Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 12:42AM |

Registered: 8 years ago Posts: 23 |

Quote

The Sto

Quote

markts

Quote

The Sto

Quote

markts

Quote

The Sto

Quote

markts

Quote

The Sto

Quote

Mopar99

Quote

The Sto

Quote

Mopar99

Quote

The Sto

After searching through this entire thread, I wasn't able to find an answer to my problem...

I have my printer built and firmware flashed (thanks therippa!), but when I try to calibrate in Repetier Host, I can only get the Z axis to move... I have checked all my connections and settings, but I can't for the life of me seem to get X or Y to move.

Any suggestions?

I found that clicking "home all" first, then you can move you axis.

I have tried that, it still won't move either axis... I can move them both by hand, but I can't in rep host... I even tried re-flashing the firmware with the hope that I did something wrong, but still no luck...

Have you checked your driver voltages for each stepper?

I have not, and now the ultimate noob question... How do I check the voltage? I'm a lot better on the building side than I am on the software / electronics side...

I take it you've already triple checked the wiring and where they are connected at the RAMPS board? I say that since checking the voltage is a little dangerous (for the electronics). There have been multiple instances just on this forum where people have gone to measure/adjust the voltage only to short them out which destroys other stuff too. Better to check the easy stuff first.You'll also want to make sure the limit switches aren't tripped (or think they're tripped).

I have triple checked all my wiring, yes. This is really throwing me for a loop... I even unplugged everything from the board and started fresh plugging it all back in from scratch.

Try swapping Z for another axis at the RAMPS board. That should rule out the steppers, motors, etc. Just be ready on the power switch as the limit switch isn't going to stop anything!

So you're saying to plug X or Y into the slot for Z on the RAMPS board? I just want to make sure that I am understanding correctly... I've already learned a lot about troubleshooting this from reading all the information here, but as was said, I don't want to short anything out and be in a worse spot than I am now...

Also, how do I go about checking the voltage for the steppers? It was mentioned earlier, but then never explained... Thanks!

Yes that's what was suggesting. Swap the connection for the two axes and see if X moves (since Z does now). The steppers have a metal screw on them that is LIVE (positive voltage) . You check the voltage across that screw and ground, preferably far away from the stepper so it reduces the chance of shorting it out.

Thanks! I'll have to try it when I get home from work tonight! I hate only having a couple hours a day to get this dialed in, and I've been trying to figure this out for 3 days now... Finally joined the forum to ask the questions... Thanks for all your help! I'll report back tonight with my findings!

Okay so I put the suggestions to test and here is what I found. When I plug X and Y into the Z connections on the RAMPS board, they both work, while the two Z steppers do not when plugged into X and Y. My guess is this means that I have a bad board? I have already emailed Folger Tech and should have a response in the morning. Until then I don't have anything that I can do. I guess I can test the extruder and make sure that both it and the bed will come up to temperature while I wait to find out some answers. Again, thanks to those of you who have offered assistance! I'm anxious to get this up and running as there are several projects that I am ready to tackle!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 12:56AM |

Registered: 8 years ago Posts: 84 |

Quote

The Sto

Quote

The Sto

Quote

markts

Quote

The Sto

Quote

markts

Quote

The Sto

Quote

markts

Quote

The Sto

Quote

Mopar99

Quote

The Sto

Quote

Mopar99

Quote

The Sto

After searching through this entire thread, I wasn't able to find an answer to my problem...

I have my printer built and firmware flashed (thanks therippa!), but when I try to calibrate in Repetier Host, I can only get the Z axis to move... I have checked all my connections and settings, but I can't for the life of me seem to get X or Y to move.

Any suggestions?

I found that clicking "home all" first, then you can move you axis.

I have tried that, it still won't move either axis... I can move them both by hand, but I can't in rep host... I even tried re-flashing the firmware with the hope that I did something wrong, but still no luck...

Have you checked your driver voltages for each stepper?

I have not, and now the ultimate noob question... How do I check the voltage? I'm a lot better on the building side than I am on the software / electronics side...

I take it you've already triple checked the wiring and where they are connected at the RAMPS board? I say that since checking the voltage is a little dangerous (for the electronics). There have been multiple instances just on this forum where people have gone to measure/adjust the voltage only to short them out which destroys other stuff too. Better to check the easy stuff first.You'll also want to make sure the limit switches aren't tripped (or think they're tripped).

I have triple checked all my wiring, yes. This is really throwing me for a loop... I even unplugged everything from the board and started fresh plugging it all back in from scratch.

Try swapping Z for another axis at the RAMPS board. That should rule out the steppers, motors, etc. Just be ready on the power switch as the limit switch isn't going to stop anything!

So you're saying to plug X or Y into the slot for Z on the RAMPS board? I just want to make sure that I am understanding correctly... I've already learned a lot about troubleshooting this from reading all the information here, but as was said, I don't want to short anything out and be in a worse spot than I am now...

Also, how do I go about checking the voltage for the steppers? It was mentioned earlier, but then never explained... Thanks!

Yes that's what was suggesting. Swap the connection for the two axes and see if X moves (since Z does now). The steppers have a metal screw on them that is LIVE (positive voltage) . You check the voltage across that screw and ground, preferably far away from the stepper so it reduces the chance of shorting it out.

Thanks! I'll have to try it when I get home from work tonight! I hate only having a couple hours a day to get this dialed in, and I've been trying to figure this out for 3 days now... Finally joined the forum to ask the questions... Thanks for all your help! I'll report back tonight with my findings!

Okay so I put the suggestions to test and here is what I found. When I plug X and Y into the Z connections on the RAMPS board, they both work, while the two Z steppers do not when plugged into X and Y. My guess is this means that I have a bad board? I have already emailed Folger Tech and should have a response in the morning. Until then I don't have anything that I can do. I guess I can test the extruder and make sure that both it and the bed will come up to temperature while I wait to find out some answers. Again, thanks to those of you who have offered assistance! I'm anxious to get this up and running as there are several projects that I am ready to tackle!

Check to make sure the jumpers are correct under the stepper drivers on the ramps board.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 01:07AM |

Registered: 8 years ago Posts: 13 |

Quote

built350camaro

Check to make sure the jumpers are correct under the stepper drivers on the ramps board.

Good point! You could be off one pin right/left.

Also, your RAMPS board came populated with an extra stepper driver. Before you swap drivers:

Did you adjust the voltage on the steppers? The ceramic screwdriver will adjust the voltage to each stepper, if you tell the Z to move.. then adjust the stepper controller to the right a bit, you may find it moves...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 01:24AM |

Registered: 8 years ago Posts: 84 |

I just printed the 80 degree overhand test thingiverse.com/699366 It looks like anything over a 45 degree angle I get stinging underneath. How do I tune this to make it better?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 02:13AM |

Registered: 8 years ago Posts: 45 |

Hi all,

Last time I posted on this thread I was probably on page 10 or so. I had built the printer successfully and then didn't really use it.

I hooked everything back up a couple days ago and started printing a whole bunch of tests and cubes.

I notice that my print surface gets rough and has some gaps on the infill. I could be wrong but it seems to do this when the machine is getting hot.

The x-motor is hot but not scolding.

The y and z motors are cool.

The extruder motor is piping hot. I'm not sure if this is because the hot end is touching the motor or not.

All my motor driver voltages are around 0.35v, with the y motor being at 0.6v

What gives?

Thanks,

U

Last time I posted on this thread I was probably on page 10 or so. I had built the printer successfully and then didn't really use it.

I hooked everything back up a couple days ago and started printing a whole bunch of tests and cubes.

I notice that my print surface gets rough and has some gaps on the infill. I could be wrong but it seems to do this when the machine is getting hot.

The x-motor is hot but not scolding.

The y and z motors are cool.

The extruder motor is piping hot. I'm not sure if this is because the hot end is touching the motor or not.

All my motor driver voltages are around 0.35v, with the y motor being at 0.6v

What gives?

Thanks,

U

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 03:38AM |

Registered: 8 years ago Posts: 276 |

Quote

Uncertainty

Hi all,

Last time I posted on this thread I was probably on page 10 or so. I had built the printer successfully and then didn't really use it.

I hooked everything back up a couple days ago and started printing a whole bunch of tests and cubes.

I notice that my print surface gets rough and has some gaps on the infill. I could be wrong but it seems to do this when the machine is getting hot.

The x-motor is hot but not scolding.

The y and z motors are cool.

The extruder motor is piping hot. I'm not sure if this is because the hot end is touching the motor or not.

All my motor driver voltages are around 0.35v, with the y motor being at 0.6v

What gives?

Thanks,

U

I feel like the motors/drivers are very picky about a lot of build variables, and you need to adjust them all to your specific setup so the motors don't run too hot. Yes, everyone says "X-axis motor should be at Nvolts", but that doesn't take into account the tension on the drive belt, which can affect how hard the motor has to work. Best thing I've found for dialing in motors is to print a big calibration piece (like, one that takes 60 minute print time), and after 10 minutes, feel the motors. If one is hot, use the ceramic screwdriver and turn down the voltage a tiny bit (like a 1/12 of a turn, think of the dial on the driver as a clock). Wait about 10 minutes, see if the heat go down. Keep turning it down until the motor is pretty much room temperature. If the motor starts skipping, turn it up 1/12 again. It's a trial and error process, and will be different on everyone's build.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 07:14AM |

Registered: 8 years ago Posts: 3 |

My extruder was running the wrong direction on initial start up. I changed the E0 to true from false in config.h to fix that problem as opposed to turning the cables around. Hope that helps...

#define INVERT_X_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_Y_DIR true // for Mendel set to true, for Orca set to false

#define INVERT_Z_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_E0_DIR true // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E1_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E2_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_X_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_Y_DIR true // for Mendel set to true, for Orca set to false

#define INVERT_Z_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_E0_DIR true // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E1_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E2_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 07:40AM |

Registered: 8 years ago Posts: 285 |

Quote

Uncertainty

Hi all,

Last time I posted on this thread I was probably on page 10 or so. I had built the printer successfully and then didn't really use it.

I hooked everything back up a couple days ago and started printing a whole bunch of tests and cubes.

I notice that my print surface gets rough and has some gaps on the infill. I could be wrong but it seems to do this when the machine is getting hot.

The x-motor is hot but not scolding.

The y and z motors are cool.

The extruder motor is piping hot. I'm not sure if this is because the hot end is touching the motor or not.

All my motor driver voltages are around 0.35v, with the y motor being at 0.6v

What gives?

Thanks,

U

I do not think that the hot end touching the motor is affecting the temp of the motor by any considerable amount. I am using a bowden setup with the original heatblock that would come in contact with the motor and it does not get hot as long as the fan is cooling the heatsink. The excess heat is most definitely coming from high stepper driver current.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 09:34AM |

Registered: 10 years ago Posts: 444 |

Quote

I just printed the 80 degree overhand test thingiverse.com/699366 It looks like anything over a 45 degree angle I get stinging underneath. How do I tune this to make it better?

Try a smaller layer height (maybe 0.1) and possibly also a narrower extrusion width. These will cause less plastic to hang off of the overhang.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 10:05AM |

Registered: 8 years ago Posts: 45 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 11:37AM |

Registered: 8 years ago Posts: 12 |

Just got a FolgerTech 2020 i3 kit and sorted the screws and small hardware last night. I have a bunch of 25mm M3 bolts which I don't see on the list stuck to the outside of the hardware pack. Everything else seems accounted for, with extras even.

I am assuming I'll use these somewhere?

This is my second run at a 3d printer kit -- I already own a Cupcake, but she and I are a little on the outs at present.

I am assuming I'll use these somewhere?

This is my second run at a 3d printer kit -- I already own a Cupcake, but she and I are a little on the outs at present.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 01:13PM |

Registered: 8 years ago Posts: 93 |

Quote

Bryg63

My extruder was running the wrong direction on initial start up. I changed the E0 to true from false in config.h to fix that problem as opposed to turning the cables around. Hope that helps...

#define INVERT_X_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_Y_DIR true // for Mendel set to true, for Orca set to false

#define INVERT_Z_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_E0_DIR true // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E1_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E2_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

If the extruder is running backwards, all you should need to do is reverse the plug where it plugs into the ramps board. Just flip it over 180 degrees and plug it back in.

Edited 1 time(s). Last edit at 10/29/2015 01:14PM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 02:17PM |

Registered: 8 years ago Posts: 30 |

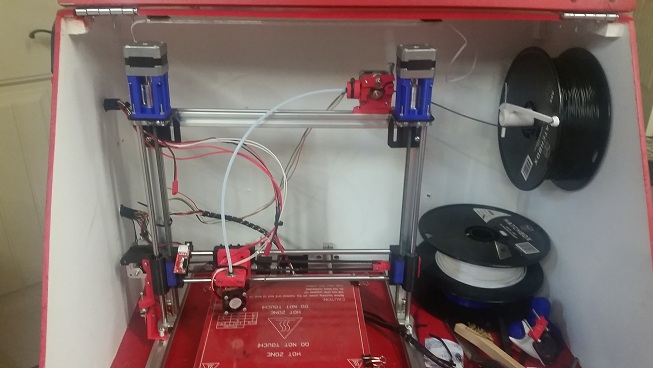

Here is a quick look at some of the recent things I have done to my FT 2020 printer. The enclosure has been really great, keeps the printer protected and clean from other work in the garage and help control the temperature better. Still have to clean up the wiring a bit and mount the LCD but I am happy with it.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 02:26PM |

Registered: 9 years ago Posts: 251 |

Quote

Uncertainty

Do you guys keep the fan on 100% when printing? Even with ABS? I was keeping it off because I heard that abs prefers no fan.

If you mean the fan attached to the heatsink on the extruder, you should be running that fan at 100% all the time, it's meant to cool heat come up from your hotend.

If you mean an additional print fan blowing on the molten plastic coming out of your nozzle, then most people only us this for PLA.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 02:57PM |

Registered: 8 years ago Posts: 23 |

Quote

Spam

Quote

built350camaro

Check to make sure the jumpers are correct under the stepper drivers on the ramps board.

Good point! You could be off one pin right/left.

Also, your RAMPS board came populated with an extra stepper driver. Before you swap drivers:

Did you adjust the voltage on the steppers? The ceramic screwdriver will adjust the voltage to each stepper, if you tell the Z to move.. then adjust the stepper controller to the right a bit, you may find it moves...

I will look into that once I get home... I was actually thinking about that this afternoon on my drive in to work... I also got an email back from Folger Tech and they will be sending me a new RAMPS board. I also realized last night that my solder job for the heat bed isn't very good, as I cannot get the bed to heat above 20 degrees Celsius. I'm going to tackle that tomorrow though. I have some other things that I need to take care of, and I want to get these steppers working.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 03:17PM |

Registered: 8 years ago Posts: 276 |

Quote

Bert3D

Quote

Bryg63

My extruder was running the wrong direction on initial start up. I changed the E0 to true from false in config.h to fix that problem as opposed to turning the cables around. Hope that helps...

#define INVERT_X_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_Y_DIR true // for Mendel set to true, for Orca set to false

#define INVERT_Z_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_E0_DIR true // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E1_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E2_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

If the extruder is running backwards, all you should need to do is reverse the plug where it plugs into the ramps board. Just flip it over 180 degrees and plug it back in.

This. You shouldn't fix physical hardware problems with firmware changes.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 09:55PM |

Registered: 8 years ago Posts: 23 |

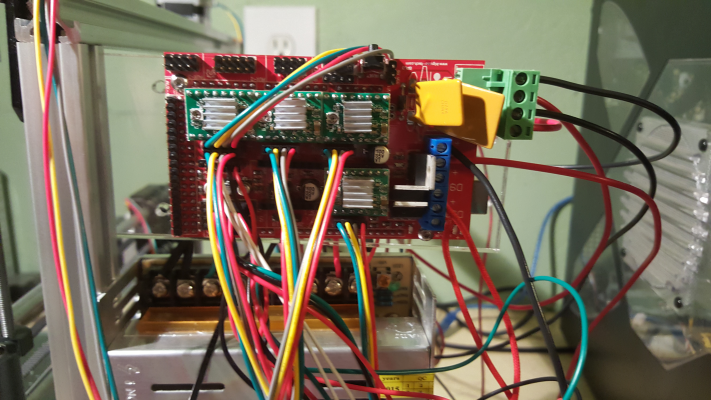

I was asked to post a picture of my board, so here goes... Still have to clean up all of my wires, but I won't do that until I get the darn thing working!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 10:16PM |

Registered: 8 years ago Posts: 16 |

Quote

Bryg63

My extruder was running the wrong direction on initial start up. I changed the E0 to true from false in config.h to fix that problem as opposed to turning the cables around. Hope that helps...

#define INVERT_X_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_Y_DIR true // for Mendel set to true, for Orca set to false

#define INVERT_Z_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_E0_DIR true // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E1_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E2_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

I had the same issue but when I changed the INVERT_X_DIR it starting to home on the wrong side so I had to change #define X_HOME_DIR -1 to 1

// ENDSTOP SETTINGS:

// Sets direction of endstops when homing; 1=MAX, -1=MIN

#define X_HOME_DIR 1

#define Y_HOME_DIR -1

#define Z_HOME_DIR -1

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 10:30PM |

Registered: 8 years ago Posts: 171 |

Mine still looks a lot like that! lol. Nothing obviously wrong that I can see, except isn't one of those connections to the RAMPs board supposed to be inverted? I don't recall all of the connectors going in the same direction (despite what the instructions say). I'll go look at mine. I think it depends on the config in the firmware too - nothing to worry about yet.

I have a question about the step sticks and setting the voltage. I wanted to turn the voltage down on the X stepper motor since it runs so hot. Since I lost my plastic screwdriver I checked the voltage, turned it off, turned it down, turned it on, etc. Maybe I was measuring it wrong (since I was trying to be so careful not to short anything out) but at last check it was down to 0.01v and not skipping. I started a print and it was working fine, and the motor was still getting hot. ??? I thought it should be around 0.4v.

I checked the voltage, turned it off, turned it down, turned it on, etc. Maybe I was measuring it wrong (since I was trying to be so careful not to short anything out) but at last check it was down to 0.01v and not skipping. I started a print and it was working fine, and the motor was still getting hot. ??? I thought it should be around 0.4v.

I have a question about the step sticks and setting the voltage. I wanted to turn the voltage down on the X stepper motor since it runs so hot. Since I lost my plastic screwdriver

I checked the voltage, turned it off, turned it down, turned it on, etc. Maybe I was measuring it wrong (since I was trying to be so careful not to short anything out) but at last check it was down to 0.01v and not skipping. I started a print and it was working fine, and the motor was still getting hot. ??? I thought it should be around 0.4v.

I checked the voltage, turned it off, turned it down, turned it on, etc. Maybe I was measuring it wrong (since I was trying to be so careful not to short anything out) but at last check it was down to 0.01v and not skipping. I started a print and it was working fine, and the motor was still getting hot. ??? I thought it should be around 0.4v.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 11:06PM |

Registered: 8 years ago Posts: 367 |

Thought you might be interested in a recent print. This uses an unusual filament called Biofila Linen which is designed to have a nice surface texture, and was printed using Slic3r's spiral vase mode. You can't tell the scale from the picture - it's about 65mm tall.

Edited 1 time(s). Last edit at 10/29/2015 11:27PM by animoose.

See my blog at [moosteria.blogspot.com].

Edited 1 time(s). Last edit at 10/29/2015 11:27PM by animoose.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 11:22PM |

Registered: 8 years ago Posts: 541 |

Quote

markts

Mine still looks a lot like that! lol. Nothing obviously wrong that I can see, except isn't one of those connections to the RAMPs board supposed to be inverted? I don't recall all of the connectors going in the same direction (despite what the instructions say). I'll go look at mine. I think it depends on the config in the firmware too - nothing to worry about yet.

I have a question about the step sticks and setting the voltage. I wanted to turn the voltage down on the X stepper motor since it runs so hot. Since I lost my plastic screwdriverI checked the voltage, turned it off, turned it down, turned it on, etc. Maybe I was measuring it wrong (since I was trying to be so careful not to short anything out) but at last check it was down to 0.01v and not skipping. I started a print and it was working fine, and the motor was still getting hot. ??? I thought it should be around 0.4v.

You evidently weren't getting a good connection to ground? Don't try to put the ground lead on the stepstick. Put it on the negative terminal on the power supply and then you only have to worry about a good contact with the pot.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 11:28PM |

Registered: 8 years ago Posts: 62 |

Quote

Bert3D

Quote

Bryg63

My extruder was running the wrong direction on initial start up. I changed the E0 to true from false in config.h to fix that problem as opposed to turning the cables around. Hope that helps...

#define INVERT_X_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_Y_DIR true // for Mendel set to true, for Orca set to false

#define INVERT_Z_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_E0_DIR true // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E1_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E2_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

If the extruder is running backwards, all you should need to do is reverse the plug where it plugs into the ramps board. Just flip it over 180 degrees and plug it back in.

Thank you guys for the suggestions, I end up changing the connector at the Ramps board and now it's working as it should be!!

I was able to complete a manual extrusion test... I set the printer to extrude 30mm and end up with 28mm, I guess now I need to find on the Marlin the steeps per mm so I can recalculate the values (did some one knows where is located in the code?).

.

Mr.Fus

<------------------------------------------------->

Green M3D (Running v.1.3.6.3Beta)

FolgerTech Prusa i3 (2020 Frame)

<------------------------------------------------>

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 11:33PM |

Registered: 8 years ago Posts: 171 |

Quote

tjnamtiw

You evidently weren't getting a good connection to ground? Don't try to put the ground lead on the stepstick. Put it on the negative terminal on the power supply and then you only have to worry about a good contact with the pot.

Yeah I know that must be the case, though I was using the ground from the power supply. I'll give it another go tomorrow.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 29, 2015 11:39PM |

Registered: 8 years ago Posts: 23 |

Quote

markts

Mine still looks a lot like that! lol. Nothing obviously wrong that I can see, except isn't one of those connections to the RAMPs board supposed to be inverted? I don't recall all of the connectors going in the same direction (despite what the instructions say). I'll go look at mine. I think it depends on the config in the firmware too - nothing to worry about yet.

I have a question about the step sticks and setting the voltage. I wanted to turn the voltage down on the X stepper motor since it runs so hot. Since I lost my plastic screwdriverI checked the voltage, turned it off, turned it down, turned it on, etc. Maybe I was measuring it wrong (since I was trying to be so careful not to short anything out) but at last check it was down to 0.01v and not skipping. I started a print and it was working fine, and the motor was still getting hot. ??? I thought it should be around 0.4v.

I'll try inverting the X and Y when I get home from work...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 30, 2015 12:22AM |

Registered: 8 years ago Posts: 285 |

Quote

Mrfus

Quote

Bert3D

Quote

Bryg63

My extruder was running the wrong direction on initial start up. I changed the E0 to true from false in config.h to fix that problem as opposed to turning the cables around. Hope that helps...

#define INVERT_X_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_Y_DIR true // for Mendel set to true, for Orca set to false

#define INVERT_Z_DIR true // for Mendel set to false, for Orca set to true

#define INVERT_E0_DIR true // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E1_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E2_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

If the extruder is running backwards, all you should need to do is reverse the plug where it plugs into the ramps board. Just flip it over 180 degrees and plug it back in.

Thank you guys for the suggestions, I end up changing the connector at the Ramps board and now it's working as it should be!!

I was able to complete a manual extrusion test... I set the printer to extrude 30mm and end up with 28mm, I guess now I need to find on the Marlin the steeps per mm so I can recalculate the values (did some one knows where is located in the code?).

.

It is at line 484, or you could ctrl + F and search #define DEFAULT_AXIS_STEPS_PER_UNIT.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 30, 2015 09:35AM |

Registered: 8 years ago Posts: 33 |

Quote

therippa

Quote

Uncertainty

Hi all,

Last time I posted on this thread I was probably on page 10 or so. I had built the printer successfully and then didn't really use it.

I hooked everything back up a couple days ago and started printing a whole bunch of tests and cubes.

I notice that my print surface gets rough and has some gaps on the infill. I could be wrong but it seems to do this when the machine is getting hot.

The x-motor is hot but not scolding.

The y and z motors are cool.

The extruder motor is piping hot. I'm not sure if this is because the hot end is touching the motor or not.

All my motor driver voltages are around 0.35v, with the y motor being at 0.6v

What gives?

Thanks,

U

I feel like the motors/drivers are very picky about a lot of build variables, and you need to adjust them all to your specific setup so the motors don't run too hot. Yes, everyone says "X-axis motor should be at Nvolts", but that doesn't take into account the tension on the drive belt, which can affect how hard the motor has to work. Best thing I've found for dialing in motors is to print a big calibration piece (like, one that takes 60 minute print time), and after 10 minutes, feel the motors. If one is hot, use the ceramic screwdriver and turn down the voltage a tiny bit (like a 1/12 of a turn, think of the dial on the driver as a clock). Wait about 10 minutes, see if the heat go down. Keep turning it down until the motor is pretty much room temperature. If the motor starts skipping, turn it up 1/12 again. It's a trial and error process, and will be different on everyone's build.

This does work, that is unless you have somthing to tight or binding. You can be sure if you can't cool it down and get a smooth operation the problem is most likely not electrical but is a problem in the build . too tight or binding. Very good post therippa.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 30, 2015 09:37AM |

Registered: 8 years ago Posts: 33 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 30, 2015 09:58AM |

Registered: 8 years ago Posts: 57 |

I messed around with the X-carriages that you guys linked.

Ended up making a remix of a remix. This one has and end-stop pusher built in, just shortened up. Plan is to use the x end-stop that therippa linked a while back. Also added some hoops at the top to use for cable tying wires up to the carriage.

[www.thingiverse.com]

Ended up making a remix of a remix. This one has and end-stop pusher built in, just shortened up. Plan is to use the x end-stop that therippa linked a while back. Also added some hoops at the top to use for cable tying wires up to the carriage.

[www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 30, 2015 11:21PM |

Registered: 8 years ago Posts: 59 |

my x stepper runs hot even with the voltage cranked down until it's just above skipping. I added a heat sink and a fan to it and it runs much much cooler now. There are also some prior posts from tjtnamtiw that show where he printed a fan shroud to blow cool air over the x stepper.Quote

markts

Mine still looks a lot like that! lol. Nothing obviously wrong that I can see, except isn't one of those connections to the RAMPs board supposed to be inverted? I don't recall all of the connectors going in the same direction (despite what the instructions say). I'll go look at mine. I think it depends on the config in the firmware too - nothing to worry about yet.

I have a question about the step sticks and setting the voltage. I wanted to turn the voltage down on the X stepper motor since it runs so hot. Since I lost my plastic screwdriverI checked the voltage, turned it off, turned it down, turned it on, etc. Maybe I was measuring it wrong (since I was trying to be so careful not to short anything out) but at last check it was down to 0.01v and not skipping. I started a print and it was working fine, and the motor was still getting hot. ??? I thought it should be around 0.4v.

Edited 1 time(s). Last edit at 10/30/2015 11:37PM by LancelotL.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) October 30, 2015 11:28PM |

Registered: 8 years ago Posts: 59 |

Does anyone know how to get Slic3er to provide a 100% fill underneath supports on the first layer to provide better adhesion with the support material? I can fix some of it by making my brim size really wid but it seems like there should be an option to fill the support material base. Some of my supports always seem to break lose because the default fill for attachment of supports seems to be 50%. Thanks!

Sorry, only registered users may post in this forum.