Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 24, 2015 01:29AM |

Registered: 8 years ago Posts: 62 |

Quote

Mach

Quote

Mrfus

I have a couple of questions guys:

One, did the LCD display should make a beep or something? I know it works, I got temperature readings, the emergency stop works and some other details but not beep.

Second, any of you has upgraded its FT Prusa adding a second extruder?

Yes, it should beep, but this may be disabled in pins.h at around line 778. If it is disabled, you can change #define BEPPER -1 to #define BEPPER 37. Btw, what display are you using, and did you have to do anything special to get it to work?

I have the 2004 LCD display from FolgerTech, just plug-in and bada bing, bada boom! I'm using TheRippa Marlin firmware and he has the display already enabled, the only modification that I have done so far it's just enabling the EEPROM memory...

Mr.Fus

<------------------------------------------------->

Green M3D (Running v.1.3.6.3Beta)

FolgerTech Prusa i3 (2020 Frame)

<------------------------------------------------>

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 24, 2015 02:21AM |

Registered: 8 years ago Posts: 13 |

Quote

therippa

Quote

Spam

Quote

therippa

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

Ok, so I gave up calibrating my 2020, and loaded the new marlin firmward from the link in your signature.

I re-calibrated the extruder. The original values were 90, my calculations showed it should be 102... so I set it in the configuration.h file and reloaded it...

Now, I can manually extrude as much PLA as I want, but when I go to print anything, the PLA does not feed. If I stop the print, I can again manually feed as much as I want...

Any ideas?

Yeah, I ran into the same problem this weekend when I was testing my new extruder, I think there's a bug in Marlin with extruding before homing (although I think they'll call it a "feature"). Just unplug the power cable and usb cable to reset the printer and it should work.

Negative, ghostrider... powered it all down. Sliced something... and told it to print...

It wouldn't heat the extruder. it sat there saying "heating" and the Bed would warm up but not the extruder. I can manually turn on the heat, then it starts to move, but never extrudes...

With the old firmware, at least I could get it to print... Any ideas?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 24, 2015 02:30AM |

Registered: 8 years ago Posts: 276 |

Quote

Spam

Quote

therippa

Quote

Spam

Quote

therippa

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

Ok, so I gave up calibrating my 2020, and loaded the new marlin firmward from the link in your signature.

I re-calibrated the extruder. The original values were 90, my calculations showed it should be 102... so I set it in the configuration.h file and reloaded it...

Now, I can manually extrude as much PLA as I want, but when I go to print anything, the PLA does not feed. If I stop the print, I can again manually feed as much as I want...

Any ideas?

Yeah, I ran into the same problem this weekend when I was testing my new extruder, I think there's a bug in Marlin with extruding before homing (although I think they'll call it a "feature"). Just unplug the power cable and usb cable to reset the printer and it should work.

Negative, ghostrider... powered it all down. Sliced something... and told it to print...

It wouldn't heat the extruder. it sat there saying "heating" and the Bed would warm up but not the extruder. I can manually turn on the heat, then it starts to move, but never extrudes...

With the old firmware, at least I could get it to print... Any ideas?

Does the bed every come up to full temperature? It will first heat up the bed to 100%, then it starts heating the hotend.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 24, 2015 03:23AM |

Registered: 8 years ago Posts: 13 |

I gave up and reloaded the old software and found it had the same issue... So I know it's not the new version... I figured I screwed something up on the Repetier, so I uninstalled and reinstalled... loaded the new arduino code and went with the defaults... It's back to printing again!

So now it's back to calibration. . .

Thanks for the moral support!

So now it's back to calibration. . .

Thanks for the moral support!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 24, 2015 08:56AM |

Registered: 8 years ago Posts: 33 |

Quote

therippa

Quote

srcga

All right, I'm officially an idiot. I can't find the carriage .

Thought I found a close one but didn't fit animoose's parts that are reworked for leadscrews.

Got a link handy?

[www.thingiverse.com]

Make sure it lines up with the holes on your extruder. If I remember correctly I think I had to drill them out for the stock Folgertech

Yes, the holes are 30mm apart insted of 31mm.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 24, 2015 06:25PM |

Registered: 8 years ago Posts: 367 |

I switched to a new extruder this weekend. It's the same MK9 extruder that comes as standard with the 2020 these days, as opposed the the MK7 which shipped with the original version. The difference is that the MK9 has a sprung lever to hold the groove bearing in place, while the MK7 used a fixed mount. I think this makes it a bit more tolerant of variations in the diameter of the filament. I needed to make a minor change to my E3D mount for this (http://www.thingiverse.com/thing:1091103). The prints are looking good, and I've succeeded getting good prints with NinjaFlex at last, though this may also be because I turned off retraction - I'll post a little more about that on my blog soon.

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 25, 2015 11:02PM |

Registered: 8 years ago Posts: 62 |

Are the settings for Repetier on the FolgerTech website correct?... I set the settings according to the guide on the website and load the ABS and PLA configurations for Slic3r, I was just wondering if that are ok for starters!

Mr.Fus

<------------------------------------------------->

Green M3D (Running v.1.3.6.3Beta)

FolgerTech Prusa i3 (2020 Frame)

<------------------------------------------------>

Mr.Fus

<------------------------------------------------->

Green M3D (Running v.1.3.6.3Beta)

FolgerTech Prusa i3 (2020 Frame)

<------------------------------------------------>

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 25, 2015 11:12PM |

Registered: 8 years ago Posts: 285 |

Quote

Mrfus

Are the settings for Repetier on the FolgerTech website correct?... I set the settings according to the guide on the website and load the ABS and PLA configurations for Slic3r, I was just wondering if that are ok for starters!

From what I saw in them and from what I have heard, the temps that FT has in their slic3r configs are way to high for those materials. As far as the other parts of the config, I am not sure since I have never used them.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 25, 2015 11:45PM |

Registered: 8 years ago Posts: 367 |

Apart from the PLA temperature, they will work at least to get going. Reduce the PLA temperature to something like 185 or 190. You can also get better results if you specify a lower speed for the first later (say 30% or 50%) or increase the thickness of it. Also I recommend adding M400 to the end code or you may lose a little of the top layer. It waits for the commands to finish. There are many more changes you can make to do it better, but these should get you going.

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 26, 2015 01:36AM |

Registered: 8 years ago Posts: 276 |

Happy Halloween!

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 26, 2015 09:59AM |

Registered: 8 years ago Posts: 171 |

So I *finally* got the printer running again after having to move it to another room. I was determined to actually run through some of the calibration steps this time.

I printed a test cube, then did the extruder calibration. It was extruding to little, so I got it dialed in and printed another cube. I couldn't get the cube off the bed! (heated with blue tape) I reheated the bed and managed to yank it off.

I reheated the bed and managed to yank it off.

After reading how some of you approach the calibration so carefully, I was determined to do the same.

In both of the cubes, two sides have "ridges" (front and back), and the other two are much smoother. There is also some "blobbing" in two of the corners. (I'll get pictures). I have determined that I have some play in the Y-belt so there is variation in the front and back movement. Ok, I can take care of that!

X-axis, however, is freaking loud. It works fine, but I have to figure out where it's coming from. The stepper voltage was ok (I didn't try turning it down though). It seems to be the bearing(s) in the X carriage. Tried some light oil on the rod and that made it a tiny bit better. At least I can print stuff!

Lastly, the pieces that hold the X and Z limit switches are giving me fits. Both have broken. The X I'm not as concerned about (if it's a little off, that's ok), but the Z is an issue. Next thing to print is something to let me adjust the height of the limit switch without having to rely on tightening down the plastic printed piece on the rod at *exactly* the right spot.

Whew! Thanks for all the tips everyone!

Edit: Ugh! Newbie mistake! FolgerTech PLA at 175, bed at 60.

Edited 1 time(s). Last edit at 10/26/2015 10:38AM by markts.

I printed a test cube, then did the extruder calibration. It was extruding to little, so I got it dialed in and printed another cube. I couldn't get the cube off the bed! (heated with blue tape)

I reheated the bed and managed to yank it off.

I reheated the bed and managed to yank it off.After reading how some of you approach the calibration so carefully, I was determined to do the same.

In both of the cubes, two sides have "ridges" (front and back), and the other two are much smoother. There is also some "blobbing" in two of the corners. (I'll get pictures). I have determined that I have some play in the Y-belt so there is variation in the front and back movement. Ok, I can take care of that!

X-axis, however, is freaking loud. It works fine, but I have to figure out where it's coming from. The stepper voltage was ok (I didn't try turning it down though). It seems to be the bearing(s) in the X carriage. Tried some light oil on the rod and that made it a tiny bit better. At least I can print stuff!

Lastly, the pieces that hold the X and Z limit switches are giving me fits. Both have broken. The X I'm not as concerned about (if it's a little off, that's ok), but the Z is an issue. Next thing to print is something to let me adjust the height of the limit switch without having to rely on tightening down the plastic printed piece on the rod at *exactly* the right spot.

Whew! Thanks for all the tips everyone!

Edit: Ugh! Newbie mistake! FolgerTech PLA at 175, bed at 60.

Edited 1 time(s). Last edit at 10/26/2015 10:38AM by markts.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 26, 2015 10:31AM |

Registered: 8 years ago Posts: 62 |

Quote

animoose

Apart from the PLA temperature, they will work at least to get going. Reduce the PLA temperature to something like 185 or 190. You can also get better results if you specify a lower speed for the first later (say 30% or 50%) or increase the thickness of it. Also I recommend adding M400 to the end code or you may lose a little of the top layer. It waits for the commands to finish. There are many more changes you can make to do it better, but these should get you going.

Thanks, i have the speed for the first layer set on 50%, first layer temperatre on 190 and the next layers are at 185 (I'm using hatchbox PLA), should i insert the M400 command as custom Gcode at the end?

Mr.Fus

<------------------------------------------------->

Green M3D (Running v.1.3.6.3Beta)

FolgerTech Prusa i3 (2020 Frame)

<------------------------------------------------>

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 26, 2015 11:21AM |

Registered: 8 years ago Posts: 285 |

What problems would you run into if you did auto bed leveling with the X axis endstop on the right instead of the left. I am planning on doing auto leveling, but I do not really want the endstop on the other side. Are there workarounds to the problems, or is it impossible?

Edited 1 time(s). Last edit at 10/26/2015 11:30AM by Mach.

Edited 1 time(s). Last edit at 10/26/2015 11:30AM by Mach.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 26, 2015 11:55AM |

Registered: 8 years ago Posts: 276 |

Quote

Mach

What problems would you run into if you did auto bed leveling with the X axis endstop on the right instead of the left. I am planning on doing auto leveling, but I do not really want the endstop on the other side. Are there workarounds to the problems, or is it impossible?

G28 (home) with autolevel will not work correctly unless there is an X-min endstop.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 26, 2015 02:17PM |

Registered: 8 years ago Posts: 33 |

Quote

markts

So I *finally* got the printer running again after having to move it to another room. I was determined to actually run through some of the calibration steps this time.

I printed a test cube, then did the extruder calibration. It was extruding to little, so I got it dialed in and printed another cube. I couldn't get the cube off the bed! (heated with blue tape)I reheated the bed and managed to yank it off.

After reading how some of you approach the calibration so carefully, I was determined to do the same.

In both of the cubes, two sides have "ridges" (front and back), and the other two are much smoother. There is also some "blobbing" in two of the corners. (I'll get pictures). I have determined that I have some play in the Y-belt so there is variation in the front and back movement. Ok, I can take care of that!

X-axis, however, is freaking loud. It works fine, but I have to figure out where it's coming from. The stepper voltage was ok (I didn't try turning it down though). It seems to be the bearing(s) in the X carriage. Tried some light oil on the rod and that made it a tiny bit better. At least I can print stuff!

Lastly, the pieces that hold the X and Z limit switches are giving me fits. Both have broken. The X I'm not as concerned about (if it's a little off, that's ok), but the Z is an issue. Next thing to print is something to let me adjust the height of the limit switch without having to rely on tightening down the plastic printed piece on the rod at *exactly* the right spot.

Whew! Thanks for all the tips everyone!

Edit: Ugh! Newbie mistake! FolgerTech PLA at 175, bed at 60.

I also had issues with not enough tension in the Y belt. This was causing issues with most of my prints.

I installed one of these and my prints are 100% better now.

[www.thingiverse.com]

When i was printing this the two slots on the outside did not come out wide enough so i sanded them down until i could fit the M4 bolts through them.

If the Y axis and X axis belts are not tight enough then calibrating the printer won't solve anything.

Hope this helps!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 26, 2015 02:30PM |

Registered: 8 years ago Posts: 171 |

Quote

Keary123

Quote

markts

So I *finally* got the printer running again after having to move it to another room. I was determined to actually run through some of the calibration steps this time.

I printed a test cube, then did the extruder calibration. It was extruding to little, so I got it dialed in and printed another cube. I couldn't get the cube off the bed! (heated with blue tape)I reheated the bed and managed to yank it off.

After reading how some of you approach the calibration so carefully, I was determined to do the same.

In both of the cubes, two sides have "ridges" (front and back), and the other two are much smoother. There is also some "blobbing" in two of the corners. (I'll get pictures). I have determined that I have some play in the Y-belt so there is variation in the front and back movement. Ok, I can take care of that!

X-axis, however, is freaking loud. It works fine, but I have to figure out where it's coming from. The stepper voltage was ok (I didn't try turning it down though). It seems to be the bearing(s) in the X carriage. Tried some light oil on the rod and that made it a tiny bit better. At least I can print stuff!

Lastly, the pieces that hold the X and Z limit switches are giving me fits. Both have broken. The X I'm not as concerned about (if it's a little off, that's ok), but the Z is an issue. Next thing to print is something to let me adjust the height of the limit switch without having to rely on tightening down the plastic printed piece on the rod at *exactly* the right spot.

Whew! Thanks for all the tips everyone!

Edit: Ugh! Newbie mistake! FolgerTech PLA at 175, bed at 60.

I also had issues with not enough tension in the Y belt. This was causing issues with most of my prints.

I installed one of these and my prints are 100% better now.

[www.thingiverse.com]

When i was printing this the two slots on the outside did not come out wide enough so i sanded them down until i could fit the M4 bolts through them.

If the Y axis and X axis belts are not tight enough then calibrating the printer won't solve anything.

Hope this helps!

That looks great, thanks! I'll print it tonight and let you know!

Edit: What kind of infill % did you use?

Edited 1 time(s). Last edit at 10/26/2015 03:32PM by markts.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 26, 2015 03:52PM |

Registered: 8 years ago Posts: 33 |

Quote

markts

Quote

Keary123

Quote

markts

So I *finally* got the printer running again after having to move it to another room. I was determined to actually run through some of the calibration steps this time.

I printed a test cube, then did the extruder calibration. It was extruding to little, so I got it dialed in and printed another cube. I couldn't get the cube off the bed! (heated with blue tape)I reheated the bed and managed to yank it off.

After reading how some of you approach the calibration so carefully, I was determined to do the same.

In both of the cubes, two sides have "ridges" (front and back), and the other two are much smoother. There is also some "blobbing" in two of the corners. (I'll get pictures). I have determined that I have some play in the Y-belt so there is variation in the front and back movement. Ok, I can take care of that!

X-axis, however, is freaking loud. It works fine, but I have to figure out where it's coming from. The stepper voltage was ok (I didn't try turning it down though). It seems to be the bearing(s) in the X carriage. Tried some light oil on the rod and that made it a tiny bit better. At least I can print stuff!

Lastly, the pieces that hold the X and Z limit switches are giving me fits. Both have broken. The X I'm not as concerned about (if it's a little off, that's ok), but the Z is an issue. Next thing to print is something to let me adjust the height of the limit switch without having to rely on tightening down the plastic printed piece on the rod at *exactly* the right spot.

Whew! Thanks for all the tips everyone!

Edit: Ugh! Newbie mistake! FolgerTech PLA at 175, bed at 60.

I also had issues with not enough tension in the Y belt. This was causing issues with most of my prints.

I installed one of these and my prints are 100% better now.

[www.thingiverse.com]

When i was printing this the two slots on the outside did not come out wide enough so i sanded them down until i could fit the M4 bolts through them.

If the Y axis and X axis belts are not tight enough then calibrating the printer won't solve anything.

Hope this helps!

That looks great, thanks! I'll print it tonight and let you know!

Edit: What kind of infill % did you use?

On that piece I believe I used 30%. Honestly that part looks pretty shitty when i printed it but after installing it all of my other prints have looked great.

It is just a temporary fix, I am in the process of printing this right now.

[www.thingiverse.com]

These are the current upgrades I am printing and then I plan on doing a rebuild this weekend or late next week.

[www.thingiverse.com] (already printed)

[www.thingiverse.com]

[www.thingiverse.com]

[www.thingiverse.com] (already printed)

[www.thingiverse.com]

[www.thingiverse.com]

[www.thingiverse.com] (already printed)

[www.thingiverse.com]

Edited 2 time(s). Last edit at 10/26/2015 03:54PM by Keary123.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 26, 2015 04:17PM |

Registered: 8 years ago Posts: 171 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 26, 2015 09:06PM |

Registered: 8 years ago Posts: 268 |

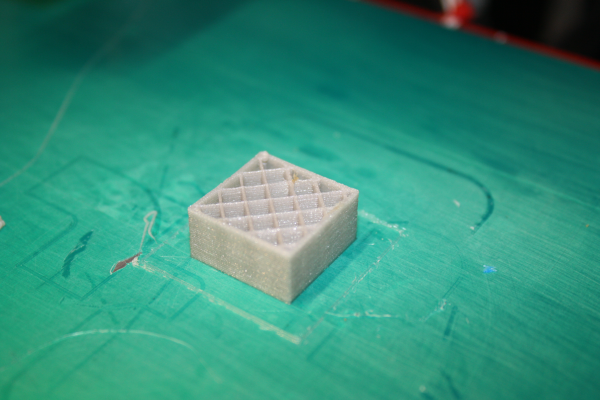

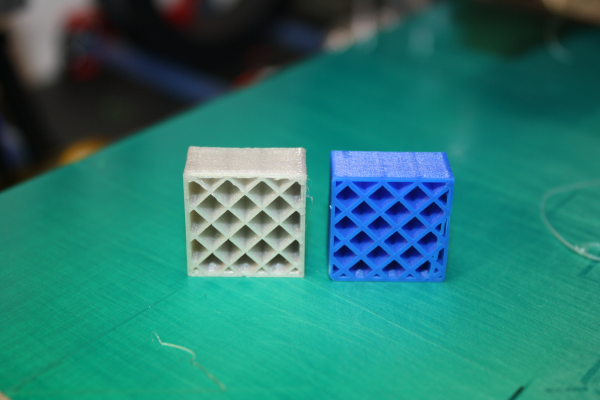

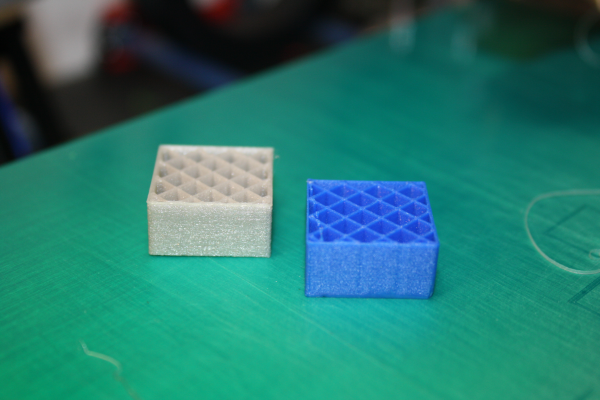

Ninjaflex...First Print

Well I just got a chance to play with the Ninjaflex tonight. I had to modify my Kuro's Bowden Extrduer, I drilled out the filament guide hole from 2mm to 4mm and pushed the Bowden tubing in until it almost touched the MK7 Drive Gear and Bearing...I did have to trim one side of the tube to let the bearing seat on the drive gear. I used therippa's recommendations as a guide and setup Cura as follows:

Filament Temp: 220C

Bed Temp: 75C

Flow: 110%

Skirts: 5

Speed 20mm/s

Layer Height: .2mm

Shell Thickness: .8mm

Top/Bottom Thickness: 0.0mm

Fill Density: 20%

I printed a 20x20x10 calibration block.

Here are my results...I am very pleased with this effort, it came out so much better than I thought it would!!! Once again I own a big thanks to therippa for giving me a starting point!!! I'll play with it some more, but damn, this is pretty good already...

The block still on the table

The block in Ninjaflex and ABS

Same blocks different angle

Sonny

Well I just got a chance to play with the Ninjaflex tonight. I had to modify my Kuro's Bowden Extrduer, I drilled out the filament guide hole from 2mm to 4mm and pushed the Bowden tubing in until it almost touched the MK7 Drive Gear and Bearing...I did have to trim one side of the tube to let the bearing seat on the drive gear. I used therippa's recommendations as a guide and setup Cura as follows:

Filament Temp: 220C

Bed Temp: 75C

Flow: 110%

Skirts: 5

Speed 20mm/s

Layer Height: .2mm

Shell Thickness: .8mm

Top/Bottom Thickness: 0.0mm

Fill Density: 20%

I printed a 20x20x10 calibration block.

Here are my results...I am very pleased with this effort, it came out so much better than I thought it would!!! Once again I own a big thanks to therippa for giving me a starting point!!! I'll play with it some more, but damn, this is pretty good already...

The block still on the table

The block in Ninjaflex and ABS

Same blocks different angle

Sonny

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 26, 2015 09:31PM |

Registered: 8 years ago Posts: 171 |

That looks cool!

So I went to print the adjustable Y axis tensioner. After seeing the calibration cube and calibrating the extruder, I thought I was good to go, at least good enough to print replacement parts and hopefully progressively get the parts better.

No luck. For one thing, after increasing the extrusion rate a bit, I can't get the prints off the bed! I'm trying it directly on glass instead of the blue tape now.

For some reason when I printed the tensioner, ir seemed as though the part was "weak". I used 40% infill, but it was thin and one part broke off in my hand.

Too hot? Too cool?

I've been using Cura as I thought I liked it better than Slic3r. It really seemed to make a difference. Now I'm wondering if I should just bite the bullet and get Simplify3d.

So I went to print the adjustable Y axis tensioner. After seeing the calibration cube and calibrating the extruder, I thought I was good to go, at least good enough to print replacement parts and hopefully progressively get the parts better.

No luck. For one thing, after increasing the extrusion rate a bit, I can't get the prints off the bed! I'm trying it directly on glass instead of the blue tape now.

For some reason when I printed the tensioner, ir seemed as though the part was "weak". I used 40% infill, but it was thin and one part broke off in my hand.

Too hot? Too cool?

I've been using Cura as I thought I liked it better than Slic3r. It really seemed to make a difference. Now I'm wondering if I should just bite the bullet and get Simplify3d.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 26, 2015 10:22PM |

Registered: 8 years ago Posts: 430 |

Quote

markts

That looks cool!

So I went to print the adjustable Y axis tensioner. After seeing the calibration cube and calibrating the extruder, I thought I was good to go, at least good enough to print replacement parts and hopefully progressively get the parts better.

No luck. For one thing, after increasing the extrusion rate a bit, I can't get the prints off the bed! I'm trying it directly on glass instead of the blue tape now.

For some reason when I printed the tensioner, ir seemed as though the part was "weak". I used 40% infill, but it was thin and one part broke off in my hand.

Too hot? Too cool?

I've been using Cura as I thought I liked it better than Slic3r. It really seemed to make a difference. Now I'm wondering if I should just bite the bullet and get Simplify3d.

Have you waited for the bed to cool down before trying to remove the print? I haven't had anything that isn't lose after everything cools down. I am just printing on the glass with glue on it though.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 26, 2015 10:30PM |

Registered: 8 years ago Posts: 99 |

Quote

msaeger

Quote

markts

That looks cool!

So I went to print the adjustable Y axis tensioner. After seeing the calibration cube and calibrating the extruder, I thought I was good to go, at least good enough to print replacement parts and hopefully progressively get the parts better.

No luck. For one thing, after increasing the extrusion rate a bit, I can't get the prints off the bed! I'm trying it directly on glass instead of the blue tape now.

For some reason when I printed the tensioner, ir seemed as though the part was "weak". I used 40% infill, but it was thin and one part broke off in my hand.

Too hot? Too cool?

I've been using Cura as I thought I liked it better than Slic3r. It really seemed to make a difference. Now I'm wondering if I should just bite the bullet and get Simplify3d.

Have you waited for the bed to cool down before trying to remove the print? I haven't had anything that isn't lose after everything cools down. I am just printing on the glass with glue on it though.

Yes let it cool. After I print something I move the extruder in front of the object and let the fan cool it. You will hear it crack and pop. About 5 minutes and the piece just falls off in your hand. I use pla heat my bed to 60c and my extruder from 180 to 195c.

Edited 1 time(s). Last edit at 10/26/2015 10:31PM by woodknack.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 26, 2015 10:35PM |

Registered: 8 years ago Posts: 276 |

Quote

markts

That looks cool!

So I went to print the adjustable Y axis tensioner. After seeing the calibration cube and calibrating the extruder, I thought I was good to go, at least good enough to print replacement parts and hopefully progressively get the parts better.

No luck. For one thing, after increasing the extrusion rate a bit, I can't get the prints off the bed! I'm trying it directly on glass instead of the blue tape now.

For some reason when I printed the tensioner, ir seemed as though the part was "weak". I used 40% infill, but it was thin and one part broke off in my hand.

Too hot? Too cool?

I've been using Cura as I thought I liked it better than Slic3r. It really seemed to make a difference. Now I'm wondering if I should just bite the bullet and get Simplify3d.

Simplify3d was probably one of the best upgrades I made for my printer. On default settings, it solved so many issues I tried tuning out of slic3r.

Edited 1 time(s). Last edit at 10/26/2015 10:36PM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 26, 2015 11:30PM |

Registered: 8 years ago Posts: 171 |

I'll get your firmware loaded up tomorrow, for sure..

Does Simplify3d come with a pre-configured setting for the Folger? At least maybe with stock parts? I question if half of my issues aren't just settings that are way off that I don't know to change (speed, etc). It seems like the calibration cubes are pretty consistent but once I try to print something bigger, the settings change (in the slicer??). I can tell the print speed differs just from the different sound the thing makes.

Does Simplify3d come with a pre-configured setting for the Folger? At least maybe with stock parts? I question if half of my issues aren't just settings that are way off that I don't know to change (speed, etc). It seems like the calibration cubes are pretty consistent but once I try to print something bigger, the settings change (in the slicer??). I can tell the print speed differs just from the different sound the thing makes.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 27, 2015 12:17AM |

Registered: 8 years ago Posts: 62 |

Quote

therippa

Quote

Mach

What problems would you run into if you did auto bed leveling with the X axis endstop on the right instead of the left. I am planning on doing auto leveling, but I do not really want the endstop on the other side. Are there workarounds to the problems, or is it impossible?

G28 (home) with autolevel will not work correctly unless there is an X-min endstop.

I was wondering about the implementation of the autolevel... so when i get ready to do it i should move the endstop to the left side and change the X enstop on Repetier to Max, I'm guessing the endstop setting on the configuration file on marlin need to be set from 1 to -1 so the carriage moves to the left.

Mr.Fus

<------------------------------------------------->

Green M3D (Running v.1.3.6.3Beta)

FolgerTech Prusa i3 (2020 Frame)

<------------------------------------------------>

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 27, 2015 12:22AM |

Registered: 8 years ago Posts: 276 |

Quote

markts

I'll get your firmware loaded up tomorrow, for sure..

Does Simplify3d come with a pre-configured setting for the Folger? At least maybe with stock parts? I question if half of my issues aren't just settings that are way off that I don't know to change (speed, etc). It seems like the calibration cubes are pretty consistent but once I try to print something bigger, the settings change (in the slicer??). I can tell the print speed differs just from the different sound the thing makes.

They do not have pre-configured settings for the Folgertech, but all you have to do is give it the correct dimensions for the printer and the rest of the defaults work pretty well.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 27, 2015 11:02AM |

Registered: 8 years ago Posts: 99 |

Quote

therippa

Quote

markts

That looks cool!

So I went to print the adjustable Y axis tensioner. After seeing the calibration cube and calibrating the extruder, I thought I was good to go, at least good enough to print replacement parts and hopefully progressively get the parts better.

No luck. For one thing, after increasing the extrusion rate a bit, I can't get the prints off the bed! I'm trying it directly on glass instead of the blue tape now.

For some reason when I printed the tensioner, ir seemed as though the part was "weak". I used 40% infill, but it was thin and one part broke off in my hand.

Too hot? Too cool?

I've been using Cura as I thought I liked it better than Slic3r. It really seemed to make a difference. Now I'm wondering if I should just bite the bullet and get Simplify3d.

Simplify3d was probably one of the best upgrades I made for my printer. On default settings, it solved so many issues I tried tuning out of slic3r.

Im glad I made the jump to S3D. It works great, though im still learning it. To me it was worth the money. Because I didn't feel like learning 3 other types of different software to print something on my printer. I love it. So far it has not let me down. Im still playing with different settings a little at a time.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 27, 2015 11:27AM |

Registered: 8 years ago Posts: 33 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 27, 2015 12:50PM |

Registered: 8 years ago Posts: 276 |

Quote

Keary123

therippa in regards to Simplify3D what problems did it solve? I have been using slicer and have had some annoyances, no real

Issues. I thought about switching to Cura. What are your thoughts on this?

Two things it immediately fixed was waviness on the walls of my calibration cubes, and one corner on them always bulging out.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 27, 2015 01:27PM |

Registered: 8 years ago Posts: 99 |

Quote

therippa

Quote

Keary123

therippa in regards to Simplify3D what problems did it solve? I have been using slicer and have had some annoyances, no real

Issues. I thought about switching to Cura. What are your thoughts on this?

Two things it immediately fixed was waviness on the walls of my calibration cubes, and one corner on them always bulging out.

Also S3D is more then just a slicer. Im still learning things I can do with it. You can bring two model into and merge them together. Like a pair of sun glass's to an aliens head. And much more. From easy to advanced.

[www.youtube.com]

Edited 2 time(s). Last edit at 10/27/2015 01:33PM by woodknack.

Sorry, only registered users may post in this forum.