Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 11:53AM |

Registered: 8 years ago Posts: 285 |

Quote

therippa

Quote

Mach

What has to be changed to the up-to-date marlin version in order to make it work with this printer. when I transfer the config.h setting and the pins.h settings from the version that FT provided to a newer version, the printer does not function properly. Could someone post a link to a newer version that works with the printer, or maybe attach a newer version that is known to work. Thanks.

Latest Marlin with Folgertech settings merged in: [www.github.com]

Thanks.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 01:51PM |

Registered: 8 years ago Posts: 95 |

Quote

zarnold16

This Kit is starting to make me regret buying it. I have a new 5mm threaded rod on the way because it wouldn't allow a nut to pass over in a certain spot and oiling it didn't help. The extruder won't work. Then lastly I just fried my Arduino and Ramps board.

Keep at it you will get it eventually .. Think positively don't let outside negativity get to you...good luck...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 01:56PM |

Registered: 9 years ago Posts: 44 |

I could hear the extruder rotate just filament wouldn't come out.Quote

mel0n

Quote

zarnold16

This Kit is starting to make me regret buying it. I have a new 5mm threaded rod on the way because it wouldn't allow a nut to pass over in a certain spot and oiling it didn't help. The extruder won't work. Then lastly I just fried my Arduino and Ramps board.

Other than the rod, these seem like user error...... nobody said building a 3d printer was the easiest thing in the world....

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 02:30PM |

Registered: 8 years ago Posts: 135 |

Quote

zarnold16

I could hear the extruder rotate just filament wouldn't come out.Quote

mel0n

Quote

zarnold16

This Kit is starting to make me regret buying it. I have a new 5mm threaded rod on the way because it wouldn't allow a nut to pass over in a certain spot and oiling it didn't help. The extruder won't work. Then lastly I just fried my Arduino and Ramps board.

Other than the rod, these seem like user error...... nobody said building a 3d printer was the easiest thing in the world....

So take it apart, and figure out whats going on! Is the hot end hot? If I try to push filament through the hotend while its heated, does it come out like its supposed to? Is the filament stripped out by the extruder?

I am not trying to be negative here, but 3D printing isn't a "set it and forget it" kind of process still. Especially not in one of the cheapest DIY kits on the market. The high end printers have their fair share of issues as well. To be honest, it seems like you have built up frustrations at this point, and you have let them get to you. I know you are probably excited about 3d printing, but my advice would be to take a break for a couple of days and do something completely different to clear your mind and let your frustrations die down. Then come back, and before touching anything, list the problems are that your having, research them thoroughly (most issues have been resolved in the past, and we have sorted most of the design specific issues of this printer by now), and try to take a new optimistic approach to fixing them. I found pretty early on that a little patience goes a long way with 3d printing.

Best of luck with your troubles and happy printing!

Edited 2 time(s). Last edit at 07/29/2015 02:33PM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 02:36PM |

Registered: 9 years ago Posts: 44 |

Quote

mel0n

Quote

zarnold16

I could hear the extruder rotate just filament wouldn't come out.Quote

mel0n

Quote

zarnold16

This Kit is starting to make me regret buying it. I have a new 5mm threaded rod on the way because it wouldn't allow a nut to pass over in a certain spot and oiling it didn't help. The extruder won't work. Then lastly I just fried my Arduino and Ramps board.

Other than the rod, these seem like user error...... nobody said building a 3d printer was the easiest thing in the world....

So take it apart, and figure out whats going on! Is the hot end hot? If I try to push filament through the hotend while its heated, does it come out like its supposed to? Is the filament stripped out by the extruder?

I am not trying to be negative here, but 3D printing isn't a "set it and forget it" kind of process still. Especially not in one of the cheapest DIY kits on the market. The high end printers have their fair share of issues as well. To be honest, it seems like you have built up frustrations at this point, and you have let them get to you. I know you are probably excited about 3d printing, but my advice would be to take a break for a couple of days and do something completely different to clear your mind and let your frustrations die down. Then come back, and before touching anything, list the problems are that your having, research them thoroughly (most issues have been resolved in the past, and we have sorted most of the design specific issues of this printer by now), and try to take a new optimistic approach to fixing them. I found pretty early on that a little patience goes a long way with 3d printing.

Best of luck with your troubles and happy printing!

Okay ill take a break. Im leaving for vacation saturday so ill come back to my printer after then. Yes I can push filament through the hotend when heated.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 02:47PM |

Registered: 8 years ago Posts: 2 |

I had the same problem when I first tested my extruder - it just clicked and clicked and wouldn't pull the filament through. I found a coupld posts about the build manual being wrong for plugging in the wires for the extruder - so I tried the solution and it worked for me. I simply turned the plug around where it plugs into the Ramps board and the motor reversed its direction and the extruder works fine now. It is worth a try. Also, when you put the filament in, there is the spring-loaded 'grabber' on the extruder - push it down, insert filament so it grabs.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 02:51PM |

Registered: 8 years ago Posts: 95 |

Quote

signalcruncher

I had the same problem when I first tested my extruder - it just clicked and clicked and wouldn't pull the filament through. I found a coupld posts about the build manual being wrong for plugging in the wires for the extruder - so I tried the solution and it worked for me. I simply turned the plug around where it plugs into the Ramps board and the motor reversed its direction and the extruder works fine now. It is worth a try. Also, when you put the filament in, there is the spring-loaded 'grabber' on the extruder - push it down, insert filament so it grabs.

Same here plugged the wrong way..it can get frustrating when the manuals are wrong..

Edited 1 time(s). Last edit at 07/29/2015 02:52PM by mike3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 03:04PM |

Registered: 9 years ago Posts: 44 |

Okay ill try that when I get my new ramps and arduino tonight.Quote

mike3

Quote

signalcruncher

I had the same problem when I first tested my extruder - it just clicked and clicked and wouldn't pull the filament through. I found a coupld posts about the build manual being wrong for plugging in the wires for the extruder - so I tried the solution and it worked for me. I simply turned the plug around where it plugs into the Ramps board and the motor reversed its direction and the extruder works fine now. It is worth a try. Also, when you put the filament in, there is the spring-loaded 'grabber' on the extruder - push it down, insert filament so it grabs.

Same here plugged the wrong way..it can get frustrating when the manuals are wrong..

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 03:12PM |

Registered: 8 years ago Posts: 2 |

Quote

brian0

Quote

animoose

Try changing the Repetier home to X max. That will set home to the position with the print head over the front right hand corner of the bed and all three limit switches activated. I have mine set up the same way. You might also need #define INVERT_X_DIR false, and #define X_HOME_DIR 1. That's "1" not "-1".

Unfortunately, that's how everything's already configured.

Brian - I had the same problem, as did many, and there are multiple solutions. I chose the simplest I could: I moved the x stop to the left side and changed X_HOME_DIR to -1. That fixed the issue - I didn't do anything else. What this does is if you look at printer from front, the front left corner is [0,0,0] on the cartesian coordinate system, just as it appears in Repetier. Hopefully this would work for you also.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 06:22PM |

Registered: 8 years ago Posts: 606 |

One other thing to note, is that the extruder shipped by Folger eats grooved bearings. I had two fail, each at a bit less than a kg of filamet fed. When they go, you lose the counterforce on the feed gear, and nothing moves. When I took the extruder apart, the shields were destroyed, and the ball and center race fell out . . . a complete rekit of the bearing. Why, I'm not certain . . . either too much pressure, or (and I think more likely), the groove on these cheap bearings seems to vary on how centered it is, and couple that with unknown tolerances on the block, I suspect a lot of side or twisting loads that these bearings just can't take. Print a spring tensioned extruder, as others have noted, and walk away from the issue.

- Tim

- Tim

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 08:33PM |

Registered: 8 years ago Posts: 121 |

So the things I learned tonight:

That odd problem with my x-carriage was due to the fact when I was looking for the firmware I ASSUMED the copy on the google drive link was the current tuned one WRONG I grabbed the copy that therippa linked on the github moved my end stop back to the right flipped my extruder back and tried the "tuned" version. Well first thing is my X would not move again then I remembered I did not flip the wires back around so for some insane reason I went into the firmware and changed the X direction instead of moving the wires. And now my X-home works!!!!!! Maybe it's a good thing though I'm learning my way around the firmware instead of flipping wires it's safer!!!

My bed takes FOREVER to heat I thought I saw a suggestion to slide cardboard between the aluminum plate and the heater. Is that safe? By the way my bed keeps climbing and stops at 130 I have it set for 100 in repetier maybe another dive into the firmware is in order.

Also I have some strings when printing most noticeable when it it printing open holes. Maybe 220 is to hot for ABS?

I turned my stepper drivers down even lower tonight cooler and still no skipping. Also notice my lower X-carriage rod slides a little side to side since my endstop is on this rod I can not see this being a good thing though I have not seen X-home change..

Edited 1 time(s). Last edit at 07/29/2015 08:35PM by jasonsaffle13@gmail.com.

That odd problem with my x-carriage was due to the fact when I was looking for the firmware I ASSUMED the copy on the google drive link was the current tuned one WRONG I grabbed the copy that therippa linked on the github moved my end stop back to the right flipped my extruder back and tried the "tuned" version. Well first thing is my X would not move again then I remembered I did not flip the wires back around so for some insane reason I went into the firmware and changed the X direction instead of moving the wires. And now my X-home works!!!!!! Maybe it's a good thing though I'm learning my way around the firmware instead of flipping wires it's safer!!!

My bed takes FOREVER to heat I thought I saw a suggestion to slide cardboard between the aluminum plate and the heater. Is that safe? By the way my bed keeps climbing and stops at 130 I have it set for 100 in repetier maybe another dive into the firmware is in order.

Also I have some strings when printing most noticeable when it it printing open holes. Maybe 220 is to hot for ABS?

I turned my stepper drivers down even lower tonight cooler and still no skipping. Also notice my lower X-carriage rod slides a little side to side since my endstop is on this rod I can not see this being a good thing though I have not seen X-home change..

Edited 1 time(s). Last edit at 07/29/2015 08:35PM by jasonsaffle13@gmail.com.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 08:44PM |

Registered: 8 years ago Posts: 276 |

Quote

[email protected]

So the things I learned tonight:

That odd problem with my x-carriage was due to the fact when I was looking for the firmware I ASSUMED the copy on the google drive link was the current tuned one WRONG I grabbed the copy that therippa linked on the github moved my end stop back to the right flipped my extruder back and tried the "tuned" version. Well first thing is my X would not move again then I remembered I did not flip the wires back around so for some insane reason I went into the firmware and changed the X direction instead of moving the wires. And now my X-home works!!!!!! Maybe it's a good thing though I'm learning my way around the firmware instead of flipping wires it's safer!!!

My bed takes FOREVER to heat I thought I saw a suggestion to slide cardboard between the aluminum plate and the heater. Is that safe? By the way my bed keeps climbing and stops at 130 I have it set for 100 in repetier maybe another dive into the firmware is in order.

Also I have some strings when printing most noticeable when it it printing open holes. Maybe 220 is to hot for ABS?

I turned my stepper drivers down even lower tonight cooler and still no skipping. Also notice my lower X-carriage rod slides a little side to side since my endstop is on this rod I can not see this being a good thing though I have not seen X-home change..

For the X carriage issue, I would recommend changing the X direction in the firmware back to what it was, moving your X-endstop connection on the RAMP board one set of pins over (the folger manual has you hooking it up to X-min for some reason), and in Repetier printer settings -> behavior -> dimension setting your Home X to max. That is how everything should really be configured without any hacks.

Bed heating - my setup takes about 10 minutes to get to 100 degrees. What do you have on top of your heatbed?

220 is probably too cold for ABS, I think most people hover around 230.

Edited 1 time(s). Last edit at 07/29/2015 08:44PM by therippa.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 08:49PM |

Registered: 8 years ago Posts: 121 |

Will make the X-carriage changes in next day or two. Printing some better filament guides right now. I have a 1/4 inch piece of 8x8 glass on my bed. I have been using hairspray. So far love it. My bed takes 10-15 minutes so not to bad then? and should the bed stay around 130 or lower it in the firmware?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 08:54PM |

Registered: 8 years ago Posts: 276 |

Quote

[email protected]

Will make the X-carriage changes in next day or two. Printing some better filament guides right now. I have a 1/4 inch piece of 8x8 glass on my bed. I have been using hairspray. So far love it. My bed takes 10-15 minutes so not to bad then? and should the bed stay around 130 or lower it in the firmware?

For PLA you don't need to heat the bed. For ABS you need to heat it, 90-110 depending on the quirks of your setup. I can get away with 100 for the first layer, and 90 for the rest, and I think that's still a little too hot because the bottom of the print comes out glassy. As for the 130, you don't set that in the firmware, that's something you set up in slic3r (or whatever slicing program you're using). After you're done with your print and it cools off, use Repetier's print panel to turn the heatbed to 100, and use the temperature curves view to watch it do its thing. It will fluctuate a little when it gets to 100 (or whatever you set the temperature to be), but it shouldn't go anymore than a degree or two over.

I guess the best advice for print/bed temps is to use slic3r's ability to have multiple profiles for print, filament, and printer. Keep tweaking your settings and give them descriptive names when saving them, like for filament, ABS 230-225 100-90 (meaning first layer temp, other layers temp, first layer bed temp, other layers bed temp). It will help you trial-and-error your way to good results.

Edited 1 time(s). Last edit at 07/29/2015 08:59PM by therippa.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 09:04PM |

Registered: 8 years ago Posts: 121 |

I have not been changing my layer temps so will learn that. Do you think the string is from my extruder being to cold? I have 2 rolls of ABS I am learning with I also have a few rolls of PAL but do not want to try switching back and forth I have heard some horror stories. Would a picture of my prints help or do you know what I mean by stringy?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 09:05PM |

Registered: 8 years ago Posts: 276 |

Quote

[email protected]

I have not been changing my layer temps so will learn that. Do you think the string is from my extruder being to cold? I have 2 rolls of ABS I am learning with I also have a few rolls of PAL but do not want to try switching back and forth I have heard some horror stories. Would a picture of my prints help or do you know what I mean by stringy?

Pics are always helpful on this forum. Post them! I found this to be helpful in diagnosing problems too - [reprap.org]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 09:05PM |

Registered: 8 years ago Posts: 430 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 09:29PM |

Registered: 8 years ago Posts: 35 |

Quote

therippa

Quote

Mach

What has to be changed to the up-to-date marlin version in order to make it work with this printer. when I transfer the config.h setting and the pins.h settings from the version that FT provided to a newer version, the printer does not function properly. Could someone post a link to a newer version that works with the printer, or maybe attach a newer version that is known to work. Thanks.

Latest Marlin with Folgertech settings merged in: [www.github.com]

I downloaded this version and loaded it on my printer and the bed won't heat beyond 87C. Weird. I put the old one back on and I can get to 101 again no problem.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 09:32PM |

Registered: 8 years ago Posts: 121 |

[jasonsaffle13.imgur.com]

Collections of pictures of build and my recent prints.

Edited 1 time(s). Last edit at 07/29/2015 09:32PM by jasonsaffle13@gmail.com.

Collections of pictures of build and my recent prints.

Edited 1 time(s). Last edit at 07/29/2015 09:32PM by jasonsaffle13@gmail.com.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 09:48PM |

Registered: 8 years ago Posts: 276 |

Quote

RedneckGeek

Quote

therippa

Quote

Mach

What has to be changed to the up-to-date marlin version in order to make it work with this printer. when I transfer the config.h setting and the pins.h settings from the version that FT provided to a newer version, the printer does not function properly. Could someone post a link to a newer version that works with the printer, or maybe attach a newer version that is known to work. Thanks.

Latest Marlin with Folgertech settings merged in: [www.github.com]

I downloaded this version and loaded it on my printer and the bed won't heat beyond 87C. Weird. I put the old one back on and I can get to 101 again no problem.

Trying going through the PID autotune with your bed?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 10:00PM |

Registered: 8 years ago Posts: 430 |

Quote

[email protected]

[jasonsaffle13.imgur.com]

Collections of pictures of build and my recent prints.

Says not publicly available.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 10:03PM |

Registered: 8 years ago Posts: 121 |

[imgur.com]

Any better?

Edited 1 time(s). Last edit at 07/29/2015 10:04PM by jasonsaffle13@gmail.com.

Any better?

Edited 1 time(s). Last edit at 07/29/2015 10:04PM by jasonsaffle13@gmail.com.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 29, 2015 10:40PM |

Registered: 8 years ago Posts: 430 |

Yes it works now.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 30, 2015 01:52AM |

Registered: 8 years ago Posts: 276 |

Well, I got my new E3D V6 Bowden setup up and running today, and just printed a test cube. I can't believe how much better the print quality is compared to the stock hotend. The difference is like using sidewalk chalk vs a fine tip mechanical pencil.

Edited 2 time(s). Last edit at 07/30/2015 02:02AM by therippa.

Edited 2 time(s). Last edit at 07/30/2015 02:02AM by therippa.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 30, 2015 06:39AM |

Registered: 8 years ago Posts: 121 |

Quote

therippa

Well, I got my new E3D V6 Bowden setup up and running today, and just printed a test cube. I can't believe how much better the print quality is compared to the stock hotend. The difference is like using sidewalk chalk vs a fine tip mechanical pencil.

Pictures (and if you would STL files for the mount, bowden setup etc.). Would like to replace my hotend with a better one. Have heard of short life and other issues with the stock one. wish to as someone put it "walk away" from those problems.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 30, 2015 08:45AM |

Registered: 8 years ago Posts: 135 |

Quote

[email protected]

Quote

therippa

Well, I got my new E3D V6 Bowden setup up and running today, and just printed a test cube. I can't believe how much better the print quality is compared to the stock hotend. The difference is like using sidewalk chalk vs a fine tip mechanical pencil.

Pictures (and if you would STL files for the mount, bowden setup etc.). Would like to replace my hotend with a better one. Have heard of short life and other issues with the stock one. wish to as someone put it "walk away" from those problems.

I have said this like 5x already, but glad your seeing the same results as me. I stayed direct drive as Bowden has too many disadvantages over direct and not enough pros to make it worth the switch. I am interested to see a pic of your printer with the Bowden setup. Their direct drive version of the v6 comes with a short Bowden tube that extends up the direct drive extruder all the way to the gear/tensioner. So its like a super short Bowden and keeps the filament completely straight the whole way into the hotend. So since it has the coupling, I could just buy a bowden tube and switch between bowden/direct as I please. Same for the bowden version.

Though the only reason I can find to switch to bowden is to take weight off of the x-carriage, which if I am going to be honest, with this design [www.thingiverse.com] I am having no weight related issues/artifacts. The weight distribution seems perfect in the design and way it rides on the rods. The stock hotend had terrible weight distribution and it was all hanging horizontally. This stacks everything vertically, and gets the extruder motor much closer to the x rods. I will post a pic of my printer in its current form later today to compare with your bowden setup.

(Oh, and since the weight distribution is so much better, my x-axis motor barely has to work at all and barely heats a few degrees above ambient temps. With the stock extruder setup it was unbelievably hot at the lowest current I could run it at without skipping)

Edited 1 time(s). Last edit at 07/30/2015 08:48AM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 30, 2015 11:42AM |

Registered: 8 years ago Posts: 276 |

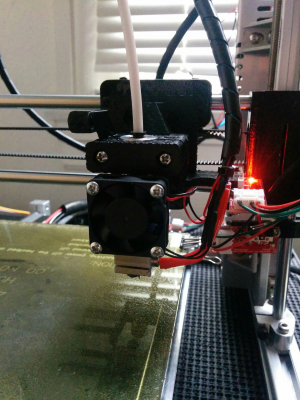

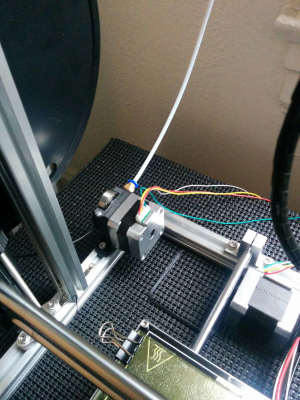

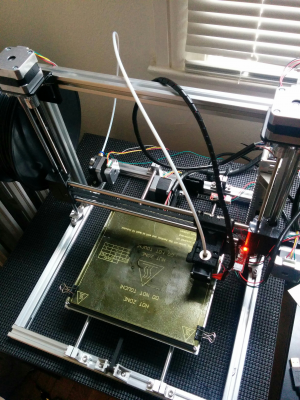

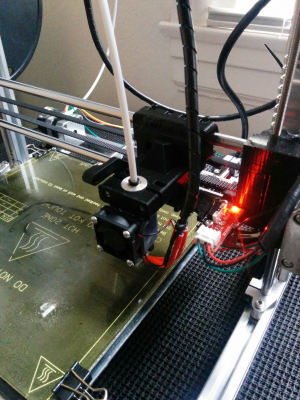

Pics...

STL's...

Extruder - [www.thingiverse.com]

Hotend holder - [www.thingiverse.com]

The hotend holder's mounting holes didn't line up with the hole on the Folgertech X-carriage, so I just brought out the drill. This weekend's project will be hooking up the fan (easy) and the capacitive sensor (not as easy) to it.

Edited 1 time(s). Last edit at 07/30/2015 11:44AM by therippa.

STL's...

Extruder - [www.thingiverse.com]

Hotend holder - [www.thingiverse.com]

The hotend holder's mounting holes didn't line up with the hole on the Folgertech X-carriage, so I just brought out the drill. This weekend's project will be hooking up the fan (easy) and the capacitive sensor (not as easy) to it.

Edited 1 time(s). Last edit at 07/30/2015 11:44AM by therippa.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 30, 2015 01:14PM |

Registered: 8 years ago Posts: 7 |

Hey guys im trying to activate the auto level function but i cant make it work this is what is doing when i do a G28 and a G29 [www.dropbox.com] i tried therippa fork, same result and now im using a marlin 1.0.2 fresh install. If i deactivate the auto level funtion the printer works flawless, check my current conf.h file [pastebin.com] any thoughts are welcome.

Ps: sorry about my english its not my first languaje.

Ps: sorry about my english its not my first languaje.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 30, 2015 01:28PM |

Registered: 8 years ago Posts: 171 |

Quote

therippa

Well, I got my new E3D V6 Bowden setup up and running today, and just printed a test cube. I can't believe how much better the print quality is compared to the stock hotend. The difference is like using sidewalk chalk vs a fine tip mechanical pencil.

I'm going to ask a dumb question here. What did you buy for this, vs what did you print? How much work was it to convert?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 30, 2015 01:46PM |

Registered: 8 years ago Posts: 276 |

Quote

markts

Quote

therippa

Well, I got my new E3D V6 Bowden setup up and running today, and just printed a test cube. I can't believe how much better the print quality is compared to the stock hotend. The difference is like using sidewalk chalk vs a fine tip mechanical pencil.

I'm going to ask a dumb question here. What did you buy for this, vs what did you print? How much work was it to convert?

I reused the motor from the Folgertech extruder for the Bowden setup. I bought the E3D and various screws, bearings, and hobbed gears (they mostly detailed in the instructions on the bowden extruder's thingiverse page). It wasn't that hard to do, I'd say the hardest part was getting everything calibrated well enough that I felt I could print the parts and have them fit, since there are some tight tolerances. Once everything was printed and I had all the necessary hardware, I'd say it took about two hours to put it all together.

Edited 2 time(s). Last edit at 07/30/2015 02:20PM by therippa.

Sorry, only registered users may post in this forum.