Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 03:03PM |

Registered: 8 years ago Posts: 135 |

Quote

animoose

I have that bounce as well. I assume it's deliberate (hypothesis: it does a fast move for the homing, then the bounce is to get a slower or shorter one with greater accuracy) and I decided not to worry about it.

Same here. I actually like the bounce. I feel like it is a reassurance "yes I hit the switch" and I wish my y axis did it too.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 03:10PM |

Registered: 8 years ago Posts: 20 |

Quote

animoose

I have that bounce as well. I assume it's deliberate (hypothesis: it does a fast move for the homing, then the bounce is to get a slower or shorter one with greater accuracy) and I decided not to worry about it.

I work with CNC tools daily, and our large ShopBot CNC routers perform "the bounce" while homing in the X and Y. As animoose stated, this is indeed to combine fast travel time and accuracy during the homing process. Our speed differential is much more aggressive though, with the travel at 80% of top speed and the small motion after the bounce at around 20% of top speed.

Edited 1 time(s). Last edit at 07/24/2015 03:11PM by cvanclev.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 05:54PM |

Registered: 8 years ago Posts: 20 |

Well, it's been an interesting 24 hours.

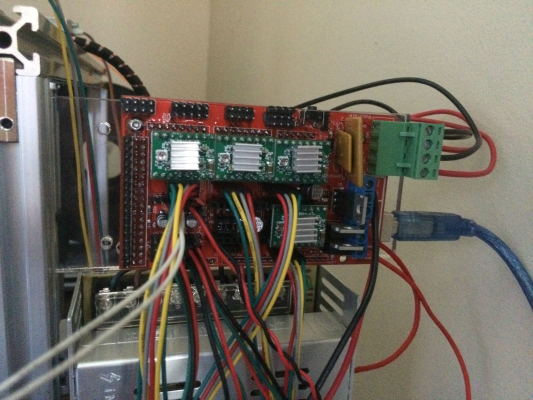

My new Arduino Mega came in today, after blowing the original board while tuning the stepper drivers. I hesitantly popped it in after downloading Marlin and powered up the unit. Limit switches displayed LED when depressed, but couldn't get ANY communication from repetier. Checked the board- the new voltage regulator was incredibly hot. Unplugged everything, computer no longer sees the Mega on COM. Looks like I burned up two Arduinos by making the decision to trust the old RAMPS board!!! How frustrating. New RAMPS AND Mega on order for arrival Sunday.. Goodbye weekend play time Now.. here's the question. I'll be really upset if I plug my A4988s into the new RAMPS and Mega and end up blowing both new components due to the stepper driver still being the problem. Animoose, didn't you say that you reused the drivers you blew your system with and had success?

Now.. here's the question. I'll be really upset if I plug my A4988s into the new RAMPS and Mega and end up blowing both new components due to the stepper driver still being the problem. Animoose, didn't you say that you reused the drivers you blew your system with and had success?

My new Arduino Mega came in today, after blowing the original board while tuning the stepper drivers. I hesitantly popped it in after downloading Marlin and powered up the unit. Limit switches displayed LED when depressed, but couldn't get ANY communication from repetier. Checked the board- the new voltage regulator was incredibly hot. Unplugged everything, computer no longer sees the Mega on COM. Looks like I burned up two Arduinos by making the decision to trust the old RAMPS board!!! How frustrating. New RAMPS AND Mega on order for arrival Sunday.. Goodbye weekend play time

Now.. here's the question. I'll be really upset if I plug my A4988s into the new RAMPS and Mega and end up blowing both new components due to the stepper driver still being the problem. Animoose, didn't you say that you reused the drivers you blew your system with and had success?

Now.. here's the question. I'll be really upset if I plug my A4988s into the new RAMPS and Mega and end up blowing both new components due to the stepper driver still being the problem. Animoose, didn't you say that you reused the drivers you blew your system with and had success?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 06:00PM |

Registered: 8 years ago Posts: 367 |

Sorry to hear about the blown electronics - it's really frustrating to be so close. One of my steppers didn't work, and I think it was the one that I was adjusting when I blew the board. However, it didn't seem to harm the replacement RAMPS or Mega. Once I found it wasn't working (because the extruder motor didn't run), I replaced it with the spare one in the kit and life was good.

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 06:28PM |

Registered: 8 years ago Posts: 95 |

Quote

sk8

Quote

mike3

Got the metric stuff.. you were right you need the larger washers.. I also had to use the socket head screws on the larger T-nuts as nothing else would fit... other pan heads were too long for there purpose.. anyway got the thing together,,, And since you are up and running .. some pictures would be great .. I am at the wiring stage.. On the where the steppers plug into the Ramps.. in the pictures it shows the wiring colors looking at the board right to left green on the left except on the third its reversed .. is that correct.. thanks

Everything is at the location of their pictures, but some are reversed. The x axis endstop is moved one pin to the left, and then in your slicer settings x home is set to max instead of min.

Thanks for the pix .. One question I see the extruder stepper is also plugged in reversed .. is that right and why is that..finally got everything wired.. almost ready to go. also I don't see anything in the Folger manuals about setting up the steppers I assume there must be a procedure .. Thanks .. Mike

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 06:31PM |

Registered: 8 years ago Posts: 20 |

Quote

animoose

Sorry to hear about the blown electronics - it's really frustrating to be so close. One of my steppers didn't work, and I think it was the one that I was adjusting when I blew the board. However, it didn't seem to harm the replacement RAMPS or Mega. Once I found it wasn't working (because the extruder motor didn't run), I replaced it with the spare one in the kit and life was good.

Hmm.. Interesting. I posted earlier about not getting the Z to respond- turns out one of my drivers was not functional, so I had 4 functional drivers "pre-short". Now if one is blown, I'm SOL. Guess I'll find out soon.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 06:48PM |

Registered: 8 years ago Posts: 367 |

One thing I did the second time around was to stick kapton tape over all the pins on the stepper board except for the ground pin. I don't know if it helped, but it made me feel better.

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 08:16PM |

Registered: 8 years ago Posts: 430 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 08:54PM |

Registered: 8 years ago Posts: 20 |

Well, looks like I'm dead in the water for "6-8 business days" as I wait for a new RAMPS board, a *third* new Arduino, and a couple new drivers. Fun stuff. In the meantime, I took advantage of the downtime today to purchase 2 8x8 glass panes from JoAnn's Craft (of all places!) as well as 8x8 Kapton sheets. I liked the idea of the sheet due to the mitigation of overlaps. I applied the Kapton sheet to one of my mirror glass panes, and blue tape to the other. I am intending to use the kapton tape glass for higher bed temps like ABS, and the blue tape glass for PLA prints. We'll see which performs better. I also attached a CNC cable chain to the heated bed, which looks like it will work fantastically. I did have problems with my X limit switch rotating downwards, as the X chrome rods don't fit tightly into the 3D printed bearing/rod holders. May shim that with a piece of blue tape if it becomes a problem, but so far so good.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 09:26PM |

Registered: 8 years ago Posts: 121 |

[imgur.com]

[imgur.com]

Well day three and couple headaches. I did not get enough socket head screw so I had used Philip head screws for the motor brackets now I can not tighten them. So tomorrow I will take some of the socket head screws out from the Y-axis rods and trade places with the mounts so I can get in and tighten them.

Also cracked the left Z-rod brace under the motor not bad and just in one spot but guess I'll be trying to print a new one soon.

[imgur.com]

Well day three and couple headaches. I did not get enough socket head screw so I had used Philip head screws for the motor brackets now I can not tighten them. So tomorrow I will take some of the socket head screws out from the Y-axis rods and trade places with the mounts so I can get in and tighten them.

Also cracked the left Z-rod brace under the motor not bad and just in one spot but guess I'll be trying to print a new one soon.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 09:31PM |

Registered: 8 years ago Posts: 35 |

Quote

therippa

Does anyone know what might be causing this waviness? I can't find it documented anywhere online...

Mine does that too and I'm using Cura. Its pretty symetrical and looks kind of like carbon fiber so I don't care, I won't spend any time trying to "fix" it.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 09:40PM |

Registered: 8 years ago Posts: 35 |

Well I'm out of comission for a few days. I cannot get this thing to print without jamming up the hot end. The PTFE is too short (maybe less than 1/2") and the filament melts up behind it and cools enough to lock up. If I do bigger prints with long runs it does fine, but it jams when doing denser infills or smaller objects with quick retractions. So, ordered some hot end barrels and a small spool of 2mm ID / 3mm OD PTFE tubing for future fixes. Probably just toss this hot end and replace it with something else at some point in the near future but when its not jamming the one I have prints so nice I'm not in a huge hurry.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 09:46PM |

Registered: 8 years ago Posts: 95 |

Quote

[email protected]

[imgur.com]

[imgur.com]

Well day three and couple headaches. I did not get enough socket head screw so I had used Philip head screws for the motor brackets now I can not tighten them. So tomorrow I will take some of the socket head screws out from the Y-axis rods and trade places with the mounts so I can get in and tighten them.

Also cracked the left Z-rod brace under the motor not bad and just in one spot but guess I'll be trying to print a new one soon.

I probably spent more time switching around screws and running down replacements than anything else.. I had lots either missing or the wrong size,,Not really complaining but you would figure that whoever stocks the kits has to take each size from separate containers . and instead of just dumping all in a bag,, put each in small zip bags that way they and us could keep track of what is what..it might save them some money also .. as I have a large amount of the smaller screws like 18mm & t-nuts left over.. anyway good luck.

Edited 1 time(s). Last edit at 07/24/2015 09:54PM by mike3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 10:42PM |

Registered: 9 years ago Posts: 44 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 10:49PM |

Registered: 8 years ago Posts: 430 |

Accidently broke a blade off the cool block cooling fan it was too loud from being unbalanced to use at all so I replaced it with one from a external cd-rom enclosure. This new one is so much quieter than the one that came with I wonder it it's moving enough air. How would I know if it's not cooling enough?

Newbie with Folgertech 2020 i3.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 10:53PM |

Registered: 8 years ago Posts: 367 |

Quote

zarnold16

quick question i accidently bought a piece of glass 9.5" x 9.5" for the heated bed. Is that too big or could I make it work?

The difficulty will be attaching it to the heated bed. It's about 8.5" x 8.5" so the glass will stick the edge by half an inch in each direction. It will be hard to clip in place.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 11:03PM |

Registered: 9 years ago Posts: 44 |

Quote

animoose

Quote

zarnold16

quick question i accidently bought a piece of glass 9.5" x 9.5" for the heated bed. Is that too big or could I make it work?

The difficulty will be attaching it to the heated bed. It's about 8.5" x 8.5" so the glass will stick the edge by half an inch in each direction. It will be hard to clip in place.

Could you loop tape underneath it? Or make an attachment from abs?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 11:05PM |

Registered: 8 years ago Posts: 430 |

Quote

zarnold16

quick question i accidently bought a piece of glass 9.5" x 9.5" for the heated bed. Is that too big or could I make it work?

I don't think you can without cutting it, it would be on top of the leveling screws. A glass cutter is only a few dollars and it's easy to do.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 11:08PM |

Registered: 8 years ago Posts: 35 |

Quote

zarnold16

quick question i accidently bought a piece of glass 9.5" x 9.5" for the heated bed. Is that too big or could I make it work?

Glass is pretty easy to cut. They have the cutters at most craft stores and places like Home Depot for 5-10 bucks. Probably take you all of 30 seconds to cut it to 8x8. At that larger size it wont fit right between the bed adjusting bolts at the corners. Even at 8x8 the glass is right up against the bolts, at least on mine. It will sit on top of the bolts and you won't be able to adjust it, which is an imperative operation to using the printer. It also won't heat right because it will be a few mm above the heat bed.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 11:12PM |

Registered: 9 years ago Posts: 44 |

Can I use the printer without the glass while I wait to get glass cutter?Quote

RedneckGeek

Quote

zarnold16

quick question i accidently bought a piece of glass 9.5" x 9.5" for the heated bed. Is that too big or could I make it work?

Glass is pretty easy to cut. They have the cutters at most craft stores and places like Home Depot for 5-10 bucks. Probably take you all of 30 seconds to cut it to 8x8. At that larger size it wont fit right between the bed adjusting bolts at the corners. Even at 8x8 the glass is right up against the bolts, at least on mine. It will sit on top of the bolts and you won't be able to adjust it, which is an imperative operation to using the printer. It also won't heat right because it will be a few mm above the heat bed.

Edited 1 time(s). Last edit at 07/24/2015 11:12PM by zarnold16.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 11:19PM |

Registered: 8 years ago Posts: 35 |

Quote

zarnold16

Can I use the printer without the glass while I wait to get glass cutter?Quote

RedneckGeek

Quote

zarnold16

quick question i accidently bought a piece of glass 9.5" x 9.5" for the heated bed. Is that too big or could I make it work?

Glass is pretty easy to cut. They have the cutters at most craft stores and places like Home Depot for 5-10 bucks. Probably take you all of 30 seconds to cut it to 8x8. At that larger size it wont fit right between the bed adjusting bolts at the corners. Even at 8x8 the glass is right up against the bolts, at least on mine. It will sit on top of the bolts and you won't be able to adjust it, which is an imperative operation to using the printer. It also won't heat right because it will be a few mm above the heat bed.

I don't think the heat bed is all that flat, at least mine wasn't. I wouldn't want to mess it up. I've seen people do it though. Think about the parts sticking to it and you trying to wedge them off with a metal scraper.... good chance to mess up your heat bed.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 11:22PM |

Registered: 8 years ago Posts: 35 |

Quote

zarnold16

Can I use the printer without the glass while I wait to get glass cutter?Quote

RedneckGeek

Quote

zarnold16

quick question i accidently bought a piece of glass 9.5" x 9.5" for the heated bed. Is that too big or could I make it work?

Glass is pretty easy to cut. They have the cutters at most craft stores and places like Home Depot for 5-10 bucks. Probably take you all of 30 seconds to cut it to 8x8. At that larger size it wont fit right between the bed adjusting bolts at the corners. Even at 8x8 the glass is right up against the bolts, at least on mine. It will sit on top of the bolts and you won't be able to adjust it, which is an imperative operation to using the printer. It also won't heat right because it will be a few mm above the heat bed.

Heres how to cut the glass:

[www.youtube.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 11:28PM |

Registered: 8 years ago Posts: 171 |

I'd just print on the bed. I've seen lots of videos of people doing it. Just be careful. That said, when I broke the first 8x10 piece of glass I had, I just stole another from a picture frame. Worked fine for pla. I clipped it on on three sides and it was fine.

Edited 1 time(s). Last edit at 07/24/2015 11:28PM by markts.

Edited 1 time(s). Last edit at 07/24/2015 11:28PM by markts.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 11:31PM |

Registered: 8 years ago Posts: 10 |

Quote

zarnold16

Can I use the printer without the glass while I wait to get glass cutter?

I would just buy a cheap 8x10 picture frame from the dollar store and use the glass from that. 8" is enough to fit between the leveling screws and there's enough clearance for the extra 2" on either side of the bed. I've never gotten a super clean cut using glass cutters, maybe because I have shaky hands.

Edited 1 time(s). Last edit at 07/24/2015 11:32PM by arxidon.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 24, 2015 11:37PM |

Registered: 9 years ago Posts: 44 |

That is what I did somewhat, I bought a 8x8 picture frame but didn't notice that the glass piece was bigger, aka 9.5x9.5. my printer comes tomorrow and that is why i'm asking all this because I bought everything before hand.Quote

arxidon

Quote

zarnold16

Can I use the printer without the glass while I wait to get glass cutter?

I would just buy a cheap 8x10 picture frame from the dollar store and use the glass from that. 8" is enough to fit between the leveling screws and there's enough clearance for the extra 2" on either side of the bed. I've never gotten a super clean cut using glass cutters, maybe because I have shaky hands.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 25, 2015 12:58AM |

Registered: 9 years ago Posts: 44 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 25, 2015 02:04AM |

Registered: 8 years ago Posts: 18 |

Quote

mike3

Thanks for the pix .. One question I see the extruder stepper is also plugged in reversed .. is that right and why is that..finally got everything wired.. almost ready to go. also I don't see anything in the Folger manuals about setting up the steppers I assume there must be a procedure .. Thanks .. Mike

It was pushing it instead of pulling so I switched it around, and you are supposed to set up the stepper's? I just felt my x axis motor get really hot, so I turned the voltage down untill it was much quiter which made it run cool.

Also how does everyone get their abs to stick? I got 2 1kg spools for $6 each from amazon, so I have plenty to waste. So far it doesn't want to stick to glass, and it doesn't stick to hairspray on the glass.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 25, 2015 05:08AM |

Registered: 8 years ago Posts: 276 |

Quote

RedneckGeek

Quote

therippa

Does anyone know what might be causing this waviness? I can't find it documented anywhere online...

Mine does that too and I'm using Cura. Its pretty symetrical and looks kind of like carbon fiber so I don't care, I won't spend any time trying to "fix" it.

I tried using cura, as someone else suggested, but the gcode it made didn't jive well with my x-axis home being at 200. I experimented with some other settings, and increasing the print speed solved it...but it also made the corners not sharp 90 degree anymore.

At least I know that some day if I become the father to a very fussy baby, I'll be prepared, because I went through the experience of building a 3d printer.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 25, 2015 07:59AM |

Registered: 8 years ago Posts: 95 |

Quote

sk8

Quote

mike3

Thanks for the pix .. One question I see the extruder stepper is also plugged in reversed .. is that right and why is that..finally got everything wired.. almost ready to go. also I don't see anything in the Folger manuals about setting up the steppers I assume there must be a procedure .. Thanks .. Mike

It was pushing it instead of pulling so I switched it around, and you are supposed to set up the stepper's? I just felt my x axis motor get really hot, so I turned the voltage down until it was much quieter which made it run cool.

Also how does everyone get their abs to stick? I got 2 1kg spools for $6 each from amazon, so I have plenty to waste. So far it doesn't want to stick to glass, and it doesn't stick to hairspray on the glass.

do you have a link to the cheap filament on Amazon? After doing some searching.. I found on the Folger Acrylic Manual step 52 how to set up the stepper voltage.. looking like you need to be careful not to short something out.. I haven't started printing yet but I bought a 3 pack of the purple glue stick at Walmart they say it make the ABS stick...

Never mind on the Cheap ABS on Amazon .. I found it and bought the last 2 rolls.. good deal..11.98 for 2 1kg rolls thanks...

Edited 3 time(s). Last edit at 07/25/2015 09:08AM by mike3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 25, 2015 08:13AM |

Registered: 8 years ago Posts: 121 |

Sorry, only registered users may post in this forum.