Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 12, 2015 10:25PM |

Registered: 8 years ago Posts: 99 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 12, 2015 10:26PM |

Registered: 8 years ago Posts: 19 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 12, 2015 10:28PM |

Registered: 8 years ago Posts: 99 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 12, 2015 10:29PM |

Registered: 8 years ago Posts: 19 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 12, 2015 10:30PM |

Registered: 8 years ago Posts: 99 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 12, 2015 10:33PM |

Registered: 8 years ago Posts: 99 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 12, 2015 10:33PM |

Registered: 8 years ago Posts: 19 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 12, 2015 10:35PM |

Registered: 8 years ago Posts: 19 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 12, 2015 10:38PM |

Registered: 8 years ago Posts: 99 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 12, 2015 10:39PM |

Registered: 8 years ago Posts: 19 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 12, 2015 10:39PM |

Registered: 8 years ago Posts: 99 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 12, 2015 10:40PM |

Registered: 8 years ago Posts: 19 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 12, 2015 10:41PM |

Registered: 8 years ago Posts: 99 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 12, 2015 10:42PM |

Registered: 8 years ago Posts: 99 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 12, 2015 10:44PM |

Registered: 8 years ago Posts: 19 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 12:41AM |

Registered: 8 years ago Posts: 276 |

canny - when adjusting the polulu pots make sure to use the ceramic screwdriver folgertech includes in the kit or you might have some serious problems. When I adjusted mine, I clipped the ground lead on my multimeter (I bought one that has the normal...pokey things and clip attachments), would turn the pot a tiny amount, and VERY carefully touch the pot with the positive lead to get the voltage.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 12:55AM |

Registered: 8 years ago Posts: 276 |

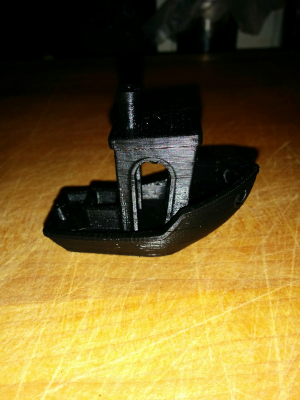

Latest Benchy calibration print at 0.15mm layer height, 15% infill, no supports... all measurements are within +/-0.02 tolerance, except for port holes, which are a little small (I'm having this problem with screw holes on other prints as well, still haven't figured it out).

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 01:07AM |

Registered: 8 years ago Posts: 367 |

Very nice!

Small interior diameters is a common issue. You can print with an extrusion multiplier slightly less than one to help (I've used 0.85 or 0.90 a few times).

See my blog at [moosteria.blogspot.com].

Small interior diameters is a common issue. You can print with an extrusion multiplier slightly less than one to help (I've used 0.85 or 0.90 a few times).

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 01:31AM |

Registered: 8 years ago Posts: 99 |

Quote

therippa

Latest Benchy calibration print at 0.15mm layer height, 15% infill, no supports... all measurements are within +/-0.02 tolerance, except for port holes, which are a little small (I'm having this problem with screw holes on other prints as well, still haven't figured it out).

What was your settings in s3d?

Ive been calibrating my x axis and Have it as close as I can get it. my y axis is right on. im wondering if the x axis should have had a bigger oz stepper like the y axis got? That little motor is doing alot and mine gets pretty warm.

What is your first layer height and speed? Im very curious of all your setting. Where im still learning. I have my first layer height at 90% and speed at 35%. Im thinking about trying 100% and maybe speed up to 50%

Edited 2 time(s). Last edit at 09/13/2015 03:10AM by woodknack.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 06:17AM |

Registered: 8 years ago Posts: 30 |

Finally got to try and print some things. I printed a 20x20 box that turned out ok so I decided to try something else. I think I need to adjust layer height, but I am not to sure why I have the issue of the sagging lines in a couple spots. I decided to turn the temp down a little to 225 and I thought that seemed to help. At one point while the print was running it really looked like the extruder was in the piece while it was trying to print. So would that mean I need to slow the feed rate?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 06:28AM |

Registered: 8 years ago Posts: 30 |

Quote

animoose

Quote

Neverdone

Has anyone tried anything besides ABS or PLA in their printer? I was looking at TPE..... Would I need a different extruder or anything for that?

I've tried PLA/PHA mix and PETG. I wrote up some notes here [moosteria.blogspot.com]. It looks like the temperature requirements for TPE (that's Ninjaflex, right?) should be OK. With a direct extruder it ought to work ok.

TPE Ninja flex yeah same thing. Thermoplastic Elastomer. One of the biggest things I want to do with this is make RC parts. I part time a hobby shop, used to run the RC department there a few years ago. Also an RC enthusiast, well fascinated by many things really. Kinda an ADD thing almost. But I want to make parts for quadcopters and stuff like that. I fly several of my own quads as well as a hex, helicopters, airplanes, have cars, trucks, boats, stuff...... All that on top of a whole other shop of larger toys. But point is that parts for the quads could be much more friendly if they weren't so stiff. Could maybe take some bounce. I have many ideas of stuff to make, once I get this dialed in. I have even talked to the owner of the shop about possibly selling some of the parts at the shop if I can make a nice finished piece.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 09:16AM |

Registered: 8 years ago Posts: 33 |

Quote

animoose

Very nice!

Small interior diameters is a common issue. You can print with an extrusion multiplier slightly less than one to help (I've used 0.85 or 0.90 a few times).

I have been playing with this issue too, I have not played with the multiplier but I am going to give it a try. I have been drawing up test circles to check diameters. If I want an 8mm hole that will give a good snug fit I have to draw an 8.42mm hole in my cad program. This is using abs and .2 layer. all my outside dimensions are very close. Yhis is why I have not tryed the multiplier. I am going to try it to see how it works.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 09:18AM |

Registered: 8 years ago Posts: 541 |

A quick question to those who have installed the FT 2004 smart LCD controller. I don't find any instructions for modifying the config and pin files in the FT downloads. I did find this YT video [www.youtube.com] which mentions

I hadn''t seen anyone else talk about enabling EEPROM SETTINGS and EEPROM CHITCHAT before. Also he doesn't talk about pin.h either although I have found other places where one line is 'uncommented'.

What did you guys change? I find it disappointing that FT doesn't offer their suggestion even though they sell the board. Maybe I'm looking in the wrong place.

Edited 1 time(s). Last edit at 09/13/2015 09:19AM by tjnamtiw.

I hadn''t seen anyone else talk about enabling EEPROM SETTINGS and EEPROM CHITCHAT before. Also he doesn't talk about pin.h either although I have found other places where one line is 'uncommented'.

What did you guys change? I find it disappointing that FT doesn't offer their suggestion even though they sell the board. Maybe I'm looking in the wrong place.

Edited 1 time(s). Last edit at 09/13/2015 09:19AM by tjnamtiw.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 09:53AM |

Registered: 8 years ago Posts: 541 |

Sorry to be bugging you all but I'm about to throw the electrons to my 2020 and I have a question about the pots on the polo drivers. I wanted to turn them all down to zero to start but I just found out there is no stop when turning counter clockwise! How do you know what position is MINIMUM? I can, I believe, see a wiper close to the top pin when the flat is facing down. All pots came with the flat facing left when the board is mounted with the power inputs to the right.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 10:17AM |

Registered: 8 years ago Posts: 99 |

Quote

tjnamtiw

Sorry to be bugging you all but I'm about to throw the electrons to my 2020 and I have a question about the pots on the polo drivers. I wanted to turn them all down to zero to start but I just found out there is no stop when turning counter clockwise! How do you know what position is MINIMUM? I can, I believe, see a wiper close to the top pin when the flat is facing down. All pots came with the flat facing left when the board is mounted with the power inputs to the right.

use a multi meter.....

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 10:34AM |

Registered: 8 years ago Posts: 541 |

Quote

woodknack

Quote

tjnamtiw

Sorry to be bugging you all but I'm about to throw the electrons to my 2020 and I have a question about the pots on the polo drivers. I wanted to turn them all down to zero to start but I just found out there is no stop when turning counter clockwise! How do you know what position is MINIMUM? I can, I believe, see a wiper close to the top pin when the flat is facing down. All pots came with the flat facing left when the board is mounted with the power inputs to the right.

use a multi meter.....

I know that!

I just don't want to power it on with the pots set at max and immediately fry the drivers.

I just don't want to power it on with the pots set at max and immediately fry the drivers. I just watched a pololu video where they tell you to adjust these values BEFORE hooking up the motors, which makes sense so I will be disconnecting them. HOWEVER, do you know if our drivers are Pololu, Stepstick, or Chinese knockoffs, all of which use different sensing resistors and therefore different REF voltages? I'm off to see what resistor value I can see.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 10:52AM |

Registered: 8 years ago Posts: 541 |

Well, they have 30K ohm R1 resistors, which is the Stepstick modification to limit current to 1.5 amps! The max VREF should be 1.25V. [reprap.org]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 11:51AM |

Registered: 8 years ago Posts: 541 |

Quote

woodknack

Ok X axis issue resolved.

Ok if your like me and put the printer together by the book, then your probably going to have and issue with your x axis moving just a little and in the wrong direction. Im a noobie to all this and it took me awhile to figure all this out and a lot of reading. Hopefully this will save some people some time.

HOW I GOT THE X AXIS WORKING THE RIGHT WAY.

1. With no power plugged into the board swap your x axis motor wire around from what folgers shows in there build. Have the red wire facing towards the usb cable just like the others (Z and Y) are.

2. open up your marlin ini file in arduino. Click on the "Configuration.h file"

3. Scroll down to where is says "Mechanical Settings"

4. Then scroll down a little farther until you find "End Stop Setting"

5. Where is says

#define X_HOME_DIR 1

put a - in front of the 1 so it looks like this.

#define X_HOME_DIR -1

6. close out the arduino box and it will ask you to save your settings and Thats just what you should do.

7. Now reopen the ini file in your marlin folder and click on the arrow up top pointing to the right to upload the firmware you just changed into the board. after its down close down the arduino box.

8. Unplug the usb again and make sure your x axis reset switch wire is plugged in the last set of prongs on the board (this should be already like that as its the way folgers shows you in there manual).

9. in repetier make sure in printer settings the x is set to max and y and z are set to min.

Now give it a shot! If this helps anyone we should make it a sticky or something. Seems like alot of people are having this problem which really should be corrected by folger tech in the first place.

Sure enough, my X was backwards! Why doesn't FT fix their instructions???? The only thing I DIDN'T do was your one step where it says in Repetier to set x to max. Do you mean to reverse the 0 and 200 settings?

EDIT: I did go ahead and swap the X coordinates. I homed and got the G90 code, meaning I am at absolute coordinates relative to home.

Now, when I try to move using Repetier's arrows I get an error message saying 'printer stopped due to errors'. Back to searching. I'm close and NO SMOKE so all is good!

Edited 1 time(s). Last edit at 09/13/2015 12:20PM by tjnamtiw.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 12:24PM |

Registered: 8 years ago Posts: 430 |

Quote

Neverdone

Quote

animoose

Quote

Neverdone

Has anyone tried anything besides ABS or PLA in their printer? I was looking at TPE..... Would I need a different extruder or anything for that?

I've tried PLA/PHA mix and PETG. I wrote up some notes here [moosteria.blogspot.com]. It looks like the temperature requirements for TPE (that's Ninjaflex, right?) should be OK. With a direct extruder it ought to work ok.

TPE Ninja flex yeah same thing. Thermoplastic Elastomer. One of the biggest things I want to do with this is make RC parts. I part time a hobby shop, used to run the RC department there a few years ago. Also an RC enthusiast, well fascinated by many things really. Kinda an ADD thing almost. But I want to make parts for quadcopters and stuff like that. I fly several of my own quads as well as a hex, helicopters, airplanes, have cars, trucks, boats, stuff...... All that on top of a whole other shop of larger toys. But point is that parts for the quads could be much more friendly if they weren't so stiff. Could maybe take some bounce. I have many ideas of stuff to make, once I get this dialed in. I have even talked to the owner of the shop about possibly selling some of the parts at the shop if I can make a nice finished piece.

I would try petg I that seemed to be more like you want where it will flex and not snap. Isn't the ninga flex stuff like rubber?

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 12:40PM |

Registered: 8 years ago Posts: 99 |

Quote

tjnamtiw

Quote

woodknack

Ok X axis issue resolved.

Ok if your like me and put the printer together by the book, then your probably going to have and issue with your x axis moving just a little and in the wrong direction. Im a noobie to all this and it took me awhile to figure all this out and a lot of reading. Hopefully this will save some people some time.

HOW I GOT THE X AXIS WORKING THE RIGHT WAY.

1. With no power plugged into the board swap your x axis motor wire around from what folgers shows in there build. Have the red wire facing towards the usb cable just like the others (Z and Y) are.

2. open up your marlin ini file in arduino. Click on the "Configuration.h file"

3. Scroll down to where is says "Mechanical Settings"

4. Then scroll down a little farther until you find "End Stop Setting"

5. Where is says

#define X_HOME_DIR 1

put a - in front of the 1 so it looks like this.

#define X_HOME_DIR -1

6. close out the arduino box and it will ask you to save your settings and Thats just what you should do.

7. Now reopen the ini file in your marlin folder and click on the arrow up top pointing to the right to upload the firmware you just changed into the board. after its down close down the arduino box.

8. Unplug the usb again and make sure your x axis reset switch wire is plugged in the last set of prongs on the board (this should be already like that as its the way folgers shows you in there manual).

9. in repetier make sure in printer settings the x is set to max and y and z are set to min.

Now give it a shot! If this helps anyone we should make it a sticky or something. Seems like alot of people are having this problem which really should be corrected by folger tech in the first place.

Sure enough, my X was backwards! Why doesn't FT fix their instructions???? The only thing I DIDN'T do was your one step where it says in Repetier to set x to max. Do you mean to reverse the 0 and 200 settings?

EDIT: I did go ahead and swap the X coordinates. I homed and got the G90 code, meaning I am at absolute coordinates relative to home.

Now, when I try to move using Repetier's arrows I get an error message saying 'printer stopped due to errors'. Back to searching. I'm close and NO SMOKE so all is good!

What error is it showing? Have you tried putting x axis to max in the repetier software and trying it?

Sorry, only registered users may post in this forum.