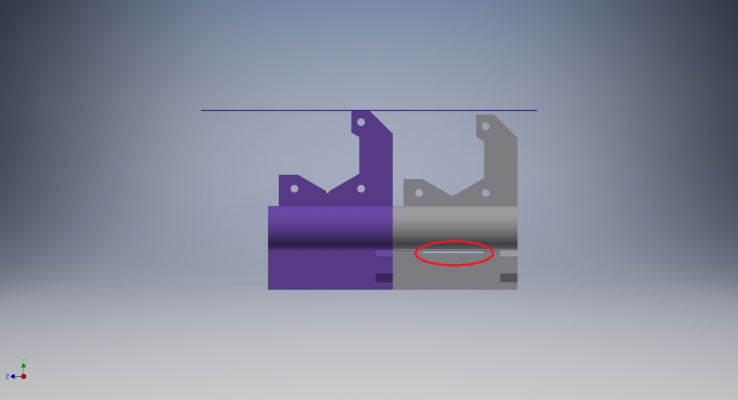

If you notice from the photo (encircled), i removed the slot along the line between the bearing holder and the nut holder. I cant find any reason for it to be there except probably when the original design was made.

Here is the STL file (no slot):

1xx-end-motor_2mm_longer.stl

With Slot:

1xx-end-motor_2mm_longer_with_slot.stl

Edited 1 time(s). Last edit at 07/23/2015 05:28AM by wderoxas.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 07:40AM |

Registered: 8 years ago Posts: 121 |

[imgur.com]

[imgur.com]

[imgur.com]

Checked this morning the socket head screws are the only ones I got to fit the larger T-nuts. When I went to try the pan head ones I found I had not noticed the diameter of them.

Wow sorry about the size will figure how to make pictures smaller. Ok that's better at least it's not messing up the forums with 4 pages of scrolling.

Edited 4 time(s). Last edit at 07/23/2015 08:01AM by jasonsaffle13@gmail.com.

[imgur.com]

[imgur.com]

Checked this morning the socket head screws are the only ones I got to fit the larger T-nuts. When I went to try the pan head ones I found I had not noticed the diameter of them.

Wow sorry about the size will figure how to make pictures smaller. Ok that's better at least it's not messing up the forums with 4 pages of scrolling.

Edited 4 time(s). Last edit at 07/23/2015 08:01AM by jasonsaffle13@gmail.com.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 08:24AM |

Registered: 8 years ago Posts: 95 |

Quote

sk8

Quote

mike3

Looks good sk8 I'm still working on my printer,, It was missing a lot of nut and bolts being metric I'm having problems located them.... but strangely it has extras of others? Its frustrating waiting for your printer then not being able to complete it because of missing such small parts..going to harbor freight later,, I think they sell metric nut and bolt kits..

Mine was also missing some, but I just winged it. Use the extras that you got, the only things i needed that weren't in the kit was some wider washers than they have provided. The ones they give you aren't great for securing the corner brackets that holds the y axis belt. And in the instructions that they had some of the wiring is wrong on the board, I can post a picture later if you want of the correct wiring.

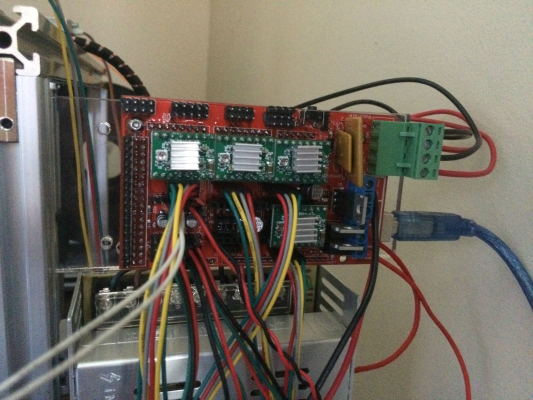

Got the metric stuff.. you were right you need the larger washers.. I also had to use the socket head screws on the larger T-nuts as nothing else would fit... other pan heads were too long for there purpose.. anyway got the thing together,,, And since you are up and running .. some pictures would be great .. I am at the wiring stage.. On the where the steppers plug into the Ramps.. in the pictures it shows the wiring colors looking at the board right to left green on the left except on the third its reversed .. is that correct.. thanks

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 08:27AM |

Registered: 8 years ago Posts: 95 |

Quote

[email protected]

[imgur.com]

[imgur.com]

[imgur.com]

Checked this morning the socket head screws are the only ones I got to fit the larger T-nuts. When I went to try the pan head ones I found I had not noticed the diameter of them.

Wow sorry about the size will figure how to make pictures smaller. Ok that's better at least it's not messing up the forums with 4 pages of scrolling.

I also only had the Socket heads to fit the larger T-nuts Mike

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 08:36AM |

Registered: 9 years ago Posts: 44 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 09:27AM |

Registered: 8 years ago Posts: 95 |

Quote

zarnold16

I was wondering where I could find a BOM for this printer I didn't seem to see on on the website or the G-Drive? My printer will be arriving Saturday if USPS doesn't mess up and before I start building I wanted to make a checklist for the parts to see what I'm missing.

A BOM would have been nice.. I havn't seen any except what's printed on the separate packs of parts you receive in the kit

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 10:22AM |

Registered: 8 years ago Posts: 430 |

Quote

mike3

Quote

zarnold16

I was wondering where I could find a BOM for this printer I didn't seem to see on on the website or the G-Drive? My printer will be arriving Saturday if USPS doesn't mess up and before I start building I wanted to make a checklist for the parts to see what I'm missing.

A BOM would have been nice.. I havn't seen any except what's printed on the separate packs of parts you receive in the kit

And I had all the parts printed on the bags but the build sheet calls for parts that were not printed on the bags.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 10:56AM |

Registered: 8 years ago Posts: 66 |

Quote

wderoxas

Got some free time..

Here's how long from the original:

[attachment 58651 comparison.jpg]

If you notice from the photo (encircled), i removed the slot along the line between the bearing holder and the nut holder. I cant find any reason for it to be there except probably when the original design was made.

Here is the STL file (no slot):

[attachment 58650 1xx-end-motor_2mm_longer.stl]

With Slot:

[attachment 58652 1xx-end-motor_2mm_longer_with_slot.stl]

Thanks a bunch! Now I need to get the 8mm screws and get printing

I'll likely do this along with the dual extruder upgrade at the same time to keep the disassembly all together.

I'll likely do this along with the dual extruder upgrade at the same time to keep the disassembly all together.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 12:00PM |

Registered: 8 years ago Posts: 18 |

Quote

mike3

Got the metric stuff.. you were right you need the larger washers.. I also had to use the socket head screws on the larger T-nuts as nothing else would fit... other pan heads were too long for there purpose.. anyway got the thing together,,, And since you are up and running .. some pictures would be great .. I am at the wiring stage.. On the where the steppers plug into the Ramps.. in the pictures it shows the wiring colors looking at the board right to left green on the left except on the third its reversed .. is that correct.. thanks

Everything is at the location of their pictures, but some are reversed. The x axis endstop is moved one pin to the left, and then in your slicer settings x home is set to max instead of min.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 01:14PM |

Registered: 8 years ago Posts: 30 |

I just purchased my Prusa about 2 weeks ago! Started assembling it Tuesday and am having a lot of fun so far putting it together. I have also been reading some of the posts on this thread but wanted to ask, are there any modifications you guys recommend right off the bat? I am planning on replacing some of the hardware because I am not too excited about how it fits, ground down a couple pieces for again a better fit.

I just downloaded the file for the Z-Axis standoff cause that seems like a REALLY good idea.

Thanks for all your help!

I just downloaded the file for the Z-Axis standoff cause that seems like a REALLY good idea.

Thanks for all your help!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 01:51PM |

Registered: 8 years ago Posts: 14 |

I heard back from Folger today. They're going to send out a replacement for the damaged rail.

Last night my extruder jammed. It seems to be a problem with the thermistor. I set the temp for 220 deg. and when I checked it with a multimeter and temp probe it read about 160.

Could the thermistor be shorted or not in good contact? The covers on the leads (is that PTFE?) have come out of where the brass tube is crimped on the thermistor. What is the best way to replace that? I haven't found any thermistors with that metal tube on the end.

Last night my extruder jammed. It seems to be a problem with the thermistor. I set the temp for 220 deg. and when I checked it with a multimeter and temp probe it read about 160.

Could the thermistor be shorted or not in good contact? The covers on the leads (is that PTFE?) have come out of where the brass tube is crimped on the thermistor. What is the best way to replace that? I haven't found any thermistors with that metal tube on the end.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 02:28PM |

Registered: 8 years ago Posts: 66 |

Quote

Neverdone

I just purchased my Prusa about 2 weeks ago! Started assembling it Tuesday and am having a lot of fun so far putting it together. I have also been reading some of the posts on this thread but wanted to ask, are there any modifications you guys recommend right off the bat? I am planning on replacing some of the hardware because I am not too excited about how it fits, ground down a couple pieces for again a better fit.

I just downloaded the file for the Z-Axis standoff cause that seems like a REALLY good idea.

Thanks for all your help!

I have a build thread here with the addons and upgrades I've done. I also collected them here.

Some of the upgrades have been removed along the way for one reason or another and removed from the collection. Currently I'm awaiting my 8mm lead screws to move on to the next step (dual E3D V6 direct drive extruder and X-Chassis upgrade).

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 02:37PM |

Registered: 8 years ago Posts: 135 |

I am super happy with my E3D V6 so far. The hot end temp curve is insanely smooth now. It used to drop/overshoot by +-5 to 7 degrees while printing. I think that was due to the 40W heater, and horrible thermistor placement. The E3D has a 25W so it can heat more frequently without overshooting, and since the heater-block is smaller the whole thing comes to temp faster even though its 15W less!

I will say that the fiberglass sleeves for the thermistor are pretty crap, but one you get it in there really good, having direct contact with the heat block is MUCH better than that crappy metal sleeve crimped on the stock thermistor. The thermistor is also placed as close as possible to the nossel so the temps are really accurate. I have been able to print down to 0.05mm layer height with the E3D and the print quality is AMAZING. At that layer height you can't really even distinguish any of the layers from each other.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

I will say that the fiberglass sleeves for the thermistor are pretty crap, but one you get it in there really good, having direct contact with the heat block is MUCH better than that crappy metal sleeve crimped on the stock thermistor. The thermistor is also placed as close as possible to the nossel so the temps are really accurate. I have been able to print down to 0.05mm layer height with the E3D and the print quality is AMAZING. At that layer height you can't really even distinguish any of the layers from each other.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 04:07PM |

Registered: 8 years ago Posts: 20 |

Quote

animoose

Quote

cvanclev

Well, got all the hardware assembled and just finished configuration. Officially up and running! Well, sort of. Did the first manual tests in Repetier, and was able to move the X,Y, and extruder steppers. However, there is absolutely no response from the Z axis motors. I've noticed that the manual communication is glitchy at best, but I'm hesitant to start a full print without at least getting the Z to respond manually first. I tuned my driver to 0.35 volts, based on a recommendation early in this thread. Absolutely zero response. Going to try swapping the driver with the extra that was provided later tonight. Until then, anyone experience a similar issue? Pictures to follow soon!

Have you tried homing the Z motor first in Repetier? As I recall, the manual control won't drive it until you do this. If you are worried about not having the position right, click home and manually press the end stop switch so it thinks it's homed.

Turns out my polulu driver was not functional. Switched for the spare one and fixed the problem. Bigger issue now though

While tuning the drivers, got through three before I barely slipped with the multimeter probe and bumped the pin next to it.. small pop and loads of smoke, looks like I fried a component on the Arduino board.

While tuning the drivers, got through three before I barely slipped with the multimeter probe and bumped the pin next to it.. small pop and loads of smoke, looks like I fried a component on the Arduino board.  Has anyone experienced this before? Do i just need a new Mega, or a new ramps/driver setup as well? Mega is fried for sure. Component is visibly torched. Really wish there was a better way to tune these, unless I overlooked something.

Has anyone experienced this before? Do i just need a new Mega, or a new ramps/driver setup as well? Mega is fried for sure. Component is visibly torched. Really wish there was a better way to tune these, unless I overlooked something.Edited 1 time(s). Last edit at 07/23/2015 04:07PM by cvanclev.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 04:20PM |

Registered: 8 years ago Posts: 367 |

Quote

cvanclev

Quote

animoose

Quote

cvanclev

Well, got all the hardware assembled and just finished configuration. Officially up and running! Well, sort of. Did the first manual tests in Repetier, and was able to move the X,Y, and extruder steppers. However, there is absolutely no response from the Z axis motors. I've noticed that the manual communication is glitchy at best, but I'm hesitant to start a full print without at least getting the Z to respond manually first. I tuned my driver to 0.35 volts, based on a recommendation early in this thread. Absolutely zero response. Going to try swapping the driver with the extra that was provided later tonight. Until then, anyone experience a similar issue? Pictures to follow soon!

Have you tried homing the Z motor first in Repetier? As I recall, the manual control won't drive it until you do this. If you are worried about not having the position right, click home and manually press the end stop switch so it thinks it's homed.

Turns out my polulu driver was not functional. Switched for the spare one and fixed the problem. Bigger issue now thoughWhile tuning the drivers, got through three before I barely slipped with the multimeter probe and bumped the pin next to it.. small pop and loads of smoke, looks like I fried a component on the Arduino board.

Has anyone experienced this before? Do i just need a new Mega, or a new ramps/driver setup as well? Mega is fried for sure. Component is visibly torched. Really wish there was a better way to tune these, unless I overlooked something.

You are not the first person to do this. I did it too in exactly the same way, and so did at least one other person on the thread. I wasn't able to tell exactly what I had damaged. It was definitely the Mega as I no longer had any serial communication to it. To be the on the safe side I ordered both a replacement Mega and a new RAMPS board. I think the drivers were OK. I got the replacements from Amazon, as I decided I was in a hurry and because my original RAMPS board from Folger was low quality.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 04:36PM |

Registered: 8 years ago Posts: 20 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 04:53PM |

Registered: 8 years ago Posts: 367 |

Quote

cvanclev

Huh. Might try just the Arduino as the budget is tight and the RAMPS board appears okay. Is there a better way to tune the drivers? Considering putting a dab of hot glue on the pins right next to it if they're that crazy close to a short.

I was just really, really careful the second time, and didn't obsess about getting the voltages exactly right, just in the ballpark. You'll know if they are really out - either the motor will skip or it will get too hot. I also stuck Kapton tape on the USB housing of the Mega board, as it's very close to the RAMPS board and I worried it could have been the source of the short (probably not, but I decided to play safe).

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 05:11PM |

Registered: 8 years ago Posts: 20 |

Quote

animoose

Quote

cvanclev

Huh. Might try just the Arduino as the budget is tight and the RAMPS board appears okay. Is there a better way to tune the drivers? Considering putting a dab of hot glue on the pins right next to it if they're that crazy close to a short.

I was just really, really careful the second time, and didn't obsess about getting the voltages exactly right, just in the ballpark. You'll know if they are really out - either the motor will skip or it will get too hot. I also stuck Kapton tape on the USB housing of the Mega board, as it's very close to the RAMPS board and I worried it could have been the source of the short (probably not, but I decided to play safe).

Here's a picture of the damaged component, right next to the DC barrel jack input. Ordered a new one one Amazon with guaranteed delivery tomorrow for 38 bucks. Not bad, but an expensive 1 mm slip of the hand. Thanks for the tuning tip.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 05:23PM |

Registered: 8 years ago Posts: 606 |

Quote

cvanclev

Huh. Might try just the Arduino as the budget is tight and the RAMPS board appears okay. Is there a better way to tune the drivers? Considering putting a dab of hot glue on the pins right next to it if they're that crazy close to a short.

Use power supply ground for your black lead, and do it with no heaters on or motors running . . . that way, with no current on the traces, there will be no differential betweenthe ground, and the ground pin on the Pololu. With that clipped on, you have two hands free for the screwdriver and probe. It's a lot harder to slip off the pot . . .

You could also likely replace what appears to be the voltage regulator on the Arduino for a buck or so . . .

- Tim

Edited 1 time(s). Last edit at 07/23/2015 05:24PM by tadawson.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 05:28PM |

Registered: 8 years ago Posts: 606 |

Quote

mel0n

I am super happy with my E3D V6 so far. The hot end temp curve is insanely smooth now. It used to drop/overshoot by +-5 to 7 degrees while printing. I think that was due to the 40W heater, and horrible thermistor placement. The E3D has a 25W so it can heat more frequently without overshooting, and since the heater-block is smaller the whole thing comes to temp faster even though its 15W less!

I will say that the fiberglass sleeves for the thermistor are pretty crap, but one you get it in there really good, having direct contact with the heat block is MUCH better than that crappy metal sleeve crimped on the stock thermistor. The thermistor is also placed as close as possible to the nossel so the temps are really accurate. I have been able to print down to 0.05mm layer height with the E3D and the print quality is AMAZING. At that layer height you can't really even distinguish any of the layers from each other.

Had you run a PID tune on the 40w, you would have been in the same place . . . the PID values in Marlin aren't correct for much. Mine was all over with 40w as per defaults, but was a straight, flat line after tuning. I am on an E3D as well now, and actually wish I still had the 40w . . if I agressively cool bridging, the 25w can't keep up, a problem I never had with 40w . . .

- Tim

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 07:20PM |

Registered: 8 years ago Posts: 66 |

Quote

tadawson

Had you run a PID tune on the 40w, you would have been in the same place . . . the PID values in Marlin aren't correct for much. Mine was all over with 40w as per defaults, but was a straight, flat line after tuning. I am on an E3D as well now, and actually wish I still had the 40w . . if I agressively cool bridging, the 25w can't keep up, a problem I never had with 40w . . .

- Tim

Is the heater a different size between the two? I haven't measured but they look about the same from the stock hot end and the E3D V6. I thought they'd be interchangeable.

Sigil Pickups || Stunt Monkey Pedals

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 07:41PM |

Registered: 8 years ago Posts: 606 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 09:21PM |

Registered: 8 years ago Posts: 121 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 12:32AM |

Registered: 8 years ago Posts: 276 |

Does anyone know what might be causing this waviness? I can't find it documented anywhere online...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 01:11AM |

Registered: 8 years ago Posts: 10 |

Quote

therippa

Does anyone know what might be causing this waviness? I can't find it documented anywhere online...

Therippa try using Cura instead of Slic3r. I had similar results in Slic3r but it went away when I switched to Cura. Also Cura seems to get overhangs better I'm not sure why.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 02:27AM |

Registered: 8 years ago Posts: 276 |

Quote

arxidon

Quote

therippa

Does anyone know what might be causing this waviness? I can't find it documented anywhere online...

Therippa try using Cura instead of Slic3r. I had similar results in Slic3r but it went away when I switched to Cura. Also Cura seems to get overhangs better I'm not sure why.

Thanks, I'll give it a try.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 09:51AM |

Registered: 8 years ago Posts: 135 |

Quote

arxidon

Quote

therippa

Does anyone know what might be causing this waviness? I can't find it documented anywhere online...

Therippa try using Cura instead of Slic3r. I had similar results in Slic3r but it went away when I switched to Cura. Also Cura seems to get overhangs better I'm not sure why.

Same thing here. Have no idea why this happens. I suspect it has to do with the slower movement speed when printing with slic3r, and resonance frequencies. The slower movement I think may allow the vibration from the steppers get into the print more. I found that at 0.1mm layer height this didnt happen either.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 10:09AM |

Registered: 8 years ago Posts: 66 |

Quote

therippa

Does anyone know what might be causing this waviness? I can't find it documented anywhere online...

Have you tried thicker shell and lower infill overlap?

Sigil Pickups || Stunt Monkey Pedals

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 11:49AM |

Registered: 8 years ago Posts: 10 |

I got my printer kit about a week after shipment confirmation. The material list was glued to the inside of the USPS box. The hardware envelope also had a contents list. there were no missing parts. Assembly took a couple of days and generally went pretty well. This is my first time playing with 3D printers.

I had three problems:

1. Making sure the linear bearings were seated all the way and straight. After several tries, I ended up putting the rod through the bearings first, then using a vise to press them in place.

2. Y and Z- Limit switchs not activating. The cause was the switch holder was just far enough in the way that the switch lever would not get depressed enough to click. Easy fix was just to bend the lever outward a few mm.

2. X-axis homing where the head would crash into the left side. Also X-axis moved opposite to the arrows. Many thanks to the forum comments above, the only change I needed to make to the latest config files from FolgerTech was making the INVERT_X_DIR true. Also moved the X limit switch plug to the max from the min.

I also changed the max limits to X=180, Y=180, and Z=140 to reflect the actual printable area. This avoids the extruder running into the clips that secure the glass to the PCB and reflects the actual Z height attainable.

Some members have commented about gluing the Z nuts into the housing. I did not do this as having them loose has the side benefit of not forcing the extruder into the glass if the limit switch is not working or configured wrong. So far gravity works OK to keep the Z axis down.

With those changes I was able to print this test 20mm box which measured 20.17mm, but 11.5mm high instead of 10.

I still need to do driver current calibration, better z-axis setting and some calibrations as recommended in the RepRap forums.

Remaining problem is X-axis homing will bounce off the switch before stopping. I'll try slowing the homing speed, but appreciate any suggestions.

I had three problems:

1. Making sure the linear bearings were seated all the way and straight. After several tries, I ended up putting the rod through the bearings first, then using a vise to press them in place.

2. Y and Z- Limit switchs not activating. The cause was the switch holder was just far enough in the way that the switch lever would not get depressed enough to click. Easy fix was just to bend the lever outward a few mm.

2. X-axis homing where the head would crash into the left side. Also X-axis moved opposite to the arrows. Many thanks to the forum comments above, the only change I needed to make to the latest config files from FolgerTech was making the INVERT_X_DIR true. Also moved the X limit switch plug to the max from the min.

I also changed the max limits to X=180, Y=180, and Z=140 to reflect the actual printable area. This avoids the extruder running into the clips that secure the glass to the PCB and reflects the actual Z height attainable.

Some members have commented about gluing the Z nuts into the housing. I did not do this as having them loose has the side benefit of not forcing the extruder into the glass if the limit switch is not working or configured wrong. So far gravity works OK to keep the Z axis down.

With those changes I was able to print this test 20mm box which measured 20.17mm, but 11.5mm high instead of 10.

I still need to do driver current calibration, better z-axis setting and some calibrations as recommended in the RepRap forums.

Remaining problem is X-axis homing will bounce off the switch before stopping. I'll try slowing the homing speed, but appreciate any suggestions.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 02:41PM |

Registered: 8 years ago Posts: 367 |

I have that bounce as well. I assume it's deliberate (hypothesis: it does a fast move for the homing, then the bounce is to get a slower or shorter one with greater accuracy) and I decided not to worry about it.

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

Sorry, only registered users may post in this forum.