Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 27, 2015 09:14PM |

Registered: 8 years ago Posts: 121 |

So I have yet to figure out my X-home issue but decided to try some prints anyways. I printed out a 20x20x20 cube and ended up with 20.5x20.5x18.5 was not alarmed since I suspected my bed leveling sucked looks like my first layer is just getting smeared and not extruded plus I would get clicks from my extruder as it tried to pull more filament in while unable to push any out against the glass.

I had to keep pulling filament from the roll since it is not well routed yet. I went to print some guides I could bolt on to help guide it better thinking the 1.5 mm error on the Z would not matter for them. It was a 90 minute print (4 pieces off thingiverse) well 45 minutes into the print my print just stopped responding. Had to kill Repetier with task manager and cut power to the printer to get it to restart. In the error log I had an error for command block reset. I checked the Temps of my steppers while it was running and found my X stepper to be running at over 105 F (41 C). Could this explain my lock up?

Though they only hit %50 print completion they are thick enough to help guide the filament until I print better ones.

Maybe I should mention I have NOT tuned my steppers yet thinking I better get on that. Will take them off and hot glue over all the unneeded pins just to be safe.

Edited 1 time(s). Last edit at 07/27/2015 09:42PM by jasonsaffle13@gmail.com.

I had to keep pulling filament from the roll since it is not well routed yet. I went to print some guides I could bolt on to help guide it better thinking the 1.5 mm error on the Z would not matter for them. It was a 90 minute print (4 pieces off thingiverse) well 45 minutes into the print my print just stopped responding. Had to kill Repetier with task manager and cut power to the printer to get it to restart. In the error log I had an error for command block reset. I checked the Temps of my steppers while it was running and found my X stepper to be running at over 105 F (41 C). Could this explain my lock up?

Though they only hit %50 print completion they are thick enough to help guide the filament until I print better ones.

Maybe I should mention I have NOT tuned my steppers yet thinking I better get on that. Will take them off and hot glue over all the unneeded pins just to be safe.

Edited 1 time(s). Last edit at 07/27/2015 09:42PM by jasonsaffle13@gmail.com.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 27, 2015 09:19PM |

Registered: 8 years ago Posts: 95 |

Quote

wderoxas

Quote

mike3

Quote

mike3

Quote

therippa

Quote

mike3

Well after several days of great printing.. my extruder stopped heating up... has anyone else had this problem.. I can still home and move x,y,z manually.. when I check the contacts on the ramps board there is no voltage... Can anyone help,, can I hook up the Extruder heater wires directly to 12v to see if it is working ..and how can you check the thermistor.. and if these both check working .. what could be the problem? thanks mike

Have you recently started using your heatbed as well? I was printing PLA fine without the bed turned on, and decided try with it on. Repetier would report "Extruder Heating", but the temp wasn't rising on the hotend. Turns out your heatbed needs to come to temperature before the hotend starts heating up, and I wasn't being patient enough to realize this.

no i have been using the bed all along... it didn't matter if the bed was up to temp... as soon as the extruder was ... it would start printing now the bed temp will go past its set value but the extruder never heats at all.. and printing never starts

I reflashed the Arduino Board .. but it still dosn't heat up

Did you physically check if the hot end is heating? If it does, yet its reporting it doesn't then likely your thermistor is the problem.

If it doesnt heat up, and there's a voltage on the hotend terminal at ramps, then your cartridge have a problem.

If it doesnt heat up, and there's no voltage on terminal at ramps yet repetier reports its heating up extruder, then its somewhere on the extruder fet or even at its gate pin that arduino is supposed to drive.

No the hot end is not heating and it dosn't report its is heating.. no voltage at the hotend terminals .. also the heat bed goes past its set value..

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 27, 2015 09:45PM |

Registered: 8 years ago Posts: 81 |

Quote

[email protected]

So I have yet to figure out my X-home issue but decided to try some prints anyways. I printed out a 20x20x20 cube and ended up with 20.5x20.5x18.5 was not alarmed since I suspected my bed leveling sucked looks like my first layer is just getting smeared and not extruded plus I would get clicks from my extruder as it tried to pull more filament in while unable to push any out against the glass.

I had to keep pulling filament from the roll since it is not well routed yet. I went to print some guides I could bolt on to help guide it better thinking the 1.5 mm error on the Z would not matter for them. It was a 90 minute print (4 pieces off thingiverse) well 45 minutes into the print my print just stopped responding. Had to kill Repetier with task manager and cut power to the printer to get it to restart. In the error log I had an error for command block reset. I checked the Temps of my steppers while it was running and found my X stepper to be running at over 105 F (41 C). Could this explain my lock up?

Though they only hit %50 print completion they are thick enough to help guide the filament until I print better ones.

Since your using repetier, then i assume you are currently printing through USB. A lot of screw ups can occur with this setup, application lock-ups, temporary freezes, etc on host pc can affect your prints. With the exception of octoprint running on a raspberrypi, i have never ran a long print again with a destop pc via USB. I only use them now to test out new settings.

If you have an LCD controller with built-in sd card reader, you'll be better off using that. Slice your model then save the gcode file generated on your SD card with a card reader/writer. Insert the sd card to the lcd controller then print using the lcd menus.

I think its more appropriate to say that overheated drivers causes the lock-up. Its only for a few seconds though and it will resume as soon as the driver cooled up a little. It could get repetitive, ruining your print so better setup a cooling fan on your drivers.

Stepper motors are designed to continue working even when hot. Unless the lamination on the stepper coil melted causing the coils to short, it will still work.

In your case, it was repetier locking up. So if you have it, i advise you to use your lcd controller's sd card reader.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 27, 2015 09:48PM |

Registered: 8 years ago Posts: 121 |

I have the LCD and card reader had not installed them yet. And uhm ye about the lock up on the lap top "MAYBE" I was also watching archer during this lock up event. So yea what'd we learn?  Where can I find information on how to attatch the LCD?

Where can I find information on how to attatch the LCD?

Edited 1 time(s). Last edit at 07/27/2015 09:49PM by jasonsaffle13@gmail.com.

Where can I find information on how to attatch the LCD?

Where can I find information on how to attatch the LCD?Edited 1 time(s). Last edit at 07/27/2015 09:49PM by jasonsaffle13@gmail.com.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 27, 2015 09:53PM |

Registered: 8 years ago Posts: 367 |

Quote

cvanclev

Hey all, really need some advice here. Pretty discouraged.

I shorted my stepper driver in the initial build out and severely damaged the Arduino Mega. I ordered a new Mega, which I then installed and instantly smoked as well. Two Megas down. I then ordered an all new RAMPS/Mega combo, went to install today, checked EVERYTHING with a multimeter before powering on, even assembled with an ESD bracelet. Loaded Marlin, everything worked great. Then I powered down and installed my 4 "good" drivers. Blew the Mega on powerup. F*CK. Three Megas down. Looks like my drivers were actually the problem. I got rid of the driver I blew initially as soon as it happened, and used the spare in my kit. So, what do I do now? 4 new drivers, a second new RAMPS, and a fourth new Mega? Or four new drivers, and a FOURTH new Mega? Hard to tell if my new Ramps is damaged. animoose.. bought the same RAMPS you did on Amazon. Much cleaner and color coded. Do I get Folgertech on the line and have them send me 4 new drivers and a new Mega? I'm in the hole here pretty deep. As an electrical/robotics engineer, I understand the problem with the initial short, but am very upset that this last round occurred, I took all the preventative steps and the drivers damaged my equipment.

Really sorry to hear this. Hang in there. One thing you could do on the next iteration is to attach things one at a time, for example add one stepper driver, then the connections to its motors, then the next one and so on, then the thermistors, then the endstops. Turn it off between each change. That way if there is still something that could harm you board (like a short in wires connecting the pieces), you'll have narrowed it down. With your background, you'd probably thought of this, but maybe it'll help. You could also do things like checking you see the expected resistance for various things measured before connecting them (e.g. around 2-4 ohms for the hot end and the heated bed, around 100k (IIRC) for the thermistors. And also do a visual check on everything, to make sure there's nothing shorting out, no nicked cables, nothing touching the frame and so on. Also that your PSU is giving out 12V.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 27, 2015 09:55PM |

Registered: 8 years ago Posts: 81 |

Quote

mike3

Quote

wderoxas

Quote

mike3

Quote

mike3

Quote

therippa

Quote

mike3

Well after several days of great printing.. my extruder stopped heating up... has anyone else had this problem.. I can still home and move x,y,z manually.. when I check the contacts on the ramps board there is no voltage... Can anyone help,, can I hook up the Extruder heater wires directly to 12v to see if it is working ..and how can you check the thermistor.. and if these both check working .. what could be the problem? thanks mike

Have you recently started using your heatbed as well? I was printing PLA fine without the bed turned on, and decided try with it on. Repetier would report "Extruder Heating", but the temp wasn't rising on the hotend. Turns out your heatbed needs to come to temperature before the hotend starts heating up, and I wasn't being patient enough to realize this.

no i have been using the bed all along... it didn't matter if the bed was up to temp... as soon as the extruder was ... it would start printing now the bed temp will go past its set value but the extruder never heats at all.. and printing never starts

I reflashed the Arduino Board .. but it still dosn't heat up

Did you physically check if the hot end is heating? If it does, yet its reporting it doesn't then likely your thermistor is the problem.

If it doesnt heat up, and there's a voltage on the hotend terminal at ramps, then your cartridge have a problem.

If it doesnt heat up, and there's no voltage on terminal at ramps yet repetier reports its heating up extruder, then its somewhere on the extruder fet or even at its gate pin that arduino is supposed to drive.

No the hot end is not heating and it dosn't report its is heating.. no voltage at the hotend terminals .. also the heat bed goes past its set value..

That's strange. From what i remember, on the manual controls tab of repetier, there is a status display at the top. It shows whether its heating bed then heating extruder.. if you have an lcd, it also shows its status.

Is the correct extruder selected on repetier? Also, if you enable the hotend on repetiers manual control, does your hotend doesnt heat-up too?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 27, 2015 09:56PM |

Registered: 8 years ago Posts: 367 |

Quote

brian0

I'm having one helluva time getting my new machine to work properly, specifically getting everything set to home. Everything assembled relatively well. Where exactly is home on this machine? I would imagine the far back right corner, but I'm not sure. I've followed some of the steps previous in this thread, but I still can't figure out what's going on.

My setup:

-Standard build according to the FT-provided instructions

-X endstop at the far right (when looking at the printer)

-Y endstop at the far back (triggered by one of the bed bearing mounts)

-Z endstop under the 3d printed mount on the right

My Repetier-Host is setup with:

Printer shape tab

Home X: Min

Home Y: Min

Home Z: Min

X min: 0

X max: 200

Y min: 0

Y Max: 200

Bed Left: 0

Bed Front: 0

Print area width: 200

Print area depth: 200

Print area height: 185

Basically, everything is configured as in the config guide.

I've trimmed my X/Y/E stepper pots to 0.35, and Z to 0.55

All that to say, I'm /not/ running the FT-provided firmware, but rather the Marlin firmware linked previously in this thread.

When a print job is started (I'm trying to do little 10mm cubes at first), everything looks good until the point where it draws the loop around the base of the object. Then it runs off far to the X left and pretends it's printing in empty space, with no bed underneath. Fortunately (?) the extruder doesn't pull any filament when it is in fact doing what would be printing.

I'd like to get this thing working today. What do?

Try changing the Repetier home to X max. That will set home to the position with the print head over the front right hand corner of the bed and all three limit switches activated. I have mine set up the same way. You might also need #define INVERT_X_DIR false, and #define X_HOME_DIR 1. That's "1" not "-1".

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 27, 2015 10:13PM |

Registered: 8 years ago Posts: 81 |

Quote

[email protected]

I have the LCD and card reader had not installed them yet. And uhm ye about the lock up on the lap top "MAYBE" I was also watching archer during this lock up event. So yea what'd we learn?Where can I find information on how to attatch the LCD?

I think i used tom's guide at youtube for the lcd setup. If your using the 12864 lcd, youre going to need a newer marlin firmware. If its the smaller lcd, then folgertech's firmware supports it.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 27, 2015 10:56PM |

Registered: 8 years ago Posts: 2 |

Quote

animoose

Try changing the Repetier home to X max. That will set home to the position with the print head over the front right hand corner of the bed and all three limit switches activated. I have mine set up the same way. You might also need #define INVERT_X_DIR false, and #define X_HOME_DIR 1. That's "1" not "-1".

Unfortunately, that's how everything's already configured.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 27, 2015 10:58PM |

Registered: 8 years ago Posts: 81 |

Quote

animoose

Quote

brian0

I'm having one helluva time getting my new machine to work properly, specifically getting everything set to home. Everything assembled relatively well. Where exactly is home on this machine? I would imagine the far back right corner, but I'm not sure. I've followed some of the steps previous in this thread, but I still can't figure out what's going on.

My setup:

-Standard build according to the FT-provided instructions

-X endstop at the far right (when looking at the printer)

-Y endstop at the far back (triggered by one of the bed bearing mounts)

-Z endstop under the 3d printed mount on the right

My Repetier-Host is setup with:

Printer shape tab

Home X: Min

Home Y: Min

Home Z: Min

X min: 0

X max: 200

Y min: 0

Y Max: 200

Bed Left: 0

Bed Front: 0

Print area width: 200

Print area depth: 200

Print area height: 185

Basically, everything is configured as in the config guide.

I've trimmed my X/Y/E stepper pots to 0.35, and Z to 0.55

All that to say, I'm /not/ running the FT-provided firmware, but rather the Marlin firmware linked previously in this thread.

When a print job is started (I'm trying to do little 10mm cubes at first), everything looks good until the point where it draws the loop around the base of the object. Then it runs off far to the X left and pretends it's printing in empty space, with no bed underneath. Fortunately (?) the extruder doesn't pull any filament when it is in fact doing what would be printing.

I'd like to get this thing working today. What do?

Try changing the Repetier home to X max. That will set home to the position with the print head over the front right hand corner of the bed and all three limit switches activated. I have mine set up the same way. You might also need #define INVERT_X_DIR false, and #define X_HOME_DIR 1. That's "1" not "-1".

In addition, setting your x to home at x max ( endstop location to the right as in your setup), requires that

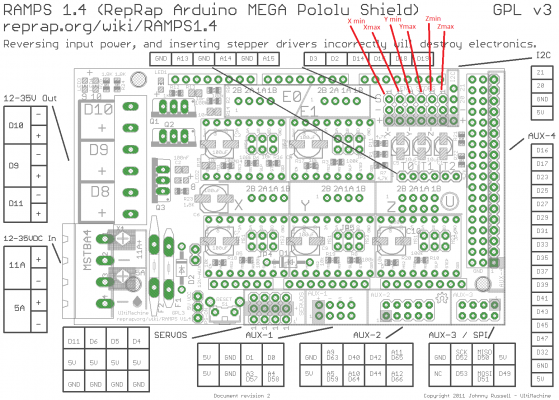

1) your x endstop connector is plugged in at xmax on ramps board

2) //#define DISABLE_MAX_ENDSTOPS and //#define DISABLE _MIN_ENDSTOPS. This ought to be commented.

3) #define X_HOME_DIR 1. This sets firmware home at x max as what animoose mentioned.

#define INVERT_(insert axis here)_DIR affects the rotation direction of your motor. Without changing this setting, you can get the same effect if you flip the motor connector on the ramps board.

FT's instruction were okay except for setting the x axis. If your going to place the endstop at the right, you ought to configure to the firmware to home at x max. While you can accomplish homing to the x right, while firmwares home is at x min, x endstop connected at x min also, and motor rotation dir set appropriately, this will result in mirrored prints.

The default mins on the cartesian plane as shown by the arrows at repetiers or slic3rs platter, falls at the lower left corner of the bed. So if you want your print head to fall in the same location when homing, then,

1) all firmwares home must be set to min

2) all repetiers home must be set to min3.

3) //#define DISABLE _MIN_ENDSTOPS should be commented

4) x endstop at the left, y endstop at the back, z endstop at the bottom of the z rod.

5) endstop connectors at ramps should connect to xmin, ymin, zmin

6) motors rotation set appropriately. You can either change the #define INVERT_(insert axis here)_DIR or flip the connectors at ramps if its not moving on the correct direction. Also keep in mind that the arrows on repetier, represents how the head will move with reference to the bed. Its easy to figure out with x axis but for y axis, if you press the arrow up, your bed will move towards you, placing the head at the back edge of the bed.

If you want to retain the x endstop at the right, then,

1) firmware must home at xmax, ymin, zmin

2) repetier must home at xmax, ymin, zmin

3) //#define DISABLE _MIN_ENDSTOPS and //#define DISABLE _MAX_ENDSTOPS must be commented

4) x endstop at the right, y endstop at the back, z endstop at bottom of the z rod.

5) endstop connectors for x,y,z must connect to ramps xmax, ymin and zmin respectively.

6) motor roation set appropriately.

Its lenghty, but hope it helps the rest of the guys.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 27, 2015 11:21PM |

Registered: 8 years ago Posts: 5 |

Quote

wderoxas

Quote

animoose

Quote

brian0

I'm having one helluva time getting my new machine to work properly, specifically getting everything set to home. Everything assembled relatively well. Where exactly is home on this machine? I would imagine the far back right corner, but I'm not sure. I've followed some of the steps previous in this thread, but I still can't figure out what's going on.

My setup:

-Standard build according to the FT-provided instructions

-X endstop at the far right (when looking at the printer)

-Y endstop at the far back (triggered by one of the bed bearing mounts)

-Z endstop under the 3d printed mount on the right

My Repetier-Host is setup with:

Printer shape tab

Home X: Min

Home Y: Min

Home Z: Min

X min: 0

X max: 200

Y min: 0

Y Max: 200

Bed Left: 0

Bed Front: 0

Print area width: 200

Print area depth: 200

Print area height: 185

Basically, everything is configured as in the config guide.

I've trimmed my X/Y/E stepper pots to 0.35, and Z to 0.55

All that to say, I'm /not/ running the FT-provided firmware, but rather the Marlin firmware linked previously in this thread.

When a print job is started (I'm trying to do little 10mm cubes at first), everything looks good until the point where it draws the loop around the base of the object. Then it runs off far to the X left and pretends it's printing in empty space, with no bed underneath. Fortunately (?) the extruder doesn't pull any filament when it is in fact doing what would be printing.

I'd like to get this thing working today. What do?

Try changing the Repetier home to X max. That will set home to the position with the print head over the front right hand corner of the bed and all three limit switches activated. I have mine set up the same way. You might also need #define INVERT_X_DIR false, and #define X_HOME_DIR 1. That's "1" not "-1".

In addition, setting your x to home at x max ( endstop location to the right as in your setup), requires that

1) your x endstop connector is plugged in at xmax on ramps board

2) //#define DISABLE_MAX_ENDSTOPS and //#define DISABLE _MIN_ENDSTOPS. This ought to be commented.

3) #define X_HOME_DIR 1. This sets firmware home at x max as what animoose mentioned.

#define INVERT_(insert axis here)_DIR affects the rotation direction of your motor. Without changing this setting, you can get the same effect if you flip the motor connector on the ramps board.

FT's instruction were okay except for setting the x axis. If your going to place the endstop at the right, you ought to configure to the firmware to home at x max. While you can accomplish homing to the x right, while firmwares home is at x min, x endstop connected at x min also, and motor rotation dir set appropriately, this will result in mirrored prints.

The default mins on the cartesian plane as shown by the arrows at repetiers or slic3rs platter, falls at the lower left corner of the bed. So if you want your print head to fall in the same location when homing, then,

1) all firmwares home must be set to min

2) all repetiers home must be set to min3.

3) //#define DISABLE _MIN_ENDSTOPS should be commented

4) x endstop at the left, y endstop at the back, z endstop at the bottom of the z rod.

5) endstop connectors at ramps should connect to xmin, ymin, zmin

6) motors rotation set appropriately. You can either change the #define INVERT_(insert axis here)_DIR or flip the connectors at ramps if its not moving on the correct direction. Also keep in mind that the arrows on repetier, represents how the head will move with reference to the bed. Its easy to figure out with x axis but for y axis, if you press the arrow up, your bed will move towards you, placing the head at the back edge of the bed.

If you want to retain the x endstop at the right, then,

1) firmware must home at xmax, ymin, zmin

2) repetier must home at xmax, ymin, zmin

3) //#define DISABLE _MIN_ENDSTOPS and //#define DISABLE _MAX_ENDSTOPS must be commented

4) x endstop at the right, y endstop at the back, z endstop at bottom of the z rod.

5) endstop connectors for x,y,z must connect to ramps xmax, ymin and zmin respectively.

6) motor roation set appropriately.

Its lenghty, but hope it helps the rest of the guys.

So your x-endstop connector is in the second to last slot instead of the very last (7th) slot as presented in the instructions? I have been having this problem with my x-carriage not homing and after I switched the endstop to the 6th slot it works! Can you guys confirm that?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 27, 2015 11:50PM |

Registered: 8 years ago Posts: 367 |

@samaral: yes you can connect the X end stop in the 6th position, where the one nearest the edge of the board is 1st and the one nearest the middle is 7th in the way Folger describe it. 6th position is for the X max endstop, 7th for X min.

(Extra note: not important since you have it working.

You can alternatively wire it up as the guide shows and change the firmware config by swapping the pin assignments for X_MIN_PIN and X_MAX_PIN in pins.h. If you do it this way, be aware that these settings occur multiple times on pins.h for different boards. The lines I changed were somewhere around line 300. The latest Marlin may be different.)

See my blog at [moosteria.blogspot.com].

(Extra note: not important since you have it working.

You can alternatively wire it up as the guide shows and change the firmware config by swapping the pin assignments for X_MIN_PIN and X_MAX_PIN in pins.h. If you do it this way, be aware that these settings occur multiple times on pins.h for different boards. The lines I changed were somewhere around line 300. The latest Marlin may be different.)

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 27, 2015 11:55PM |

Registered: 8 years ago Posts: 81 |

Quote

samaral

Quote

wderoxas

Quote

animoose

Quote

brian0

I'm having one helluva time getting my new machine to work properly, specifically getting everything set to home. Everything assembled relatively well. Where exactly is home on this machine? I would imagine the far back right corner, but I'm not sure. I've followed some of the steps previous in this thread, but I still can't figure out what's going on.

My setup:

-Standard build according to the FT-provided instructions

-X endstop at the far right (when looking at the printer)

-Y endstop at the far back (triggered by one of the bed bearing mounts)

-Z endstop under the 3d printed mount on the right

My Repetier-Host is setup with:

Printer shape tab

Home X: Min

Home Y: Min

Home Z: Min

X min: 0

X max: 200

Y min: 0

Y Max: 200

Bed Left: 0

Bed Front: 0

Print area width: 200

Print area depth: 200

Print area height: 185

Basically, everything is configured as in the config guide.

I've trimmed my X/Y/E stepper pots to 0.35, and Z to 0.55

All that to say, I'm /not/ running the FT-provided firmware, but rather the Marlin firmware linked previously in this thread.

When a print job is started (I'm trying to do little 10mm cubes at first), everything looks good until the point where it draws the loop around the base of the object. Then it runs off far to the X left and pretends it's printing in empty space, with no bed underneath. Fortunately (?) the extruder doesn't pull any filament when it is in fact doing what would be printing.

I'd like to get this thing working today. What do?

Try changing the Repetier home to X max. That will set home to the position with the print head over the front right hand corner of the bed and all three limit switches activated. I have mine set up the same way. You might also need #define INVERT_X_DIR false, and #define X_HOME_DIR 1. That's "1" not "-1".

In addition, setting your x to home at x max ( endstop location to the right as in your setup), requires that

1) your x endstop connector is plugged in at xmax on ramps board

2) //#define DISABLE_MAX_ENDSTOPS and //#define DISABLE _MIN_ENDSTOPS. This ought to be commented.

3) #define X_HOME_DIR 1. This sets firmware home at x max as what animoose mentioned.

#define INVERT_(insert axis here)_DIR affects the rotation direction of your motor. Without changing this setting, you can get the same effect if you flip the motor connector on the ramps board.

FT's instruction were okay except for setting the x axis. If your going to place the endstop at the right, you ought to configure to the firmware to home at x max. While you can accomplish homing to the x right, while firmwares home is at x min, x endstop connected at x min also, and motor rotation dir set appropriately, this will result in mirrored prints.

The default mins on the cartesian plane as shown by the arrows at repetiers or slic3rs platter, falls at the lower left corner of the bed. So if you want your print head to fall in the same location when homing, then,

1) all firmwares home must be set to min

2) all repetiers home must be set to min3.

3) //#define DISABLE _MIN_ENDSTOPS should be commented

4) x endstop at the left, y endstop at the back, z endstop at the bottom of the z rod.

5) endstop connectors at ramps should connect to xmin, ymin, zmin

6) motors rotation set appropriately. You can either change the #define INVERT_(insert axis here)_DIR or flip the connectors at ramps if its not moving on the correct direction. Also keep in mind that the arrows on repetier, represents how the head will move with reference to the bed. Its easy to figure out with x axis but for y axis, if you press the arrow up, your bed will move towards you, placing the head at the back edge of the bed.

If you want to retain the x endstop at the right, then,

1) firmware must home at xmax, ymin, zmin

2) repetier must home at xmax, ymin, zmin

3) //#define DISABLE _MIN_ENDSTOPS and //#define DISABLE _MAX_ENDSTOPS must be commented

4) x endstop at the right, y endstop at the back, z endstop at bottom of the z rod.

5) endstop connectors for x,y,z must connect to ramps xmax, ymin and zmin respectively.

6) motor roation set appropriately.

Its lenghty, but hope it helps the rest of the guys.

So your x-endstop connector is in the second to last slot instead of the very last (7th) slot as presented in the instructions? I have been having this problem with my x-carriage not homing and after I switched the endstop to the 6th slot it works! Can you guys confirm that?

My endstop switch is currently at the right, so my x endstop connector is at ramps' x max, firmware's x home set to max (1) and repetier's x home also at x max. Yes its the 6th ( 2nd from the last) connector if count starts from the I2C pin connector..

Here is a picture:

Edited 1 time(s). Last edit at 07/28/2015 12:05AM by wderoxas.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 28, 2015 06:37AM |

Registered: 8 years ago Posts: 121 |

Is there a program more stable for printing from my windows 7 laptop then Repetier? I do not want to mess with python right now so I guess that rules out Octoprint. Little nervous about switching over to the LCD/SD reader. I need to trim up my X and Y values and level my bed better so right now using Repetier feels safer with the manual controls handy. I don't trust my X-axis not homing like my Y and Z does but running long prints with my laptop/repetier did not end well or does one lock up not mean anythign and just try it again anyways? (without the web browsing and watching videos at the same time. Yeah I see what a bad idea that was now!)

Edited 1 time(s). Last edit at 07/28/2015 06:38AM by jasonsaffle13@gmail.com.

Edited 1 time(s). Last edit at 07/28/2015 06:38AM by jasonsaffle13@gmail.com.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 28, 2015 07:45AM |

Registered: 8 years ago Posts: 95 |

OK I am trying to Use my 2004 smart lcd instead of my laptop.to see if thats the problem. so how do I get the file on the sd card when I click on the save for SD a little window pops up with options what do I select so it will show up on the Card LCD menu ? And print

Edited 1 time(s). Last edit at 07/28/2015 07:45AM by mike3.

Edited 1 time(s). Last edit at 07/28/2015 07:45AM by mike3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 28, 2015 09:19AM |

Registered: 8 years ago Posts: 135 |

Quote

dbrewski

Quote

mel0n

Quote

Lagomorph

I'll look into that. How did you attach yours? Do you leave off the heatsink and attach it like the stock hot end or do you need something else to hold it?

I made one of these : [www.thingiverse.com]

It has a couple issues, and I am working on improvements, though for now, it seems to be working pretty good.

read earlier in the thread for more information. I posted a bunch in this thread about my clogging issues.

If you don't mind me asking, what issues are you having with the current design?

I am having a hard time getting proper tension on the tensioner pulley. I basically have to tighten it to the point where it makes my motor skip to get enough bite on the filament. Then I had to up my stepper voltage to the extruder by a lot. It runs REALLY HOT, but it doesn't skip.... much. I had fine tuned the Esteps and flow/extrusion multiplier to compensate for a lack of push on the filament. I just got in some more M3 bolts the other day and I am trying to find a bigger/stronger spring to hopefully give me some more adjustment over tension. Overall I like the design and it works well with the hot end design, but I am having issues with the direct drive extruder exclusively.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 28, 2015 11:54AM |

Registered: 9 years ago Posts: 41 |

I never tested it with the smaller stepper motor. I designed it using a stepper motor with a lot more torque, but I know of others that have used the smaller stepper motor that came with the kit and had no problems. This might sound crazy, but try using a prefilter on the filament with a little bit of canola or olive oil to lubricate the filament.Filter I don't know if dust was getting into my hotend or if the PLA I was using needed a little lubrication to flow smoothly. I was having all kinds of jams and extruder clicking and was about to go crazy trying to figure it out. I was originally using a wade's big gear set up that had so much bite and torque that it would twist the filament in the extruder trying to push the filament through. After installing the pre filter and lubrication, I was able to drastically reduce my voltage to my stepper motor and its been running great ever since. I just finished a 13 hour print and I was astonished such a simple fix made such a huge difference.

A few other things you might want to check is if the grooved bearing is allowed to rotate freely, the idler is allowed to move freely, and if the spring is actually forcing the idler into the toothed gear. I had to clean up my print a little to get everything to move like it should. I had to go through a couple of iterations to get make sure there was enough clearance when installed and since no two printers are the same there could still be some interference.\

Let me know if that helps. I was also working on a geared design using some of the FolgerTech original equipment. I wanted something that would give me more torque because of the jams I was experiencing. Now that I have my extruder running well I put the design on the back burner.

A few other things you might want to check is if the grooved bearing is allowed to rotate freely, the idler is allowed to move freely, and if the spring is actually forcing the idler into the toothed gear. I had to clean up my print a little to get everything to move like it should. I had to go through a couple of iterations to get make sure there was enough clearance when installed and since no two printers are the same there could still be some interference.\

Let me know if that helps. I was also working on a geared design using some of the FolgerTech original equipment. I wanted something that would give me more torque because of the jams I was experiencing. Now that I have my extruder running well I put the design on the back burner.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 28, 2015 01:14PM |

Registered: 8 years ago Posts: 135 |

Quote

dbrewski

I never tested it with the smaller stepper motor. I designed it using a stepper motor with a lot more torque, but I know of others that have used the smaller stepper motor that came with the kit and had no problems. This might sound crazy, but try using a prefilter on the filament with a little bit of canola or olive oil to lubricate the filament.Filter I don't know if dust was getting into my hotend or if the PLA I was using needed a little lubrication to flow smoothly. I was having all kinds of jams and extruder clicking and was about to go crazy trying to figure it out. I was originally using a wade's big gear set up that had so much bite and torque that it would twist the filament in the extruder trying to push the filament through. After installing the pre filter and lubrication, I was able to drastically reduce my voltage to my stepper motor and its been running great ever since. I just finished a 13 hour print and I was astonished such a simple fix made such a huge difference.

A few other things you might want to check is if the grooved bearing is allowed to rotate freely, the idler is allowed to move freely, and if the spring is actually forcing the idler into the toothed gear. I had to clean up my print a little to get everything to move like it should. I had to go through a couple of iterations to get make sure there was enough clearance when installed and since no two printers are the same there could still be some interference.\

Let me know if that helps. I was also working on a geared design using some of the FolgerTech original equipment. I wanted something that would give me more torque because of the jams I was experiencing. Now that I have my extruder running well I put the design on the back burner.

Cool, I will give your suggestions a try. If I pushed on the filament it would come out no problem, so I think its a bite/grip/torque issue. it was so tight that at one point it was just grinding up filament, but I cleaned out the teeth before trying again. I currently have it printing really well, but that motor is just WAY too hot. I also had to clean up the parts a bit with a file, and the v-pully/bearing is rotating pretty well. Since I have it printing really well, I have been reluctant to take it apart again. I will be taking it apart and cleaning it all up/adding some of your suggestions next time I change filament. I got my bolts, but none of them are longer, so I will order some 50mm-60mm M3 bolts from McMaster tonight as well. I will start a new thread about it once I make the revisions as to not clog up this already clogged thread (people still posting about the x-axis problems that have been resolved multiple times, etc.).

Edited 1 time(s). Last edit at 07/28/2015 01:16PM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 28, 2015 05:12PM |

Registered: 9 years ago Posts: 44 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 28, 2015 05:23PM |

Registered: 8 years ago Posts: 121 |

Mine did that I had to flip the extruder plug wires. I took the 2 screws off that held the hot end on and watched which way it turned when I commanded it. Though as i get more familiar with the configuration file i bet there is an extruder direction 1 or -1 line that would do it too I bet.

Edited 1 time(s). Last edit at 07/28/2015 05:31PM by jasonsaffle13@gmail.com.

Edited 1 time(s). Last edit at 07/28/2015 05:31PM by jasonsaffle13@gmail.com.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 28, 2015 06:19PM |

Registered: 9 years ago Posts: 44 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 28, 2015 07:27PM |

Registered: 8 years ago Posts: 27 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 28, 2015 08:40PM |

Registered: 8 years ago Posts: 367 |

Quote

ejnelson

Anyone tried printing any exotic filaments or know what the hot end can handle? It is the Mk7 right? I'm thinking about buying some taulman bridge, any experiences anybody?

No experiences yet. I bought small samples of PETG and a PLA/PHA blend (supposed to be a bit less brittle than plain PLA), and I'm going to try them out next time I change filament.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 28, 2015 09:15PM |

Registered: 8 years ago Posts: 81 |

Quote

animoose

Quote

ejnelson

Anyone tried printing any exotic filaments or know what the hot end can handle? It is the Mk7 right? I'm thinking about buying some taulman bridge, any experiences anybody?

No experiences yet. I bought small samples of PETG and a PLA/PHA blend (supposed to be a bit less brittle than plain PLA), and I'm going to try them out next time I change filament.

Just had my hot-end trashed out after much abuse. A very bad clog of molten PLA creeped up until the top of the hotend after god-knows-how-many hours of "air printing" when i left it with a job overnight. Had no choice but to disassemble the hotend, and guess what, destroyed the 2mm inner/3mm outer PTFE lining inside it.

So, if you have plans to print with plastics that needs more than 250'C, you really need to reconsider.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 28, 2015 09:20PM |

Registered: 8 years ago Posts: 121 |

So I completed my first real print tonight!!! Hour and 10 minutes! A large L like filament guide. I had followed Tom's advice [youtu.be] on how to tune my steppers plus I re leveled my bed. I turned my X and Z stepper drivers about 1/4 turn counter clockwise. My Z is now almost cool to the touch and my X while better is a little warm. So the thing I learned tonight is do not add a blowing fan during a print!! I pointed it at my X stepper motor and yes it cooled down the motor but it also caused my print on that end to lift off the bed a little (still usable print though). I need to print and check another cube and also need to figure out how to center my prints. In the Y it is always much closer to the back of the bed then the front (endstop on the right hand rod near the power supply in the back). Home for me is front left corner for X and Y. So goal for tomorrow is better tuning so I can print out some spare parts like the X carriage brackets with screw holes to hold bearings better.

Does anyone have a file for the X under motor mounts? I cracked one a little and would like to have son in law mill me one or I may try to print one.

Does anyone have a file for the X under motor mounts? I cracked one a little and would like to have son in law mill me one or I may try to print one.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 28, 2015 10:01PM |

Registered: 8 years ago Posts: 3 |

First post...

I've been watching the 3D printers for years, mostly RepRap kits, but never could figure out realistically what I would do with one, especially for the cost and limited configurability. A couple weeks ago, I realized I actually have a project that would be perfect for 3D prints, some customized Lego compatible pieces that will hold various electronic items for grandkids robotics Hummingbird Duo boards. I stumbled across the FolgerTech 2020, great price and can be expanded/modified if the mood suits me. I ordered the kit + LCD panel from Ebay, received about 10 days later (apparently held up due to being out of stock on an item or few). I started putting it together this past Thursday evening and wrapped up assembly Saturday evening, probably around 8 or 10 hours. Had a couple hours Sunday getting it running; Ubuntu Linux laptop, Repetier, etc., per config guide, although Slicer wasn't installed by default so I presently have only Cura available.

I was able to manually, via Repetier, move all axes, heat the bed and nozzle, pushed through a little bit of filament, so believe that all works to at least some degree. However, I'm having some issues with the X axis not working well (maybe homing related, seems to be a common mention on last couple pages and I couldn't get it to move right to home, just moved a short bit to the left instead). Also, the controls for the extruder seemed backwards, e.g., click on the up arrow to push filament down, down arrow to pull up. Hoping I have some time to begin troubleshooting and tuning this weekend. Definitely need to read through this entire thread.

FolgerTech 2020 i3

Home designed and built CNC router

800x600 80watt laser engraver

I've been watching the 3D printers for years, mostly RepRap kits, but never could figure out realistically what I would do with one, especially for the cost and limited configurability. A couple weeks ago, I realized I actually have a project that would be perfect for 3D prints, some customized Lego compatible pieces that will hold various electronic items for grandkids robotics Hummingbird Duo boards. I stumbled across the FolgerTech 2020, great price and can be expanded/modified if the mood suits me. I ordered the kit + LCD panel from Ebay, received about 10 days later (apparently held up due to being out of stock on an item or few). I started putting it together this past Thursday evening and wrapped up assembly Saturday evening, probably around 8 or 10 hours. Had a couple hours Sunday getting it running; Ubuntu Linux laptop, Repetier, etc., per config guide, although Slicer wasn't installed by default so I presently have only Cura available.

I was able to manually, via Repetier, move all axes, heat the bed and nozzle, pushed through a little bit of filament, so believe that all works to at least some degree. However, I'm having some issues with the X axis not working well (maybe homing related, seems to be a common mention on last couple pages and I couldn't get it to move right to home, just moved a short bit to the left instead). Also, the controls for the extruder seemed backwards, e.g., click on the up arrow to push filament down, down arrow to pull up. Hoping I have some time to begin troubleshooting and tuning this weekend. Definitely need to read through this entire thread.

FolgerTech 2020 i3

Home designed and built CNC router

800x600 80watt laser engraver

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 28, 2015 10:04PM |

Registered: 8 years ago Posts: 430 |

Quote

ejnelson

Anyone tried printing any exotic filaments or know what the hot end can handle? It is the Mk7 right? I'm thinking about buying some taulman bridge, any experiences anybody?

I have used PETG if that's exotic. [forums.reprap.org]

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 28, 2015 11:25PM |

Registered: 8 years ago Posts: 285 |

What has to be changed to the up-to-date marlin version in order to make it work with this printer. when I transfer the config.h setting and the pins.h settings from the version that FT provided to a newer version, the printer does not function properly. Could someone post a link to a newer version that works with the printer, or maybe attach a newer version that is known to work. Thanks.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 12:51AM |

Registered: 8 years ago Posts: 276 |

Quote

Mach

What has to be changed to the up-to-date marlin version in order to make it work with this printer. when I transfer the config.h setting and the pins.h settings from the version that FT provided to a newer version, the printer does not function properly. Could someone post a link to a newer version that works with the printer, or maybe attach a newer version that is known to work. Thanks.

Latest Marlin with Folgertech settings merged in: [www.github.com]

Edited 1 time(s). Last edit at 07/29/2015 01:49AM by therippa.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 08:35AM |

Registered: 8 years ago Posts: 135 |

Quote

zarnold16

This Kit is starting to make me regret buying it. I have a new 5mm threaded rod on the way because it wouldn't allow a nut to pass over in a certain spot and oiling it didn't help. The extruder won't work. Then lastly I just fried my Arduino and Ramps board.

Other than the rod, these seem like user error...... nobody said building a 3d printer was the easiest thing in the world....

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

Sorry, only registered users may post in this forum.