Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 14, 2015 11:57AM |

Registered: 8 years ago Posts: 81 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 14, 2015 12:00PM |

Registered: 8 years ago Posts: 10 |

Thanks, Mel0n! The top on the left cube was because I accidently pushed it in with my finger while it was still warm, lol. I'm printing PLA for now using the makerbot fillament from Staples. I think it's pretty good stuff. Seems ok so far. Not cheap but it's nice to just go to Staples and buy some. I think I could definitely use a fan though. I'm noticing on very small but tall parts it tends to stay warm and bendible and when the hotend puts another layer on it you can see it move around. The left arm of the robot was doing that but it still managed to be ok in the end. Does anyone just blow a small fan on the whole print bed or is that a big no no?

Dan

Dan

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 14, 2015 12:01PM |

Registered: 8 years ago Posts: 135 |

Quote

wderoxas

My endstop was at the head cause i was using Auto Bed Levelling. There's a servo just left of the fan to place that endstop into position during Z homing or auto levelling routine.

Oh cool, does it still function as the x endstop?

Quote

Danmst3k

Thanks, Mel0n! The top on the left cube was because I accidently pushed it in with my finger while it was still warm, lol. I'm printing PLA for now using the makerbot fillament from Staples. I think it's pretty good stuff. Seems ok so far. Not cheap but it's nice to just go to Staples and buy some. I think I could definitely use a fan though. I'm noticing on very small but tall parts it tends to stay warm and bendible and when the hotend puts another layer on it you can see it move around. The left arm of the robot was doing that but it still managed to be ok in the end. Does anyone just blow a small fan on the whole print bed or is that a big no no?

Dan

Well the point of the fan is to cool the PLA right as it comes out of the tip. The reason being, since PLA is so much more sensitive to heat, it doesnt hold its shape very well untill it is mostly cooled down (60C or so) which makes it hard to print overhangs and bridges with. I wouldn't put a fan across the whole print bed, as you will most likely see your prints comming off the bed during printing pretty frequently. When printing with PLA I usually print straight to glass with the bed temp at 40-50C and have found that it works well, but any sort of draft/air movement will cool the bottom too much and the print pops off. I have since been only printing with ABS because I really like working with it. Its stronger, prints better overhangs and bridges, stays stuck to the bed really well with glue stick and just pops off by itself when its done and the bed cools. Just all around more convenient IMO and I like to print parts/tool/practical stuff so strength is a major plus. Not to mention ABS jams are pretty rare. PLA jams A LOT because of its thermal expansion properties and sensitivity to heat.

Edited 2 time(s). Last edit at 08/14/2015 12:07PM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 14, 2015 12:06PM |

Registered: 8 years ago Posts: 81 |

It functions as endstop only during a a homing (G28) or auto bed level (G29) . If you drive the head further down manually, it could crash into the bed. Reason is, the servo only gets activated during a G28 or G29.

Not sure if case is the same for those with inductive or capacitive sensors.

Not sure if case is the same for those with inductive or capacitive sensors.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 14, 2015 12:09PM |

Registered: 8 years ago Posts: 135 |

Quote

wderoxas

It functions as endstop only during a a homing (G28) or auto bed level (G29) . If you drive the head further down manually, it could crash into the bed. Reason is, the servo only gets activated during a G28 or G29.

Not sure if case is the same for those with inductive or capacitive sensors.

Ahh thats pretty cool! With switch-less sensors, you typically have them higher than the print head so they arent in the way during printing, and during auto leveling they dont go all the way down since they work on proximity/thresholds. I really want to go capacitive because I like glass too much for inductive, but havent really decided yet, and I honestly dont mind leveling my bed anymore (I have gotten really good at it).

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 14, 2015 01:47PM |

Registered: 8 years ago Posts: 10 |

Quote

mel0n

Quote

wderoxas

My endstop was at the head cause i was using Auto Bed Levelling. There's a servo just left of the fan to place that endstop into position during Z homing or auto levelling routine.

Oh cool, does it still function as the x endstop?

Quote

Danmst3k

Thanks, Mel0n! The top on the left cube was because I accidently pushed it in with my finger while it was still warm, lol. I'm printing PLA for now using the makerbot fillament from Staples. I think it's pretty good stuff. Seems ok so far. Not cheap but it's nice to just go to Staples and buy some. I think I could definitely use a fan though. I'm noticing on very small but tall parts it tends to stay warm and bendible and when the hotend puts another layer on it you can see it move around. The left arm of the robot was doing that but it still managed to be ok in the end. Does anyone just blow a small fan on the whole print bed or is that a big no no?

Dan

Well the point of the fan is to cool the PLA right as it comes out of the tip. The reason being, since PLA is so much more sensitive to heat, it doesnt hold its shape very well untill it is mostly cooled down (60C or so) which makes it hard to print overhangs and bridges with. I wouldn't put a fan across the whole print bed, as you will most likely see your prints comming off the bed during printing pretty frequently. When printing with PLA I usually print straight to glass with the bed temp at 40-50C and have found that it works well, but any sort of draft/air movement will cool the bottom too much and the print pops off. I have since been only printing with ABS because I really like working with it. Its stronger, prints better overhangs and bridges, stays stuck to the bed really well with glue stick and just pops off by itself when its done and the bed cools. Just all around more convenient IMO and I like to print parts/tool/practical stuff so strength is a major plus. Not to mention ABS jams are pretty rare. PLA jams A LOT because of its thermal expansion properties and sensitivity to heat.

Thanks Mel0n for the great info. I definitely want to try ABS at some point. Sounds like there's a lot of benefits.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 14, 2015 01:54PM |

Registered: 8 years ago Posts: 135 |

There are, but layer separation and warping are a bitch. Once you get it sorted out I don't see any reason to use PLA other than to be environmentally friendly?

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 15, 2015 02:12AM |

Registered: 8 years ago Posts: 66 |

Quote

mel0n

There are, but layer separation and warping are a bitch. Once you get it sorted out I don't see any reason to use PLA other than to be environmentally friendly?

I'm an exclusive ABS user, Washable Glue Stick and proper heat are the keys to my success. Too low an extruder temp and breezes in the room will cause separation... 230 Nozzle / 100 Bed are my magic numbers. Glue Stick has saved me a lot of headaches that I was having on warping and the ABS slurry was hit or miss. The other nice thing about Glue Stick is just add water to clean it up; no Acetone needed!

Sigil Pickups || Stunt Monkey Pedals

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 15, 2015 06:14AM |

Registered: 8 years ago Posts: 30 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 15, 2015 01:25PM |

Registered: 8 years ago Posts: 2 |

Hello everyone! I'm glad I found this forum and thread as I'm learning a lot reading through it. However, I have an issue I'm hoping someone can help me with. It seems that my endstops are not being recognized. I double-checked the wiring and it looks good, but when using Rep-Host to set the homes it tries to overrun the stops. They light up when the switch is triggered, but the motors don't stop. Any ideas?

UPDATE: So I decided to not trust my assembly skills and used my multimeter to test out the endstop switches and somehow I had all 3 of them on the wrong jumpers! After figuring them out and reviewing the assembly instructions I got them to the right pins and now they are working correctly.

Edited 1 time(s). Last edit at 08/15/2015 01:53PM by FLJim.

UPDATE: So I decided to not trust my assembly skills and used my multimeter to test out the endstop switches and somehow I had all 3 of them on the wrong jumpers! After figuring them out and reviewing the assembly instructions I got them to the right pins and now they are working correctly.

Edited 1 time(s). Last edit at 08/15/2015 01:53PM by FLJim.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 15, 2015 04:01PM |

Registered: 8 years ago Posts: 33 |

What's the wait time on the day you guys order the kit until it's delivered to your door? I ordered one on Wednesday. The tracking number is registered but the kit ain't even at the post office. So I am sure they are filling in orders. I hate the fact that they have it listed but it ain't in stock. I'll wait but I canceled a order on a Geeetech i3x for this one since the wait for the Geeetech would have been way longer. The plus side is, I chose the 2020 version. I had 2nd thoughts on the acrylic frame.

I ordered filament, cork dampeners for the steppers, and cork for the heated bed the day after I ordered the kit. I have all 3 of the accessories here at the house and its making me impatient!

I also ordered 5 extra A4988 drivers and 2 extra thermisters for backup (from Folgers also and still ain't shipped out).. I keep hearing about bad drivers. I was going to order a backup Ramps 1.4 board also because of reading all the dead ones people have been receiving. I'm not sure if there is a better board out there than Ramps 1.4 so I'm going to hold off on that.

I'll post some details once I receive the kit and start on the build. I've already found some mistakes on the instructions provided in their google drive. Looks like the instructions was the acrylic version but just edited.

That's it for now.. I hope they ship it out Monday... ugh!

Edited 1 time(s). Last edit at 08/15/2015 04:03PM by hoang82.

I ordered filament, cork dampeners for the steppers, and cork for the heated bed the day after I ordered the kit. I have all 3 of the accessories here at the house and its making me impatient!

I also ordered 5 extra A4988 drivers and 2 extra thermisters for backup (from Folgers also and still ain't shipped out).. I keep hearing about bad drivers. I was going to order a backup Ramps 1.4 board also because of reading all the dead ones people have been receiving. I'm not sure if there is a better board out there than Ramps 1.4 so I'm going to hold off on that.

I'll post some details once I receive the kit and start on the build. I've already found some mistakes on the instructions provided in their google drive. Looks like the instructions was the acrylic version but just edited.

That's it for now.. I hope they ship it out Monday... ugh!

Edited 1 time(s). Last edit at 08/15/2015 04:03PM by hoang82.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 15, 2015 04:23PM |

Registered: 8 years ago Posts: 14 |

So I finally got mine built, and have been trying to get a successful cube. Been wrestling with proper homing/positioning. Learned the M119 command, and saw that Y_MAX and Z_MAX are registering as triggered, even though nothing is plugged in. I had some spare end-stops, so I plugged those in, now the positions report as open. Any ideas why that might be? things seem to be working now.

BTW, regarding end-stops, is there any advantage to having both min and max on both axises? I bought extras with that idea in mind. Could that be used for both homing and proper sizing?

BTW, regarding end-stops, is there any advantage to having both min and max on both axises? I bought extras with that idea in mind. Could that be used for both homing and proper sizing?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 15, 2015 06:37PM |

Registered: 8 years ago Posts: 10 |

Quote

billyb2

Bed Temperature goes High out of control:

In manual mode, bed temp control seems to work fine. Heater comes on until almost 60C then shuts off and cycles on and off to maintain temp. Sensed temperature is pretty accurate.

When I print, the bed temp continues to rise even though the correct setting (60C) is indicated. It will rise past 100C even though that is the configured limit

Bed heats up first, then extruder starts heating when bed hits 60C. However bed does not stop heating. Full power is always applied, not PWM as the LED is full on.

the stop button will turn the heater off.

It looks like the logs show setting to the right temperature. I don't notice any other M140 or M190 commands.

I'm using Repetier V1.5.4 with the stock Ftech marlin config files (only change was to the endstop location) and slic3r settings changed to reduce PLA temps to 185/65.

I tried reinstalling Marlin and Repetier with the same results.

Any other ideas??

Update: I tried the Cura slicer with the same results. I noticed from the temp log the set temps are correct, but about 90-100 seconds from the bed hitting and maintaining its correct temperature, it starts full on. The logs show there is no other M140 or M190 bed set temperature comands.

Next Steps: install and look at the USB serial monitor to see if any weird commands are being issued.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 15, 2015 08:32PM |

Registered: 8 years ago Posts: 33 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 15, 2015 08:43PM |

Registered: 8 years ago Posts: 367 |

Quote

kn4ud

Guys, I am looking for the Xcarrage/extruder mount stl file that is the one with 4 bearings. The one like animoose and some others are using when they switch to 8 mm threaded rod setup. I can't seem to find it , I am sure I am over looking it.

It's in wderoxas google drive folder at [drive.google.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 15, 2015 08:56PM |

Registered: 8 years ago Posts: 33 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 16, 2015 05:56PM |

Registered: 8 years ago Posts: 121 |

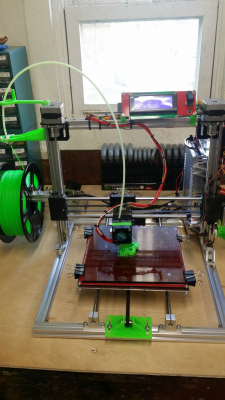

Current state of my printer. I am printing the x-carriage ends to switch over to 8mm rods.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 16, 2015 07:33PM |

Registered: 8 years ago Posts: 430 |

Quote

[email protected]

Current state of my printer. I am printing the x-carriage ends to switch over to 8mm rods.

That's a good idea for the Y belt pulley.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 16, 2015 07:40PM |

Registered: 8 years ago Posts: 121 |

Thanks but that is not my design I need to look back to were i got it to give credit where it's due.

WOW took forever to find here it is all credit to orangclockwerk

[www.thingiverse.com]

Edited 1 time(s). Last edit at 08/16/2015 07:52PM by jasonsaffle13@gmail.com.

WOW took forever to find here it is all credit to orangclockwerk

[www.thingiverse.com]

Edited 1 time(s). Last edit at 08/16/2015 07:52PM by jasonsaffle13@gmail.com.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 16, 2015 09:26PM |

Registered: 8 years ago Posts: 276 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 16, 2015 11:03PM |

Registered: 8 years ago Posts: 3 |

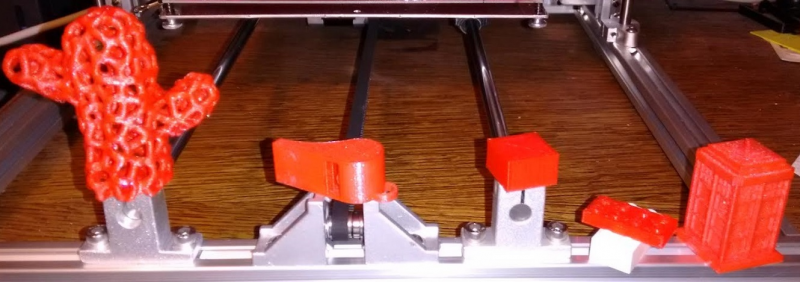

Today was awesome after two weeks since completing the build! After two simple fixes, thanks to tidbits from this group, I was up and running. My extruder connection was backwards and the X limit switch needed to be moved one set to the left. Also spent some time leveling the bed.

I've since printed 4+ hours in PLA, attached, and a calibration cube in ABS (not shown); the white piece is real Lego in an attempt to better show the red printed lego. Both calibration cubes came out within a few hundredths of a mm of 20mm square. Over 4 hours printing PLA and a bit for the ABS piece; no clogs, lifts, separations, or any other print problems and I haven't even prepared the bed glass. I sourced my material from MakerGeeks.com, seems like high quality material.

When starting the ABS print, however, it took about 18 minutes for the bed to warm up to 110C, is that normal with the stock power supply? Any tips for getting it to heat faster?

FolgerTech 2020 i3

Home designed and built CNC router

800x600 80watt laser engraver

I've since printed 4+ hours in PLA, attached, and a calibration cube in ABS (not shown); the white piece is real Lego in an attempt to better show the red printed lego. Both calibration cubes came out within a few hundredths of a mm of 20mm square. Over 4 hours printing PLA and a bit for the ABS piece; no clogs, lifts, separations, or any other print problems and I haven't even prepared the bed glass. I sourced my material from MakerGeeks.com, seems like high quality material.

When starting the ABS print, however, it took about 18 minutes for the bed to warm up to 110C, is that normal with the stock power supply? Any tips for getting it to heat faster?

FolgerTech 2020 i3

Home designed and built CNC router

800x600 80watt laser engraver

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 16, 2015 11:18PM |

Registered: 8 years ago Posts: 121 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 16, 2015 11:57PM |

Registered: 8 years ago Posts: 19 |

Quote

therippa

Where is the reference chart for the stepper motor voltages? I can't seem to find it anywhere, and the search function on this forum software sucks

Try google or whatever search engine you use.

To search the entire forum:

site:forums.reprap.org stepper motor voltages

This will search the entire forum looking for the words stepper motor voltages

You can use any word(s) for your search criteria

Rick

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 17, 2015 04:20AM |

Registered: 8 years ago Posts: 276 |

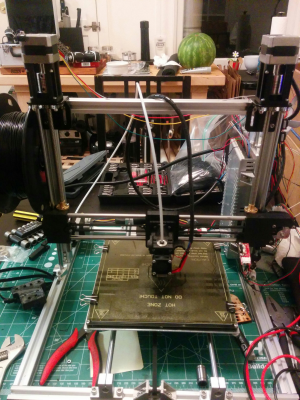

So, tonight I finally had time to perform the following upgrades...

1. Move the Z-axis stepper motors up a bit to gain more space

2. Switched to lead screws/printed new Z-axis mounts

3. Calibrated the voltage on all stepper drivers

4. Replaced Folgertech LMU88 with higher quality bearings.

I CANNOT BELIVE how much quieter everything is...

[www.youtube.com]

The power supply fan is louder than the movements now. Hopefully, this will make the neighbor below me stop giving me crap about the noise (and he had to suffer through the 12 hours it took to print the new parts)

A question though - X-axis noise is non-existent until it gets to about 9cm, then it grinds ever so slightly, and then stops grinding again around 13mm. No where near what it was like before, but I'd still like to fix it. Any ideas on what to tune/calibrate to fix this?

1. Move the Z-axis stepper motors up a bit to gain more space

2. Switched to lead screws/printed new Z-axis mounts

3. Calibrated the voltage on all stepper drivers

4. Replaced Folgertech LMU88 with higher quality bearings.

I CANNOT BELIVE how much quieter everything is...

[www.youtube.com]

The power supply fan is louder than the movements now. Hopefully, this will make the neighbor below me stop giving me crap about the noise (and he had to suffer through the 12 hours it took to print the new parts)

A question though - X-axis noise is non-existent until it gets to about 9cm, then it grinds ever so slightly, and then stops grinding again around 13mm. No where near what it was like before, but I'd still like to fix it. Any ideas on what to tune/calibrate to fix this?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 17, 2015 12:22PM |

Registered: 8 years ago Posts: 14 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 17, 2015 12:42PM |

Registered: 8 years ago Posts: 27 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 17, 2015 01:09PM |

Registered: 8 years ago Posts: 14 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 17, 2015 03:27PM |

Registered: 8 years ago Posts: 367 |

I used a 4 start one, but didn't really have any idea what I was doing. It seems to work fine. Should I consider switching to a 1 start or 2 start version?

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 17, 2015 03:29PM |

Registered: 8 years ago Posts: 33 |

Quote

ejnelson

while we're asking questions for the lead screw upgraders... anyone have a good US source? I feel like the folgertech ones are overpriced. Looks like openbuilds has them for 10$ but with no nut.

I ordered 2 last night from banggood USA warehouse (so it said) with nuts and 400mm long for a little over $26 with shipping.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 17, 2015 04:51PM |

Registered: 8 years ago Posts: 121 |

Quote

kn4ud

Quote

ejnelson

while we're asking questions for the lead screw upgraders... anyone have a good US source? I feel like the folgertech ones are overpriced. Looks like openbuilds has them for 10$ but with no nut.

I ordered 2 last night from banggood USA warehouse (so it said) with nuts and 400mm long for a little over $26 with shipping.

I also got the 400mm ones. So now going to try to cut them down to 300-ish to even fit in the printer!!

Sorry, only registered users may post in this forum.