Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 10, 2015 09:24AM |

Registered: 8 years ago Posts: 4 |

Quote

msaeger

[The E3D Lite6 I upgraded to does not leak at all not yet anywayIt actually will start putting down material right when the print starts because it all didn't leak out while heating up like the Folger one would. Defiantly was a good upgrade.

What modifications are required to switch over to this hot end?

Does the extra length of the heat sink take away from the vertical printing area?

Edited 2 time(s). Last edit at 11/10/2015 10:52AM by TollBoothWilly.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 10, 2015 11:58AM |

Registered: 8 years ago Posts: 20 |

So.... what a night.

[imgur.com]

I made it all pretty to only plug it back in and 1 Z motor not work. Ordered new parts only to wake up and check the wires on the cable were cut. All fixed.

Auto leveling question.

My bed is 220 x 220 b/c i can use the full bed. (No glass)

I run G0 X0 Y0. I then run G29 for auto leveling. Then sensor goes straight down no matter what I put in

#define LEFT_PROBE_BED_POSITION 33

If I run G28 the sensor is in the middle of the bed. G29 after and it does not go to the corner.

Do you run X0 Y0 or G28 before G29?

hmmmm

[imgur.com]

I made it all pretty to only plug it back in and 1 Z motor not work. Ordered new parts only to wake up and check the wires on the cable were cut. All fixed.

Auto leveling question.

My bed is 220 x 220 b/c i can use the full bed. (No glass)

I run G0 X0 Y0. I then run G29 for auto leveling. Then sensor goes straight down no matter what I put in

#define LEFT_PROBE_BED_POSITION 33

If I run G28 the sensor is in the middle of the bed. G29 after and it does not go to the corner.

Do you run X0 Y0 or G28 before G29?

hmmmm

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 10, 2015 12:11PM |

Registered: 8 years ago Posts: 430 |

Quote

TollBoothWilly

Quote

msaeger

[The E3D Lite6 I upgraded to does not leak at all not yet anywayIt actually will start putting down material right when the print starts because it all didn't leak out while heating up like the Folger one would. Defiantly was a good upgrade.

What modifications are required to switch over to this hot end?

Does the extra length of the heat sink take away from the vertical printing area?

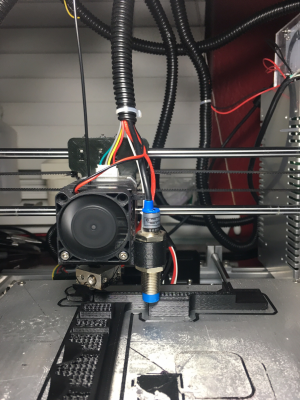

You just need to print the new mounting block. Make sure the mounting block is mode for your extruder version or you will be taking it apart again like me.

I didn't lose any height because I mounted the motor to the Y carriage into the lower holes like animoose suggested.

[moosteria.blogspot.com]

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 10, 2015 01:59PM |

Registered: 8 years ago Posts: 276 |

Quote

Yelloow-Snow

So.... what a night.

[imgur.com]

I made it all pretty to only plug it back in and 1 Z motor not work. Ordered new parts only to wake up and check the wires on the cable were cut. All fixed.

Auto leveling question.

My bed is 220 x 220 b/c i can use the full bed. (No glass)

I run G0 X0 Y0. I then run G29 for auto leveling. Then sensor goes straight down no matter what I put in

#define LEFT_PROBE_BED_POSITION 33

If I run G28 the sensor is in the middle of the bed. G29 after and it does not go to the corner.

Do you run X0 Y0 or G28 before G29?

hmmmm

What does it do after you run G29?

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 10, 2015 06:21PM |

Registered: 8 years ago Posts: 51 |

Quote

Yelloow-Snow

So.... what a night.

[imgur.com]

I made it all pretty to only plug it back in and 1 Z motor not work. Ordered new parts only to wake up and check the wires on the cable were cut. All fixed.

Auto leveling question.

My bed is 220 x 220 b/c i can use the full bed. (No glass)

I run G0 X0 Y0. I then run G29 for auto leveling. Then sensor goes straight down no matter what I put in

#define LEFT_PROBE_BED_POSITION 33

If I run G28 the sensor is in the middle of the bed. G29 after and it does not go to the corner.

Do you run X0 Y0 or G28 before G29?

hmmmm

Any link to the bracket you used for the sensor and also any problems heating a alu bed, I guess your running the stock heater?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 10, 2015 06:33PM |

Registered: 8 years ago Posts: 541 |

Quote

Slaghton

Ah thanks, not sure how I missed those stl's. I downloaded some other batch. I saw your modification. I might have to look into it if it reduces vibration/increases print quality =).

P.S. For people talking about Y axis vibration sound. My plastic bearing holders having their screw holes getting stripped so the bed isn't fastened securely is causing a loud vibration sound. Printing 3 new ones since I can still print pretty good.

The bearing holders take bolts and nuts, not screws. They should have through holes, not threaded holes. There shouldn't be any stripped screw holes.

I found that I had to enlarge the holes in the aluminum plate so that the bearing holders would be in alignment with the chrome rods and not cause binding and premature death to the bearings.

Edited 1 time(s). Last edit at 11/10/2015 06:41PM by tjnamtiw.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 10, 2015 06:37PM |

Registered: 8 years ago Posts: 62 |

Quote

Slaghton

Ah thanks, not sure how I missed those stl's. I downloaded some other batch. I saw your modification. I might have to look into it if it reduces vibration/increases print quality =).

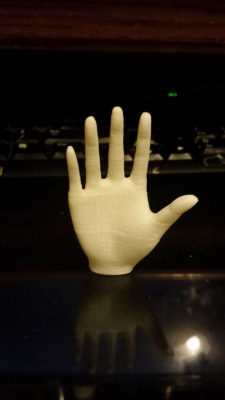

Here's my most recent print even with my heavy vibration for my bearing holders being loose.

(the band artifact was caused by me pressing my finger lightly against a rattling bearing)

P.S. For people talking about Y axis vibration sound. My plastic bearing holders having their screw holes getting stripped so the bed isn't fastened securely is causing a loud vibration sound. Printing 3 new ones since I can still print pretty good.

Nice print!!! I just order two spools of Hatchbox on different colors so I can split my prints on multiple parts and colors!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 10, 2015 07:22PM |

Registered: 8 years ago Posts: 45 |

I feel like I have my prints mirrored. My Y-endstop is a "max" and it is located at 200mm at the back of the printer.

I have found this drawing online, do people agree with this? [www.lincade.org]

Also could you post your lines from Configuration.h where the endstops, direction and invert are defined?

Thanks

I have found this drawing online, do people agree with this? [www.lincade.org]

Also could you post your lines from Configuration.h where the endstops, direction and invert are defined?

Thanks

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 11, 2015 06:08AM |

Registered: 8 years ago Posts: 268 |

Quote

Uncertainty

I feel like I have my prints mirrored. My Y-endstop is a "max" and it is located at 200mm at the back of the printer.

I have found this drawing online, do people agree with this? [www.lincade.org]

Also could you post your lines from Configuration.h where the endstops, direction and invert are defined?

Thanks

The drawing is correct as far as showing the coordinate system, it is not intended (or at least I don't think so) to show travel direction. It does not appear to show the Y endstop correctly. Keep in mind that when the bed is all the way back (hitting the endstop like the drawing) the hotend is actually at the front of the bed, the Y-0 position...so your Y-enstop needs to be set to "min". The arrows are there to show coordinate directions, not travel directions, although they coincidentally show the correct travel direction for both X & Z, that is not the travel direction for Y, it is the Y coordinate direction.

As far as Confg.h, check out "therippa" sig for his Marlin link, he's got it going on and most of us are running some variation of his confg.h setup...

Hope this helps :-)

Edited 1 time(s). Last edit at 11/11/2015 08:27AM by sonnylowe.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 11, 2015 04:20PM |

Registered: 8 years ago Posts: 3 |

Quote

Uncertainty

I feel like I have my prints mirrored. My Y-endstop is a "max" and it is located at 200mm at the back of the printer.

I have found this drawing online, do people agree with this? [www.lincade.org]

Also could you post your lines from Configuration.h where the endstops, direction and invert are defined?

Thanks

If your Y endstop is at the back of your kit then it is in the "min" position. This is because the software is using the position of the hot end as it's reference, not the position of the bed itself (aka moving the bed to the back of the frame brings the hot end to the front of the print area or the min position in this case).

Change your configuration.h file to match below and see if it fixes the mirroring issue:

#define INVERT_Y_DIR true

#define Y_HOME_DIR -1

Also, make sure that your Y endstop is plugged into the correct set of pins for the min position (5th from the left)

In Repetier set your Y home position as min

If your prints are still mirrored after making that change then it is likely the X axis that is inverted. In this case make the following changes:

#define INVERT_X_DIR false

#define X_HOME_DIR 1

Connect the X endstop to the pins for max position (6th from the left)

In Repetier set you X home position as max

I had an issue with inverted prints and the above setup took care of it for me, so let me know if it doesn't work

Edited because I should probably read the post directly above mine before replying (sorry for the duplicate Sonnylowe)

Edited 2 time(s). Last edit at 11/11/2015 04:33PM by Smuggler17.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 11, 2015 05:22PM |

Registered: 8 years ago Posts: 276 |

Is anyone else starting to have problem printing now that the weather is getting colder? It doesn't get very cold in San Francisco, but my printer is right next to a window and I've been having warping/layer separation issues. It may be time to resurrect the idea of building an enclosure...

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 11, 2015 05:28PM |

Registered: 8 years ago Posts: 20 |

Quote

therippa

Is anyone else starting to have problem printing now that the weather is getting colder? It doesn't get very cold in San Francisco, but my printer is right next to a window and I've been having warping/layer separation issues. It may be time to resurrect the idea of building an enclosure...

Nope tho its still warm in Louisiana. that and my large reef tank in the room keeps it hot.

Maybe PID Tuning again when the weather changes?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 11, 2015 05:31PM |

Registered: 8 years ago Posts: 367 |

Quote

therippa

Is anyone else starting to have problem printing now that the weather is getting colder? It doesn't get very cold in San Francisco, but my printer is right next to a window and I've been having warping/layer separation issues. It may be time to resurrect the idea of building an enclosure...

Oddly enough, I have noticed this recently, though I also started a new roll of filament which seems to have some different characteristics to the previous one. I'm in LA and we're definitely starting to feel the brutal Southern California winter kicking in this week.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 11, 2015 07:27PM |

Registered: 8 years ago Posts: 4 |

I am trying to print this thing.

Turtle

On the first layer, there are 14 little circular contact points. I can't seem to get them all to stick to the bed.

I have tried turning up the bed temp and the extruder temp as well as increasing the first layer thickness and width and printing the first layer slower.

I just can't seem to get them to all stick.

Any ideas?

Turtle

On the first layer, there are 14 little circular contact points. I can't seem to get them all to stick to the bed.

I have tried turning up the bed temp and the extruder temp as well as increasing the first layer thickness and width and printing the first layer slower.

I just can't seem to get them to all stick.

Any ideas?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 11, 2015 07:49PM |

Registered: 8 years ago Posts: 276 |

Quote

animoose

Quote

therippa

Is anyone else starting to have problem printing now that the weather is getting colder? It doesn't get very cold in San Francisco, but my printer is right next to a window and I've been having warping/layer separation issues. It may be time to resurrect the idea of building an enclosure...

Oddly enough, I have noticed this recently, though I also started a new roll of filament which seems to have some different characteristics to the previous one. I'm in LA and we're definitely starting to feel the brutal Southern California winter kicking in this week.

Another potential theory is that this spool has been sitting out for a while and it has picked up quite a bit of humidity.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 11, 2015 11:01PM |

Registered: 8 years ago Posts: 45 |

Quote

Smuggler17

Quote

Uncertainty

I feel like I have my prints mirrored. My Y-endstop is a "max" and it is located at 200mm at the back of the printer.

I have found this drawing online, do people agree with this? [www.lincade.org]

Also could you post your lines from Configuration.h where the endstops, direction and invert are defined?

Thanks

If your Y endstop is at the back of your kit then it is in the "min" position. This is because the software is using the position of the hot end as it's reference, not the position of the bed itself (aka moving the bed to the back of the frame brings the hot end to the front of the print area or the min position in this case).

Change your configuration.h file to match below and see if it fixes the mirroring issue:

#define INVERT_Y_DIR true

#define Y_HOME_DIR -1

Also, make sure that your Y endstop is plugged into the correct set of pins for the min position (5th from the left)

In Repetier set your Y home position as min

If your prints are still mirrored after making that change then it is likely the X axis that is inverted. In this case make the following changes:

#define INVERT_X_DIR false

#define X_HOME_DIR 1

Connect the X endstop to the pins for max position (6th from the left)

In Repetier set you X home position as max

I had an issue with inverted prints and the above setup took care of it for me, so let me know if it doesn't work

Edited because I should probably read the post directly above mine before replying (sorry for the duplicate Sonnylowe)

Thank you Smuggler17 & sonnylowe

My problem was that I was so focused on the software that I forgot to change the connector on the RAMPS board lol...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 12, 2015 10:35AM |

Registered: 8 years ago Posts: 268 |

Quote

Uncertainty

Quote

Smuggler17

Quote

Uncertainty

I feel like I have my prints mirrored. My Y-endstop is a "max" and it is located at 200mm at the back of the printer.

I have found this drawing online, do people agree with this? [www.lincade.org]

Also could you post your lines from Configuration.h where the endstops, direction and invert are defined?

Thanks

If your Y endstop is at the back of your kit then it is in the "min" position. This is because the software is using the position of the hot end as it's reference, not the position of the bed itself (aka moving the bed to the back of the frame brings the hot end to the front of the print area or the min position in this case).

Change your configuration.h file to match below and see if it fixes the mirroring issue:

#define INVERT_Y_DIR true

#define Y_HOME_DIR -1

Also, make sure that your Y endstop is plugged into the correct set of pins for the min position (5th from the left)

In Repetier set your Y home position as min

If your prints are still mirrored after making that change then it is likely the X axis that is inverted. In this case make the following changes:

#define INVERT_X_DIR false

#define X_HOME_DIR 1

Connect the X endstop to the pins for max position (6th from the left)

In Repetier set you X home position as max

I had an issue with inverted prints and the above setup took care of it for me, so let me know if it doesn't work

Edited because I should probably read the post directly above mine before replying (sorry for the duplicate Sonnylowe)

Thank you Smuggler17 & sonnylowe

My problem was that I was so focused on the software that I forgot to change the connector on the RAMPS board lol...

Haha, it's always the simple stuff that gets us ;-)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 12, 2015 10:45AM |

Registered: 8 years ago Posts: 430 |

Quote

Yelloow-Snow

Quote

therippa

Is anyone else starting to have problem printing now that the weather is getting colder? It doesn't get very cold in San Francisco, but my printer is right next to a window and I've been having warping/layer separation issues. It may be time to resurrect the idea of building an enclosure...

Nope tho its still warm in Louisiana. that and my large reef tank in the room keeps it hot.

Maybe PID Tuning again when the weather changes?

That was a good idea my stuff wasn't sticking as good so I ran auto tune on the bed again and it's sticking much better.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 12, 2015 11:57AM |

Registered: 8 years ago Posts: 20 |

Quote

msaeger

Quote

Yelloow-Snow

Quote

therippa

Is anyone else starting to have problem printing now that the weather is getting colder? It doesn't get very cold in San Francisco, but my printer is right next to a window and I've been having warping/layer separation issues. It may be time to resurrect the idea of building an enclosure...

Nope tho its still warm in Louisiana. that and my large reef tank in the room keeps it hot.

Maybe PID Tuning again when the weather changes?

That was a good idea my stuff wasn't sticking as good so I ran auto tune on the bed again and it's sticking much better.

Awesome! Maybe run it on the extruder also? :: shrug :: I'm still a noob.

I ordered a new hot end. Going to do Bowden but i want to do something different. I want to mount the extruder right above the hot end on the top rail. Reduce the distance and keep the weight low on the X axis. It will feed it straight down.

hmmm Why hasent anyone else done this?

Also... after hours and hours of work here is my S3D starting script.

I unchecked "Wait for temp to stablize before beginning build" This allows me to auto level with 16 points while the bed is heating up.

Also things to note: I disabled the checkbox "Relative extrusion distances" and "Update firmware configuration"

Still confused why I have to G92 after G29. At the end of G29 it says X is -36 which is the distance of the probe.

G21 ; Units to mm

G90 ; Absolute positioning

M82 ; Use absolute distances for extruder

G92 E0 ; Zero the extruder position

G28 ; Center all Axis

G0 X0 Y13 ; Move to start of auto leveling

G29 ; Auto Leveling

G92 X0 Y210 ;Set the extruder to the actually coordinates. Back left.

M105 ; Read current temp

M190 S110 ; Set bed temp and wait to be reached

M109 S230 ; Set extruder temp and wait to be reached

M105 ; Read current temp

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 12, 2015 12:40PM |

Registered: 8 years ago Posts: 62 |

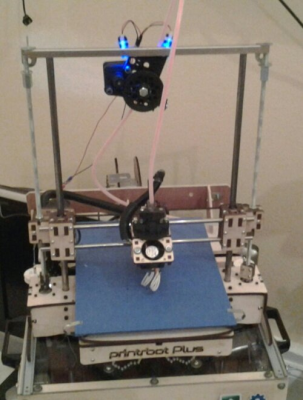

Finally I'm done with the cooling fan!

Not sure if it helps or not but it blows a stream of air to the extruder nozzle, in a theoretical way should help to cool down the PLA that it's just extruded and help to stop the sagging on areas where there is overhanging...

If you are interested I will link the STL file, I tried to print it as one single object but there was too much interference of material support in the inside and was impossible to remove it all clean. So I decide to cut it on half and use some superglue to join it at the end, the screw holes are a little bit small for #4-40 bolts, but with some elbow grease and patience will work (better than loose holes where screws come loose constantly).

ExtruderPLAFan

Not sure if it helps or not but it blows a stream of air to the extruder nozzle, in a theoretical way should help to cool down the PLA that it's just extruded and help to stop the sagging on areas where there is overhanging...

If you are interested I will link the STL file, I tried to print it as one single object but there was too much interference of material support in the inside and was impossible to remove it all clean. So I decide to cut it on half and use some superglue to join it at the end, the screw holes are a little bit small for #4-40 bolts, but with some elbow grease and patience will work (better than loose holes where screws come loose constantly).

ExtruderPLAFan

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 12, 2015 12:57PM |

Registered: 8 years ago Posts: 268 |

Quote

Yelloow-Snow

Quote

msaeger

Quote

Yelloow-Snow

Quote

therippa

Is anyone else starting to have problem printing now that the weather is getting colder? It doesn't get very cold in San Francisco, but my printer is right next to a window and I've been having warping/layer separation issues. It may be time to resurrect the idea of building an enclosure...

Nope tho its still warm in Louisiana. that and my large reef tank in the room keeps it hot.

Maybe PID Tuning again when the weather changes?

That was a good idea my stuff wasn't sticking as good so I ran auto tune on the bed again and it's sticking much better.

Awesome! Maybe run it on the extruder also? :: shrug :: I'm still a noob.

I ordered a new hot end. Going to do Bowden but i want to do something different. I want to mount the extruder right above the hot end on the top rail. Reduce the distance and keep the weight low on the X axis. It will feed it straight down.

hmmm Why hasent anyone else done this?

Also... after hours and hours of work here is my S3D starting script.

I unchecked "Wait for temp to stablize before beginning build" This allows me to auto level with 16 points while the bed is heating up.

Also things to note: I disabled the checkbox "Relative extrusion distances" and "Update firmware configuration"

Still confused why I have to G92 after G29. At the end of G29 it says X is -36 which is the distance of the probe.

G21 ; Units to mm

G90 ; Absolute positioning

M82 ; Use absolute distances for extruder

G92 E0 ; Zero the extruder position

G28 ; Center all Axis

G0 X0 Y13 ; Move to start of auto leveling

G29 ; Auto Leveling

G92 X0 Y210 ;Set the extruder to the actually coordinates. Back left.

M105 ; Read current temp

M190 S110 ; Set bed temp and wait to be reached

M109 S230 ; Set extruder temp and wait to be reached

M105 ; Read current temp

Thanks for the S3D info, I am about to make that purchase so any and all advice is welcome :-)

As far as the Bowden directly above the hotend on the rail, I've actually thought of that as well, but I'm not sure it will work. It works with the filament roll there because the filament can lengthen and shorten as the X-Axis raises and the hotend move left to right. The Bowden tube will not do that and would most likely bind as the X-Axis moves. Maybe if you built a loop into the tube it would allow for the flexibility required to move with the X carriage, but that seems to defeat the purpose of that location!?!?

I'd like to hear more about this...like I said, I thought about it but quickly dismissed it...

Sonny

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 12, 2015 01:02PM |

Registered: 8 years ago Posts: 20 |

Quote

sonnylowe

Quote

Yelloow-Snow

Quote

msaeger

Quote

Yelloow-Snow

Quote

therippa

Is anyone else starting to have problem printing now that the weather is getting colder? It doesn't get very cold in San Francisco, but my printer is right next to a window and I've been having warping/layer separation issues. It may be time to resurrect the idea of building an enclosure...

Nope tho its still warm in Louisiana. that and my large reef tank in the room keeps it hot.

Maybe PID Tuning again when the weather changes?

That was a good idea my stuff wasn't sticking as good so I ran auto tune on the bed again and it's sticking much better.

Awesome! Maybe run it on the extruder also? :: shrug :: I'm still a noob.

I ordered a new hot end. Going to do Bowden but i want to do something different. I want to mount the extruder right above the hot end on the top rail. Reduce the distance and keep the weight low on the X axis. It will feed it straight down.

hmmm Why hasent anyone else done this?

Also... after hours and hours of work here is my S3D starting script.

I unchecked "Wait for temp to stablize before beginning build" This allows me to auto level with 16 points while the bed is heating up.

Also things to note: I disabled the checkbox "Relative extrusion distances" and "Update firmware configuration"

Still confused why I have to G92 after G29. At the end of G29 it says X is -36 which is the distance of the probe.

G21 ; Units to mm

G90 ; Absolute positioning

M82 ; Use absolute distances for extruder

G92 E0 ; Zero the extruder position

G28 ; Center all Axis

G0 X0 Y13 ; Move to start of auto leveling

G29 ; Auto Leveling

G92 X0 Y210 ;Set the extruder to the actually coordinates. Back left.

M105 ; Read current temp

M190 S110 ; Set bed temp and wait to be reached

M109 S230 ; Set extruder temp and wait to be reached

M105 ; Read current temp

Thanks for the S3D info, I am about to make that purchase so any and all advice is welcome :-)

As far as the Bowden directly above the hotend on the rail, I've actually thought of that as well, but I'm not sure it will work. It works with the filament roll there because the filament can lengthen and shorten as the X-Axis raises and the hotend move left to right. The Bowden tube will not do that and would most likely bind as the X-Axis moves. Maybe if you built a loop into the tube it would allow for the flexibility required to move with the X carriage, but that seems to defeat the purpose of that location!?!?

I'd like to hear more about this...like I said, I thought about it but quickly dismissed it...

Sonny

I have been told to check out Meshmixer and Mattercontrol. Those 2 combined can work just as good as S3D. Thats just what I was told. Might as well check it out b/c its free.

Also S3D allows you to install it on 2 computers so you can find someone to split the cost. My dad bought it so I used his other licenses.

There are still a few features in S3D I wish it had. Its ok to me. Sure everyone says it slices perfectly and fast but im a noob and haven't really tested it.

Edited 1 time(s). Last edit at 11/12/2015 01:03PM by Yelloow-Snow.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 12, 2015 01:07PM |

Registered: 8 years ago Posts: 268 |

Quote

Yelloow-Snow

Quote

sonnylowe

Quote

Yelloow-Snow

Quote

msaeger

Quote

Yelloow-Snow

Quote

therippa

Is anyone else starting to have problem printing now that the weather is getting colder? It doesn't get very cold in San Francisco, but my printer is right next to a window and I've been having warping/layer separation issues. It may be time to resurrect the idea of building an enclosure...

Nope tho its still warm in Louisiana. that and my large reef tank in the room keeps it hot.

Maybe PID Tuning again when the weather changes?

That was a good idea my stuff wasn't sticking as good so I ran auto tune on the bed again and it's sticking much better.

Awesome! Maybe run it on the extruder also? :: shrug :: I'm still a noob.

I ordered a new hot end. Going to do Bowden but i want to do something different. I want to mount the extruder right above the hot end on the top rail. Reduce the distance and keep the weight low on the X axis. It will feed it straight down.

hmmm Why hasent anyone else done this?

Also... after hours and hours of work here is my S3D starting script.

I unchecked "Wait for temp to stablize before beginning build" This allows me to auto level with 16 points while the bed is heating up.

Also things to note: I disabled the checkbox "Relative extrusion distances" and "Update firmware configuration"

Still confused why I have to G92 after G29. At the end of G29 it says X is -36 which is the distance of the probe.

G21 ; Units to mm

G90 ; Absolute positioning

M82 ; Use absolute distances for extruder

G92 E0 ; Zero the extruder position

G28 ; Center all Axis

G0 X0 Y13 ; Move to start of auto leveling

G29 ; Auto Leveling

G92 X0 Y210 ;Set the extruder to the actually coordinates. Back left.

M105 ; Read current temp

M190 S110 ; Set bed temp and wait to be reached

M109 S230 ; Set extruder temp and wait to be reached

M105 ; Read current temp

Thanks for the S3D info, I am about to make that purchase so any and all advice is welcome :-)

As far as the Bowden directly above the hotend on the rail, I've actually thought of that as well, but I'm not sure it will work. It works with the filament roll there because the filament can lengthen and shorten as the X-Axis raises and the hotend move left to right. The Bowden tube will not do that and would most likely bind as the X-Axis moves. Maybe if you built a loop into the tube it would allow for the flexibility required to move with the X carriage, but that seems to defeat the purpose of that location!?!?

I'd like to hear more about this...like I said, I thought about it but quickly dismissed it...

Sonny

I have been told to check out Meshmixer and Mattercontrol. Those 2 combined can work just as good as S3D. Thats just what I was told. Might as well check it out b/c its free.

Also S3D allows you to install it on 2 computers so you can find someone to split the cost. My dad bought it so I used his other licenses.

There are still a few features in S3D I wish it had. Its ok to me. Sure everyone says it slices perfectly and fast but im a noob and haven't really tested it.

Yeah, I thought about sharing it as well, I have a coworker that has a printer but can't seem to get him on board ;-) It would definitely be worth looking at the other software's as well...free is always good!!!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 12, 2015 01:48PM |

Registered: 8 years ago Posts: 276 |

Quote

Yelloow-Snow

I ordered a new hot end. Going to do Bowden but i want to do something different. I want to mount the extruder right above the hot end on the top rail. Reduce the distance and keep the weight low on the X axis. It will feed it straight down.

hmmm Why hasent anyone else done this?

Also... after hours and hours of work here is my S3D starting script.

I unchecked "Wait for temp to stablize before beginning build" This allows me to auto level with 16 points while the bed is heating up.

You want the bowden cable to be long enough to comfortable flex as it goes side-to-side. I think mounting it on the top rail would cause feeding/buckling issues.

...and I like this temp stabilization change you've made, but my immediate though would be that the bed expands a little heating up, so the autolevel might be a little off by the time it's ready to go.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 12, 2015 02:24PM |

Registered: 8 years ago Posts: 20 |

Quote

therippa

Quote

Yelloow-Snow

I ordered a new hot end. Going to do Bowden but i want to do something different. I want to mount the extruder right above the hot end on the top rail. Reduce the distance and keep the weight low on the X axis. It will feed it straight down.

hmmm Why hasent anyone else done this?

Also... after hours and hours of work here is my S3D starting script.

I unchecked "Wait for temp to stablize before beginning build" This allows me to auto level with 16 points while the bed is heating up.

You want the bowden cable to be long enough to comfortable flex as it goes side-to-side. I think mounting it on the top rail would cause feeding/buckling issues.

...and I like this temp stabilization change you've made, but my immediate though would be that the bed expands a little heating up, so the autolevel might be a little off by the time it's ready to go.

I'll start off like this. I'll make something where I can keep rotating the angle of it until its vertically over the hot end.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 12, 2015 02:46PM |

Registered: 8 years ago Posts: 10 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 12, 2015 07:36PM |

Registered: 8 years ago Posts: 51 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 12, 2015 09:47PM |

Registered: 8 years ago Posts: 430 |

Quote

Yelloow-Snow

Quote

msaeger

Quote

Yelloow-Snow

Quote

therippa

Is anyone else starting to have problem printing now that the weather is getting colder? It doesn't get very cold in San Francisco, but my printer is right next to a window and I've been having warping/layer separation issues. It may be time to resurrect the idea of building an enclosure...

Nope tho its still warm in Louisiana. that and my large reef tank in the room keeps it hot.

Maybe PID Tuning again when the weather changes?

That was a good idea my stuff wasn't sticking as good so I ran auto tune on the bed again and it's sticking much better.

Awesome! Maybe run it on the extruder also? :: shrug :: I'm still a noob.

I ordered a new hot end. Going to do Bowden but i want to do something different. I want to mount the extruder right above the hot end on the top rail. Reduce the distance and keep the weight low on the X axis. It will feed it straight down.

hmmm Why hasent anyone else done this?

Also... after hours and hours of work here is my S3D starting script.

I unchecked "Wait for temp to stablize before beginning build" This allows me to auto level with 16 points while the bed is heating up.

Also things to note: I disabled the checkbox "Relative extrusion distances" and "Update firmware configuration"

Still confused why I have to G92 after G29. At the end of G29 it says X is -36 which is the distance of the probe.

G21 ; Units to mm

G90 ; Absolute positioning

M82 ; Use absolute distances for extruder

G92 E0 ; Zero the extruder position

G28 ; Center all Axis

G0 X0 Y13 ; Move to start of auto leveling

G29 ; Auto Leveling

G92 X0 Y210 ;Set the extruder to the actually coordinates. Back left.

M105 ; Read current temp

M190 S110 ; Set bed temp and wait to be reached

M109 S230 ; Set extruder temp and wait to be reached

M105 ; Read current temp

I got that aluminum bed plate like you have in the pictures but haven't installed it yet. Are you putting anything on it to get the print to stick? I was planning to still have the glass on there because I am thinking it would be hard to clean the glue or whatever off with it attached to the printer.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 12, 2015 10:26PM |

Registered: 8 years ago Posts: 20 |

Quote

msaeger

I got that aluminum bed plate like you have in the pictures but haven't installed it yet. Are you putting anything on it to get the print to stick? I was planning to still have the glass on there because I am thinking it would be hard to clean the glue or whatever off with it attached to the printer.

Glass is best if you dont have an inductive sensor. If you use the sensor for auto leveling you cant use glass.

I use gluestick. I don't wipe it off. it sticks so crazy I have issues removing it.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 12, 2015 10:49PM |

Registered: 8 years ago Posts: 430 |

Quote

Yelloow-Snow

Quote

msaeger

I got that aluminum bed plate like you have in the pictures but haven't installed it yet. Are you putting anything on it to get the print to stick? I was planning to still have the glass on there because I am thinking it would be hard to clean the glue or whatever off with it attached to the printer.

Glass is best if you dont have an inductive sensor. If you use the sensor for auto leveling you cant use glass.

I use gluestick. I don't wipe it off. it sticks so crazy I have issues removing it.

I am using watered down elmers applied with a brush and I take the glass to the sink to wash it off once and a while. I think after I put on a few layers it starts to get uneven. So the inductive sensor won't read through the glass?

Newbie with Folgertech 2020 i3.

Sorry, only registered users may post in this forum.