Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 21, 2015 07:27PM |

Registered: 8 years ago Posts: 16 |

Stepper issue, driver issue or ramps issue?

I need help, I got a nearly acceptable print on the first print, the second was much better as I tweaked the temps. I then made mounts for the LCD controller, a new x-axis endstop mount and a new filament spool holder. My point is that everything worked, and actually worked pretty well with minimal tuning time.

The spool holder was my longest print and the x-axis motor got too hot to touch. After it finished, I shut it down and had other things to take care of and let the whole thing sit for a few weeks.

When I started it all up to re-level the bed, the x-axis started acting erratically, like how people describe it should when it's over heating. I reduced the voltage by rotating the pot on the driver, I've not measured it, but it's turned all the way counter-clockwise. I can home all every axis, Y and Z act normally, but when I use Repetier to move the X-axis to the left, it ignores the first 50mm or 100mm of movement I send, if I tell it to move after that, then it finally moves, but thinks it's now in the middle of the build plate (100mm), even though I wanted it to move left 150mm.

I replaced the driver board with the spare and turned it all the way counter clockwise before I installed it. I also replaced the X-axis end-stop with the spare. I still acts erratically on the X-axis when trying to move to the left (now sometimes it doesn't move to the left at all), and after I replaced the driver, it's started to act erratically when moving to the right, but still moves most of the time, it doesn't seem like it's missing steps. Just trying to home the X-axis, the X stepper still gets warm, as long as the printer is plugged in.

I carefully inspected the Ramps board when I was initially building the printer and only found two very small stray solder blobs that were easily removed with my fingernail before I mated the Ramps to the Arduino Mega. (blob removed before I ever gave it power.)

Did I accidentally fry the stepper motor? Is it getting warm (with less than a minute of movement) due to an internal short?

If so I'll likely upgrade to the next larger size since so many people seem to have an X-axis motor that runs warm, and I live in a warm/hot climate without air conditioning.

What are your thoughts?

Where's the best place to start?

Any help is greatly appreciated. Overall I'm pretty happy with this kit, I expected some issues, but until this kit came along I couldn't afford to get into 3d printing, as I never wanted to build a printer with a threaded rod frame, and prebuilt units are out of my budget.

Thanks for all the great knowledge I've been able to glean over the last 43 pages.

I need help, I got a nearly acceptable print on the first print, the second was much better as I tweaked the temps. I then made mounts for the LCD controller, a new x-axis endstop mount and a new filament spool holder. My point is that everything worked, and actually worked pretty well with minimal tuning time.

The spool holder was my longest print and the x-axis motor got too hot to touch. After it finished, I shut it down and had other things to take care of and let the whole thing sit for a few weeks.

When I started it all up to re-level the bed, the x-axis started acting erratically, like how people describe it should when it's over heating. I reduced the voltage by rotating the pot on the driver, I've not measured it, but it's turned all the way counter-clockwise. I can home all every axis, Y and Z act normally, but when I use Repetier to move the X-axis to the left, it ignores the first 50mm or 100mm of movement I send, if I tell it to move after that, then it finally moves, but thinks it's now in the middle of the build plate (100mm), even though I wanted it to move left 150mm.

I replaced the driver board with the spare and turned it all the way counter clockwise before I installed it. I also replaced the X-axis end-stop with the spare. I still acts erratically on the X-axis when trying to move to the left (now sometimes it doesn't move to the left at all), and after I replaced the driver, it's started to act erratically when moving to the right, but still moves most of the time, it doesn't seem like it's missing steps. Just trying to home the X-axis, the X stepper still gets warm, as long as the printer is plugged in.

I carefully inspected the Ramps board when I was initially building the printer and only found two very small stray solder blobs that were easily removed with my fingernail before I mated the Ramps to the Arduino Mega. (blob removed before I ever gave it power.)

Did I accidentally fry the stepper motor? Is it getting warm (with less than a minute of movement) due to an internal short?

If so I'll likely upgrade to the next larger size since so many people seem to have an X-axis motor that runs warm, and I live in a warm/hot climate without air conditioning.

What are your thoughts?

Where's the best place to start?

Any help is greatly appreciated. Overall I'm pretty happy with this kit, I expected some issues, but until this kit came along I couldn't afford to get into 3d printing, as I never wanted to build a printer with a threaded rod frame, and prebuilt units are out of my budget.

Thanks for all the great knowledge I've been able to glean over the last 43 pages.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 21, 2015 08:43PM |

Registered: 8 years ago Posts: 18 |

Quote

Bert3D

That was exactly it. Found a loose ball of solder floating around on the back of the ramps. Just plugging and unplugging cables was enough to shift it somewhere it shouldn't be. Reflowed all the solder points that looked suspect, and now it works fine.

Awesome, glad it worked out for you!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 21, 2015 08:52PM |

Registered: 8 years ago Posts: 81 |

Quote

widespreaddeadhead

I'm going to try a different slicer(Cura, using Slic3r now), because I've only had one heart gears print off correctly, and four print with shifts.Quote

widespreaddeadhead

Another shift in my axes, I'm starting to lose it now.

Try to use the z lift feature. Lifting it 0.2 or 0.15 mm on every retraction only marginally adds to the printing time. Its better than starting things all over again.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 21, 2015 09:54PM |

Registered: 8 years ago Posts: 276 |

Quote

ejnelson

Quote

therippa

Quote

kn4ud

Very nice print therippa, what filament did you use?

Hatchbox ABS.

Here is another one, I really feel like I have this thing damn near perfectly calibrated...

Now I need to figure out what left the "scar" on his face and forehead

There had to have been supports for those arms right?! Otherwise, I find it amazing that those little arms didn't curl right up into the extruder. Did you use a fan or an enclosure? What speed did you print at and did you print just the alien man or were there other objects on the build plate as well?

No supports on the arms, used this as a stress test of sorts. No fan (ABS), and no enclosure. I printed this at 110% speed at 0.2mm layers, and I just printed Roger by himself.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 21, 2015 11:19PM |

Registered: 8 years ago Posts: 3 |

@therippa, looking at the great print you've made, I can see a tiny little curly piece at the top. I have an issue that I've been trying to figure out and seems it might be present in your print. When my prints are finishing up the last layer, the extruder tends to finish a couple lines early and just tail off to reset itself. Is this something common?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 22, 2015 03:28PM |

Registered: 8 years ago Posts: 16 |

Quote

rollinns

Stepper issue, driver issue or ramps issue?

I need help, I got a nearly acceptable print on the first print, the second was much better as I tweaked the temps. I then made mounts for the LCD controller, a new x-axis endstop mount and a new filament spool holder. My point is that everything worked, and actually worked pretty well with minimal tuning time.

The spool holder was my longest print and the x-axis motor got too hot to touch. After it finished, I shut it down and had other things to take care of and let the whole thing sit for a few weeks.

When I started it all up to re-level the bed, the x-axis started acting erratically, like how people describe it should when it's over heating. I reduced the voltage by rotating the pot on the driver, I've not measured it, but it's turned all the way counter-clockwise. I can home all every axis, Y and Z act normally, but when I use Repetier to move the X-axis to the left, it ignores the first 50mm or 100mm of movement I send, if I tell it to move after that, then it finally moves, but thinks it's now in the middle of the build plate (100mm), even though I wanted it to move left 150mm.

I replaced the driver board with the spare and turned it all the way counter clockwise before I installed it. I also replaced the X-axis end-stop with the spare. I still acts erratically on the X-axis when trying to move to the left (now sometimes it doesn't move to the left at all), and after I replaced the driver, it's started to act erratically when moving to the right, but still moves most of the time, it doesn't seem like it's missing steps. Just trying to home the X-axis, the X stepper still gets warm, as long as the printer is plugged in.

I carefully inspected the Ramps board when I was initially building the printer and only found two very small stray solder blobs that were easily removed with my fingernail before I mated the Ramps to the Arduino Mega. (blob removed before I ever gave it power.)

Did I accidentally fry the stepper motor? Is it getting warm (with less than a minute of movement) due to an internal short?

If so I'll likely upgrade to the next larger size since so many people seem to have an X-axis motor that runs warm, and I live in a warm/hot climate without air conditioning.

What are your thoughts?

Where's the best place to start?

Any help is greatly appreciated. Overall I'm pretty happy with this kit, I expected some issues, but until this kit came along I couldn't afford to get into 3d printing, as I never wanted to build a printer with a threaded rod frame, and prebuilt units are out of my budget.

Thanks for all the great knowledge I've been able to glean over the last 43 pages.

While I'm still hoping for more help on this, I'm proceeding the best I can.

To test the motor, I plugged the X-axis motor wires temporarily into one of the Z-axis motors and the Z motor started getting warm too (running on the newly replaced driver). I'm not convinced the driver is faulty, I ordered a new Ramps board and a larger X-axis motor, since the stock X-axis motor size seems to be borderline acceptable.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 22, 2015 05:17PM |

Registered: 8 years ago Posts: 16 |

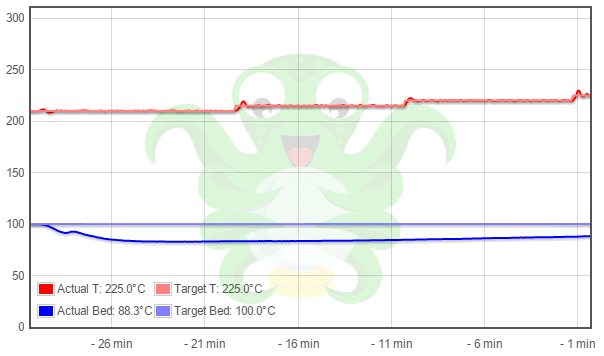

I am still struggling with ABS. My heated bed (@14v) cannot stay at 100c during a print. It seems that once it drops to 80c, the print (w/brim) releases from the glue stick coated glass. I have cleaned the glass, applied fresh glue stick, and the printer is now enclosed in an Ikea Lack table with foamboard taped to the sides.

I have been at this for several hours today. I am on my 5th attempt at printing a filament temperature calibration tower, and it is looking good. The first two attempts both failed in the first 20mm of height, and the next two didn't even stick to the glass. This one is now at 30mm and the bed temp has stabilized around 85c and is rising.

I have been at this for several hours today. I am on my 5th attempt at printing a filament temperature calibration tower, and it is looking good. The first two attempts both failed in the first 20mm of height, and the next two didn't even stick to the glass. This one is now at 30mm and the bed temp has stabilized around 85c and is rising.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 22, 2015 08:22PM |

Registered: 9 years ago Posts: 44 |

Okay, Ive had some great prints but now the bed it unleveled and when I go to level it, it won't level. If I tighten the thumb screws all the way the back and the front have a difference of about .5 cm. Im trying to get my printer back to printing but now it wont. Here is a print I made before this. [www.imgur.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 22, 2015 08:51PM |

Registered: 8 years ago Posts: 35 |

Tim, what is the temperature in your room? Do you have any A/C vents blowing on your printer?

I keep my house at 76-77F and run my bed at 103C and it never drops below 100C... I had an issue with the new Marlin someone posted in this thread where my bed would not go past 86 or so degrees so I went back to the stock firmware and it works fine. What firmware are you using?

I keep my house at 76-77F and run my bed at 103C and it never drops below 100C... I had an issue with the new Marlin someone posted in this thread where my bed would not go past 86 or so degrees so I went back to the stock firmware and it works fine. What firmware are you using?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 22, 2015 09:18PM |

Registered: 8 years ago Posts: 121 |

Quote

zarnold16

Okay, Ive had some great prints but now the bed it unleveled and when I go to level it, it won't level. If I tighten the thumb screws all the way the back and the front have a difference of about .5 cm. Im trying to get my printer back to printing but now it wont. Here is a print I made before this. [www.imgur.com]

Check that your bearings are seated under the bed evenly!!! is one of the three are off it will tilt your bed more then the screws can adjust!!!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 22, 2015 09:19PM |

Registered: 8 years ago Posts: 121 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 22, 2015 09:23PM |

Registered: 8 years ago Posts: 16 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 22, 2015 09:24PM |

Registered: 8 years ago Posts: 121 |

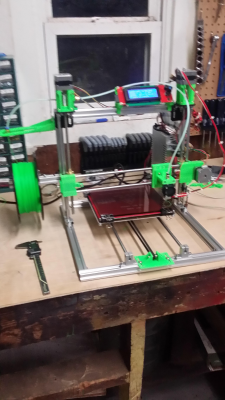

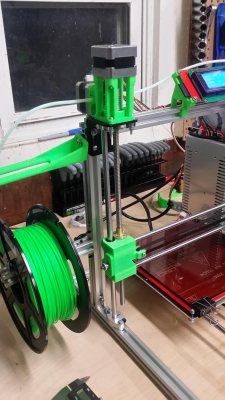

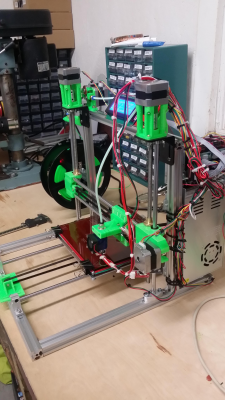

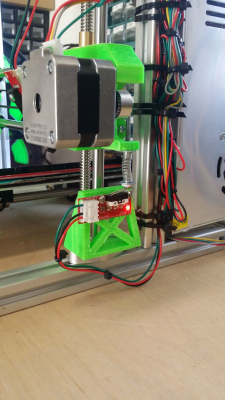

Current state of the printer. I still need to add the adjustable Z-endstop, level the bed, and tidy up some wires. to tired to do it tonight though. May not show well in the photos but I also flipped over the bed heater over to grid side up and added a piece of cardboard between the heater and the aluminum bed plate.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 22, 2015 09:55PM |

Registered: 9 years ago Posts: 44 |

Okay, I just checked and one of the bearings were off slightly. Now the bed is level. Ignore the last part, i'm really stupid. I accidentally set something on the bundle of wires and the carriage did not have enough wire to move.Quote

[email protected]

Quote

zarnold16

Okay, Ive had some great prints but now the bed it unleveled and when I go to level it, it won't level. If I tighten the thumb screws all the way the back and the front have a difference of about .5 cm. Im trying to get my printer back to printing but now it wont. Here is a print I made before this. [www.imgur.com]

Check that your bearings are seated under the bed evenly!!! is one of the three are off it will tilt your bed more then the screws can adjust!!!

Edited 1 time(s). Last edit at 08/22/2015 09:59PM by zarnold16.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 22, 2015 10:01PM |

Registered: 8 years ago Posts: 121 |

Quote

zarnold16

Okay, I just checked and one of the bearings were off slightly. Now the bed is level. Ignore the last part, i'm really stupid. I accidentally set something on the bundle of wires and the carriage did not have enough wire to move.Quote

[email protected]

Quote

zarnold16

Okay, Ive had some great prints but now the bed it unleveled and when I go to level it, it won't level. If I tighten the thumb screws all the way the back and the front have a difference of about .5 cm. Im trying to get my printer back to printing but now it wont. Here is a print I made before this. [www.imgur.com]

Check that your bearings are seated under the bed evenly!!! is one of the three are off it will tilt your bed more then the screws can adjust!!!

Just a quick guess but I think maybe your z-endstop is not set right. If it's to low the first layer will smear but others will print fine. Also if it's to low the carriage will not lift until the Z screws turn enough to take up the slack to lift the carriage off the bed.

Edited 1 time(s). Last edit at 08/22/2015 10:08PM by jasonsaffle13@gmail.com.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 22, 2015 10:22PM |

Registered: 9 years ago Posts: 44 |

Quote

[email protected]

Quote

zarnold16

Okay, I just checked and one of the bearings were off slightly. Now the bed is level. Ignore the last part, i'm really stupid. I accidentally set something on the bundle of wires and the carriage did not have enough wire to move.Quote

[email protected]

Quote

zarnold16

Okay, Ive had some great prints but now the bed it unleveled and when I go to level it, it won't level. If I tighten the thumb screws all the way the back and the front have a difference of about .5 cm. Im trying to get my printer back to printing but now it wont. Here is a print I made before this. [www.imgur.com]

Check that your bearings are seated under the bed evenly!!! is one of the three are off it will tilt your bed more then the screws can adjust!!!

Just a quick guess but I think maybe your z-endstop is not set right. If it's to low the first layer will smear but others will print fine.

No it was me being slightly tired and being really dumb. I put my computer on my bundle of wire and it did not allow the axis to move in the correct direction.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 22, 2015 10:41PM |

Registered: 8 years ago Posts: 35 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 23, 2015 10:47AM |

Registered: 8 years ago Posts: 121 |

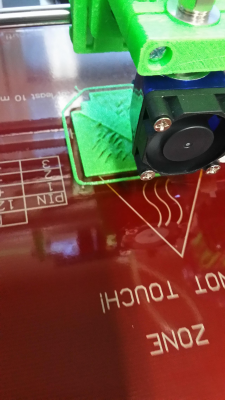

New adjustable Z-endstop. I have set the extruder now I just have to adjust the Z steps it's way off!!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 23, 2015 02:10PM |

Registered: 8 years ago Posts: 13 |

Hey guys, I'm new to printing and I bought one of these 2020 i3 folger tech printers. The only Issue I am having is that the left stepper motor will spin for a bit while it's moving up or down, but then it will start to stutter and then reverse its direction. It seems that adjusting the screw on the ramps board will fix the issue for a bit but then it will return back to its normal stutter issue. The right motor on the other hand, always does what it is told whether it receives high voltage or low voltage. I've tried switching the cables around and nothing. Do you guys think I should just buy a new stepper motor?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 23, 2015 02:31PM |

Registered: 8 years ago Posts: 121 |

Ever since i flipped my bed I can not get the temp over 90 uhg time to trouble shoot.

Looks like I loaded my PLA profile and not my ABS so bed was doing as it should!! Changed back and looks good.

Edited 1 time(s). Last edit at 08/23/2015 04:06PM by jasonsaffle13@gmail.com.

Looks like I loaded my PLA profile and not my ABS so bed was doing as it should!! Changed back and looks good.

Edited 1 time(s). Last edit at 08/23/2015 04:06PM by jasonsaffle13@gmail.com.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 23, 2015 03:49PM |

Registered: 8 years ago Posts: 285 |

Quote

meeuuch

Hey guys, I'm new to printing and I bought one of these 2020 i3 folger tech printers. The only Issue I am having is that the left stepper motor will spin for a bit while it's moving up or down, but then it will start to stutter and then reverse its direction. It seems that adjusting the screw on the ramps board will fix the issue for a bit but then it will return back to its normal stutter issue. The right motor on the other hand, always does what it is told whether it receives high voltage or low voltage. I've tried switching the cables around and nothing. Do you guys think I should just buy a new stepper motor?

If the right stepper motor works when connected to the cable that the bad one was connected to, then the problem is almost certainly the stepper motor. I would get a new one if that is the case, but first check the continuity of the stepper motor's coils just to be sure 100% sure that is the problem. If the right motor does not work when switched, then it is probably a ramps or stepper driver problem.

Edited 1 time(s). Last edit at 08/23/2015 03:50PM by Mach.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 24, 2015 09:48AM |

Registered: 8 years ago Posts: 95 |

I have had my Folger Tech 2020 printer now for over a month.. would I buy again.. yes I would.. granted it was missing some screws and other small parts.. and They had to replace the Ramps board.. But after those issues were solved.. it was printing great from the first print... I know others did not have this experience.. but I can say 99% of any problems were on the hardware side of things.. I have not touched any or changed anything thing in the software/firmware side.. didn't have too.. I started with ABS and after using A glue stick it prints fine.. on the other hand.. their customer service could use an overhaul .. I believe its the most bang for the buck.. all for 269.00 well below anything else in it class.. I used it to create another homebuilt printer a Smartcore .. and that was a real learning experience .. on both the hardware and software side.. if you want to learn more build one from scratch...

Edited 1 time(s). Last edit at 08/24/2015 09:50AM by mike3.

Edited 1 time(s). Last edit at 08/24/2015 09:50AM by mike3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 24, 2015 10:00AM |

Registered: 9 years ago Posts: 251 |

+1Quote

mike3

I have had my Folger Tech 2020 printer now for over a month.. would I buy again.. yes I would.. granted it was missing some screws and other small parts.. and They had to replace the Ramps board.. But after those issues were solved.. it was printing great from the first print... I know others did not have this experience.. but I can say 99% of any problems were on the hardware side of things.. I have not touched any or changed anything thing in the software/firmware side.. didn't have too.. I started with ABS and after using A glue stick it prints fine.. on the other hand.. their customer service could use an overhaul .. I believe its the most bang for the buck.. all for 269.00 well below anything else in it class.. I used it to create another homebuilt printer a Smartcore .. and that was a real learning experience .. on both the hardware and software side.. if you want to learn more build one from scratch...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 24, 2015 10:13AM |

Registered: 11 years ago Posts: 335 |

Quote

mike3

I believe its the most bang for the buck.. all for 269.00 well below anything else in it class...

I agree completely. I still see people talking about the Aliexpress/Hobbyking printers at $300+ with inferior build quality. Why would you gamble on a box of lasercut acrylic when this printer is available?

Support might not be great but when there is a 50 page thread on forums.reprap.com you at least know there is a community to back it up.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 24, 2015 11:04AM |

Registered: 8 years ago Posts: 10 |

Quote

billyb2

Quote

billyb2

Bed Temperature goes High out of control:

In manual mode, bed temp control seems to work fine. Heater comes on until almost 60C then shuts off and cycles on and off to maintain temp. Sensed temperature is pretty accurate.

When I print, the bed temp continues to rise even though the correct setting (60C) is indicated. It will rise past 100C even though that is the configured limit

Bed heats up first, then extruder starts heating when bed hits 60C. However bed does not stop heating. Full power is always applied, not PWM as the LED is full on.

the stop button will turn the heater off.

It looks like the logs show setting to the right temperature. I don't notice any other M140 or M190 commands.

I'm using Repetier V1.5.4 with the stock Ftech marlin config files (only change was to the endstop location) and slic3r settings changed to reduce PLA temps to 185/65.

I tried reinstalling Marlin and Repetier with the same results.

Any other ideas??

Update: I tried the Cura slicer with the same results. I noticed from the temp log the set temps are correct, but about 90-100 seconds from the bed hitting and maintaining its correct temperature, it starts full on. The logs show there is no other M140 or M190 bed set temperature comands.

Next Steps: install and look at the USB serial monitor to see if any weird commands are being issued.

Problem solved! It turned out that on the RAMPS 1.4 board, the tabs (drain connection) of Q3 and Q2 were touching. Q3 controls the bed heater and Q2 controls the fan. When the fan was turned on (M106) it also heated the bed because of the short circuit.

It's always the simplest stuff that's sometimes hardest to find....

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 24, 2015 11:16AM |

Registered: 9 years ago Posts: 251 |

Thanks! Will try again tonight.Quote

wderoxas

Quote

widespreaddeadhead

I'm going to try a different slicer(Cura, using Slic3r now), because I've only had one heart gears print off correctly, and four print with shifts.Quote

widespreaddeadhead

Another shift in my axes, I'm starting to lose it now.

Try to use the z lift feature. Lifting it 0.2 or 0.15 mm on every retraction only marginally adds to the printing time. Its better than starting things all over again.

On another note, I got a sheet of PEI to stop all the ABS warping I've been getting and I have to say, WOW! No more hairspray, no more glue stick, and no more slurry!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 24, 2015 03:16PM |

Registered: 8 years ago Posts: 1 |

I had my printer more or less working (x home never worked and the code changes suggested near the beginning of this thread were already implemented) but messed it up when I went to adjust the stepper drivers. I used the ground on the driver like the documentation said and accidentally touched a powered pin on the adjacent driver. Now I use one of the grounds on the green plug.

The computer didn't recognize the printer with the ramps board attached. It recognized the Arduino when I took it off, so I bought a new ramps board. The printer didn't work with the new board, either. At one point only the z-axis worked. Then it switched to the y-axis. I tried swapping through all the drivers and there doesn't seem to be one consistently not working. In fact, at one point I cycled all the drivers through the y-axis socket and they each worked. Later, the bed changed to travel away from the switch when the home button was pressed.

I noticed that the temperature for the bed and extruder were starting almost immediately at 173 degrees. This caused me to buy a new Arduino. Now none of the axis move and the temperature is measuring the same thing. I have also found that only some of the switches are registering when I click them and do the m119 command. I've tried all the pairings of old and new boards and tried swapping drivers.

Any suggestions on how to fix these problems? Maybe some ways to verify whether a driver or board is working.

Thanks

The computer didn't recognize the printer with the ramps board attached. It recognized the Arduino when I took it off, so I bought a new ramps board. The printer didn't work with the new board, either. At one point only the z-axis worked. Then it switched to the y-axis. I tried swapping through all the drivers and there doesn't seem to be one consistently not working. In fact, at one point I cycled all the drivers through the y-axis socket and they each worked. Later, the bed changed to travel away from the switch when the home button was pressed.

I noticed that the temperature for the bed and extruder were starting almost immediately at 173 degrees. This caused me to buy a new Arduino. Now none of the axis move and the temperature is measuring the same thing. I have also found that only some of the switches are registering when I click them and do the m119 command. I've tried all the pairings of old and new boards and tried swapping drivers.

Any suggestions on how to fix these problems? Maybe some ways to verify whether a driver or board is working.

Thanks

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 24, 2015 06:07PM |

Registered: 8 years ago Posts: 121 |

Any thoughts on this? stepper skip, bad stl file? bad slice?

Maybe I should mention I was blasting my build plate with a heat gun to get it up to temperature just before the print started so maybe those are thermal induced?

Edited 3 time(s). Last edit at 08/24/2015 06:20PM by jasonsaffle13@gmail.com.

Maybe I should mention I was blasting my build plate with a heat gun to get it up to temperature just before the print started so maybe those are thermal induced?

Edited 3 time(s). Last edit at 08/24/2015 06:20PM by jasonsaffle13@gmail.com.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 24, 2015 11:14PM |

Registered: 8 years ago Posts: 81 |

Those looks like portion of the plastic lines laid out didn't stick on the build plate. Those are aren't due to stepper skips.

This happened to me when i tried to apply glue stick while the build platform is still hot then immediately printing after that. They seemed like bubbles came out of the first layer.

The only thing i can think of to cause this is unbalanced heating. You can still blast it off with a heatgun but let it stabilize for a few minutes till the heat is distributed uniformly on the build plate.

This happened to me when i tried to apply glue stick while the build platform is still hot then immediately printing after that. They seemed like bubbles came out of the first layer.

The only thing i can think of to cause this is unbalanced heating. You can still blast it off with a heatgun but let it stabilize for a few minutes till the heat is distributed uniformly on the build plate.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 25, 2015 09:01AM |

Registered: 8 years ago Posts: 27 |

seems there is a sub on reddit just for folgertech if you all aren't aware. Could be a better place to organize thoughts/questions now that this thread is one big jumble of questions and answers.

[www.reddit.com]

[www.reddit.com]

Sorry, only registered users may post in this forum.