Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 25, 2015 10:53AM |

Registered: 8 years ago Posts: 430 |

Quote

ejnelson

seems there is a sub on reddit just for folgertech if you all aren't aware. Could be a better place to organize thoughts/questions now that this thread is one big jumble of questions and answers.

[www.reddit.com]

People could just start new threads on this forum too instead of posting on this one.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 25, 2015 01:25PM |

Registered: 8 years ago Posts: 8 |

Hi everyone, not sure if this is still a relevant thread but I'm having issues with my folger tech 2020:

The endstops don't work at all!!!

I've been trying to get them to work for a couple of weeks now to no avail, I've tried messing with the configuration.h and quadruple checked the wiring, I've also emailed folger tech and they have responded but not given any real help as to what the problem is.

When the endstops are triggered they light up but they do not stop the motors from running. Ive used the m119 command and they always read open, even when triggered. So I'm not sure if all of the endstops are broken or if it is the board, or if its something else entirely, any help would be appreciated!

Also I'm new to this

Thanks in advance

-Joe

The endstops don't work at all!!!

I've been trying to get them to work for a couple of weeks now to no avail, I've tried messing with the configuration.h and quadruple checked the wiring, I've also emailed folger tech and they have responded but not given any real help as to what the problem is.

When the endstops are triggered they light up but they do not stop the motors from running. Ive used the m119 command and they always read open, even when triggered. So I'm not sure if all of the endstops are broken or if it is the board, or if its something else entirely, any help would be appreciated!

Also I'm new to this

Thanks in advance

-Joe

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 25, 2015 01:45PM |

Registered: 8 years ago Posts: 93 |

So I upgraded to the latest marlin code posted earlier in this topic, and now by bed won't go much above 85 or 90 degrees, and takes much longer than before. Has anyone fixed this? What's the trick?

Also, is the throat on the extruder a 26mm or a 30mm?

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

Also, is the throat on the extruder a 26mm or a 30mm?

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 25, 2015 02:27PM |

Registered: 8 years ago Posts: 276 |

Quote

Bert3D

So I upgraded to the latest marlin code posted earlier in this topic, and now by bed won't go much above 85 or 90 degrees, and takes much longer than before. Has anyone fixed this? What's the trick?

Also, is the throat on the extruder a 26mm or a 30mm?

Re-run the PID autotune for the bed.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 25, 2015 03:51PM |

Registered: 8 years ago Posts: 35 |

Quote

Bert3D

So I upgraded to the latest marlin code posted earlier in this topic, and now by bed won't go much above 85 or 90 degrees, and takes much longer than before. Has anyone fixed this? What's the trick?

Also, is the throat on the extruder a 26mm or a 30mm?

I had the exact same issue and never bothered to fix it. I never had any issues with the original older Folder firmware so I just put it back and have been using it since. I'm guessing some tables in the new firmware are wrong for the parts we have. The auto tune never worked for me because the bed could never get hot enough.

I've been using the 26mm replacement tubes with the PFTE liners. I found a biomedical lab that sells the right size PFTE tube to replace the liners if you need some, rather than replacing the whole metal tube.

Edited 2 time(s). Last edit at 08/25/2015 03:53PM by RedneckGeek.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 25, 2015 09:34PM |

Registered: 8 years ago Posts: 14 |

Quote

therippa

Quote

Bert3D

So I upgraded to the latest marlin code posted earlier in this topic, and now by bed won't go much above 85 or 90 degrees, and takes much longer than before. Has anyone fixed this? What's the trick?

Also, is the throat on the extruder a 26mm or a 30mm?

Re-run the PID autotune for the bed.

I had the same problem until I changed the thermistor settings in Configuration.h to use table 1 instead of 6. At first I couldn't get a temperature above about 86C. I switched back to the original code and it was working again. Then I ran a diff on the new code versus the one from Folger Tech and saw a lot of changes to table 6 in the thermistor tables. (and whats with that note in the configuration about table 6 being not as accurate as table 1? Why even have it in there then?)

Also, does the PID autotune make any difference for the bed? It looks like the configuration is set to use bang-bang for the bed as #define PIDTEMPBED is commented out. On mine the LED for the bed is only on or off, it does not blink like the LED for the hotend.

Not sure if it makes a difference, but I also replaced the heat bed power wires with #14 gauge wires.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 26, 2015 02:49AM |

Registered: 8 years ago Posts: 14 |

I had a similar issue and tried every fix I could. People started talking a little more advanced than I could keep up with, but I deciphered a lot of it and kept trying... and failing...Quote

jdcarlet

Hi everyone, not sure if this is still a relevant thread but I'm having issues with my folger tech 2020:

The endstops don't work at all!!!

I've been trying to get them to work for a couple of weeks now to no avail, I've tried messing with the configuration.h and quadruple checked the wiring, I've also emailed folger tech and they have responded but not given any real help as to what the problem is.

When the endstops are triggered they light up but they do not stop the motors from running. Ive used the m119 command and they always read open, even when triggered. So I'm not sure if all of the endstops are broken or if it is the board, or if its something else entirely, any help would be appreciated!

Also I'm new to this

Thanks in advance

-Joe

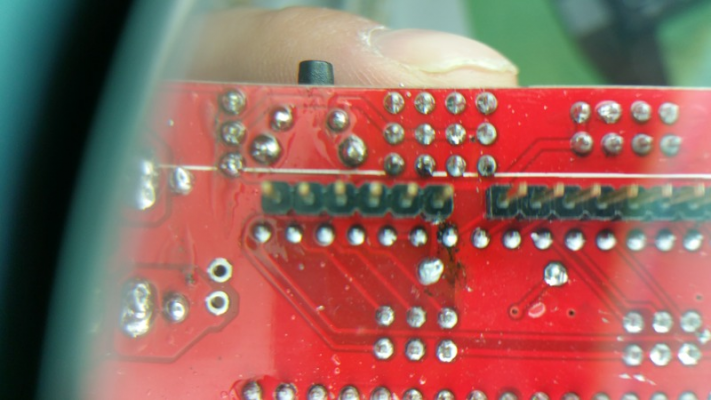

Turned out my RAMPS board was bad. I thought I had accidentally shorted something when I tried re-arranging the endstop plugs but actually the pins weren't soldered well in place on the board. I didn't notice this at first... I'm not sure I even inspected the board before I installed it (I'm a total beginner with this stuff and assumed it was in working order).

So maybe try unplugging everything and inspect your ramps board for problems. 1/3 or more of my pins were so poorly soldered they were loose enough to wiggle around. Replaced the board and now it works like a charm.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 26, 2015 09:22AM |

Registered: 8 years ago Posts: 276 |

Quote

Lagomorph

Quote

therippa

Quote

Bert3D

So I upgraded to the latest marlin code posted earlier in this topic, and now by bed won't go much above 85 or 90 degrees, and takes much longer than before. Has anyone fixed this? What's the trick?

Also, is the throat on the extruder a 26mm or a 30mm?

Re-run the PID autotune for the bed.

I had the same problem until I changed the thermistor settings in Configuration.h to use table 1 instead of 6. At first I couldn't get a temperature above about 86C. I switched back to the original code and it was working again. Then I ran a diff on the new code versus the one from Folger Tech and saw a lot of changes to table 6 in the thermistor tables. (and whats with that note in the configuration about table 6 being not as accurate as table 1? Why even have it in there then?)

Also, does the PID autotune make any difference for the bed? It looks like the configuration is set to use bang-bang for the bed as #define PIDTEMPBED is commented out. On mine the LED for the bed is only on or off, it does not blink like the LED for the hotend.

Not sure if it makes a difference, but I also replaced the heat bed power wires with #14 gauge wires.

Interesting. I'll try changing to table 1 too, and if it works better I'll update the firmware settings on github.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 26, 2015 12:33PM |

Registered: 8 years ago Posts: 3 |

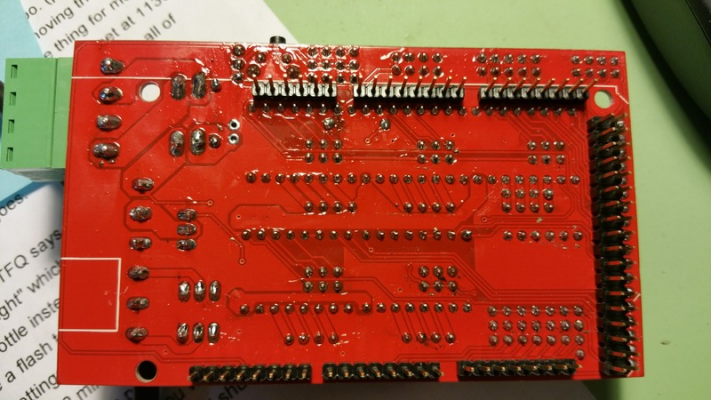

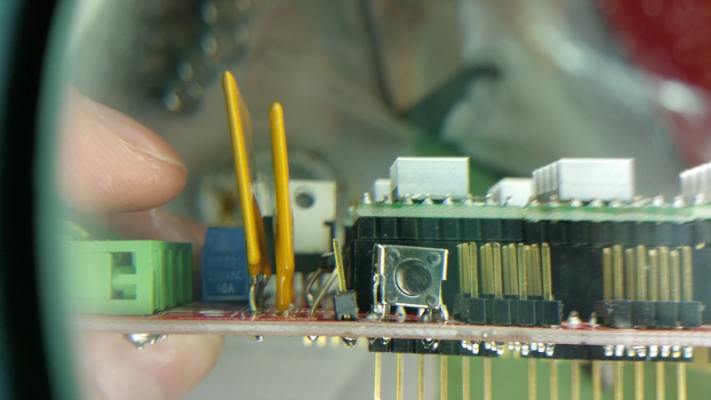

In the process of building my Prusa i3 (acrylic, not 2020) and am so far up to page 28 of this thread. One thing that keeps coming up is the quality (or lack thereof) of the RAMPS board. I decided last night to take a good look at mine under a magnifier to see if I had any issues that needed to be dealt with prior to first power up. Well, I've found some stuff that concerns me. Didn't find any solder bridges, as many others have found. What I've found however is what appears to be some fairly rough handling of the board, either during the clamping process for soldering or in the feeble attempt at removing excess flux. There are sections where the red covering has been removed and I fear potential damage to the traces below. I have contacted FolgerTech on this, but have yet to get a response. I also tried calling the number listed on their website, but apparently you can't actually TALK to someone about a tech issue (via Option 2 of the automated system).

Should I be worried about this be in pursuit of a replacement board before I end up frying both the RAMPS board and my Mega?

Should I be worried about this be in pursuit of a replacement board before I end up frying both the RAMPS board and my Mega?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 26, 2015 01:27PM |

Registered: 8 years ago Posts: 93 |

Quote

[email protected]

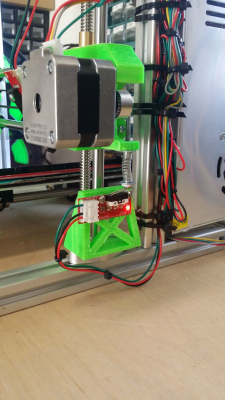

New adjustable Z-endstop. I have set the extruder now I just have to adjust the Z steps it's way off!!

Got a link to the STL for that endstop?

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 26, 2015 05:26PM |

Registered: 8 years ago Posts: 30 |

Hello.. new member here, just got my kit in the mail and started working on building the base, however there seems to be an issue with using M5x8mm bolts to hold down the SK8. The SK8 is 6.53mm thick so there is not enough thread left to get a good bite on the T-nut. Has anyone else seen this issue? Did i just get really thick SK8's?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 26, 2015 06:01PM |

Registered: 8 years ago Posts: 16 |

Quote

Brotherbrown831

Hello.. new member here, just got my kit in the mail and started working on building the base, however there seems to be an issue with using M5x8mm bolts to hold down the SK8. The SK8 is 6.53mm thick so there is not enough thread left to get a good bite on the T-nut. Has anyone else seen this issue? Did i just get really thick SK8's?

I ran into this issue as well. I went to Home Depot and picked up M5x10mm screws to solve the issue.

[www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 26, 2015 07:24PM |

Registered: 8 years ago Posts: 30 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 26, 2015 08:36PM |

Registered: 8 years ago Posts: 121 |

Quote

therippa

Quote

Lagomorph

Quote

therippa

Quote

Bert3D

So I upgraded to the latest marlin code posted earlier in this topic, and now by bed won't go much above 85 or 90 degrees, and takes much longer than before. Has anyone fixed this? What's the trick?

Also, is the throat on the extruder a 26mm or a 30mm?

Re-run the PID autotune for the bed.

I had the same problem until I changed the thermistor settings in Configuration.h to use table 1 instead of 6. At first I couldn't get a temperature above about 86C. I switched back to the original code and it was working again. Then I ran a diff on the new code versus the one from Folger Tech and saw a lot of changes to table 6 in the thermistor tables. (and whats with that note in the configuration about table 6 being not as accurate as table 1? Why even have it in there then?)

Also, does the PID autotune make any difference for the bed? It looks like the configuration is set to use bang-bang for the bed as #define PIDTEMPBED is commented out. On mine the LED for the bed is only on or off, it does not blink like the LED for the hotend.

Not sure if it makes a difference, but I also replaced the heat bed power wires with #14 gauge wires.

Interesting. I'll try changing to table 1 too, and if it works better I'll update the firmware settings on github.

I am going to try this as well. My bed refuse to get above 85 where before it worked fine. I have been blasting my bed with a heat gun to get it up to temp. Though after it prints for awhile the temp comes up!! I tried setting my preheat temp to 100 and let it go for an hour stopped at 85. I am printing a kossel motor mount right now so since it seems to be printing well right now not gonna bother it till it is done!! (preheat 100 first layer 105 others 102 printing with ABS)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 27, 2015 05:32AM |

Registered: 8 years ago Posts: 121 |

Quote

Bert3D

Quote

[email protected]

New adjustable Z-endstop. I have set the extruder now I just have to adjust the Z steps it's way off!!

Got a link to the STL for that endstop?

[www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 27, 2015 05:57AM |

Registered: 8 years ago Posts: 121 |

Quote

therippa

Quote

Lagomorph

Quote

therippa

Quote

Bert3D

So I upgraded to the latest marlin code posted earlier in this topic, and now by bed won't go much above 85 or 90 degrees, and takes much longer than before. Has anyone fixed this? What's the trick?

Also, is the throat on the extruder a 26mm or a 30mm?

Re-run the PID autotune for the bed.

I had the same problem until I changed the thermistor settings in Configuration.h to use table 1 instead of 6. At first I couldn't get a temperature above about 86C. I switched back to the original code and it was working again. Then I ran a diff on the new code versus the one from Folger Tech and saw a lot of changes to table 6 in the thermistor tables. (and whats with that note in the configuration about table 6 being not as accurate as table 1? Why even have it in there then?)

Also, does the PID autotune make any difference for the bed? It looks like the configuration is set to use bang-bang for the bed as #define PIDTEMPBED is commented out. On mine the LED for the bed is only on or off, it does not blink like the LED for the hotend.

Not sure if it makes a difference, but I also replaced the heat bed power wires with #14 gauge wires.

Interesting. I'll try changing to table 1 too, and if it works better I'll update the firmware settings on github.

SO HAPPY THIS WORKED!!! Though I will have an extra black mkb2 PCB heater now LOL!!! I changed the bed sensor from 6 to 1 and the bed heated up to to 105 in about 12 minutes!!!!!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 27, 2015 03:47PM |

Registered: 8 years ago Posts: 171 |

Quote

[email protected]

Quote

therippa

Quote

Lagomorph

Quote

therippa

Quote

Bert3D

So I upgraded to the latest marlin code posted earlier in this topic, and now by bed won't go much above 85 or 90 degrees, and takes much longer than before. Has anyone fixed this? What's the trick?

Also, is the throat on the extruder a 26mm or a 30mm?

Re-run the PID autotune for the bed.

I had the same problem until I changed the thermistor settings in Configuration.h to use table 1 instead of 6. At first I couldn't get a temperature above about 86C. I switched back to the original code and it was working again. Then I ran a diff on the new code versus the one from Folger Tech and saw a lot of changes to table 6 in the thermistor tables. (and whats with that note in the configuration about table 6 being not as accurate as table 1? Why even have it in there then?)

Also, does the PID autotune make any difference for the bed? It looks like the configuration is set to use bang-bang for the bed as #define PIDTEMPBED is commented out. On mine the LED for the bed is only on or off, it does not blink like the LED for the hotend.

Not sure if it makes a difference, but I also replaced the heat bed power wires with #14 gauge wires.

Interesting. I'll try changing to table 1 too, and if it works better I'll update the firmware settings on github.

SO HAPPY THIS WORKED!!! Though I will have an extra black mkb2 PCB heater now LOL!!! I changed the bed sensor from 6 to 1 and the bed heated up to to 105 in about 12 minutes!!!!!

I can't wait to try this too!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 27, 2015 04:05PM |

Registered: 8 years ago Posts: 121 |

Quote

markts

Quote

[email protected]

Quote

therippa

Quote

Lagomorph

Quote

therippa

Quote

Bert3D

So I upgraded to the latest marlin code posted earlier in this topic, and now by bed won't go much above 85 or 90 degrees, and takes much longer than before. Has anyone fixed this? What's the trick?

Also, is the throat on the extruder a 26mm or a 30mm?

Re-run the PID autotune for the bed.

I had the same problem until I changed the thermistor settings in Configuration.h to use table 1 instead of 6. At first I couldn't get a temperature above about 86C. I switched back to the original code and it was working again. Then I ran a diff on the new code versus the one from Folger Tech and saw a lot of changes to table 6 in the thermistor tables. (and whats with that note in the configuration about table 6 being not as accurate as table 1? Why even have it in there then?)

Also, does the PID autotune make any difference for the bed? It looks like the configuration is set to use bang-bang for the bed as #define PIDTEMPBED is commented out. On mine the LED for the bed is only on or off, it does not blink like the LED for the hotend.

Not sure if it makes a difference, but I also replaced the heat bed power wires with #14 gauge wires.

Interesting. I'll try changing to table 1 too, and if it works better I'll update the firmware settings on github.

SO HAPPY THIS WORKED!!! Though I will have an extra black mkb2 PCB heater now LOL!!! I changed the bed sensor from 6 to 1 and the bed heated up to to 105 in about 12 minutes!!!!!

I can't wait to try this too!

Well I still need to check bed temp tonight with laser thermo or with my multimeter to verify that the reading is correct but my prints are staying on the bed.

Checked the glass on my bed with my laser thermo it would show from 2-5 degrees of my thermistor reading in repetier!!! Since this is on the glass I'll take it!! I guess I'll stick with profile 1

Edited 1 time(s). Last edit at 08/27/2015 07:28PM by jasonsaffle13@gmail.com.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 27, 2015 08:44PM |

Registered: 8 years ago Posts: 276 |

Ran a test now that I have cork under the heating plate (and as always, I have a piece of cardboard on top while it's heating)...

Starting from 25c using glass/PEI:

Reached 60c in 1:58

Reached 100c in 9:21

Reached 110c in 11:54

Starting from 25c using aluminum:

Reached 60c in 2:30

Reached 100c in 10:18

Reached 110c 13:06

It used to take about 16-18 minutes to reach 110c on glass, and I could never get it past 90 on aluminum before. This is making me consider going with an inductive sensor for auto-level and using the buildplate, instead of the capacitive sensor/glass combo I was going to use (is less reliable). Only problem is if I have to really pry something off the aluminum I'd have to take the screws out to remove it.

Anyway, the change has been merged in to the Release branch on my Marlin fork.

Edited 2 time(s). Last edit at 08/27/2015 09:17PM by therippa.

Starting from 25c using glass/PEI:

Reached 60c in 1:58

Reached 100c in 9:21

Reached 110c in 11:54

Starting from 25c using aluminum:

Reached 60c in 2:30

Reached 100c in 10:18

Reached 110c 13:06

It used to take about 16-18 minutes to reach 110c on glass, and I could never get it past 90 on aluminum before. This is making me consider going with an inductive sensor for auto-level and using the buildplate, instead of the capacitive sensor/glass combo I was going to use (is less reliable). Only problem is if I have to really pry something off the aluminum I'd have to take the screws out to remove it.

Anyway, the change has been merged in to the Release branch on my Marlin fork.

Edited 2 time(s). Last edit at 08/27/2015 09:17PM by therippa.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 28, 2015 06:54PM |

Registered: 8 years ago Posts: 19 |

Hey all,

I just got my Prusa put together, but when I go into repetier and try to move things using manual control, it only will move one way, x,y and z are all affected the same and all say the endstops are hit. I know they are not hit, and the little red LED that lights when they are hit is not lit.

Has anyone seen this issue? Thanks in advance.

15:31:00.350 : FIRMWARE_NAME:Marlin V1; Sprinter/grbl mashup for gen6 FIRMWARE_URL:[www.mendel-parts.com] PROTOCOL_VERSION:1.0 MACHINE_TYPE:FolgerTech EXTRUDER_COUNT:1

15:31:00.354 : echo:Active Extruder: 0

15:31:00.354 : Begin file list

15:31:00.354 : End file list

15:31:00.357 : echo:Active Extruder: 0

15:31:02.831 : echo:endstops hit: Y:0.00

15:31:04.392 : echo:endstops hit: Y:0.01

15:31:05.416 : echo:endstops hit: Y:0.03

I just got my Prusa put together, but when I go into repetier and try to move things using manual control, it only will move one way, x,y and z are all affected the same and all say the endstops are hit. I know they are not hit, and the little red LED that lights when they are hit is not lit.

Has anyone seen this issue? Thanks in advance.

15:31:00.350 : FIRMWARE_NAME:Marlin V1; Sprinter/grbl mashup for gen6 FIRMWARE_URL:[www.mendel-parts.com] PROTOCOL_VERSION:1.0 MACHINE_TYPE:FolgerTech EXTRUDER_COUNT:1

15:31:00.354 : echo:Active Extruder: 0

15:31:00.354 : Begin file list

15:31:00.354 : End file list

15:31:00.357 : echo:Active Extruder: 0

15:31:02.831 : echo:endstops hit: Y:0.00

15:31:04.392 : echo:endstops hit: Y:0.01

15:31:05.416 : echo:endstops hit: Y:0.03

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 28, 2015 07:23PM |

Registered: 8 years ago Posts: 30 |

Extremely impressed.

I ordered my kit on sunday, it arrived at my house on wednesday, I built it in two evenings and was able to print a 1cm calibration cube using 100% stock settings downloaded from folgertech on my first print. It's not perfect but a lot better than I was expecting. For the money this kit is great!!! Now the bad news, on my seconds print the job shutdown mid print and n ow I'm getting a min temp warning error from the extruder, I'm hoping the thermistor isn't fried already, can anyone tell the the best way to test with a mulitmeter?

Edit: I don't know a lot about thermristors but I think open line on a ohm test is a pretty definitive test this thing is shot.. Can anyone advise where to get a replacement and what rating to match the factory settings?

Edited 2 time(s). Last edit at 08/28/2015 11:26PM by Brotherbrown831.

I ordered my kit on sunday, it arrived at my house on wednesday, I built it in two evenings and was able to print a 1cm calibration cube using 100% stock settings downloaded from folgertech on my first print. It's not perfect but a lot better than I was expecting. For the money this kit is great!!! Now the bad news, on my seconds print the job shutdown mid print and n ow I'm getting a min temp warning error from the extruder, I'm hoping the thermistor isn't fried already, can anyone tell the the best way to test with a mulitmeter?

Edit: I don't know a lot about thermristors but I think open line on a ohm test is a pretty definitive test this thing is shot.. Can anyone advise where to get a replacement and what rating to match the factory settings?

Edited 2 time(s). Last edit at 08/28/2015 11:26PM by Brotherbrown831.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 28, 2015 11:58PM |

Registered: 8 years ago Posts: 19 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 29, 2015 11:22AM |

Registered: 8 years ago Posts: 30 |

I searched but was unable to find my question. I have a RepRap discount full graphics display I would like to add but the version of Marlin that folgertech supplies does not have the option for that LCD in the config.h file. In order to use this panel am I going to have to use a fresh verion of Marlin from Github and transpose all the Folgertech settings into it or is it as simple as me adding this line into the folgertech version?

"#define REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER"

If there is a better way to accomplish this, I am all ear. Thanks everyone!

"#define REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER"

If there is a better way to accomplish this, I am all ear. Thanks everyone!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 29, 2015 12:54PM |

Registered: 8 years ago Posts: 367 |

Quote

Brotherbrown831

Extremely impressed.

I ordered my kit on sunday, it arrived at my house on wednesday, I built it in two evenings and was able to print a 1cm calibration cube using 100% stock settings downloaded from folgertech on my first print. It's not perfect but a lot better than I was expecting. For the money this kit is great!!! Now the bad news, on my seconds print the job shutdown mid print and n ow I'm getting a min temp warning error from the extruder, I'm hoping the thermistor isn't fried already, can anyone tell the the best way to test with a mulitmeter?

Edit: I don't know a lot about thermristors but I think open line on a ohm test is a pretty definitive test this thing is shot.. Can anyone advise where to get a replacement and what rating to match the factory settings?

It does sound like the thermistor is broken. The other thing that can happen is for the sleeving to come off the leads and then you get a short on the metal block, but that would show as zero ohms rather than an open circuit. Folger sell thermistors on their web site - I assume they are the same type used in the extruder, but I don't know for sure. Folger link: [folgertech.com] (or order through their ebay store and avoid the shipping cost).

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 29, 2015 03:28PM |

Registered: 8 years ago Posts: 16 |

Quote

Brotherbrown831

I searched but was unable to find my question. I have a RepRap discount full graphics display I would like to add but the version of Marlin that folgertech supplies does not have the option for that LCD in the config.h file. In order to use this panel am I going to have to use a fresh verion of Marlin from Github and transpose all the Folgertech settings into it or is it as simple as me adding this line into the folgertech version?

"#define REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER"

If there is a better way to accomplish this, I am all ear. Thanks everyone!

I have the full graphic LCD as well and got it running with the information below.

Get therippa's FT i3 configured version of Marlin by clicking the "download zip" button on GitHub, and modify Configuration.h with the information from the RepRap wiki page for the graphical LCD (remember to get u8glib).

Also, uncomment #define EEPROM_SETTINGS from configuration.h so that you can save settings to EEPROM from the LCD. Otherwise, Marlin will revert back to the configuration.h defined settings after the printer is power cycled. I also uncommented #define EEPROM_CHITCHAT and commented out //#define REPRAP_DISCOUNT_SMART_CONTROLLER.

Edited 1 time(s). Last edit at 08/29/2015 03:30PM by TimJC.

[www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 29, 2015 06:01PM |

Registered: 8 years ago Posts: 30 |

I ended up downloading a fresh version of marlin and then just changing the values on config.h to match the folger tech values. Thanks for the tip about eeprom.

One of the big differences between the default values and the folger tech values was in the acceleration and speed settings. The folger tech values are very small compared to the defaults.

One of the big differences between the default values and the folger tech values was in the acceleration and speed settings. The folger tech values are very small compared to the defaults.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 29, 2015 06:07PM |

Registered: 8 years ago Posts: 367 |

Today's change: replaced the hot end with a E3D lite6.

Details at [moosteria.blogspot.com].

Edited 1 time(s). Last edit at 08/30/2015 01:36PM by animoose.

See my blog at [moosteria.blogspot.com].

Details at [moosteria.blogspot.com].

Edited 1 time(s). Last edit at 08/30/2015 01:36PM by animoose.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 29, 2015 11:36PM |

Registered: 8 years ago Posts: 30 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 30, 2015 10:58PM |

Registered: 8 years ago Posts: 276 |

I finished the induction autolevel sensor this weekend. The hardest part was getting it dialed in initially, and then having to do some serious changes in the configuration since Folgertech makes the X endstop max, which doesn't work with autolevel. Also, animoose and others using E3D's, I would HIGHLY recommend getting this thermistor...

[www.amazon.com]

I learned this weekend taking apart the head to fix a clog that the thermistor/insulation is only good for one screw tightening, after that the insulation falls apart and the thermistor shorts, showing a temp of 999F.

[www.amazon.com]

I learned this weekend taking apart the head to fix a clog that the thermistor/insulation is only good for one screw tightening, after that the insulation falls apart and the thermistor shorts, showing a temp of 999F.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 30, 2015 11:24PM |

Registered: 8 years ago Posts: 367 |

Quote

therippa

I finished the induction autolevel sensor this weekend. The hardest part was getting it dialed in initially, and then having to do some serious changes in the configuration since Folgertech makes the X endstop max, which doesn't work with autolevel. Also, animoose and others using E3D's, I would HIGHLY recommend getting this thermistor...

[www.amazon.com]

I learned this weekend taking apart the head to fix a clog that the thermistor/insulation is only good for one screw tightening, after that the insulation falls apart and the thermistor shorts, showing a temp of 999F.

Thanks for the tip - looks like a good product.

See my blog at [moosteria.blogspot.com].

Sorry, only registered users may post in this forum.