Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 23, 2015 02:06PM |

Registered: 8 years ago Posts: 57 |

Cool prints woodknack

I've just been doing upgrades like tensioner, end stops, fan bracket, etc... but I did print a scaled down T800 head from Thingiverse, at .2mm layer height. Looked neat

With the exception of the extruder stepper, all of my steppers are 0.9 deg ones (these I believe - [www.sparkfun.com]) . No other major modifications from the original kit besides what I just listed

Right, not that you did it -- just was kind enough to merge in the settings and share. I would have done it myself, not hard, but, really appreciate you taking the time and sharing!!!!!! Thank you! Wasn't hard at all to go through my config.h and update all my specific settings.

I'm one of those idiots that likes to stay current on firmware unless there is a massive amount of bugs or caveats. (although I missed that 1.1 just came out the other day, will have to check that out).

For me, I wanted 1.0.2 for auto bed leveling.

Bed leveling manually is not too much of a burden. I'm printing on borosillicate glass + kapton + abs goo -- I check all 4 corners with my calipers to level the bed, then, level the z axis manually via feeler gauge from left to right. Took a little bit of trial and error, but I can do it reliably now... just..........

If I change out parts, or knock something on the Z by accident (I'm clumsy), or whatever... I have to do it from scratch, so, it's annoying. I'd rather let it do it itself if I can.

Edited 2 time(s). Last edit at 09/23/2015 02:10PM by srcga.

I've just been doing upgrades like tensioner, end stops, fan bracket, etc... but I did print a scaled down T800 head from Thingiverse, at .2mm layer height. Looked neat

With the exception of the extruder stepper, all of my steppers are 0.9 deg ones (these I believe - [www.sparkfun.com]) . No other major modifications from the original kit besides what I just listed

Quote

therippa

Quote

tjnamtiw

What are the advantages of therippa firmware?

It's not really *my* firmware, I just took the latest version of Marlin and merged in all the Folgertech-specific settings. But the advantages are all the new things added (like autolevel) and bug fixes.

Right, not that you did it -- just was kind enough to merge in the settings and share. I would have done it myself, not hard, but, really appreciate you taking the time and sharing!!!!!! Thank you! Wasn't hard at all to go through my config.h and update all my specific settings.

Quote

tjnamtiw

What are the advantages of therippa firmware?

I'm one of those idiots that likes to stay current on firmware unless there is a massive amount of bugs or caveats. (although I missed that 1.1 just came out the other day, will have to check that out).

For me, I wanted 1.0.2 for auto bed leveling.

Bed leveling manually is not too much of a burden. I'm printing on borosillicate glass + kapton + abs goo -- I check all 4 corners with my calipers to level the bed, then, level the z axis manually via feeler gauge from left to right. Took a little bit of trial and error, but I can do it reliably now... just..........

If I change out parts, or knock something on the Z by accident (I'm clumsy), or whatever... I have to do it from scratch, so, it's annoying. I'd rather let it do it itself if I can.

Edited 2 time(s). Last edit at 09/23/2015 02:10PM by srcga.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 23, 2015 02:12PM |

Registered: 8 years ago Posts: 276 |

Quote

srcga

I'm on the forked firmware from therippa, going to get to the servo + auto bed leveling tomorrow, hopefully.

I would really recommend moving your x-axis to where it should be, on the left side, while you're doing this upgrade. It will solve a bunch of problems, some of which are being able to run G28 (it homes differently after autolevel is configured) and G29 successfully. If you need any pointers you can view the diffs on the branch I actually use for my setup (I use inductive autolevel, but the settings are similar) - [github.com]

Also, as soon as Marlin 1.1 is officially released, I'll put out a new release with the folgertech settings

Edited 2 time(s). Last edit at 09/23/2015 02:15PM by therippa.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 23, 2015 02:17PM |

Registered: 8 years ago Posts: 57 |

Quote

therippa

Quote

srcga

I'm on the forked firmware from therippa, going to get to the servo + auto bed leveling tomorrow, hopefully.

I would really recommend moving your x-axis to where it should be, on the left side, while you're doing this upgrade. It will solve a bunch of problems, one being able to run G29 successfully. If you need any pointers you can view the diffs on the branch I actually use for my setup (I use inductive autolevel, but the settings are similar) - [github.com]

Also, as soon as Marlin 1.1 is officially released, I'll put out a new release with the folgertech settings

X-axis is already on the left (0) my friend, probably the first print I did was the left side X end stop on Thingiverse

Was getting annoyed like most others in this thread. I try to take the idiot (meaning me) out of things as much as possible. If all homes are 0/min then I don't have to remember as much and I can have more beer while printing.

Was getting annoyed like most others in this thread. I try to take the idiot (meaning me) out of things as much as possible. If all homes are 0/min then I don't have to remember as much and I can have more beer while printing.Thanks for the link, much appreciated!

Not that I'm doing anything revolutionary but I am just getting my setup documented for some friends of mine, I'll share that here too. The more info the merrier.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 23, 2015 02:45PM |

Registered: 8 years ago Posts: 276 |

I think it's about time I posted this as well...

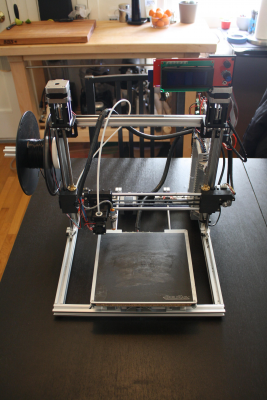

My Folgertech Prusa i3 - The Final Form (except for the igus drylin bushings I still have to install)

Mods: raised the Z motors, installed E3D V6 hotend, inductive autoleveling, aluminum bed with cork underneath for better insulation, BuildTak surface (ABS sticks at 80C!)

Moved X-axis to left side (where it should be)

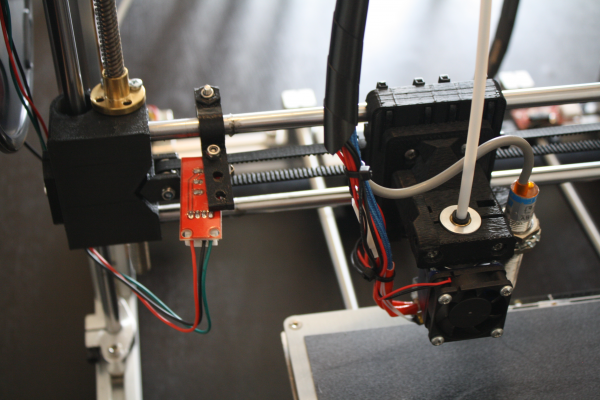

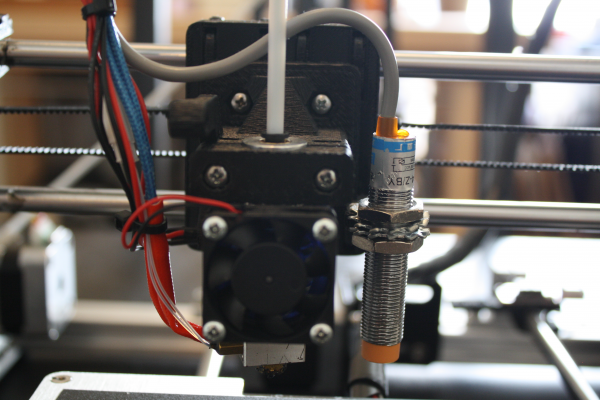

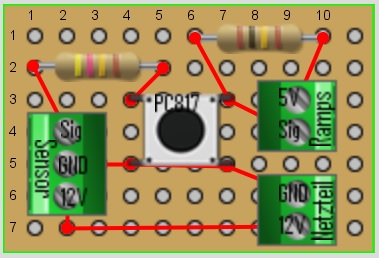

Inductive sensor

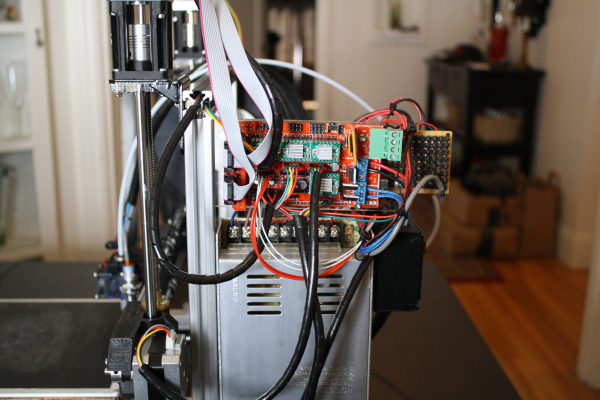

Board I put together - it has the optocoupler circuit for the inductive sensor on the left, and I added a power distribution block on the right so I wouldn't have to keep twisting wires and screwing them down on the power supply

Power supply I designed - you can get it here

Wire cleanup, ended up buying a crimper and redid all the connectors (looks good enough for me)

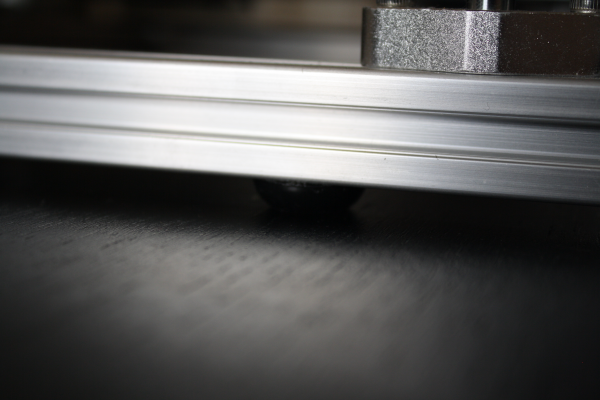

Sorbothane rubber anti-vibration feet. Added six of them. These greatly reduce vibrations, and my downstairs neighbor no longer complains about the noise. You can get them here

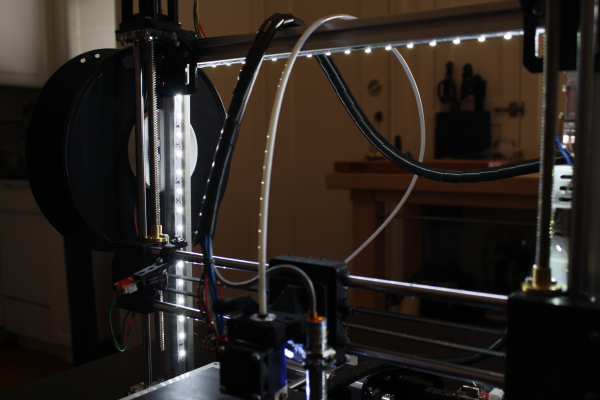

Let there be light! I added LED's to the frame and to the hotend. Still have some shadows to deal with, but I don't have to use a flashlight anymore to see how the print is doing

Added a quick-disconnect for the LED's surrounding the frame so I can turn them off during night prints

Edited 1 time(s). Last edit at 09/23/2015 05:28PM by therippa.

My Folgertech Prusa i3 - The Final Form (except for the igus drylin bushings I still have to install)

Mods: raised the Z motors, installed E3D V6 hotend, inductive autoleveling, aluminum bed with cork underneath for better insulation, BuildTak surface (ABS sticks at 80C!)

Moved X-axis to left side (where it should be)

Inductive sensor

Board I put together - it has the optocoupler circuit for the inductive sensor on the left, and I added a power distribution block on the right so I wouldn't have to keep twisting wires and screwing them down on the power supply

Power supply I designed - you can get it here

Wire cleanup, ended up buying a crimper and redid all the connectors (looks good enough for me)

Sorbothane rubber anti-vibration feet. Added six of them. These greatly reduce vibrations, and my downstairs neighbor no longer complains about the noise. You can get them here

Let there be light! I added LED's to the frame and to the hotend. Still have some shadows to deal with, but I don't have to use a flashlight anymore to see how the print is doing

Added a quick-disconnect for the LED's surrounding the frame so I can turn them off during night prints

Edited 1 time(s). Last edit at 09/23/2015 05:28PM by therippa.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 23, 2015 03:24PM |

Registered: 8 years ago Posts: 57 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 23, 2015 03:47PM |

Registered: 8 years ago Posts: 276 |

Quote

srcga

Thanks for posting. Lead screws on the Z are on my list as well.. slowly but surely.

How do you like the buildtak? How often do you find yourself re-applying it?

I ruined the first sheet of BuildTak by having the print nozzle too close, causing the plastic to permanently bond with it (this was pre-autolevel days). Now with autolevel, everything is fine. I still use purple glue on it, my theory is that the very thin layer of glue helps with separation, so removing pieces is easy. Even with the glue, I can still print at 80C and have no warping issues (like none at all, ever since I started using it and I've been through 3/4 of a roll of filament). I haven't had to replace it yet, and the only place it's starting to show wear is in the front-left homing corner.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 23, 2015 03:55PM |

Registered: 8 years ago Posts: 14 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 23, 2015 05:37PM |

Registered: 8 years ago Posts: 276 |

Quote

awmyhr

That is a pretty awesome set up upgrades therippa! Could you point me to details on how to install/implement the auto-leveling? I saw a post way back where you linked to a thread/diagram in German, but that was not enough for me to follow. I'd really like to add this feature...

First you need to get an aluminum build plate, and this sensor

Then you need to build a circuit that handles the switch connection, since the probe runs on 12v, but the RAMPS board needs 5v. It's just this guy...

You need to order a 4k7 resistor and a 10k resistor, some terminal blocks, and a PC817 optocoupler, and wire it as it is in the diagram.

Once you get it all together, you can follow Tom's video on adding autoleveling/autotramming.

Edited 3 time(s). Last edit at 09/23/2015 05:44PM by therippa.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 23, 2015 06:12PM |

Registered: 8 years ago Posts: 57 |

When you guys added the servo for auto-leveling -- what did you have to do with the jumper (VCC?) next to the reset button on the RAMPS?

Edit

NM, figured it out.

The jumper has to be towards the inside of the board for the servo to power.

Although now that I did that, the LCD flickers. Not sure if I have a power supply issue or not.. going to dig into it. Doesn't do it when the USB is connected so seems like a 5v issue.

Yeah, prob not enough juice. I have a 5v regulator around here somewhere

Edited 3 time(s). Last edit at 09/23/2015 06:37PM by srcga.

Edit

NM, figured it out.

The jumper has to be towards the inside of the board for the servo to power.

Although now that I did that, the LCD flickers. Not sure if I have a power supply issue or not.. going to dig into it. Doesn't do it when the USB is connected so seems like a 5v issue.

Yeah, prob not enough juice. I have a 5v regulator around here somewhere

Edited 3 time(s). Last edit at 09/23/2015 06:37PM by srcga.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 23, 2015 08:24PM |

Registered: 8 years ago Posts: 59 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 23, 2015 08:30PM |

Registered: 8 years ago Posts: 367 |

You can take the fan and heatsink off the front of the extruder and check its turning when you click extrude on the manual control tab of repetier. You have to have the hot end up to temperature to do this.

A check you might do first is this: is the nozzle underneath the left or the right hole on the top of the extruder. The Folger instructions show it under the right hand one. Mine was under the left, so I had to feed the filament in the left hand hole and also to reverse the direction of the extruder motor. See [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

A check you might do first is this: is the nozzle underneath the left or the right hole on the top of the extruder. The Folger instructions show it under the right hand one. Mine was under the left, so I had to feed the filament in the left hand hole and also to reverse the direction of the extruder motor. See [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 23, 2015 08:39PM |

Registered: 8 years ago Posts: 99 |

Quote

LancelotL

Hello. I have managed to patch my broken thermistor while I await the replacement. I can now get the extruder up to temp and I am working on printing my first object but my extruder motor does not appear to be working. How do I test the extruder motor other than printing something?

Check to make sure you extruder is turning in the right direction too. Mine was reverseing the filament when I hit extrude. I just rotated my extruder stepper plug wire.

In your software get your extruder up to temp then extrude 50mm . Put your fingers on the filament and see if it is,sucking it in or trying to push it back out of the feed.

Edited 1 time(s). Last edit at 09/23/2015 08:41PM by woodknack.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 23, 2015 09:13PM |

Registered: 8 years ago Posts: 59 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 23, 2015 09:18PM |

Registered: 8 years ago Posts: 430 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 23, 2015 10:06PM |

Registered: 8 years ago Posts: 57 |

Quote

msaeger

Quote

therippa

Wire cleanup, ended up buying a crimper and redid all the connectors (looks good enough for me)

Got a link to the crimper and pins or what they are called? I want to shorten those wires too.

Crimper -> [www.amazon.com]

Connectors

[www.pololu.com]

Picked up a big assortment of connectors when I got black stepper drivers. Why not.

Edited 1 time(s). Last edit at 09/23/2015 10:07PM by srcga.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 23, 2015 10:12PM |

Registered: 8 years ago Posts: 541 |

Quote

LancelotL

Ok thanks, it's feeding the right way now. It feeds for about 200 mm before it gets stuck. I'm guessing I need to adjust the feed/flow rate. What's the difference between the two?

Before you do that first print you must calibrate your extruder. Watch this video. [www.youtube.com] You can input his coding in the Manual section of Repetier. When you input the R1 E100 S90, you'll see that the S90 slides over to the left. Leave it there but make sure when you are typing it in that you put one space in there. Don't ask me why but that's the way it works!

Edited 1 time(s). Last edit at 09/23/2015 10:53PM by tjnamtiw.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 23, 2015 11:12PM |

Registered: 8 years ago Posts: 285 |

Quote

LancelotL

Ok thanks, it's feeding the right way now. It feeds for about 200 mm before it gets stuck. I'm guessing I need to adjust the feed/flow rate. What's the difference between the two?

The feedrate is the speed at which the printer prints, and the flowrate is the rate that the filament gets extruded.

Edited 1 time(s). Last edit at 09/23/2015 11:20PM by Mach.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 24, 2015 01:11AM |

Registered: 8 years ago Posts: 99 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 24, 2015 01:14AM |

Registered: 8 years ago Posts: 99 |

Quote

woodknack

Quote

srcga

I had my challenges with missing parts on the build, and the issue with crimped thermistor + broken wires on the hot end.. however.. have been printing and am super satisfied with this printer. I've been printing exclusively ABS. Information is power on these printers... I did a ton of reading, did all the calibration, and basically hit the ground running.

Anyone I've emailed at Folger Tech has been super nice and responsive, and replacements have gone out no questions asked and quickly. I'm a patient tinkerer and don't expect perfection. Really recommend this kit as a great base for 3d printing and especially Folger Tech's service.

I'm on the forked firmware from therippa, going to get to the servo + auto bed leveling tomorrow, hopefully.

Great thread. Hope I can contribute as much as I've taken from it

I had the same issue with the thermister. they crimped the coupler so hard the thermister was shattered.

I too am using the lasted firmware by therippa too!

I've been just running pla right now and same as you after she is dialed in, it works flawless so far!

I'm new to all this 3d printing stuff and am still learning. I'm having a ball. I already have ideas of making my own rep rap just from ideas I got off building this kit.

Led light enclosure I downloaded from thingiverse. I modded the switch box in my cad program so it had a clip to slide onto the shelf like the light.Next time im going to just join it right to the light clip.

img upload

I redesigned the bracket for the led light with the switch housing built into the bracket instead of separate. I also beefed up the bracket a little by adding a 12v sign. I'll print it in the morning. Im having as much fun playing around in the cad program as I am printing off the stuff. You really can get your creative side out there with a 3d printer..

New printed bracket. works great!

Edited 1 time(s). Last edit at 09/24/2015 12:20PM by woodknack.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 24, 2015 08:23AM |

Registered: 8 years ago Posts: 14 |

Quote

therippa

Quote

awmyhr

That is a pretty awesome set up upgrades therippa! Could you point me to details on how to install/implement the auto-leveling? I saw a post way back where you linked to a thread/diagram in German, but that was not enough for me to follow. I'd really like to add this feature...

First you need to get an aluminum build plate, and this sensor

Then you need to build a circuit that handles the switch connection, since the probe runs on 12v, but the RAMPS board needs 5v. It's just this guy...

You need to order a 4k7 resistor and a 10k resistor, some terminal blocks, and a PC817 optocoupler, and wire it as it is in the diagram.

Once you get it all together, you can follow Tom's video on adding autoleveling/autotramming.

Thank you very much, I've added this to my project list!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 24, 2015 10:03AM |

Registered: 9 years ago Posts: 251 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 24, 2015 10:58AM |

Registered: 8 years ago Posts: 99 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 24, 2015 11:36AM |

Registered: 8 years ago Posts: 57 |

Here's the left hand X End stop that I notched to be able to clear the add-on X-axis tensioner

[www.thingiverse.com]

[www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 24, 2015 02:54PM |

Registered: 8 years ago Posts: 276 |

Quote

srcga

Here's the left hand X End stop that I notched to be able to clear the add-on X-axis tensioner

[www.thingiverse.com]

awesome!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 24, 2015 06:15PM |

Registered: 8 years ago Posts: 59 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 24, 2015 06:58PM |

Registered: 8 years ago Posts: 276 |

Quote

LancelotL

Anyone have a pic showing how the belt tensioners get installed?

The belt tensioners they include are pretty much useless, but here ya go

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 24, 2015 07:04PM |

Registered: 8 years ago Posts: 99 |

Quote

therippa

Quote

LancelotL

Anyone have a pic showing how the belt tensioners get installed?

The belt tensioners they include are pretty much useless, but here ya go

Why are they useless? Just curios as I have one on my Y axis and it's been working just fine......

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 24, 2015 07:39PM |

Registered: 8 years ago Posts: 276 |

Quote

woodknack

Quote

therippa

Quote

LancelotL

Anyone have a pic showing how the belt tensioners get installed?

The belt tensioners they include are pretty much useless, but here ya go

Why are they useless? Just curios as I have one on my Y axis and it's been working just fine......

I guess I just want to snap my belts and have it sound like a bass string, which these can't really accomplish. There are better ways of increasing tension that can be printed after everything is set up right

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 24, 2015 08:26PM |

Registered: 8 years ago Posts: 59 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) September 24, 2015 10:35PM |

Registered: 8 years ago Posts: 59 |

Sorry, only registered users may post in this forum.