Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 02, 2015 11:45AM |

Registered: 8 years ago Posts: 5 |

Quote

animoose

I'm about to start rebuilding the X/Z axes using wderoxas's parts ( [www.thingiverse.com] and [www.thingiverse.com], with one small change). If you don't hear me say any more about this, it means it all went wrong and I took up a different hobby, like knitting brightly colored socks for small dogs.

@animoose: What material will you print these parts in (e.g., ABS, PLA, ... )?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 02, 2015 01:30PM |

Registered: 8 years ago Posts: 66 |

Quote

zarnold16

What is the thingiverse link for the dual extruder?Quote

CheopisIV

Quote

animoose

I'm about to start rebuilding the X/Z axes using wderoxas's parts ( [www.thingiverse.com] and [www.thingiverse.com], with one small change). If you don't hear me say any more about this, it means it all went wrong and I took up a different hobby, like knitting brightly colored socks for small dogs.

The motor standoffs are awesome! I'm waiting on some 8mm screws and other parts from Folger Tech before I tear down the X/Z axis again but I have those parts (with one small mod) and a dual E3D assembly printed and ready to go! I may join you in the knitting if my own venture goes south... dibs on the red wool.

E3D V6 Dual Extruder

I like that it goes over the X-Axis and I don't lose anything in that direction; should also be able to compensate in the Y-Axis with the way the bed mounts are designed. The Z-Axis might lose a bit but with the standoffs or longer extrusions it's not an issue.

Sigil Pickups || Stunt Monkey Pedals

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 02, 2015 03:00PM |

Registered: 8 years ago Posts: 367 |

Quote

samaral

Quote

animoose

I'm about to start rebuilding the X/Z axes using wderoxas's parts ( [www.thingiverse.com] and [www.thingiverse.com], with one small change). If you don't hear me say any more about this, it means it all went wrong and I took up a different hobby, like knitting brightly colored socks for small dogs.

@animoose: What material will you print these parts in (e.g., ABS, PLA, ... )?

I printed in PLA, as that's the only thing I've been using. I don't think I will ever use ABS, as I am not keen on the risk from fumes (and my wife, who has respiratory problems, is less so). I've read of people who do print ABS putting the printer in an enclosure and then having problems with PLA parts softening.

Side note: I plan to try out PLA/PHA mix soon. It's said the have the temperature and smell characteristics of PLA but tougher and less brittle. I have a few samples and will try them next time I need to change filament for other reasons.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 02, 2015 03:06PM |

Registered: 8 years ago Posts: 430 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 02, 2015 03:16PM |

Registered: 8 years ago Posts: 276 |

Quote

animoose

I'm about to start rebuilding the X/Z axes using wderoxas's parts ( [www.thingiverse.com] and [www.thingiverse.com], with one small change). If you don't hear me say any more about this, it means it all went wrong and I took up a different hobby, like knitting brightly colored socks for small dogs.

What's the one small change you're making?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 02, 2015 03:19PM |

Registered: 8 years ago Posts: 276 |

Quote

msaeger

I used ABS and I actually didn't really smell anything. I don't think I will get anymore after this roll because PLA and PETG were easier with better results.

I don't really get fumes either. And I'm with you on switching back to PLA. I'm tired of waiting for the heatbed to reach temperature, and ABS is way more finicky than PLA is.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 02, 2015 03:32PM |

Registered: 8 years ago Posts: 14 |

I haven't had much time to work on my printer in the last week, but the extruder seems to be working well again after disassembling and reassembling it. I am now trying to print with ABS.

I tried printing some of the Y Axis bearing holders (there seems to be some variation in height on the ones the kit came with), but I am having trouble with the parts cracking and layer delamination.

I am printing with some purple ABS from Folger Tech with extruder temperature at 230 C. and Bed temperature at 100 C.

I haven't tried enclosing the printer yet. Does anyone here use an enclosure? And if so what ambient temp is good?

I'm also looking for any tips on slic3r settings to use for printing this type of structural part (infill pattern/density, speeds etc.)

Thanks for all the help everyone! You have been very helpfull in getting this printer assembled and running.

I tried printing some of the Y Axis bearing holders (there seems to be some variation in height on the ones the kit came with), but I am having trouble with the parts cracking and layer delamination.

I am printing with some purple ABS from Folger Tech with extruder temperature at 230 C. and Bed temperature at 100 C.

I haven't tried enclosing the printer yet. Does anyone here use an enclosure? And if so what ambient temp is good?

I'm also looking for any tips on slic3r settings to use for printing this type of structural part (infill pattern/density, speeds etc.)

Thanks for all the help everyone! You have been very helpfull in getting this printer assembled and running.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 02, 2015 04:11PM |

Registered: 8 years ago Posts: 95 |

the few days I had my printer working correctly I used only ABS.. you had to almost put your nose very close to printer to smell anything... and after I got the heat settings dialed in the ABS worked great.. I started at 260 and 110 bed.. and went down when I got around 23o and lower that's when I started having problems with parts breaking more easily and not fully bonding... this is with the ABS black I got from Folger Tech.. I ended up printing at 238-242 and bed at 96-104 with outstanding results.. only have to use enough glue stick on the bed.. I then tried some cheap 5.99/1kg brown from justpla on Amazon and I had to print at 248 and 108 bed to get good results .. I really like ABS but I haven't tried PLA .. just my experiences

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 02, 2015 04:40PM |

Registered: 8 years ago Posts: 367 |

The moosebot is back in operation after its X/Z axis transplant. Phew. No need to take up knitting. Still some adjustments to do. I'll probably write up what I did on my blog in a day or two.

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 02, 2015 05:28PM |

Registered: 8 years ago Posts: 20 |

Well, seeing some pretty great results on the printer after many trial and error rounds with Repetier. I attached two images of the Dimensional Accuracy test from Make Magazine as a reference for current print quality. Some discoveries that I have made:

I'm printing blue PLA (DeltaMaker filament purchased from a local 3D printer shop) on Kapton tape sheets at temps of 200/70 for nozzle and bed, and seeing great results. As you can tell from the pictures though, on very fine features, the PLA does not cool enough for the next layer to be printed accurately.. I'm thinking my options are add a cooling fan for the parts, or tun down the nozzle temp. Any thoughts on this?

I also found that setting the nozzle diameter in Reptier to 0.3mm rather than 0.4 mm yields much better results, from a brief look at FT's website, they only sell 0.4 and 0.3mm nozzles, not entirely out of the question that they shipped me a 0.3. Haven't been super concerned about it, otherwise I'd pull it off and gauge exactly what it is.

Still playing around with the retraction settings and have been experiencing mixed results as my extruder is a bit "drool-y". Currently printing at a layer height of 0.2mm.

Very happy with the results considering the price, even after the electronics fiasco.

Edited 2 time(s). Last edit at 08/02/2015 05:32PM by cvanclev.

I'm printing blue PLA (DeltaMaker filament purchased from a local 3D printer shop) on Kapton tape sheets at temps of 200/70 for nozzle and bed, and seeing great results. As you can tell from the pictures though, on very fine features, the PLA does not cool enough for the next layer to be printed accurately.. I'm thinking my options are add a cooling fan for the parts, or tun down the nozzle temp. Any thoughts on this?

I also found that setting the nozzle diameter in Reptier to 0.3mm rather than 0.4 mm yields much better results, from a brief look at FT's website, they only sell 0.4 and 0.3mm nozzles, not entirely out of the question that they shipped me a 0.3. Haven't been super concerned about it, otherwise I'd pull it off and gauge exactly what it is.

Still playing around with the retraction settings and have been experiencing mixed results as my extruder is a bit "drool-y". Currently printing at a layer height of 0.2mm.

Very happy with the results considering the price, even after the electronics fiasco.

Edited 2 time(s). Last edit at 08/02/2015 05:32PM by cvanclev.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 02, 2015 05:51PM |

Registered: 8 years ago Posts: 95 |

Quote

mike3

the few days I had my printer working correctly I used only ABS.. you had to almost put your nose very close to printer to smell anything... and after I got the heat settings dialed in the ABS worked great.. I started at 260 and 110 bed.. and went down when I got around 23o and lower that's when I started having problems with parts breaking more easily and not fully bonding... this is with the ABS black I got from Folger Tech.. I ended up printing at 238-242 and bed at 96-104 with outstanding results.. only have to use enough glue stick on the bed.. I then tried some cheap 5.99/1kg brown from justpla on Amazon and I had to print at 248 and 108 bed to get good results .. I really like ABS but I haven't tried PLA .. just my experiences

A few parts I made.. Using webcan not very good pix phone cam broke

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 02, 2015 06:08PM |

Registered: 8 years ago Posts: 14 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 02, 2015 07:02PM |

Registered: 8 years ago Posts: 121 |

[imgur.com]

I tuned my extruder (99.2 when asking for 100) tried printing the calibration for fine tuning it and got a stringy mess. So I tried a 25 mm open topped cube came out fine. Tried A small figure and it failed tried a holder for my lcd screen and got this picture above. I'm trying a fan shroud right now looks like it is not going well I tried upping the stepper driver a little for my Y axis no change. ABS extruder at 230 bed at 100.

[imgur.com]

Maybe my first layer looked bad? This thing has been giving me fits today. I enabled my eeprom and tuned my extruder butI just am unable to print some objects the duplicate in the Y axis. Others seem fine very frustrating. I tried slicer3 and cura both.

[imgur.com]

[imgur.com]

I forgot I had changed glass plates today bet I messed up my bed level since i failed to check it afterwards.

Edited 2 time(s). Last edit at 08/02/2015 07:58PM by jasonsaffle13@gmail.com.

I tuned my extruder (99.2 when asking for 100) tried printing the calibration for fine tuning it and got a stringy mess. So I tried a 25 mm open topped cube came out fine. Tried A small figure and it failed tried a holder for my lcd screen and got this picture above. I'm trying a fan shroud right now looks like it is not going well I tried upping the stepper driver a little for my Y axis no change. ABS extruder at 230 bed at 100.

[imgur.com]

Maybe my first layer looked bad? This thing has been giving me fits today. I enabled my eeprom and tuned my extruder butI just am unable to print some objects the duplicate in the Y axis. Others seem fine very frustrating. I tried slicer3 and cura both.

[imgur.com]

[imgur.com]

I forgot I had changed glass plates today bet I messed up my bed level since i failed to check it afterwards.

Edited 2 time(s). Last edit at 08/02/2015 07:58PM by jasonsaffle13@gmail.com.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 02, 2015 07:41PM |

Registered: 8 years ago Posts: 95 |

Quote

Lagomorph

I tried "heat treating" a piece on the heated bed with a box over the piece as suggested on another thread. It made the part worse. Layers seperated and the top of the part expanded.

All I can give you is from my limited experience .. What I see looking at your picture .. Make sure your bed is as level as you can get it... and set the space of the, extruder nozzle between it and your glass.. what I did to set it at all 4 corners was i used a strip of printer paper doubled over and set the nozzle so you could feel a slight friction when pulling it out .. this is just about where it needs to be.. maybe a little tighter later on.. if you have too much space (or not enough heat) between the nozzle and glass/bed you can get what you see in your picture.. also you will need to find the best temp also for the filament you have.. all this is providing you haven't messed with the software/firmware.. The reason being that some people that have mechanical problems are trying to fix it by messing with the software/firmware.. and compounding the problem..making it nearly impossible to diagnose the problems they are having ... I am using the stock software/firmware that is there to be downloaded ,, and after I fixed all the mechanical problems the printer printed almost perfect.. until the extruder stopped heating .. and Folger Tech hasn't been any help..

Edited 2 time(s). Last edit at 08/02/2015 07:47PM by mike3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 02, 2015 11:45PM |

Registered: 8 years ago Posts: 367 |

Here's a description of the X/Z rebuild: [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2015 02:46AM |

Registered: 8 years ago Posts: 276 |

Would you be so kind as to put your modified STL's on your thingiverse page?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2015 03:30AM |

Registered: 8 years ago Posts: 81 |

Good going with your "moosebot". The kit's ability to go for a 50 micron layer height was an unexpected effect of using the leadscrew.

In your case, using a 4 start lead screw (8 mm per turn) further reduced the available steps/mm but still, theoretically, you could go until 2.5 micron layer height with that.

It's really fun to see this machine evolving.

I had few changes on my machine too. I switched to a dual extruder bowden after the orignal hotend got trashed. That set me back a couple of days since i don't have spare printer to produce new hot-end mounts and other stuff.

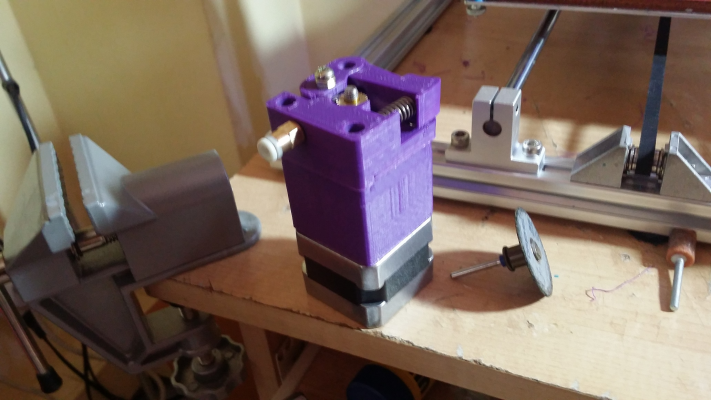

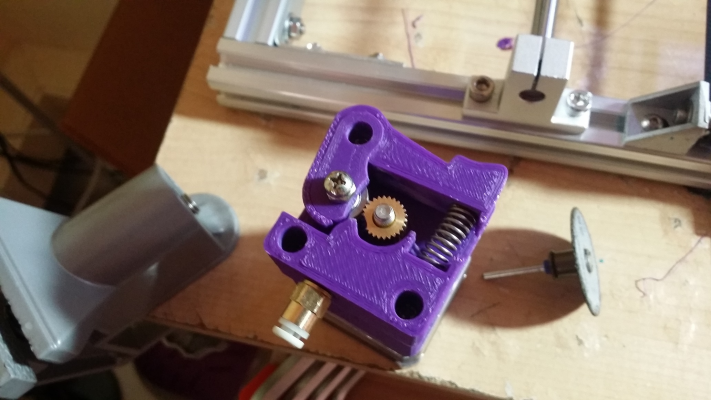

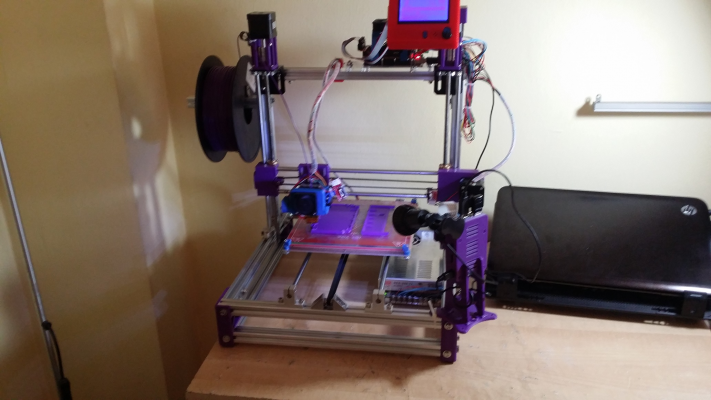

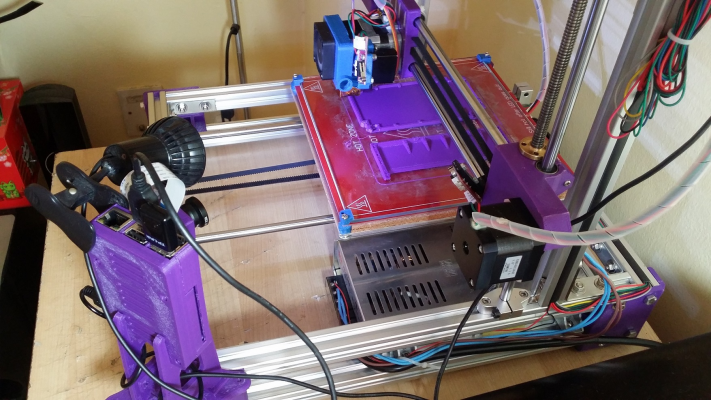

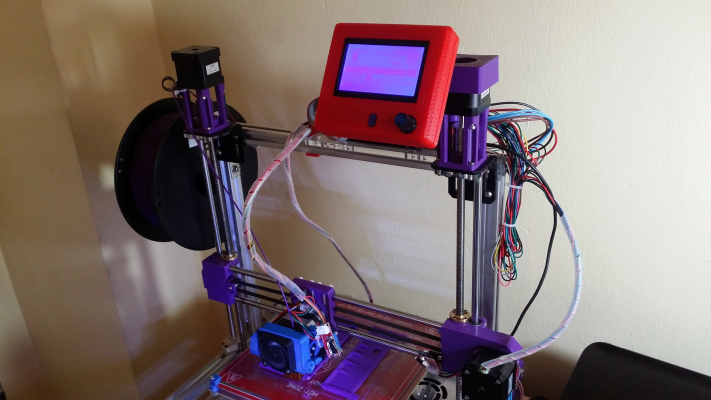

So i ended up using aluminum flat bar to mount them. I haven't taken photos of the new hotend but here are some of the pics i had:

This is the extruder im using. Its a printed NEMA 17 planetary gearbox with an extruder i designed (rather, modified from an existing design i saw on thingiverse). There are some flaws on the new extruder design, specifically, the filament holes aren't tangential to the drive gear causing the filament to grind into it when manually pulled or inserted. I think the drive gear's tangent line coincides with the center of the filament so even with the idle bearing disengaged, the filament will still rub in with the gear. Im gonna need to do some modification on it once i got the new bowden system dialed-up but for now, i have to make do with it.

The NEMA 17 planetary gears were taken from raldrich's design with slight modification on the output to fit an M5 bolt and 10mm OD 5mm ID bearing (taken from a 1/8 scale RC car's wheel bearing). I also did slight modification on the planet gears and its cages since the original gears were a bit thin to my liking. By design, it will multiply the torque by 4.444 (and reduce the speed as much too), so its a pretty good drive for a bowden.

This is how she looked now, (except for the extruder and hot-end assembly. I'll post them later if anyone's interested). The lcd is being held by the right Z motor. I sort of printed a cap fitted on the motor to hold the LCD.

Next plans:

1) a better hotend mount on the X carriage

2) modify the extruder (filament drive)

3) triangular bracket/support for the z post which will also be used as support for the spool holders and the filament drives.

4) optional - move the control board at the bottom together with the PSU? Not sure if its a good idea though since im going to reroute the wirings again.

Edited 1 time(s). Last edit at 08/03/2015 07:05AM by wderoxas.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2015 11:01AM |

Registered: 8 years ago Posts: 95 |

Quote

mike3

Quote

mike3

the few days I had my printer working correctly I used only ABS.. you had to almost put your nose very close to printer to smell anything... and after I got the heat settings dialed in the ABS worked great.. I started at 260 and 110 bed.. and went down when I got around 23o and lower that's when I started having problems with parts breaking more easily and not fully bonding... this is with the ABS black I got from Folger Tech.. I ended up printing at 238-242 and bed at 96-104 with outstanding results.. only have to use enough glue stick on the bed.. I then tried some cheap 5.99/1kg brown from justpla on Amazon and I had to print at 248 and 108 bed to get good results .. I really like ABS but I haven't tried PLA .. just my experiences

A few parts I made.. Using webcan not very good pix phone cam broke

better pix

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2015 11:34AM |

Registered: 8 years ago Posts: 27 |

first question for you all, I've been printing ABS at about 185 and PLA at 170 and just started PET at 175. I've done push plastic, microcenter inland, sainsmart, and hatchbox so far and they all fall into about those temperatures. I have done PID tune on my hotend. I've gotten some great prints, only major problem has been the stringies from the nozzle which seems to be a common problem. Should I worry, or just keep printing?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2015 11:39AM |

Registered: 8 years ago Posts: 27 |

P.S. great work on all the upgrades and such everyone. I'd commend everyone by name but I think pretty much if you're in the forum you have contributed and are worthy of thanks.

I'm about to embark on pretty much reprinting all of the plastic components. I'm thinking about switching the arrangement of the x carriage rods from vertically stacked to horizontally planar. (trying to avoid a big cantilevered extruder/fan/hotend/autolevel-probe mass) Will be using all of the parts posted on thingiverse to guide me.

Edited 1 time(s). Last edit at 08/03/2015 11:52AM by ejnelson.

I'm about to embark on pretty much reprinting all of the plastic components. I'm thinking about switching the arrangement of the x carriage rods from vertically stacked to horizontally planar. (trying to avoid a big cantilevered extruder/fan/hotend/autolevel-probe mass) Will be using all of the parts posted on thingiverse to guide me.

Edited 1 time(s). Last edit at 08/03/2015 11:52AM by ejnelson.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2015 11:48AM |

Registered: 8 years ago Posts: 95 |

Quote

ejnelson

first question for you all, I've been printing ABS at about 185 and PLA at 170 and just started PET at 175. I've done push plastic, microcenter inland, sainsmart, and hatchbox so far and they all fall into about those temperatures. I have done PID tune on my hotend. I've gotten some great prints, only major problem has been the stringies from the nozzle which seems to be a common problem. Should I worry, or just keep printing?

I had been printing ABS between 238-248 and even at 260 in the beginning no strings but just my personal experience

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2015 12:08PM |

Registered: 8 years ago Posts: 19 |

Quote

ejnelson

first question for you all, I've been printing ABS at about 185 and PLA at 170 and just started PET at 175. I've done push plastic, microcenter inland, sainsmart, and hatchbox so far and they all fall into about those temperatures. I have done PID tune on my hotend. I've gotten some great prints, only major problem has been the stringies from the nozzle which seems to be a common problem. Should I worry, or just keep printing?

Hi ejnelson,

Just getting into 3d printing and plan to get the FT 2020 I3. The filament brands you listed have they printed well or would you stay away from any brand. I believed I read that people were having problems with hatchbox. I am curious about the inland print quality. I have been lurking for a year now watching the development of different printers and I love the mods the guys are doing. I will definitely make the mods done by CheopisIV, animoose, wderoxas and any others I might of missed. There is a strong possibility we are getting an Utilmaker 2 at work so in theory I could have the mod parts before I buy/build my printer.

Thanks

Rick.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2015 12:48PM |

Registered: 8 years ago Posts: 10 |

Almost done with my Prusa i3 2020 build. It's my first 3d printer. I noticed in the build pdf manual that the X Stepper is plugged into the ramps reversed when compared to the other steppers but there isn't any mention of it in the manual. I also have read about people having problems with the X stepper direction and endstop. So, I'm thinking I'll do the same and see what happens with it reversed. Has anyone else done this? Sorry if this was already covered in this thread. I didn't get a chance to go through the entire thing yet.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2015 12:59PM |

Registered: 8 years ago Posts: 121 |

Quote

Danmst3k

Almost done with my Prusa i3 2020 build. It's my first 3d printer. I noticed in the build pdf manual that the X Stepper is plugged into the ramps reversed when compared to the other steppers but there isn't any mention of it in the manual. I also have read about people having problems with the X stepper direction and endstop. So, I'm thinking I'll do the same and see what happens with it reversed. Has anyone else done this? Sorry if this was already covered in this thread. I didn't get a chance to go through the entire thing yet.

Make sure to grab the copy of Marlin that therippa linked in a past thread NOT the one on the google drive., and go ahead and hook it backwards like they show. Make sure you have home set in repetier for the X axis (read back 3-5 pages) and it should work fine.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2015 04:12PM |

Registered: 8 years ago Posts: 27 |

Quote

rrowan327

Quote

ejnelson

first question for you all, I've been printing ABS at about 185 and PLA at 170 and just started PET at 175. I've done push plastic, microcenter inland, sainsmart, and hatchbox so far and they all fall into about those temperatures. I have done PID tune on my hotend. I've gotten some great prints, only major problem has been the stringies from the nozzle which seems to be a common problem. Should I worry, or just keep printing?

Hi ejnelson,

Just getting into 3d printing and plan to get the FT 2020 I3. The filament brands you listed have they printed well or would you stay away from any brand. I believed I read that people were having problems with hatchbox. I am curious about the inland print quality. I have been lurking for a year now watching the development of different printers and I love the mods the guys are doing. I will definitely make the mods done by CheopisIV, animoose, wderoxas and any others I might of missed. There is a strong possibility we are getting an Utilmaker 2 at work so in theory I could have the mod parts before I buy/build my printer.

Thanks

Rick.

Hey Rick,

Inland and Push I can definitely recommend. Inland has been great, and for the price I'll definitely be going back. The Blue octo is in inland ABS at 50 microns. The yoda is in push plastic 'gold' at 50 or 60 microns i believe (with no supports for the ears, btw, which i thought was amazing).

Hatchbox hasn't been the greatest, i haven't printed a whole bunch with that though. could just be me or my settings but on nice flat external walls that should be easy i get a good amount of what looks like could be over extrusion waviness. i did measure the diameter of the filament and messed with the flow multiplier a bit, but haven't nailed that one yet.

I got PETG from sainsmart and it is awesome. it does string a bit, but the parts have been great, no warp, strong i love the translucency as well

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2015 07:01PM |

Registered: 8 years ago Posts: 367 |

Quote

therippa

Would you be so kind as to put your modified STL's on your thingiverse page?

[www.thingiverse.com] for the modified motor mount.

[www.thingiverse.com] for the end stop bracket.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2015 07:32PM |

Registered: 8 years ago Posts: 121 |

So my printer is slowly turning green as I print new parts and things for it.

[imgur.com]

The fan shroud and resetting my Z height after changing the glass seems to make the difference.

Right now I am printing the LCD mounts from animoose. Still some minor stringing but not bad.

[imgur.com]

I ordered a J head v6 and a bowden extruder setup now just gotta print the mounting for the J head.

[imgur.com]

The fan shroud and resetting my Z height after changing the glass seems to make the difference.

Right now I am printing the LCD mounts from animoose. Still some minor stringing but not bad.

[imgur.com]

I ordered a J head v6 and a bowden extruder setup now just gotta print the mounting for the J head.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2015 09:23PM |

Registered: 8 years ago Posts: 81 |

Quote

ejnelson

P.S. great work on all the upgrades and such everyone. I'd commend everyone by name but I think pretty much if you're in the forum you have contributed and are worthy of thanks.

I'm about to embark on pretty much reprinting all of the plastic components. I'm thinking about switching the arrangement of the x carriage rods from vertically stacked to horizontally planar. (trying to avoid a big cantilevered extruder/fan/hotend/autolevel-probe mass) Will be using all of the parts posted on thingiverse to guide me.

That's gonna be quite a task. I too had considered to try that configuration since my biggest concern for the cantilevered style is the weight distribution of the extruder-hotend assembly. With the hotend tip too far away from the center of gravity, minor vibrations on x assembly are compounded on the tip. Thats probably the reason why i see my old extruder prints wavy lines.

However, the fix i found was quite simple - switch to bowden. The biggest mass was eliminated and furthermore, the tip is now nearer on the the x rod. I cant see the waviness anymore. Cons associated with bowden like stringing and blobs can be easily fixed with retractions. I can get better speeds too since x carriage is a lot lighter. Except for the inability to print flexible materials (which i havent tried yet), i dont see any disadvantage when i switched to bowden. Ill probably see some in the future, but then, thats what tinkers love anyway.

Im not discouraging you in anyway. Just giving you something to ponder about. Im all for folks trying out something new and learning along the way.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2015 09:32PM |

Registered: 8 years ago Posts: 121 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2015 09:46PM |

Registered: 8 years ago Posts: 276 |

ProTip: When pasting links from imgur, wrap them with [ img ] [ /img ] (without the spaces)

Sorry, only registered users may post in this forum.