Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 08:56PM |

Registered: 8 years ago Posts: 30 |

Quote

markts

Quote

Neverdone

So I been using the printer for a couple days, getting some bugs worked out. Now all the sudden Repetier Host just freezes randomly after I hav eloaded an object to print. Doesn't matter what the object is, even if it is something I have printed before. It just locks up and says program not responding. When this first started happening I was running v1.5.4 so I updated to 1.5.6 and has the same issue. Has anyone else ran in to this?

It does it to me very consistently if I slice an object, then try to load another instead. I have to quit the program, otherwise I get the "not responding" message. Not sure if that's the issue you're seeing.

For me it is right after I slice something. Can't print anything.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 09:00PM |

Registered: 8 years ago Posts: 285 |

Quote

Neverdone

So I been using the printer for a couple days, getting some bugs worked out. Now all the sudden Repetier Host just freezes randomly after I hav eloaded an object to print. Doesn't matter what the object is, even if it is something I have printed before. It just locks up and says program not responding. When this first started happening I was running v1.5.4 so I updated to 1.5.6 and has the same issue. Has anyone else ran in to this?

I get that problem too, but not as frequent. I use version 1.0.6 since the newer versions seem to have those connection issues way to frequently. You also may need to lower your received cache size. Having that to high can cause problems for certain boards. I have mine at 63.

Edited 1 time(s). Last edit at 09/15/2015 09:03PM by Mach.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 09:21PM |

Registered: 8 years ago Posts: 99 |

Quote

built350camaro

LOL I fail, I printed the extruder fan shroud just to find out my print is mirrored. When I home the X it moves away from the endstop.

Why would you even print if you haven't got your home switches working right? How did you print the 20mm cube?

Also I put my x limit switch to the left hand side. That makes it home to the top left of the build plate like all the software is anyway. Why they(folger tech) set it up to home on the right is beyond me!?

Edited 1 time(s). Last edit at 09/15/2015 09:31PM by woodknack.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 10:14PM |

Registered: 8 years ago Posts: 84 |

the 20x20 cube doesn't care if it is mirrored so I didn't notice. Oh well just a little wasted pla. Printed the right way now lol I printed a cube that had xyz +- on it the other day but I forgot which way it was on the board so I didn't notice it was mirrored. Live and learn.

Whats some good G-codes to run?

Whats some good G-codes to run?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 10:19PM |

Registered: 8 years ago Posts: 285 |

Quote

woodknack

Quote

built350camaro

LOL I fail, I printed the extruder fan shroud just to find out my print is mirrored. When I home the X it moves away from the endstop.

Why would you even print if you haven't got your home switches working right? How did you print the 20mm cube?

Also I put my x limit switch to the left hand side. That makes it home to the top left of the build plate like all the software is anyway. Why they(folger tech) set it up to home on the right is beyond me!?

It's set like that so that the print moves to the front of the printer when it is done printing. That make it easier to remove a print when you have the printer on a desk against the wall.

Edited 1 time(s). Last edit at 09/15/2015 10:19PM by Mach.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 10:50PM |

Registered: 8 years ago Posts: 99 |

I think that will only do that if your software is set to home. I'm using s3d and after a print it just stopped right there. I had to go into the ending script (easy task with this software) and tell the table where to go after my print. Which is anywhere you want it.I just have the x home after a job right now just to get it away from the object. I could have the y axis send the bed to the front to if I wanted .bUT I see no need for that at the moment.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 11:00PM |

Registered: 8 years ago Posts: 541 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 11:07PM |

Registered: 8 years ago Posts: 84 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 15, 2015 11:22PM |

Registered: 8 years ago Posts: 430 |

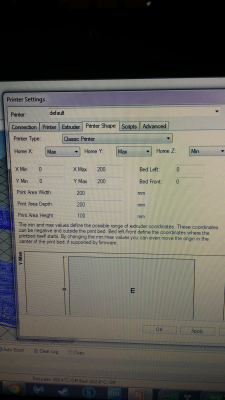

Quote

built350camaro

Quote

tjnamtiw

In Repetier, you can set where you want the print table to go after the part is done. No special coding needed.

How do you do that?

Under printer settings you can tell it a park position then there is a check box to tell it to go to the park position at the end of the print.

[www.repetier.com]

Edited 1 time(s). Last edit at 09/15/2015 11:23PM by msaeger.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 16, 2015 07:33PM |

Registered: 8 years ago Posts: 541 |

The kind folks at FT came through today in the mail with not only a new thermistor, which was bad, but an ENTIRE NEW HOT END! I'm up and running at last! As an easy project to wow the Mrs. I printed a couple of snowflakes at various scales. [www.thingiverse.com]

They all came out looking good BUT 'overstuffed' so I knew I needed to check my extruder feed rate. I followed along with Tom on his YT video [www.youtube.com] . Using Repetier, I sent the commands he gave to the Arduino via the 'G Code' line in the Manual Control section. As suspected, I got way too much plastic, which, using his formula, gave me a new E code of just 66. I put that into the configuration.h line to replace the 90, saved it and uploaded it. I repeated the test and told the extruder to extrude 100mm as before using Tom's command line. This time it extruded even MORE. In fact, it extruded the entire 150 mm that I had made the mark at. This made no sense, of course. I went to the manual extruder control icon on the Repetier Manual page and selected 100 mm and that is EXACTLY how much it extruded with the E code at 66. Why would I extrude MORE plastic with a LOWER E code number >>#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,3840,66} // default steps per unit for ultimaker {78.7402,78.7402,200*8/3,760*1.1}920 when using the commands that Tom says?

The problem now is that whatever I print comes out REALLY lacking for enough plastic. I'm using PLA at 190 degrees. I even bumped up my extrusion multiplier to 1.1 in Slicer's configuration settings. I've set my table lever at one paper thickness and everything sticks like glue to my tempered glass with hair spray. No problems with curling.

What am I missing?

Edited 1 time(s). Last edit at 09/17/2015 11:34AM by tjnamtiw.

They all came out looking good BUT 'overstuffed' so I knew I needed to check my extruder feed rate. I followed along with Tom on his YT video [www.youtube.com] . Using Repetier, I sent the commands he gave to the Arduino via the 'G Code' line in the Manual Control section. As suspected, I got way too much plastic, which, using his formula, gave me a new E code of just 66. I put that into the configuration.h line to replace the 90, saved it and uploaded it. I repeated the test and told the extruder to extrude 100mm as before using Tom's command line. This time it extruded even MORE. In fact, it extruded the entire 150 mm that I had made the mark at. This made no sense, of course. I went to the manual extruder control icon on the Repetier Manual page and selected 100 mm and that is EXACTLY how much it extruded with the E code at 66. Why would I extrude MORE plastic with a LOWER E code number >>#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,3840,66} // default steps per unit for ultimaker {78.7402,78.7402,200*8/3,760*1.1}920 when using the commands that Tom says?

The problem now is that whatever I print comes out REALLY lacking for enough plastic. I'm using PLA at 190 degrees. I even bumped up my extrusion multiplier to 1.1 in Slicer's configuration settings. I've set my table lever at one paper thickness and everything sticks like glue to my tempered glass with hair spray. No problems with curling.

What am I missing?

Edited 1 time(s). Last edit at 09/17/2015 11:34AM by tjnamtiw.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 16, 2015 08:05PM |

Registered: 8 years ago Posts: 121 |

I just tried a "larger" print a case for the smoothieboard for the delta I am building but when I try to print it the printer runs off the back of the bed!! I tried changing where I set the item down in repitier with out luck. The case should fit with about 15 mm between it and the edge of the glass bed. It keeps coming off the rear near the y endstop edge right over the Y drive motor. Should I set up some kind of offset amount and if so how? I am getting great prints and trying to learn as I go.

Edited 1 time(s). Last edit at 09/16/2015 08:08PM by jasonsaffle13@gmail.com.

Edited 1 time(s). Last edit at 09/16/2015 08:08PM by jasonsaffle13@gmail.com.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 16, 2015 11:17PM |

Registered: 8 years ago Posts: 430 |

Quote

[email protected]

I just tried a "larger" print a case for the smoothieboard for the delta I am building but when I try to print it the printer runs off the back of the bed!! I tried changing where I set the item down in repitier with out luck. The case should fit with about 15 mm between it and the edge of the glass bed. It keeps coming off the rear near the y endstop edge right over the Y drive motor. Should I set up some kind of offset amount and if so how? I am getting great prints and trying to learn as I go.

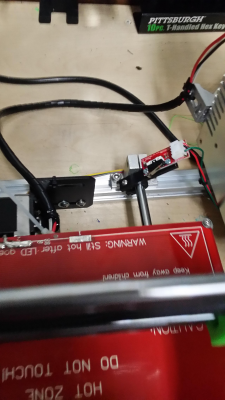

Are you sure you have the end stop switch set to where you can get the maximum travel from the bed? I had this problem in the beginning and it was because I didn't have the Y end stop switch positioned close enough to the back.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 16, 2015 11:39PM |

Registered: 8 years ago Posts: 276 |

Just a little heads up - the bearings Folgertech gave for the Y-axis belt are crap and may fail after printing a kilogram of filament...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 17, 2015 06:10AM |

Registered: 8 years ago Posts: 30 |

Quote

therippa

Just a little heads up - the bearings Folgertech gave for the Y-axis belt are crap and may fail after printing a kilogram of filament...

I wasn't too impressed with them when I put it together. I have a full set of bearings on order through my local hobby shop. I also ordered some spare linear bearings online. I am going to order some spare drivers too and probably a motor just in case. But since I can't print anything right now I am not too concerned.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 17, 2015 01:38PM |

Registered: 8 years ago Posts: 99 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 17, 2015 07:43PM |

Registered: 8 years ago Posts: 541 |

Well, after two days of pulling what's left of my hair out, I think I finally solved my inconsistent filament feed rate. I had the dreaded click-click-click sound today while feeding, which could mean a number of things, from what I've read. Anything from 'wet' PLA, to not enough power to the extruder motor, to misalignment of the filament into the hot end, to not enough heat in the hot end, ad nauseum. After checking several of them, I got rid of the clicking by upping my voltage setting on my feed drive. However, I still had inconsistent flow. VERY inconsistent flow.

At that point, I ripped the entire feeder apart down to the brass gear on the extruder motor to check the set screws. I rotated the gear, which fits partially inside of the end bell of the motor. I could feel that for each revolution, it was dragging seriously at one spot. I took it off and used my mini-lathe to take about .005" off of each side. I polished the shaft with crocus cloth and put the brass gear back on. No more scrubbing/dragging! It printed out my LCD mounts no problem but now back to calibrating the extruder tomorrow.

This is one place to look if anyone else has similar problems with feed rates all over the place. I only had .265 volts to the extruder motor, which probably made the situation stand out. I'm up to .450 now and the motor was pretty warm so I'll be backing it down to the mid 300's tomorrow and see how it goes.

At that point, I ripped the entire feeder apart down to the brass gear on the extruder motor to check the set screws. I rotated the gear, which fits partially inside of the end bell of the motor. I could feel that for each revolution, it was dragging seriously at one spot. I took it off and used my mini-lathe to take about .005" off of each side. I polished the shaft with crocus cloth and put the brass gear back on. No more scrubbing/dragging! It printed out my LCD mounts no problem but now back to calibrating the extruder tomorrow.

This is one place to look if anyone else has similar problems with feed rates all over the place. I only had .265 volts to the extruder motor, which probably made the situation stand out. I'm up to .450 now and the motor was pretty warm so I'll be backing it down to the mid 300's tomorrow and see how it goes.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 17, 2015 07:46PM |

Registered: 8 years ago Posts: 541 |

Quote

woodknack

I feel like a mad scientist in his office with the door closed printing stuff off... The machine has a little mid evil tune it plays while it prints...... MAAAWWW HAAAAA HAAAA...... Yes Egor...... LOL

I know how you feel! I'm madly going through thingiverse finding things to print. Gotta use up that PLA before it goes bad!!!!!!

Next up after I mount my LCD screen is a better filament roller. That setup on the side just doesn't hack it at all. What are others using to replace it?

Edited 1 time(s). Last edit at 09/17/2015 07:46PM by tjnamtiw.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 17, 2015 08:05PM |

Registered: 8 years ago Posts: 99 |

Quote

tjnamtiw

Quote

woodknack

Next up after I mount my LCD screen is a better filament roller. That setup on the side just doesn't hack it at all. What are others using to replace it?

Mine seems to work ok but I'd like to mount it to the top. I think it would just roll better and less bends. That's on my list too.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 17, 2015 09:24PM |

Registered: 8 years ago Posts: 33 |

Quote

therippa

Just a little heads up - the bearings Folgertech gave for the Y-axis belt are crap and may fail after printing a kilogram of filament...

I just found this out myself. Just got through doing a 5 + hour print and near the end got to hearing a strange noise in the Y axis, put my fingure in the idler and could feel it. I have some of these bearings without the flandge on them , was thinking of making a sleeve with a flange on each end and press 2 bearings into it. Another note on the 5 hour print S3D said it would be 3 hours and 32 minutes it ended up being 5 hours and 12 minutes. It don't figure time well but it slices and works GREAT.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 17, 2015 09:47PM |

Registered: 8 years ago Posts: 121 |

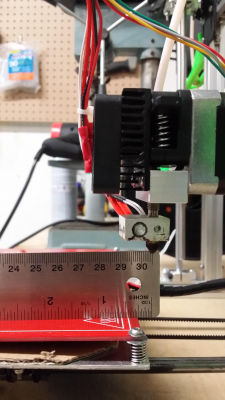

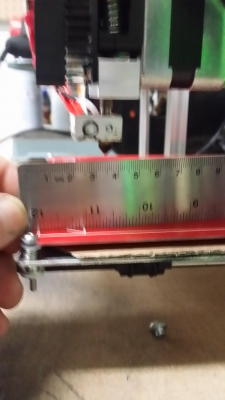

Can anyone shed some light on how I center my bed better? It acts like I need to mount the endstop farther back but how? Maybe these pictures will help:

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 17, 2015 10:02PM |

Registered: 8 years ago Posts: 33 |

Quote

[email protected]

Can anyone shed some light on how I center my bed better? It acts like I need to mount the endstop farther back but how? Maybe these pictures will help:

It looks like your end stop is hitting the bed and not the bearing retainer under the bed. I t should be laying almost flat. Also the mount is on backwards. When it is correct the switch is centered over the guide rod. The hole in the circuit bord close to the switch is where the clamp bolt goes.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 17, 2015 10:48PM |

Registered: 8 years ago Posts: 541 |

Quote

kn4ud

Quote

[email protected]

Can anyone shed some light on how I center my bed better? It acts like I need to mount the endstop farther back but how? Maybe these pictures will help:

It looks like your end stop is hitting the bed and not the bearing retainer under the bed. I t should be laying almost flat. Also the mount is on backwards. When it is correct the switch is centered over the guide rod. The hole in the circuit bord close to the switch is where the clamp bolt goes.

Yep, it should be under the bed. Pay close attention to the instructions as to which hole to use for mounting.

Also, once you clamp your glass on top of the bed, you'll have to reduce your bed size down to about 180 x 180 to clear the clamps. You'll have to move your X and y stops again to center things.

Edited 1 time(s). Last edit at 09/18/2015 12:00AM by tjnamtiw.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 18, 2015 01:36AM |

Registered: 8 years ago Posts: 276 |

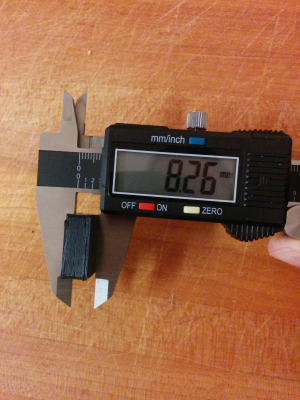

If anyone is interested, I made a minimalist calibration cube (shorter than the one I've been using, so it prints faster) with a notch cut out of one corner so you can tell orientation. [www.thingiverse.com] . Btw, my dimensions come out to 20.02x20.02x8.26, so I'm pretty happy

Edited 3 time(s). Last edit at 09/18/2015 02:30AM by therippa.

Edited 3 time(s). Last edit at 09/18/2015 02:30AM by therippa.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 18, 2015 08:07AM |

Registered: 8 years ago Posts: 541 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 18, 2015 08:41AM |

Registered: 10 years ago Posts: 444 |

Those with thermistor wiring problems might consider soldering them with a high-temp solder, like silver solder.

And here is some start Gcode (from Slic3r) that might help:

M190 S80 ; Set bed temp, wait till temp reached

M140 S100 ; Set bed temp, no wait

M109 S225 ; Set nozzle temp, wait till temp reached

G28 ; Home all axes

G1 Z15 F10000 ; lift nozzle so can extrude to clear-out nozzle

G1 E30 F200 ; Prime extruder 30mm

G1 X50 F3000 ; Move extruder right to lay-out plastic

G1 Z5 F8000 ; Move extruder down to lay-out plastic

G1 X100 F3000; Move extruder more right to lay-out plastic

G1 Z0 F5000 ; Move extruder down to lay-out plastic

G1 X120 F2000; Move extruder right a bit more, to knock plastic off

End Gcode:

G1 X0 F3000 ; Move X out of way

G1 Y180 F3000 ; Move Y forward

G1 Z50 F8000 ; Move Z out of way

M104 S0 ; Turn off nozzle

M140 S0 ; Turn off bed

M84 ; Turn off motors

G4 3600 ; Wait one hour

M81 ; Turn off power

And here is some start Gcode (from Slic3r) that might help:

M190 S80 ; Set bed temp, wait till temp reached

M140 S100 ; Set bed temp, no wait

M109 S225 ; Set nozzle temp, wait till temp reached

G28 ; Home all axes

G1 Z15 F10000 ; lift nozzle so can extrude to clear-out nozzle

G1 E30 F200 ; Prime extruder 30mm

G1 X50 F3000 ; Move extruder right to lay-out plastic

G1 Z5 F8000 ; Move extruder down to lay-out plastic

G1 X100 F3000; Move extruder more right to lay-out plastic

G1 Z0 F5000 ; Move extruder down to lay-out plastic

G1 X120 F2000; Move extruder right a bit more, to knock plastic off

End Gcode:

G1 X0 F3000 ; Move X out of way

G1 Y180 F3000 ; Move Y forward

G1 Z50 F8000 ; Move Z out of way

M104 S0 ; Turn off nozzle

M140 S0 ; Turn off bed

M84 ; Turn off motors

G4 3600 ; Wait one hour

M81 ; Turn off power

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 18, 2015 12:13PM |

Registered: 8 years ago Posts: 541 |

I spent this morning dialing in the extruder rate AGAIN after taking apart my feeder and removing the interference between the feed gear and the extruder motor endbell. I am now extruding exactly 100mm when I tell it to and the parts look great HOWEVER to do this, my Estep for the extruder is all the way down to 26!!!!! There must be somewhere else perhaps in the configuration file where something is amiss. Any ideas?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 18, 2015 06:55PM |

Registered: 8 years ago Posts: 33 |

LOL, I like Harbor Freight too, I wanted the caliper with the black face on it but I had to settle for stainless face.... sold out.Quote

tjnamtiw

That's great, rippa! Is that cube on thingaverse? I see so many different ones, I don't know which one to use.

I see you like Harbor Freight too.I needed an 8" caliper and didn't want to pay Starrett..................

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 18, 2015 08:53PM |

Registered: 8 years ago Posts: 121 |

Thanks for the help guys I have my print centered now. Though my Y axis seems to have changed - and + directions and I have no clue why. My X axis stop was also not in the right spot. But it is centered now I need to change the print size down to 180x180 and I am also going to do a rework of my bed. The bas plate is off level I think and I have a new black PCB heater for it.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 18, 2015 09:18PM |

Registered: 8 years ago Posts: 541 |

Quote

[email protected]

Thanks for the help guys I have my print centered now. Though my Y axis seems to have changed - and + directions and I have no clue why. My X axis stop was also not in the right spot. But it is centered now I need to change the print size down to 180x180 and I am also going to do a rework of my bed. The bas plate is off level I think and I have a new black PCB heater for it.

I can't think of any reason that Y would reverse. Always HOME before you do anything else. Sometimes the printer will do strange things if it doesn't 'know' where it is. Just change to 180 for both in configuration.h and in Repetier and then move the X stop 10 mm left and the Y stop 10 mm frontwards. You're done!

I bought a piece of tempered glass on Amazon that's 200 x 200. I use a light coat of hairspray and the parts stick like crazy. I've only applied the hair spray twice and I don't even know if it's needed with the bed at 70C. I'd still like to know why my ESTEP is so low at 26 but I don't want to change it just for the sake of changing it. IT WORKS!

Is anyone else's EStep that low for the latest version of the spring loaded direct drive extruder?

Edited 1 time(s). Last edit at 09/19/2015 09:37AM by tjnamtiw.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 19, 2015 11:02AM |

Registered: 8 years ago Posts: 84 |

Sorry, only registered users may post in this forum.