Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 12:54AM |

Registered: 8 years ago Posts: 276 |

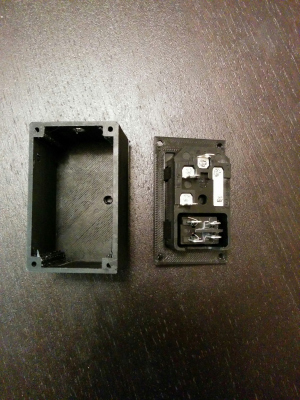

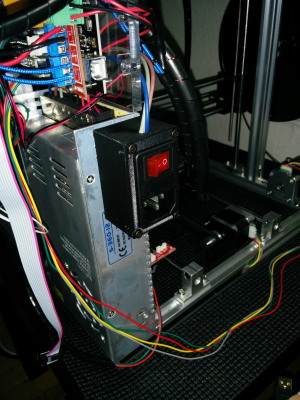

I made a power switch for the Folgertech power supply tonight. It mounts with one screw, but uses two ridges that fit into the groove above and below the screw hole to keep it secure...

You can grab it here - [www.thingiverse.com]

You can grab it here - [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 06:52AM |

Registered: 8 years ago Posts: 19 |

OK.... I screwed up bad...  I forgot to change the input voltage on the power supply after I traveled and I hastily plugged in 220V supply when the power supply was in 110 V mode... Heard a small pop.... not sure which part went bad... The power supply led doesnt come ON and extruder fan, wired directly, doesn't work. As I understand it ,the power supply has over voltage protection, but I'm not sure which part would go first in case of my problem. The on board fuse is rated for 250 V and shows continuity.

I forgot to change the input voltage on the power supply after I traveled and I hastily plugged in 220V supply when the power supply was in 110 V mode... Heard a small pop.... not sure which part went bad... The power supply led doesnt come ON and extruder fan, wired directly, doesn't work. As I understand it ,the power supply has over voltage protection, but I'm not sure which part would go first in case of my problem. The on board fuse is rated for 250 V and shows continuity.

Should I change out the complete power supply or look for a specific part? How do I check if the RAMPS and Arduino board are OK? Help!

Edited 2 time(s). Last edit at 08/04/2015 06:55AM by go_gn.

I forgot to change the input voltage on the power supply after I traveled and I hastily plugged in 220V supply when the power supply was in 110 V mode... Heard a small pop.... not sure which part went bad... The power supply led doesnt come ON and extruder fan, wired directly, doesn't work. As I understand it ,the power supply has over voltage protection, but I'm not sure which part would go first in case of my problem. The on board fuse is rated for 250 V and shows continuity.

I forgot to change the input voltage on the power supply after I traveled and I hastily plugged in 220V supply when the power supply was in 110 V mode... Heard a small pop.... not sure which part went bad... The power supply led doesnt come ON and extruder fan, wired directly, doesn't work. As I understand it ,the power supply has over voltage protection, but I'm not sure which part would go first in case of my problem. The on board fuse is rated for 250 V and shows continuity.Should I change out the complete power supply or look for a specific part? How do I check if the RAMPS and Arduino board are OK? Help!

Edited 2 time(s). Last edit at 08/04/2015 06:55AM by go_gn.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 07:37AM |

Registered: 8 years ago Posts: 81 |

Quote

go_gn

OK.... I screwed up bad...I forgot to change the input voltage on the power supply after I traveled and I hastily plugged in 220V supply when the power supply was in 110 V mode... Heard a small pop.... not sure which part went bad... The power supply led doesnt come ON and extruder fan, wired directly, doesn't work. As I understand it ,the power supply has over voltage protection, but I'm not sure which part would go first in case of my problem. The on board fuse is rated for 250 V and shows continuity.

Should I change out the complete power supply or look for a specific part? How do I check if the RAMPS and Arduino board are OK? Help!

I had my psu blown too when i was assembling my kit due to the same reason - wrong voltage input. It's fuse was useless since the input stage mosfet on the PSU blew up first. If you opened up your PSU, the FET attached to the case is most likely cracked. Replacing it wouldn't guarantee a fix for the PSU so i bought a new one.

Ramps was plugged in when it happened, but fortunately, it wasn't damaged so there's a high chance yours wouldn't too. For a quick test, you can try using any 12V supply with at least an amp or two current capacity. Wire it up on ramps but take note of the polarity. The most this supply can do is move your steppers so you can check your drivers. All the heating components are out of the question with a puny 1 or 2 amp supply so they can only be checked by probing its terminals with a multimeter or check their corresponding led. The terminals should register a 12V when you manually enable them at repetier.

A wifi router psu seems to be rated with an amp or more.. Its what i used when i tested mine.

Edited 1 time(s). Last edit at 08/04/2015 07:41AM by wderoxas.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 09:27AM |

Registered: 8 years ago Posts: 18 |

Anyone experience this?

This is my second i3 2020 kit - the first one has been running great for 2 months. Ordered a second and it arrived last week. Had some issues with wrong screws, washers, corner brackets larger than first kit, etc.... - but I soldiered on with the install.

I have flashed with the original and the updated Marlin firmware and have these issues.

1. Z-axis tried to home going up (reversed the plugs and now it seem to work alright

2. Thermistor for bed is causing a MAXTEMP error. Would this be caused by a bad RAMPS board?

Any help would be greatly appreciated!

This is my second i3 2020 kit - the first one has been running great for 2 months. Ordered a second and it arrived last week. Had some issues with wrong screws, washers, corner brackets larger than first kit, etc.... - but I soldiered on with the install.

I have flashed with the original and the updated Marlin firmware and have these issues.

1. Z-axis tried to home going up (reversed the plugs and now it seem to work alright

2. Thermistor for bed is causing a MAXTEMP error. Would this be caused by a bad RAMPS board?

Any help would be greatly appreciated!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 10:45AM |

Registered: 8 years ago Posts: 18 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 01:59PM |

Registered: 8 years ago Posts: 27 |

Quote

wderoxas

Quote

ejnelson

P.S. great work on all the upgrades and such everyone. I'd commend everyone by name but I think pretty much if you're in the forum you have contributed and are worthy of thanks.

I'm about to embark on pretty much reprinting all of the plastic components. I'm thinking about switching the arrangement of the x carriage rods from vertically stacked to horizontally planar. (trying to avoid a big cantilevered extruder/fan/hotend/autolevel-probe mass) Will be using all of the parts posted on thingiverse to guide me.

That's gonna be quite a task. I too had considered to try that configuration since my biggest concern for the cantilevered style is the weight distribution of the extruder-hotend assembly. With the hotend tip too far away from the center of gravity, minor vibrations on x assembly are compounded on the tip. Thats probably the reason why i see my old extruder prints wavy lines.

However, the fix i found was quite simple - switch to bowden. The biggest mass was eliminated and furthermore, the tip is now nearer on the the x rod. I cant see the waviness anymore. Cons associated with bowden like stringing and blobs can be easily fixed with retractions. I can get better speeds too since x carriage is a lot lighter. Except for the inability to print flexible materials (which i havent tried yet), i dont see any disadvantage when i switched to bowden. Ill probably see some in the future, but then, thats what tinkers love anyway.

Im not discouraging you in anyway. Just giving you something to ponder about. Im all for folks trying out something new and learning along the way.

Exactly! Thanks for your thoughts, and I love the bowden idea, especially since I'd like to try for dual extruders, but I also really like the idea of doing flexible material. I'm thinking that possibly a set up with one bowden and one direct might be what I end up doing. I'm thinking as I get into the CAD some of the dimensional constraints might guide my design decisions. We'll see.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 05:02PM |

Registered: 8 years ago Posts: 50 |

Tring to get you all to help with my issue but email responce is slow. here is my problem. let em know what you think.

So at this point I know the motor works and the step drivers are good. I also switch plugs so I know that isn't the issue. So I'm down to 2 possible problems one being program witch I don't think is the problem since this is not the first time folger tech made this printer.So that leaves the board, not sure if its the Arduino clone (which I already had to get a new one (works as far as I know)) or the ramps 1.4 board.

Here a copy paste of the Repetier Host connection info (look for the line with " Error:Line Number is not Last Line Number+1, Last Line: 0" there are a few of them:

15:21:13.131 : OpenGL version:4.4.0

15:21:13.131 : OpenGL extensions:GL_AMD_multi_draw_indirect GL_ARB_arrays_of_arrays GL_ARB_base_instance GL_ARB_blend_func_extended GL_ARB_buffer_storage GL_ARB_clear_buffer_object GL_ARB_clear_texture GL_ARB_color_buffer_float GL_ARB_compatibility GL_ARB_compressed_texture_pixel_storage GL_ARB_conservative_depth GL_ARB_compute_shader GL_ARB_compute_variable_group_size GL_ARB_copy_buffer GL_ARB_copy_image GL_ARB_debug_output GL_ARB_depth_buffer_float GL_ARB_depth_clamp GL_ARB_depth_texture GL_ARB_draw_buffers GL_ARB_draw_buffers_blend GL_ARB_draw_indirect GL_ARB_draw_elements_base_vertex GL_ARB_draw_instanced GL_ARB_enhanced_layouts GL_ARB_ES2_compatibility GL_ARB_ES3_compatibility GL_ARB_explicit_attrib_location GL_ARB_explicit_uniform_location GL_ARB_fragment_coord_conventions GL_ARB_fragment_layer_viewport GL_ARB_fragment_program GL_ARB_fragment_program_shadow GL_ARB_fragment_shader GL_ARB_framebuffer_no_attachments GL_ARB_framebuffer_object GL_ARB_framebuffer_sRGB GL_ARB_geometry_shader4 GL_ARB_get_program_binary GL_ARB_gpu_shader5 GL_ARB_gpu_shader_fp64 GL_ARB_half_float_pixel GL_ARB_half_float_vertex GL_ARB_imaging GL_ARB_indirect_parameters GL_ARB_instanced_arrays GL_ARB_internalformat_query GL_ARB_internalformat_query2 GL_ARB_invalidate_subdata GL_ARB_map_buffer_alignment GL_ARB_map_buffer_range GL_ARB_multi_bind GL_ARB_multi_draw_indirect GL_ARB_multisample GL_ARB_multitexture GL_ARB_occlusion_query GL_ARB_occlusion_query2 GL_ARB_pixel_buffer_object GL_ARB_point_parameters GL_ARB_point_sprite GL_ARB_program_interface_query GL_ARB_provoking_vertex GL_ARB_robust_buffer_access_behavior GL_ARB_robustness GL_ARB_sample_shading GL_ARB_sampler_objects GL_ARB_seamless_cube_map GL_ARB_separate_shader_objects GL_ARB_shader_atomic_counters GL_ARB_shader_bit_encoding GL_ARB_shader_draw_parameters GL_ARB_shader_group_vote GL_ARB_shader_image_load_store GL_ARB_shader_image_size GL_ARB_shader_objects GL_ARB_shader_precision GL_ARB_query_buffer_object GL_ARB_shader_storage_buffer_object GL_ARB_shader_subroutine GL_ARB_shader_texture_lod GL_ARB_shading_language_100 GL_ARB_shading_language_420pack GL_ARB_shading_language_include GL_ARB_shading_language_packing GL_ARB_shadow GL_ARB_stencil_texturing GL_ARB_sync GL_ARB_tessellation_shader GL_ARB_texture_border_clamp GL_ARB_texture_buffer_object GL_ARB_texture_buffer_object_rgb32 GL_ARB_texture_buffer_range GL_ARB_texture_compression GL_ARB_texture_compression_bptc GL_ARB_texture_compression_rgtc GL_ARB_texture_cube_map GL_ARB_texture_cube_map_array GL_ARB_texture_env_add GL_ARB_texture_env_combine GL_ARB_texture_env_crossbar GL_ARB_texture_env_dot3 GL_ARB_texture_float GL_ARB_texture_gather GL_ARB_texture_mirror_clamp_to_edge GL_ARB_texture_mirrored_repeat GL_ARB_texture_multisample GL_ARB_texture_non_power_of_two GL_ARB_texture_query_levels GL_ARB_texture_query_lod GL_ARB_texture_rectangle GL_ARB_texture_rg GL_ARB_texture_rgb10_a2ui GL_ARB_texture_stencil8 GL_ARB_texture_storage GL_ARB_texture_storage_multisample GL_ARB_texture_swizzle GL_ARB_texture_view GL_ARB_timer_query GL_ARB_transform_feedback2 GL_ARB_transform_feedback3 GL_ARB_transform_feedback_instanced GL_ARB_transpose_matrix GL_ARB_uniform_buffer_object GL_ARB_vertex_array_bgra GL_ARB_vertex_array_object GL_ARB_vertex_attrib_64bit GL_ARB_vertex_attrib_binding GL_ARB_vertex_buffer_object GL_ARB_vertex_program GL_ARB_vertex_shader GL_ARB_vertex_type_10f_11f_11f_rev GL_ARB_vertex_type_2_10_10_10_rev GL_ARB_viewport_array GL_ARB_window_pos GL_ATI_draw_buffers GL_ATI_texture_float GL_ATI_texture_mirror_once GL_S3_s3tc GL_EXT_texture_env_add GL_EXT_abgr GL_EXT_bgra GL_EXT_bindable_uniform GL_EXT_blend_color GL_EXT_blend_equation_separate GL_EXT_blend_func_separate GL_EXT_blend_minmax GL_EXT_blend_subtract GL_EXT_compiled_vertex_array GL_EXT_Cg_shader GL_EXT_depth_bounds_test GL_EXT_direct_state_access GL_EXT_draw_buffers2 GL_EXT_draw_instanced GL_EXT_draw_range_elements GL_EXT_fog_coord GL_EXT_framebuffer_blit GL_EXT_framebuffer_multisample GL_EXTX_framebuffer_mixed_formats GL_EXT_framebuffer_multisample_blit_scaled GL_EXT_framebuffer_object GL_EXT_framebuffer_sRGB GL_EXT_geometry_shader4 GL_EXT_gpu_program_parameters GL_EXT_gpu_shader4 GL_EXT_multi_draw_arrays GL_EXT_packed_depth_stencil GL_EXT_packed_float GL_EXT_packed_pixels GL_EXT_pixel_buffer_object GL_EXT_point_parameters GL_EXT_provoking_vertex GL_EXT_rescale_normal GL_EXT_secondary_color GL_EXT_separate_shader_objects GL_EXT_separate_specular_color GL_EXT_shader_integer_mix GL_EXT_shader_image_load_store GL_EXT_shadow_funcs GL_EXT_stencil_two_side GL_EXT_stencil_wrap GL_EXT_texture3D GL_EXT_texture_array GL_EXT_texture_buffer_object GL_EXT_texture_compression_dxt1 GL_EXT_texture_compression_latc GL_EXT_texture_compression_rgtc GL_EXT_texture_compression_s3tc GL_EXT_texture_cube_map GL_EXT_texture_edge_clamp GL_EXT_texture_env_combine GL_EXT_texture_env_dot3 GL_EXT_texture_filter_anisotropic GL_EXT_texture_integer GL_EXT_texture_lod GL_EXT_texture_lod_bias GL_EXT_texture_mirror_clamp GL_EXT_texture_object GL_EXT_texture_shared_exponent GL_EXT_texture_sRGB GL_EXT_texture_sRGB_decode GL_EXT_texture_storage GL_EXT_texture_swizzle GL_EXT_timer_query GL_EXT_transform_feedback2 GL_EXT_vertex_array GL_EXT_vertex_array_bgra GL_EXT_vertex_attrib_64bit GL_EXT_import_sync_object GL_IBM_rasterpos_clip GL_IBM_texture_mirrored_repeat GL_KHR_debug GL_KTX_buffer_region GL_NV_bindless_multi_draw_indirect GL_NV_blend_equation_advanced GL_NV_blend_square GL_NV_compute_program5 GL_NV_conditional_render GL_NV_copy_depth_to_color GL_NV_copy_image GL_NV_depth_buffer_float GL_NV_depth_clamp GL_NV_draw_texture GL_NV_ES1_1_compatibility GL_NV_explicit_multisample GL_NV_fence GL_NV_float_buffer GL_NV_fog_distance GL_NV_fragment_program GL_NV_fragment_program_option GL_NV_fragment_program2 GL_NV_framebuffer_multisample_coverage GL_NV_geometry_shader4 GL_NV_gpu_program4 GL_NV_gpu_program4_1 GL_NV_gpu_program5 GL_NV_gpu_program5_mem_extended GL_NV_gpu_program_fp64 GL_NV_gpu_shader5 GL_NV_half_float GL_NV_light_max_exponent GL_NV_multisample_coverage GL_NV_multisample_filter_hint GL_NV_occlusion_query GL_NV_packed_depth_stencil GL_NV_parameter_buffer_object GL_NV_parameter_buffer_object2 GL_NV_path_rendering GL_NV_pixel_data_range GL_NV_point_sprite GL_NV_primitive_restart GL_NV_register_combiners GL_NV_register_combiners2 GL_NV_shader_atomic_counters GL_NV_shader_atomic_float GL_NV_shader_buffer_load GL_NV_shader_storage_buffer_object GL_ARB_sparse_texture GL_NV_texgen_reflection GL_NV_texture_barrier GL_NV_texture_compression_vtc GL_NV_texture_env_combine4 GL_NV_texture_expand_normal GL_NV_texture_multisample GL_NV_texture_rectangle GL_NV_texture_shader GL_NV_texture_shader2 GL_NV_texture_shader3 GL_NV_transform_feedback GL_NV_transform_feedback2 GL_NV_vertex_array_range GL_NV_vertex_array_range2 GL_NV_vertex_attrib_integer_64bit GL_NV_vertex_buffer_unified_memory GL_NV_vertex_program GL_NV_vertex_program1_1 GL_NV_vertex_program2 GL_NV_vertex_program2_option GL_NV_vertex_program3 GL_NVX_conditional_render GL_NVX_gpu_memory_info GL_NV_shader_thread_group GL_SGIS_generate_mipmap GL_SGIS_texture_lod GL_SGIX_depth_texture GL_SGIX_shadow GL_SUN_slice_accum GL_WIN_swap_hint WGL_EXT_swap_control

15:21:13.131 : OpenGL renderer:GeForce GT 520/PCIe/SSE2/3DNOW!

15:21:13.131 : Using fast VBOs for rendering is possible

15:21:19.574 : Printer reset detected - initalizing

15:21:19.621 : start

15:21:19.621 : echo:Marlin 1.0.0

15:21:19.621 : echo: Last Updated: Aug 1 2015 5-20-15 12:43:49 | Author: (FOLGER TECH, 8 i3 Prusa Config)

15:21:19.621 : Compiled: Aug 1 2015

15:21:19.621 : echo: Free Memory: 4519 PlannerBufferBytes: 1232

15:21:20.136 : N1 M110 *2

15:21:20.136 : N2 M115 *4

15:21:20.744 : N4 M111 S6 *67

15:21:20.791 : N5 T0 *31

15:21:21.977 : echoconfused smileyD init fail

15:21:22.023 : echo:Unknown command: ""

15:21:22.023 : ok

15:21:22.023 : Error:Line Number is not Last Line Number+1, Last Line: 0

15:21:22.023 : Resend: 1

15:21:22.039 : N6 M20 *55

15:21:22.039 : ok

15:21:22.039 : Resend: N1 M110 *2

15:21:22.039 : Resend: N2 M115 *4

15:21:22.039 : Resend: N4 M111 S6 *67

15:21:22.039 : Resend: N5 T0 *31

15:21:22.039 : Error:Line Number is not Last Line Number+1, Last Line: 0

15:21:22.039 : Resend: 1

15:21:22.055 : ok

15:21:22.055 : Resend: N1 M110 *2

15:21:22.055 : Resend: N2 M115 *4

15:21:22.055 : Resend: N4 M111 S6 *67

15:21:22.055 : Resend: N5 T0 *31

15:21:22.055 : Error:No Line Number with checksum, Last Line: 0

15:21:22.055 : Error:Line Number is not Last Line Number+1, Last Line: 0

15:21:22.055 : Resend: 1

15:21:22.070 : ok

15:21:22.070 : ok

15:21:22.070 : Resend: N1 M110 *2

15:21:22.070 : Resend: N2 M115 *4

15:21:22.070 : Resend: N4 M111 S6 *67

15:21:22.070 : Resend: N5 T0 *31

15:21:22.070 : FIRMWARE_NAME:Marlin V1; Sprinter/grbl mashup for gen6 FIRMWARE_URL:[www.mendel-parts.com] PROTOCOL_VERSION:1.0 MACHINE_TYPE:FolgerTech EXTRUDER_COUNT:1

15:21:22.070 : ok

15:21:22.148 : ok

15:21:22.148 : echo:Active Extruder: 0

15:21:22.148 : ok

15:21:22.148 : Resend: N6 M20 *55

15:21:22.148 : ok

15:21:22.148 : N7 M80 *60

15:21:22.148 : N8 M220 S100 *73

15:21:22.148 : N9 M221 S100 *73

15:21:22.148 : FIRMWARE_NAME:Marlin V1; Sprinter/grbl mashup for gen6 FIRMWARE_URL:[www.mendel-parts.com] PROTOCOL_VERSION:1.0 MACHINE_TYPE:FolgerTech EXTRUDER_COUNT:1

15:21:22.148 : ok

15:21:22.148 : ok

15:21:22.148 : N10 M111 S6 *118

15:21:22.148 : echo:Active Extruder: 0

15:21:22.148 : ok

15:21:22.148 : N11 T0 *42

15:21:22.148 : N12 M220 S100 *114

15:21:22.148 : Begin file list

15:21:22.148 : End file list

15:21:22.148 : ok

15:21:22.148 : ok

15:21:22.148 : N13 M221 S100 *114

15:21:22.148 : N14 M111 S6 *114

15:21:22.148 : ok

15:21:22.148 : ok

15:21:22.148 : N15 T0 *46

15:21:22.148 : ok

15:21:22.148 : echo:Active Extruder: 0

15:21:22.148 : ok

15:21:22.148 : ok

15:21:22.148 : ok

15:21:22.164 : ok

15:21:22.164 : echo:Active Extruder: 0

15:21:22.164 : ok

15:21:23.396 : N1 M110 *2

15:21:23.396 : N2 M115 *4

15:21:23.396 : N3 M111 S6 *68

15:21:23.396 : N4 T0 *30

15:21:23.396 : N5 M20 *52

15:21:23.412 : ok

15:21:23.412 : FIRMWARE_NAME:Marlin V1; Sprinter/grbl mashup for gen6 FIRMWARE_URL:[www.mendel-parts.com] PROTOCOL_VERSION:1.0 MACHINE_TYPE:FolgerTech EXTRUDER_COUNT:1

15:21:23.412 : ok

15:21:23.412 : ok

15:21:23.412 : N6 M80 *61

15:21:23.412 : echo:Active Extruder: 0

15:21:23.412 : N7 M220 S100 *70

15:21:23.412 : ok

15:21:23.412 : Begin file list

15:21:23.412 : End file list

15:21:23.412 : ok

15:21:23.412 : N8 M221 S100 *72

15:21:23.412 : ok

15:21:23.412 : ok

15:21:23.412 : N9 M111 S6 *78

15:21:23.412 : ok

15:21:23.412 : N10 T0 *43

15:21:23.427 : ok

15:21:23.427 : echo:Active Extruder: 0

15:21:23.427 : ok

So at this point I know the motor works and the step drivers are good. I also switch plugs so I know that isn't the issue. So I'm down to 2 possible problems one being program witch I don't think is the problem since this is not the first time folger tech made this printer.So that leaves the board, not sure if its the Arduino clone (which I already had to get a new one (works as far as I know)) or the ramps 1.4 board.

Here a copy paste of the Repetier Host connection info (look for the line with " Error:Line Number is not Last Line Number+1, Last Line: 0" there are a few of them:

15:21:13.131 : OpenGL version:4.4.0

15:21:13.131 : OpenGL extensions:GL_AMD_multi_draw_indirect GL_ARB_arrays_of_arrays GL_ARB_base_instance GL_ARB_blend_func_extended GL_ARB_buffer_storage GL_ARB_clear_buffer_object GL_ARB_clear_texture GL_ARB_color_buffer_float GL_ARB_compatibility GL_ARB_compressed_texture_pixel_storage GL_ARB_conservative_depth GL_ARB_compute_shader GL_ARB_compute_variable_group_size GL_ARB_copy_buffer GL_ARB_copy_image GL_ARB_debug_output GL_ARB_depth_buffer_float GL_ARB_depth_clamp GL_ARB_depth_texture GL_ARB_draw_buffers GL_ARB_draw_buffers_blend GL_ARB_draw_indirect GL_ARB_draw_elements_base_vertex GL_ARB_draw_instanced GL_ARB_enhanced_layouts GL_ARB_ES2_compatibility GL_ARB_ES3_compatibility GL_ARB_explicit_attrib_location GL_ARB_explicit_uniform_location GL_ARB_fragment_coord_conventions GL_ARB_fragment_layer_viewport GL_ARB_fragment_program GL_ARB_fragment_program_shadow GL_ARB_fragment_shader GL_ARB_framebuffer_no_attachments GL_ARB_framebuffer_object GL_ARB_framebuffer_sRGB GL_ARB_geometry_shader4 GL_ARB_get_program_binary GL_ARB_gpu_shader5 GL_ARB_gpu_shader_fp64 GL_ARB_half_float_pixel GL_ARB_half_float_vertex GL_ARB_imaging GL_ARB_indirect_parameters GL_ARB_instanced_arrays GL_ARB_internalformat_query GL_ARB_internalformat_query2 GL_ARB_invalidate_subdata GL_ARB_map_buffer_alignment GL_ARB_map_buffer_range GL_ARB_multi_bind GL_ARB_multi_draw_indirect GL_ARB_multisample GL_ARB_multitexture GL_ARB_occlusion_query GL_ARB_occlusion_query2 GL_ARB_pixel_buffer_object GL_ARB_point_parameters GL_ARB_point_sprite GL_ARB_program_interface_query GL_ARB_provoking_vertex GL_ARB_robust_buffer_access_behavior GL_ARB_robustness GL_ARB_sample_shading GL_ARB_sampler_objects GL_ARB_seamless_cube_map GL_ARB_separate_shader_objects GL_ARB_shader_atomic_counters GL_ARB_shader_bit_encoding GL_ARB_shader_draw_parameters GL_ARB_shader_group_vote GL_ARB_shader_image_load_store GL_ARB_shader_image_size GL_ARB_shader_objects GL_ARB_shader_precision GL_ARB_query_buffer_object GL_ARB_shader_storage_buffer_object GL_ARB_shader_subroutine GL_ARB_shader_texture_lod GL_ARB_shading_language_100 GL_ARB_shading_language_420pack GL_ARB_shading_language_include GL_ARB_shading_language_packing GL_ARB_shadow GL_ARB_stencil_texturing GL_ARB_sync GL_ARB_tessellation_shader GL_ARB_texture_border_clamp GL_ARB_texture_buffer_object GL_ARB_texture_buffer_object_rgb32 GL_ARB_texture_buffer_range GL_ARB_texture_compression GL_ARB_texture_compression_bptc GL_ARB_texture_compression_rgtc GL_ARB_texture_cube_map GL_ARB_texture_cube_map_array GL_ARB_texture_env_add GL_ARB_texture_env_combine GL_ARB_texture_env_crossbar GL_ARB_texture_env_dot3 GL_ARB_texture_float GL_ARB_texture_gather GL_ARB_texture_mirror_clamp_to_edge GL_ARB_texture_mirrored_repeat GL_ARB_texture_multisample GL_ARB_texture_non_power_of_two GL_ARB_texture_query_levels GL_ARB_texture_query_lod GL_ARB_texture_rectangle GL_ARB_texture_rg GL_ARB_texture_rgb10_a2ui GL_ARB_texture_stencil8 GL_ARB_texture_storage GL_ARB_texture_storage_multisample GL_ARB_texture_swizzle GL_ARB_texture_view GL_ARB_timer_query GL_ARB_transform_feedback2 GL_ARB_transform_feedback3 GL_ARB_transform_feedback_instanced GL_ARB_transpose_matrix GL_ARB_uniform_buffer_object GL_ARB_vertex_array_bgra GL_ARB_vertex_array_object GL_ARB_vertex_attrib_64bit GL_ARB_vertex_attrib_binding GL_ARB_vertex_buffer_object GL_ARB_vertex_program GL_ARB_vertex_shader GL_ARB_vertex_type_10f_11f_11f_rev GL_ARB_vertex_type_2_10_10_10_rev GL_ARB_viewport_array GL_ARB_window_pos GL_ATI_draw_buffers GL_ATI_texture_float GL_ATI_texture_mirror_once GL_S3_s3tc GL_EXT_texture_env_add GL_EXT_abgr GL_EXT_bgra GL_EXT_bindable_uniform GL_EXT_blend_color GL_EXT_blend_equation_separate GL_EXT_blend_func_separate GL_EXT_blend_minmax GL_EXT_blend_subtract GL_EXT_compiled_vertex_array GL_EXT_Cg_shader GL_EXT_depth_bounds_test GL_EXT_direct_state_access GL_EXT_draw_buffers2 GL_EXT_draw_instanced GL_EXT_draw_range_elements GL_EXT_fog_coord GL_EXT_framebuffer_blit GL_EXT_framebuffer_multisample GL_EXTX_framebuffer_mixed_formats GL_EXT_framebuffer_multisample_blit_scaled GL_EXT_framebuffer_object GL_EXT_framebuffer_sRGB GL_EXT_geometry_shader4 GL_EXT_gpu_program_parameters GL_EXT_gpu_shader4 GL_EXT_multi_draw_arrays GL_EXT_packed_depth_stencil GL_EXT_packed_float GL_EXT_packed_pixels GL_EXT_pixel_buffer_object GL_EXT_point_parameters GL_EXT_provoking_vertex GL_EXT_rescale_normal GL_EXT_secondary_color GL_EXT_separate_shader_objects GL_EXT_separate_specular_color GL_EXT_shader_integer_mix GL_EXT_shader_image_load_store GL_EXT_shadow_funcs GL_EXT_stencil_two_side GL_EXT_stencil_wrap GL_EXT_texture3D GL_EXT_texture_array GL_EXT_texture_buffer_object GL_EXT_texture_compression_dxt1 GL_EXT_texture_compression_latc GL_EXT_texture_compression_rgtc GL_EXT_texture_compression_s3tc GL_EXT_texture_cube_map GL_EXT_texture_edge_clamp GL_EXT_texture_env_combine GL_EXT_texture_env_dot3 GL_EXT_texture_filter_anisotropic GL_EXT_texture_integer GL_EXT_texture_lod GL_EXT_texture_lod_bias GL_EXT_texture_mirror_clamp GL_EXT_texture_object GL_EXT_texture_shared_exponent GL_EXT_texture_sRGB GL_EXT_texture_sRGB_decode GL_EXT_texture_storage GL_EXT_texture_swizzle GL_EXT_timer_query GL_EXT_transform_feedback2 GL_EXT_vertex_array GL_EXT_vertex_array_bgra GL_EXT_vertex_attrib_64bit GL_EXT_import_sync_object GL_IBM_rasterpos_clip GL_IBM_texture_mirrored_repeat GL_KHR_debug GL_KTX_buffer_region GL_NV_bindless_multi_draw_indirect GL_NV_blend_equation_advanced GL_NV_blend_square GL_NV_compute_program5 GL_NV_conditional_render GL_NV_copy_depth_to_color GL_NV_copy_image GL_NV_depth_buffer_float GL_NV_depth_clamp GL_NV_draw_texture GL_NV_ES1_1_compatibility GL_NV_explicit_multisample GL_NV_fence GL_NV_float_buffer GL_NV_fog_distance GL_NV_fragment_program GL_NV_fragment_program_option GL_NV_fragment_program2 GL_NV_framebuffer_multisample_coverage GL_NV_geometry_shader4 GL_NV_gpu_program4 GL_NV_gpu_program4_1 GL_NV_gpu_program5 GL_NV_gpu_program5_mem_extended GL_NV_gpu_program_fp64 GL_NV_gpu_shader5 GL_NV_half_float GL_NV_light_max_exponent GL_NV_multisample_coverage GL_NV_multisample_filter_hint GL_NV_occlusion_query GL_NV_packed_depth_stencil GL_NV_parameter_buffer_object GL_NV_parameter_buffer_object2 GL_NV_path_rendering GL_NV_pixel_data_range GL_NV_point_sprite GL_NV_primitive_restart GL_NV_register_combiners GL_NV_register_combiners2 GL_NV_shader_atomic_counters GL_NV_shader_atomic_float GL_NV_shader_buffer_load GL_NV_shader_storage_buffer_object GL_ARB_sparse_texture GL_NV_texgen_reflection GL_NV_texture_barrier GL_NV_texture_compression_vtc GL_NV_texture_env_combine4 GL_NV_texture_expand_normal GL_NV_texture_multisample GL_NV_texture_rectangle GL_NV_texture_shader GL_NV_texture_shader2 GL_NV_texture_shader3 GL_NV_transform_feedback GL_NV_transform_feedback2 GL_NV_vertex_array_range GL_NV_vertex_array_range2 GL_NV_vertex_attrib_integer_64bit GL_NV_vertex_buffer_unified_memory GL_NV_vertex_program GL_NV_vertex_program1_1 GL_NV_vertex_program2 GL_NV_vertex_program2_option GL_NV_vertex_program3 GL_NVX_conditional_render GL_NVX_gpu_memory_info GL_NV_shader_thread_group GL_SGIS_generate_mipmap GL_SGIS_texture_lod GL_SGIX_depth_texture GL_SGIX_shadow GL_SUN_slice_accum GL_WIN_swap_hint WGL_EXT_swap_control

15:21:13.131 : OpenGL renderer:GeForce GT 520/PCIe/SSE2/3DNOW!

15:21:13.131 : Using fast VBOs for rendering is possible

15:21:19.574 : Printer reset detected - initalizing

15:21:19.621 : start

15:21:19.621 : echo:Marlin 1.0.0

15:21:19.621 : echo: Last Updated: Aug 1 2015 5-20-15 12:43:49 | Author: (FOLGER TECH, 8 i3 Prusa Config)

15:21:19.621 : Compiled: Aug 1 2015

15:21:19.621 : echo: Free Memory: 4519 PlannerBufferBytes: 1232

15:21:20.136 : N1 M110 *2

15:21:20.136 : N2 M115 *4

15:21:20.744 : N4 M111 S6 *67

15:21:20.791 : N5 T0 *31

15:21:21.977 : echoconfused smileyD init fail

15:21:22.023 : echo:Unknown command: ""

15:21:22.023 : ok

15:21:22.023 : Error:Line Number is not Last Line Number+1, Last Line: 0

15:21:22.023 : Resend: 1

15:21:22.039 : N6 M20 *55

15:21:22.039 : ok

15:21:22.039 : Resend: N1 M110 *2

15:21:22.039 : Resend: N2 M115 *4

15:21:22.039 : Resend: N4 M111 S6 *67

15:21:22.039 : Resend: N5 T0 *31

15:21:22.039 : Error:Line Number is not Last Line Number+1, Last Line: 0

15:21:22.039 : Resend: 1

15:21:22.055 : ok

15:21:22.055 : Resend: N1 M110 *2

15:21:22.055 : Resend: N2 M115 *4

15:21:22.055 : Resend: N4 M111 S6 *67

15:21:22.055 : Resend: N5 T0 *31

15:21:22.055 : Error:No Line Number with checksum, Last Line: 0

15:21:22.055 : Error:Line Number is not Last Line Number+1, Last Line: 0

15:21:22.055 : Resend: 1

15:21:22.070 : ok

15:21:22.070 : ok

15:21:22.070 : Resend: N1 M110 *2

15:21:22.070 : Resend: N2 M115 *4

15:21:22.070 : Resend: N4 M111 S6 *67

15:21:22.070 : Resend: N5 T0 *31

15:21:22.070 : FIRMWARE_NAME:Marlin V1; Sprinter/grbl mashup for gen6 FIRMWARE_URL:[www.mendel-parts.com] PROTOCOL_VERSION:1.0 MACHINE_TYPE:FolgerTech EXTRUDER_COUNT:1

15:21:22.070 : ok

15:21:22.148 : ok

15:21:22.148 : echo:Active Extruder: 0

15:21:22.148 : ok

15:21:22.148 : Resend: N6 M20 *55

15:21:22.148 : ok

15:21:22.148 : N7 M80 *60

15:21:22.148 : N8 M220 S100 *73

15:21:22.148 : N9 M221 S100 *73

15:21:22.148 : FIRMWARE_NAME:Marlin V1; Sprinter/grbl mashup for gen6 FIRMWARE_URL:[www.mendel-parts.com] PROTOCOL_VERSION:1.0 MACHINE_TYPE:FolgerTech EXTRUDER_COUNT:1

15:21:22.148 : ok

15:21:22.148 : ok

15:21:22.148 : N10 M111 S6 *118

15:21:22.148 : echo:Active Extruder: 0

15:21:22.148 : ok

15:21:22.148 : N11 T0 *42

15:21:22.148 : N12 M220 S100 *114

15:21:22.148 : Begin file list

15:21:22.148 : End file list

15:21:22.148 : ok

15:21:22.148 : ok

15:21:22.148 : N13 M221 S100 *114

15:21:22.148 : N14 M111 S6 *114

15:21:22.148 : ok

15:21:22.148 : ok

15:21:22.148 : N15 T0 *46

15:21:22.148 : ok

15:21:22.148 : echo:Active Extruder: 0

15:21:22.148 : ok

15:21:22.148 : ok

15:21:22.148 : ok

15:21:22.164 : ok

15:21:22.164 : echo:Active Extruder: 0

15:21:22.164 : ok

15:21:23.396 : N1 M110 *2

15:21:23.396 : N2 M115 *4

15:21:23.396 : N3 M111 S6 *68

15:21:23.396 : N4 T0 *30

15:21:23.396 : N5 M20 *52

15:21:23.412 : ok

15:21:23.412 : FIRMWARE_NAME:Marlin V1; Sprinter/grbl mashup for gen6 FIRMWARE_URL:[www.mendel-parts.com] PROTOCOL_VERSION:1.0 MACHINE_TYPE:FolgerTech EXTRUDER_COUNT:1

15:21:23.412 : ok

15:21:23.412 : ok

15:21:23.412 : N6 M80 *61

15:21:23.412 : echo:Active Extruder: 0

15:21:23.412 : N7 M220 S100 *70

15:21:23.412 : ok

15:21:23.412 : Begin file list

15:21:23.412 : End file list

15:21:23.412 : ok

15:21:23.412 : N8 M221 S100 *72

15:21:23.412 : ok

15:21:23.412 : ok

15:21:23.412 : N9 M111 S6 *78

15:21:23.412 : ok

15:21:23.412 : N10 T0 *43

15:21:23.427 : ok

15:21:23.427 : echo:Active Extruder: 0

15:21:23.427 : ok

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 05:56PM |

Registered: 8 years ago Posts: 19 |

I would dl the latest firmware from therippa then load it in the Arduino software and upload to the Arduino board. See belowQuote

shaol

Tring to get you all to help with my issue but email responce is slow. here is my problem. let em know what you think.

So at this point I know the motor works and the step drivers are good. I also switch plugs so I know that isn't the issue. So I'm down to 2 possible problems one being program witch I don't think is the problem since this is not the first time folger tech made this printer.So that leaves the board, not sure if its the Arduino clone (which I already had to get a new one (works as far as I know)) or the ramps 1.4 board.

Here a copy paste of the Repetier Host connection info (look for the line with " Error:Line Number is not Last Line Number+1, Last Line: 0" there are a few of them:

therippa [ PM ]

Re: Folger Tech 2020 i3 Printer Kit (Official Thread)

July 26, 2015 12:51PM Registered: 4 weeks ago

Posts: 50

Quote

nmh5028

INteresting, wonder if there is an issue with the Folgertech firmware. This is my log when connection to the printer in Reptier. Lots of errors but I'm not sure what they mean. Also, the RAMPS test code runs fine, so I'm pretty sure FOlgertech has an error in the config, but I'm not sure how to troubleshoot that.

15:38:09.066 : Printer reset detected - initalizing

15:38:09.066 : start

15:38:09.066 : echo:Marlin 1.0.0

15:38:09.070 : echo: Last Updated: Jul 26 2015 5-20-15 15:37:02 | Author: (FOLGER TECH, 8 i3 Prusa Config)

15:38:09.070 : Compiled: Jul 26 2015

15:38:09.073 : echo: Free Memory: 4519 PlannerBufferBytes: 1232

15:38:11.477 : echoconfused smileyD init fail

15:38:11.547 : echo:Unknown command: ""

15:38:11.551 : Error:Line Number is not Last Line Number+1, Last Line: 0

15:38:11.551 : Resend: 1

15:38:11.555 : Error:Line Number is not Last Line Number+1, Last Line: 0

15:38:11.560 : Resend: 1

15:38:11.563 : echo:Unknown command: "0"

15:38:11.563 : Error:No Line Number with checksum, Last Line: 0

15:38:11.564 : Error:Line Number is not Last Line Number+1, Last Line: 0

15:38:11.564 : Resend: 1

15:38:11.568 : Error:checksum mismatch, Last Line: 0

15:38:11.568 : Resend: 1

15:38:11.573 : Error:Line Number is not Last Line Number+1, Last Line: 0

15:38:11.573 : Resend: 1

15:38:11.576 : Error:No Line Number with checksum, Last Line: 0

15:38:11.576 : Error:Line Number is not Last Line Number+1, Last Line: 0

15:38:11.576 : Resend: 1

15:38:11.580 : Error:No Line Number with checksum, Last Line: 0

15:38:11.580 : Error:Line Number is not Last Line Number+1, Last Line: 0

15:38:11.580 : Resend: 1

15:38:11.586 : Error:No Line Number with checksum, Last Line: 0

15:38:11.588 : Error:Line Number is not Last Line Number+1, Last Line: 0

15:38:11.588 : Resend: 1

15:38:11.597 : FIRMWARE_NAME:Marlin V1; Sprinter/grbl mashup for gen6 FIRMWARE_URL:[www.mendel-parts.com] PROTOCOL_VERSION:1.0 MACHINE_TYPE:FolgerTech EXTRUDER_COUNT:1

15:38:11.612 : echo:Active Extruder: 0

15:38:11.612 : Begin file list

15:38:11.613 : End file list

15:38:11.614 : FIRMWARE_NAME:Marlin V1; Sprinter/grbl mashup for gen6 FIRMWARE_URL:[www.mendel-parts.com] PROTOCOL_VERSION:1.0 MACHINE_TYPE:FolgerTech EXTRUDER_COUNT:1

15:38:11.615 : echo:Active Extruder: 0

** SNIP **

15:38:12.829 : Begin file list

15:38:12.829 : End file list

15:38:12.833 : echo:Active Extruder: 0

Try loading the latest firmware with the Folgertech settings already merged in - www.github.com

Edited 2 time(s). Last edit at 08/04/2015 06:02PM by rrowan327.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 06:24PM |

Registered: 8 years ago Posts: 50 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 06:24PM |

Registered: 8 years ago Posts: 276 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 06:25PM |

Registered: 8 years ago Posts: 276 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 06:34PM |

Registered: 8 years ago Posts: 50 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 06:40PM |

Registered: 8 years ago Posts: 50 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 06:45PM |

Registered: 8 years ago Posts: 276 |

Quote

shaol

Am I replacing Marlin_RAMPS_EPCOS_i38.ino (came from folger tech) with Merlin.ino

You're starting a whole new project.

Re-download the firmware here - [github.com]

Unzip that folder, and you'll see a file called Marlin.ino. Double-click it and it should open the project in Arduino. Make sure your port and board are set right, and upload it.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 06:59PM |

Registered: 8 years ago Posts: 5 |

So I have skimmed the bulk of this thread and feel I should just come out and ask.

FYI: I am working in ABS plastic at 230c

I just finished building my 2020 aluminum Folger Tech Prusa i3 and worked out a chunk of issues I am having but every time I come up with a solution it becomes a little more clear to me that the configuration.h file is not at all meant for this model or what came in my box. I usually enjoy doing things “hard mode” but I am getting into an annoying amount of guess work regarding steps per unit and what not. Does anyone have a working configuration.h file that works with the out of the box machine? I would love to know some of your values.

Issues I am having with the prints range from inconsistency in extrusion thickness against the build platform and on the parts (I’ve nicknamed it homemade birthday cake decoration syndrome).

Other issue is as the extruder works it way up the z axis it just stops printing, and it extruding into air, though notable it’s not really extruding anything.

Note: I had to change some setting to get the Z axis to even rotate, it just made cool noises and moved no where. Even when I put in calculated values with adjustments that made it move it would move way more than what I told it to do with the manual movement, so one of the values is a total “tung at the right angle” value. (Again, please provide a working configuration.h please)

thank you!

FYI: I am working in ABS plastic at 230c

I just finished building my 2020 aluminum Folger Tech Prusa i3 and worked out a chunk of issues I am having but every time I come up with a solution it becomes a little more clear to me that the configuration.h file is not at all meant for this model or what came in my box. I usually enjoy doing things “hard mode” but I am getting into an annoying amount of guess work regarding steps per unit and what not. Does anyone have a working configuration.h file that works with the out of the box machine? I would love to know some of your values.

Issues I am having with the prints range from inconsistency in extrusion thickness against the build platform and on the parts (I’ve nicknamed it homemade birthday cake decoration syndrome).

Other issue is as the extruder works it way up the z axis it just stops printing, and it extruding into air, though notable it’s not really extruding anything.

Note: I had to change some setting to get the Z axis to even rotate, it just made cool noises and moved no where. Even when I put in calculated values with adjustments that made it move it would move way more than what I told it to do with the manual movement, so one of the values is a total “tung at the right angle” value. (Again, please provide a working configuration.h please)

thank you!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 07:05PM |

Registered: 8 years ago Posts: 50 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 08:35PM |

Registered: 8 years ago Posts: 14 |

Quote

Morrobotz

So I have skimmed the bulk of this thread and feel I should just come out and ask.

FYI: I am working in ABS plastic at 230c

I just finished building my 2020 aluminum Folger Tech Prusa i3 and worked out a chunk of issues I am having but every time I come up with a solution it becomes a little more clear to me that the configuration.h file is not at all meant for this model or what came in my box. I usually enjoy doing things “hard mode” but I am getting into an annoying amount of guess work regarding steps per unit and what not. Does anyone have a working configuration.h file that works with the out of the box machine? I would love to know some of your values.

Issues I am having with the prints range from inconsistency in extrusion thickness against the build platform and on the parts (I’ve nicknamed it homemade birthday cake decoration syndrome).

Other issue is as the extruder works it way up the z axis it just stops printing, and it extruding into air, though notable it’s not really extruding anything.

Note: I had to change some setting to get the Z axis to even rotate, it just made cool noises and moved no where. Even when I put in calculated values with adjustments that made it move it would move way more than what I told it to do with the manual movement, so one of the values is a total “tung at the right angle” value. (Again, please provide a working configuration.h please)

thank you!

Your extruder problem sounds like your temperature is a little too low. I am still experimenting with ABS temps. I started with 230, and did some prints last night at 240. That seemed OK for bigger print sections, but on long narrow sections the plastic was building up too much creating a rope like pattern. I could see the nozzle riding up and down over these ridges. I might drop the temperature back down to 235, and see what effect changing the infill/perimeters overlap has.

Yours sounds like it is starting fine, but can't keep up. Maybe slowing the speed down a bit, or maybe it needs PID tuning? (I haven't done that yet on mine, but it's on the TO DO list).

I haven't made many changes to the configuration.h file provided by Folger Tech. In the "Mechanical Settings" section I changed DEFAULT_AXIS_STEPS_PER_UNIT.

The Stock file had the values (80,80,3840,90) which correspond to the X axis, Y axis, Z axis, and Extruder. I left the X and Y values at 80, changed the Z value to 4000, and changed the Extruder value to 96.3.

I don't know why they had a different value for the Z axis. For the 5mm leadscrew 4000 should be right and I confirmed it on my printer with a digital height gauge.

As for the extruder value, that may be different for each printer. Slight differences in the diameter of the drive gear and pressure from spring may alter it and it needs to be calibrated by extruding some filament and measuring how far it actually moved. There's a good tutorial on doing that here: 3D printing guides - Calibrating your extruder

Note that when sending gcode to the printer manually in Repetier, I found I needed to insert spaces (such as G1 E100 F90 instead of G1E100F90 as done in the video).

I also found a good tutorial on configuring the extrusion width: Setting your 3D printer's extrusion Part 2

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 10:25PM |

Registered: 8 years ago Posts: 5 |

Oddly my Z axis was only working correctly at 250 not 4,000

Fun news however. I went to go work on the machine again and it was having issues, I unplugged the USB and it gave out a death screech for a second (power supply I assume, since nothing else has a piezo on it). Then it only wanted to connect to the laptop when the mains 110 was pulled..... (Mother trucker.....) Yea I pulled the controller and and tested the voltage regulator on the mega you guessed it... shot. I have some 5v regulators but they are TO-220's so MacGyver and I would need to have a chat. Though it's likely the mega may have suffered damage. The supply voltage to the ATMega 2560 was likely about 9 or 10 volts department, double its datasheet (though the data sheet did not directly state a maximum just listed an operating range second hand, fun fact don't try and run one on less than 2.5 volts). The mega still can connect to the laptop with 5v USB power so my theory is without the regulator the mega is trying to communicate with 8v logic over USB with the PSU is plugged in so naturally the laptop told it to away and not talk to it.

I'm not going to lie, this printer is starting to become a real headache, The price was just too good.....

The parts that came in the kit were not exactly audited for accuracy, I ended up having a lot of extras, particularly M3 screws. (Note: I am glad I had more parts and not less...) Some of the aluminum brackets were clearly not original release spec as the bolts intended for them nearly passed right through the holes; holes to big. The bolts used in the build guide are also different than what was provided (They used machine screws, however pan head was provided, though the text referenced pan head). Moreover the some of the linear bearings it shipped with are rough even after alignment and lubrication. The printed parts in the kit had issues, overall they were “Ok” and I actually was going to remake them once the printer was dialed in. The parts that I had the greatest issue with where the linear bearing mounts. The mounts were too short to accommodate the bearings, I had to use a rotary tool to hog out some plastic to make them fit. This also brings me to the zip ties provided, they work but are clearly inexpensive, I can’t log that under complaint since it's clear the price of this kit has been optimized and I can always get nicer ones. I also had extra washers and T nuts, even after using some in places where the build guide did not call for them. Extra washers in a kit always makes me nervous since they are rather important. I will say It was nice seeing one extra of some parts, a real good guy move on Folger Tech’s part but 37 M3 pan heads....

Am I happy with my purchase? not yet, I expected some headache and even told myself to reserve judgment until I have my first finished print.

Mid project feedback:

Folger Tech - check your kits parts, I’m speculating you are using a chinese provider for a bulk of the hardware (if not all of it). Nothing wrong with that but you may want to rebuild the kit once and a while to just make sure they are sending the right stuff. Also provide your calibration settings from the build, It may not be perfect for some people but it sure as hell would be more accurate than just taking the stock configuration.h file from a whole different printer.

Fun news however. I went to go work on the machine again and it was having issues, I unplugged the USB and it gave out a death screech for a second (power supply I assume, since nothing else has a piezo on it). Then it only wanted to connect to the laptop when the mains 110 was pulled..... (Mother trucker.....) Yea I pulled the controller and and tested the voltage regulator on the mega you guessed it... shot. I have some 5v regulators but they are TO-220's so MacGyver and I would need to have a chat. Though it's likely the mega may have suffered damage. The supply voltage to the ATMega 2560 was likely about 9 or 10 volts department, double its datasheet (though the data sheet did not directly state a maximum just listed an operating range second hand, fun fact don't try and run one on less than 2.5 volts). The mega still can connect to the laptop with 5v USB power so my theory is without the regulator the mega is trying to communicate with 8v logic over USB with the PSU is plugged in so naturally the laptop told it to away and not talk to it.

I'm not going to lie, this printer is starting to become a real headache, The price was just too good.....

The parts that came in the kit were not exactly audited for accuracy, I ended up having a lot of extras, particularly M3 screws. (Note: I am glad I had more parts and not less...) Some of the aluminum brackets were clearly not original release spec as the bolts intended for them nearly passed right through the holes; holes to big. The bolts used in the build guide are also different than what was provided (They used machine screws, however pan head was provided, though the text referenced pan head). Moreover the some of the linear bearings it shipped with are rough even after alignment and lubrication. The printed parts in the kit had issues, overall they were “Ok” and I actually was going to remake them once the printer was dialed in. The parts that I had the greatest issue with where the linear bearing mounts. The mounts were too short to accommodate the bearings, I had to use a rotary tool to hog out some plastic to make them fit. This also brings me to the zip ties provided, they work but are clearly inexpensive, I can’t log that under complaint since it's clear the price of this kit has been optimized and I can always get nicer ones. I also had extra washers and T nuts, even after using some in places where the build guide did not call for them. Extra washers in a kit always makes me nervous since they are rather important. I will say It was nice seeing one extra of some parts, a real good guy move on Folger Tech’s part but 37 M3 pan heads....

Am I happy with my purchase? not yet, I expected some headache and even told myself to reserve judgment until I have my first finished print.

Mid project feedback:

Folger Tech - check your kits parts, I’m speculating you are using a chinese provider for a bulk of the hardware (if not all of it). Nothing wrong with that but you may want to rebuild the kit once and a while to just make sure they are sending the right stuff. Also provide your calibration settings from the build, It may not be perfect for some people but it sure as hell would be more accurate than just taking the stock configuration.h file from a whole different printer.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2015 10:51PM |

Registered: 8 years ago Posts: 285 |

Quote

Morrobotz

So I have skimmed the bulk of this thread and feel I should just come out and ask.

FYI: I am working in ABS plastic at 230c

I just finished building my 2020 aluminum Folger Tech Prusa i3 and worked out a chunk of issues I am having but every time I come up with a solution it becomes a little more clear to me that the configuration.h file is not at all meant for this model or what came in my box. I usually enjoy doing things “hard mode” but I am getting into an annoying amount of guess work regarding steps per unit and what not. Does anyone have a working configuration.h file that works with the out of the box machine? I would love to know some of your values.

Issues I am having with the prints range from inconsistency in extrusion thickness against the build platform and on the parts (I’ve nicknamed it homemade birthday cake decoration syndrome).

Other issue is as the extruder works it way up the z axis it just stops printing, and it extruding into air, though notable it’s not really extruding anything.

Note: I had to change some setting to get the Z axis to even rotate, it just made cool noises and moved no where. Even when I put in calculated values with adjustments that made it move it would move way more than what I told it to do with the manual movement, so one of the values is a total “tung at the right angle” value. (Again, please provide a working configuration.h please)

thank you!

Sorry to hear about what happened to your controller. Not sure I you will be able to use this right now, but here is my config.h file. You may want to check the endstop positions and such to make sure they are

in the right positions for you printer setup. The steps per mm settings should work as I have not seen any problems with the printers motion.

config.h file Here

Edited 1 time(s). Last edit at 08/04/2015 10:54PM by Mach.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 05, 2015 12:51AM |

Registered: 8 years ago Posts: 367 |

@morrobotz: if your Z axis was working at 250 instead of 4000 you probably didn't attach the headers to the RAMPS board. The three headers (per motor) set it to 16x microstepping, and 250*16 = 4000.

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 05, 2015 12:00PM |

Registered: 8 years ago Posts: 30 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 05, 2015 05:58PM |

Registered: 8 years ago Posts: 5 |

Hi

I've been using my 2020 for about a month now. No real problems other than errors in the installation documents. THEN, I tried to install the LCD display that I purchased from FolgerTech. I have not found any documentation on the display installation. I did use a flick from youtube (https://www.youtube.com/watch?v=wP0LlOF8z58) that led me to the proper way to plug the device into the RAMPS board as well as a hint about configuration changes that may or may not be required. I tried using the config changes suggested in the flick. No go. So I reverted back to the FolgerTech provided Marlin. As a result I have the following results:

With the PC to Arduino USB cable unplugged, powering up the Arduino gives me cooling fan rotation but no life in the display (as if not attached)

With the PC to Arduino USB cable installed, PC on, but the power supply for the printer off, I get the display illuminated, but with no display content. (Arduino not powered ???) The contrast pot works as expected.

With the PC to Arduino USB cable installed, PC on, power supply for the printer on, the printer works as it did prior to the installation of the display (Repetier controls the printer).

If you have that bit of knowledge that I am missing, I would really appreciate your assistance.

Bill

I've been using my 2020 for about a month now. No real problems other than errors in the installation documents. THEN, I tried to install the LCD display that I purchased from FolgerTech. I have not found any documentation on the display installation. I did use a flick from youtube (https://www.youtube.com/watch?v=wP0LlOF8z58) that led me to the proper way to plug the device into the RAMPS board as well as a hint about configuration changes that may or may not be required. I tried using the config changes suggested in the flick. No go. So I reverted back to the FolgerTech provided Marlin. As a result I have the following results:

With the PC to Arduino USB cable unplugged, powering up the Arduino gives me cooling fan rotation but no life in the display (as if not attached)

With the PC to Arduino USB cable installed, PC on, but the power supply for the printer off, I get the display illuminated, but with no display content. (Arduino not powered ???) The contrast pot works as expected.

With the PC to Arduino USB cable installed, PC on, power supply for the printer on, the printer works as it did prior to the installation of the display (Repetier controls the printer).

If you have that bit of knowledge that I am missing, I would really appreciate your assistance.

Bill

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 05, 2015 06:53PM |

Registered: 8 years ago Posts: 121 |

I want to reprint the x-carriage parts, I thought I saw a copy of them with screws to snug up the bearings but without the 8 mm collars like these have [www.thingiverse.com] I like wderoxas design but for some reason I am nervous about changing out the 5 mm rods to the 8mm collared ones. I cracked the under motor bracket for the Z rod holders. I have been asking Folger tech to sell me new ones.

Does anyone know where I can find the ones I mentioned> I have yet to play with 3d modeling software so maybe this could be my first project in google sketch up?

Does anyone know where I can find the ones I mentioned> I have yet to play with 3d modeling software so maybe this could be my first project in google sketch up?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 05, 2015 07:07PM |

Registered: 8 years ago Posts: 5 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 05, 2015 07:30PM |

Registered: 8 years ago Posts: 33 |

Well I am up and running (second time) . I put it togeather first and found some problems I thought needed changing. The vertical Z axis rods did not align properly, the X axis rods needed a stop to keep them from slipping inwards after tension was applied to belt. Motor mount bearings did not align properly. The Y axis rods had some runout when turned in the mounts. I felt it needed some braces to make it more rigid frame. The bearing noise was not acceptable. So I fixed all the things and made my first print today. Now it runs smooth and no noise and cool on all motors. I am attempting to send image but they are too big. I am very happy with this printer. I just need to learn more about using it. LOL.. The mechanical part is easy, it's the rest of it I need to learn. This site has been the biggest help to me. Thanks Guys.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 05, 2015 07:41PM |

Registered: 8 years ago Posts: 276 |

Quote

kn4ud

Well I am up and running (second time) . I put it togeather first and found some problems I thought needed changing. The vertical Z axis rods did not align properly, the X axis rods needed a stop to keep them from slipping inwards after tension was applied to belt. Motor mount bearings did not align properly. The Y axis rods had some runout when turned in the mounts. I felt it needed some braces to make it more rigid frame. The bearing noise was not acceptable. So I fixed all the things and made my first print today. Now it runs smooth and no noise and cool on all motors. I am attempting to send image but they are too big. I am very happy with this printer. I just need to learn more about using it. LOL.. The mechanical part is easy, it's the rest of it I need to learn. This site has been the biggest help to me. Thanks Guys.

I'm interested in seeing your changes, why not use imgur.com to host the pictures?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 05, 2015 08:46PM |

Registered: 8 years ago Posts: 5 |

I like this comment! (fixed it)Quote

animoose

@morrobotz: if your Z axis was working at 250 instead of 4000 you probably didn't attach the headers to the RAMPS board. The three headers (per motor) set it to 16x microstepping, and 250*16 = 4000.

Well good news, I'm printing just fine now, working on calibrations but all and all things are looking good.

I MacGyvered the Ramps 1.4 Board by unsoldering one of the leeds on the 1N4001 Diode going to Vin. Now the Mega is powered off of the USB 5v rail and not the shot regulator. (Fun fact kids!!! a ATMega can take like 9 volts on Vcc and not die. I had this appfiniy laying down in bed looking over the ATMEGA 2560 data sheet and I noticed they did not list a specefic max voltage, only implied a max voltage of 5.5v. (many micro processors can run at higher voltages than 5 and 3.3. FYI) It must have survived due to the high impeedance inputs on the steper drivers.

now I am just tuning rates in Slic3r to get an ideal print. (lots of test cilinders) I'm using ABS, but I need to pick up some other types like PLA, Nylon, and Ninja flex.

I mounted the belt tensioners as well, did not see anything in the guide so I guessed, looks like they work.

now the addiction begins.....

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 05, 2015 10:01PM |

Registered: 8 years ago Posts: 33 |

[imgur.com]

[imgur.com]

[imgur.com]

[imgur.com]

[imgur.com]

[imgur.com]

[imgur.com]

Thanks therippa for telling me how to post the images. This shows some of the mods and the first print which was .5mm wall square with abs at 205c on extruder and 105c on the bed. I will try to make some better pictures on the complete unit. I still have to add 2 more braces but have ran out of sheet metal but going to pick up some tomorrow.

[imgur.com]

[imgur.com]

[imgur.com]

[imgur.com]

[imgur.com]

[imgur.com]

Thanks therippa for telling me how to post the images. This shows some of the mods and the first print which was .5mm wall square with abs at 205c on extruder and 105c on the bed. I will try to make some better pictures on the complete unit. I still have to add 2 more braces but have ran out of sheet metal but going to pick up some tomorrow.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 05, 2015 10:02PM |

Registered: 8 years ago Posts: 81 |

Quote

robodog

Hi

I've been using my 2020 for about a month now. No real problems other than errors in the installation documents. THEN, I tried to install the LCD display that I purchased from FolgerTech. I have not found any documentation on the display installation. I did use a flick from youtube (https://www.youtube.com/watch?v=wP0LlOF8z58) that led me to the proper way to plug the device into the RAMPS board as well as a hint about configuration changes that may or may not be required. I tried using the config changes suggested in the flick. No go. So I reverted back to the FolgerTech provided Marlin. As a result I have the following results:

With the PC to Arduino USB cable unplugged, powering up the Arduino gives me cooling fan rotation but no life in the display (as if not attached)

With the PC to Arduino USB cable installed, PC on, but the power supply for the printer off, I get the display illuminated, but with no display content. (Arduino not powered ???) The contrast pot works as expected.

With the PC to Arduino USB cable installed, PC on, power supply for the printer on, the printer works as it did prior to the installation of the display (Repetier controls the printer).

If you have that bit of knowledge that I am missing, I would really appreciate your assistance.

Bill

1) "With the PC to Arduino USB cable installed, PC on, power supply for the printer on, the printer works as it did prior to the installation of the display (Repetier controls the printer)." - does the LCD still shows no display but lits up??

2) "With the PC to Arduino USB cable unplugged, powering up the Arduino gives me cooling fan rotation but no life in the display (as if not attached)" - This is usually an indication that the voltage regulator on Mega is broken. 12V from PSU pass through D1 then to the Vin of voltage regulator at Mega to step it down to 5V. This 5V powers the Mega, the lcd and the 5V needed by the stepper drivers. Aside from the voltage regulator, this 5V can also come from the USB.

3) "With the PC to Arduino USB cable installed, PC on, power supply for the printer on, the printer works as it did prior to the installation of the display (Repetier controls the printer)" - If the display still shows nothing but lits up, then its either, you have connected the two ribbon cables wrongly (there should be labels on mega's adapter that corresponds to the label at the lcd pcb), or somethings wrong with your config.

|

thermistor location? power cable connections? August 05, 2015 10:16PM |

Registered: 8 years ago Posts: 4 |

Greetings all,

Here's my first msg here. I have gone through a lot of the thread - tons of great info!

I have two questions, both related to my build which is 90% complete.

1) The tape holding the thermistor to the heatbed let go so I need to re-do it. While I am at it I should ask - where precisely should the bulb-tip be placed? I had it right in the hole in the middle of the heatbed, essentially filling it level with the surface. Is that best?

2) Please note this part of step 21 (on page 29) in the build manual. Is there a misprint here or am I dreaming? Does this really refer to BOTH the first and second place on the ramp board's blue power strip as (-)? Does the picture really show the black cable connecting to the (+) terminal?

Thanks much. I am looking forward to getting to the end of this build and seeing just what it can do.

Steve

Here's my first msg here. I have gone through a lot of the thread - tons of great info!

I have two questions, both related to my build which is 90% complete.

1) The tape holding the thermistor to the heatbed let go so I need to re-do it. While I am at it I should ask - where precisely should the bulb-tip be placed? I had it right in the hole in the middle of the heatbed, essentially filling it level with the surface. Is that best?

2) Please note this part of step 21 (on page 29) in the build manual. Is there a misprint here or am I dreaming? Does this really refer to BOTH the first and second place on the ramp board's blue power strip as (-)? Does the picture really show the black cable connecting to the (+) terminal?

Thanks much. I am looking forward to getting to the end of this build and seeing just what it can do.

Steve

Sorry, only registered users may post in this forum.