Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 12:49PM |

Registered: 8 years ago Posts: 541 |

My patience is wearing thin! That error message has to do with the hot end. Sure enough, I see 0.0C on the hot end. Also it registered open on my meter. Under a magnifying glass, I can see that one of the wires running to the thermistor is about 1/8" away from the thermistor! Back to emailing FT to get more parts! Grrrrrrrrrrrrrr.

Edited 1 time(s). Last edit at 09/13/2015 06:31PM by tjnamtiw.

Edited 1 time(s). Last edit at 09/13/2015 06:31PM by tjnamtiw.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 03:57PM |

Registered: 8 years ago Posts: 276 |

Quote

woodknack

Quote

therippa

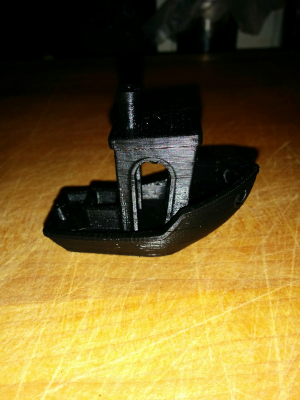

Latest Benchy calibration print at 0.15mm layer height, 15% infill, no supports... all measurements are within +/-0.02 tolerance, except for port holes, which are a little small (I'm having this problem with screw holes on other prints as well, still haven't figured it out).

What was your settings in s3d?

Ive been calibrating my x axis and Have it as close as I can get it. my y axis is right on. im wondering if the x axis should have had a bigger oz stepper like the y axis got? That little motor is doing alot and mine gets pretty warm.

What is your first layer height and speed? Im very curious of all your setting. Where im still learning. I have my first layer height at 90% and speed at 35%. Im thinking about trying 100% and maybe speed up to 50%

Here's my current process settings file - [db.tt]

Keep in mind if you import it and try using it 1) the temps are set for ABS and printing on Buildtak, 2) I have my x-endstop physically located on the left now, so x-endstop in the process is set to min, and 3) I have a G29 call in my starting script to run autolevel

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 05:23PM |

Registered: 8 years ago Posts: 30 |

Quote

Neverdone

Finally got to try and print some things. I printed a 20x20 box that turned out ok so I decided to try something else. I think I need to adjust layer height, but I am not to sure why I have the issue of the sagging lines in a couple spots. I decided to turn the temp down a little to 225 and I thought that seemed to help. At one point while the print was running it really looked like the extruder was in the piece while it was trying to print. So would that mean I need to slow the feed rate?

Anyone have any suggestions for what my problem may be?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 13, 2015 06:30PM |

Registered: 8 years ago Posts: 276 |

Quote

Neverdone

Quote

Neverdone

Finally got to try and print some things. I printed a 20x20 box that turned out ok so I decided to try something else. I think I need to adjust layer height, but I am not to sure why I have the issue of the sagging lines in a couple spots. I decided to turn the temp down a little to 225 and I thought that seemed to help. At one point while the print was running it really looked like the extruder was in the piece while it was trying to print. So would that mean I need to slow the feed rate?

Anyone have any suggestions for what my problem may be?

Post a pic of the "sagging lines" issue. Also, if the the nozzle was digging into the piece, it could be that your bed is too close to the nozzle (a piece of paper should fit through), or it could be extruding too much. Try reducing the flow/extrusion multiplier on the print panel and see if that helps.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 14, 2015 01:36PM |

Registered: 8 years ago Posts: 541 |

Quote

Tenny

Ok I got it fixed.

So if you keep the cables wired as they are in the manual this will fix it:

Change the following in configuration.h

- #define INVERT_X_DIR true to #define INVERT_X_DIR false

- #define X_HOME_DIR -1 to #define X_HOME_DIR 1

- With the printer off PHYSICALLY move the x-axis stopper to the left one set of pins (this makes it so it's the x max instead of x-min)

Now if you are using rep host, you need to go to printer settings > printer shape and change home X: from min to Max.

In Octoprint it looks like nothing is needed.

Now there are ways of changing pins.h so you don't have to do #3 but I prefer to do it this way.

EDIT: Ok, yes this fixed the problem. The error i was having after this was another change I set that I forgot about.

Thanks go out to Tenny for this one! This set up completely solved my X axis problems! So darn simple too. One key was to move the X end stop plug from the right most set of pins to the set just to the left of that one. Those are for X axis MAX. Also in Repetier, by choosing home X to Max, it eliminates the red numbers over 200 that I was seeing.

Got my bed leveled and, since I'm using those black clips to hold down my glass, I squeezed in my max dimensions to 180 by 180 and moved my end stops to clear the clips. Now all I need is a thermistor for my hotend and I can set up the extruder. I moved the bed thermistor lead over to the hotend plug so I could work the motions.

Can't wait! Thank heavens that you all are here!

[www.google.com]

Edited 1 time(s). Last edit at 09/14/2015 01:38PM by tjnamtiw.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 14, 2015 01:57PM |

Registered: 8 years ago Posts: 1 |

Like others I had problems getting the extruder working correctly. When I tried to calibrate it, extruding 100mm of filament only ended up pushing out 25mm. Turns out the teeth on the gear were just barely touching the filament. I recentered the gear on the filament path and have been getting much better results since.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 14, 2015 03:15PM |

Registered: 8 years ago Posts: 99 |

Quote

therippa

Quote

woodknack

Quote

therippa

Latest Benchy calibration print at 0.15mm layer height, 15% infill, no supports... all measurements are within +/-0.02 tolerance, except for port holes, which are a little small (I'm having this problem with screw holes on other prints as well, still haven't figured it out).

What was your settings in s3d?

Ive been calibrating my x axis and Have it as close as I can get it. my y axis is right on. im wondering if the x axis should have had a bigger oz stepper like the y axis got? That little motor is doing alot and mine gets pretty warm.

What is your first layer height and speed? Im very curious of all your setting. Where im still learning. I have my first layer height at 90% and speed at 35%. Im thinking about trying 100% and maybe speed up to 50%

Here's my current process settings file - [db.tt]

Keep in mind if you import it and try using it 1) the temps are set for ABS and printing on Buildtak, 2) I have my x-endstop physically located on the left now, so x-endstop in the process is set to min, and 3) I have a G29 call in my starting script to run autolevel

Too funny I moved my x axis end stop to the left too. So it would home like the software.

I also printed off the auto leveling holder and arm as that's my next project.

Thanks for the settings I'm currently using pla. Still learning. So far I'm hooked! ;-)

After you set your auto leveling comand does it home then start your print?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 14, 2015 03:27PM |

Registered: 8 years ago Posts: 3 |

Guys how critical is the alignment of the top (z) stepper motors? On the bottom I have like 14" from outside to outside. On the top by the motors the rods are 14 and 1/16th. If I try to squeeze them do they are same distance then z gets rough and doesn't slide nice. I noticed that the top rod on the left side top of x idler mount is very tight and may not be going all the way in.

I guess my question is should the z rods be straight vertical or does a few mm off make a diff on my prints?

Thanks

I guess my question is should the z rods be straight vertical or does a few mm off make a diff on my prints?

Thanks

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 14, 2015 04:41PM |

Registered: 8 years ago Posts: 99 |

As long as you x carriage move nice and free up and down then I'd say your fine. You can tweak your z later when leveling your bed.Quote

cmenchion

Guys how critical is the alignment of the top (z) stepper motors? On the bottom I have like 14" from outside to outside. On the top by the motors the rods are 14 and 1/16th. If I try to squeeze them do they are same distance then z gets rough and doesn't slide nice. I noticed that the top rod on the left side top of x idler mount is very tight and may not be going all the way in.

I guess my question is should the z rods be straight vertical or does a few mm off make a diff on my prints?

Thanks

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 14, 2015 06:30PM |

Registered: 8 years ago Posts: 3 |

Awesome thanks.

Another question. I replaced my bearings and since then if I have Park enabled in repeitier when the print ends or i kill it the Y axis will bounce/grind against the endstop. I've switched endstops and readjusted location etc. If I turn off Park then just the x homes as per gcode.

Any idea there lol??

Another question. I replaced my bearings and since then if I have Park enabled in repeitier when the print ends or i kill it the Y axis will bounce/grind against the endstop. I've switched endstops and readjusted location etc. If I turn off Park then just the x homes as per gcode.

Any idea there lol??

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 14, 2015 07:01PM |

Registered: 8 years ago Posts: 276 |

Quote

woodknack

Too funny I moved my x axis end stop to the left too. So it would home like the software.

I also printed off the auto leveling holder and arm as that's my next project.

Thanks for the settings I'm currently using pla. Still learning. So far I'm hooked! ;-)

After you set your auto leveling comand does it home then start your print?

I have it home (G28), then autolevel (G29), then it starts printing.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 14, 2015 08:15PM |

Registered: 8 years ago Posts: 99 |

Cool thanks.Quote

therippa

Quote

woodknack

Too funny I moved my x axis end stop to the left too. So it would home like the software.

I also printed off the auto leveling holder and arm as that's my next project.

Thanks for the settings I'm currently using pla. Still learning. So far I'm hooked! ;-)

After you set your auto leveling comand does it home then start your print?

I have it home (G28), then autolevel (G29), then it starts printing.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 14, 2015 10:06PM |

Registered: 8 years ago Posts: 541 |

Quote

cmenchion

Guys how critical is the alignment of the top (z) stepper motors? On the bottom I have like 14" from outside to outside. On the top by the motors the rods are 14 and 1/16th. If I try to squeeze them do they are same distance then z gets rough and doesn't slide nice. I noticed that the top rod on the left side top of x idler mount is very tight and may not be going all the way in.

I guess my question is should the z rods be straight vertical or does a few mm off make a diff on my prints?

Thanks

I am a complete noob as far as 3D printing is concerned but I have a career history of dealing with alignment of linear bearings. IMHO, these reprap printers all have one serious flaw and that is relying on the accuracy of printed parts to ensure precise alignment of parallel linear bearings. Both rails must be exactly aligned to precisely hold bearings to prevent destroying them. Maybe that's why these bearings are sold all over EBay at 10 per lot! IF both bearings on the one rail are indeed aligned exactly, then the other rail AND bearing must be exactly parallel in all three axes. If possible, letting the single bearing side 'float' slightly will reduce wear on the bearings. If you are 1/16" off from top to bottom, then you are asking for premature failure and binding of the Z axis. You might also see the servo motors skipping, which will throw your alignment to the bed off as well. I would (already have) invest in a larger calipers to measure this distance more accurately

Just my humble opinion, seeing what I've seen so far in my build. Looking at a modified bearing holder to allow some bearing float might be a worthwhile endeavor, especially for the Y axis. The Z axis might be better attacked by looking at some 'slop' in how the vertical rods are held and locking them down when there is no movement as the carriage travels up and down.

Edited 2 time(s). Last edit at 09/14/2015 10:12PM by tjnamtiw.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 14, 2015 10:10PM |

Registered: 8 years ago Posts: 541 |

Quote

tjnamtiw

My patience is wearing thin! That error message has to do with the hot end. Sure enough, I see 0.0C on the hot end. Also it registered open on my meter. Under a magnifying glass, I can see that one of the wires running to the thermistor is about 1/8" away from the thermistor! Back to emailing FT to get more parts! Grrrrrrrrrrrrrr.

I have to praise the crap out of Folger Tech! Got an email today that my thermistor is ready to be shipped! IMAGINE what this would be like if I ordered it on EBay or Aliexppress from China!!!! I've dealt with China on numerous occasions and, if it's a simple item, no problem, but anything complex, TOTAL DISASTER.

Thank heavens for FT!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 14, 2015 11:44PM |

Registered: 8 years ago Posts: 430 |

PID auto tune is great!

[www.youtube.com]

When I would try to get the bed up to 100 it seemed like it could just barley do it and would take a extremely long time to go from 90 to 100. After running PID auto tune it just slowly keeps climbing to 100 and doesn't stop and it's way faster than before.

Newbie with Folgertech 2020 i3.

[www.youtube.com]

When I would try to get the bed up to 100 it seemed like it could just barley do it and would take a extremely long time to go from 90 to 100. After running PID auto tune it just slowly keeps climbing to 100 and doesn't stop and it's way faster than before.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 10:06AM |

Registered: 8 years ago Posts: 84 |

I have been printing for a couple of days with my 2020 and it has been great, but now I have ran into an error I cant seem to figure out. I printed the benchy boat thing and it was fine so I was going to print a extruder tip shroud and I keep getting MINTEMP error and it kills the print. The first time it done it it was about 75 percent done with the print, then I tried again and it got the first 4 layers done. Just tried it again after checking all of my wiring and the resistance on both thermistors and it didn't even print the skirt and killed the print. Any ideas?

Judging by the temp graph the extruder went from the correct temp to zero for just a second and then went back to the correct temp. I did have a broken wire on that thermistor when I got the printer but I was able to solder it back together.

Judging by the temp graph the extruder went from the correct temp to zero for just a second and then went back to the correct temp. I did have a broken wire on that thermistor when I got the printer but I was able to solder it back together.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 10:23AM |

Registered: 8 years ago Posts: 541 |

Quote

built350camaro

I have been printing for a couple of days with my 2020 and it has been great, but now I have ran into an error I cant seem to figure out. I printed the benchy boat thing and it was fine so I was going to print a extruder tip shroud and I keep getting MINTEMP error and it kills the print. The first time it done it it was about 75 percent done with the print, then I tried again and it got the first 4 layers done. Just tried it again after checking all of my wiring and the resistance on both thermistors and it didn't even print the skirt and killed the print. Any ideas?

Judging by the temp graph the extruder went from the correct temp to zero for just a second and then went back to the correct temp. I did have a broken wire on that thermistor when I got the printer but I was able to solder it back together.

It sounds like you still have a bad connection to your thermistor, at least intermittently. As others have posted, it seems the Chinese are not too reliable on crimping those little tabs that fit into the plug that attaches to the Ramps board. Pull it off, depress the little silver button and pull out the connectors. Check to see if they crimped it onto insulation rather than bare wire. I'd solder it, if it were me.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 10:55AM |

Registered: 8 years ago Posts: 84 |

Mine was actually broke where it goes into the extruder block the first time. When they crimped the metal tube to hold it they also cut the wires, glad I have a good set of helping hands and a magnify glass to solder that back. I will check the plug as well since one of my endstop wires was that way.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 12:52PM |

Registered: 8 years ago Posts: 541 |

Quote

built350camaro

Mine was actually broke where it goes into the extruder block the first time. When they crimped the metal tube to hold it they also cut the wires, glad I have a good set of helping hands and a magnify glass to solder that back. I will check the plug as well since one of my endstop wires was that way.

EXACTLY what happened to mine!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 01:43PM |

Registered: 8 years ago Posts: 541 |

Quote

built350camaro

Mine was actually broke where it goes into the extruder block the first time. When they crimped the metal tube to hold it they also cut the wires, glad I have a good set of helping hands and a magnify glass to solder that back. I will check the plug as well since one of my endstop wires was that way.

The melting point of most solders starts at about 365 degrees,F which just happens to be the 185 degree C that your hotend is probably running at. With the resoldered joint so close to the thermistor bulb, I'd guess that's where your problem is. Time for a new thermistor, me thinks.

Edited 1 time(s). Last edit at 09/15/2015 01:43PM by tjnamtiw.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 03:37PM |

Registered: 8 years ago Posts: 84 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 04:30PM |

Registered: 8 years ago Posts: 30 |

So I been using the printer for a couple days, getting some bugs worked out. Now all the sudden Repetier Host just freezes randomly after I hav eloaded an object to print. Doesn't matter what the object is, even if it is something I have printed before. It just locks up and says program not responding. When this first started happening I was running v1.5.4 so I updated to 1.5.6 and has the same issue. Has anyone else ran in to this?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 04:35PM |

Registered: 8 years ago Posts: 171 |

Quote

Neverdone

So I been using the printer for a couple days, getting some bugs worked out. Now all the sudden Repetier Host just freezes randomly after I hav eloaded an object to print. Doesn't matter what the object is, even if it is something I have printed before. It just locks up and says program not responding. When this first started happening I was running v1.5.4 so I updated to 1.5.6 and has the same issue. Has anyone else ran in to this?

It does it to me very consistently if I slice an object, then try to load another instead. I have to quit the program, otherwise I get the "not responding" message. Not sure if that's the issue you're seeing.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 05:25PM |

Registered: 8 years ago Posts: 84 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 06:02PM |

Registered: 8 years ago Posts: 84 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 07:15PM |

Registered: 8 years ago Posts: 99 |

check this outI'm new to this to but I think this is what you should do.

If you wanted 20mm and you got 20.32 then you take 20/20.32 which =0.984 take that number and times it by your steps in the firmware for that axis. Say that axis Is 80. 80×.984=78.72 that is your new step number.delete the 80 and put in 78.72 and save it then reflash the mega.

Do this for all the axis.

Edited 2 time(s). Last edit at 09/15/2015 07:32PM by woodknack.

If you wanted 20mm and you got 20.32 then you take 20/20.32 which =0.984 take that number and times it by your steps in the firmware for that axis. Say that axis Is 80. 80×.984=78.72 that is your new step number.delete the 80 and put in 78.72 and save it then reflash the mega.

Do this for all the axis.

Edited 2 time(s). Last edit at 09/15/2015 07:32PM by woodknack.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 08:09PM |

Registered: 8 years ago Posts: 84 |

Thanks a bunch. it isn't off enough to really worry about but I want it closer lol. I just printed the heat sink shroud that will blow on the print. See if that changes anything.

I am having some stringing issues that I need to figure out, looks like spider web between to edges of a gap. I tried upping the retraction but it didn't seem to help.

I am having some stringing issues that I need to figure out, looks like spider web between to edges of a gap. I tried upping the retraction but it didn't seem to help.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 08:18PM |

Registered: 8 years ago Posts: 99 |

What are you using pla? That's what I'm using. I'm also going to print the fan shroud too. I'm printing on glass bed 70c and 195c extruder. Black pla. Sticks to the glass perfect. After the the print I take glass off and let cool a bit and object pops right off. Sometimes on its own. I clean glass with denatured alcohol.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 08:33PM |

Registered: 8 years ago Posts: 367 |

Quote

built350camaro

Thanks a bunch. it isn't off enough to really worry about but I want it closer lol. I just printed the heat sink shroud that will blow on the print. See if that changes anything.

I am having some stringing issues that I need to figure out, looks like spider web between to edges of a gap. I tried upping the retraction but it didn't seem to help.

For fixing spider webs, I found that you need to increase not only the extraction, but also the maximum extruder acceleration. See the paragraph at the end of [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 08:50PM |

Registered: 8 years ago Posts: 84 |

Sorry, only registered users may post in this forum.