Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 01:26AM |

Registered: 8 years ago Posts: 20 |

I'm thinking about converting my printer into a CoreXY

[www.mcmaster.com]

Who wants to go first? therippa? animoose? haha

[www.google.com]

Unlimited weight on the X axis!

[www.mcmaster.com]

Who wants to go first? therippa? animoose? haha

[www.google.com]

Unlimited weight on the X axis!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 01:59AM |

Registered: 8 years ago Posts: 276 |

I hereby rescind any recommendation I may have made for the igus drylin bearings.

I ran into two problems:

2/10 would not use again.

Edited 1 time(s). Last edit at 11/20/2015 01:59AM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

I ran into two problems:

- The X-axis was (just) tight enough that it skipped a step during a print. I wasn't expecting this not to happen at some point because the drylin bearings need a little more oomph to get moving, and all it took was upping the voltage to fix, but in retrospect it shows an underlying problem.

- Serious y-axis vibrations. Upon research tonight, other people have experienced this too (https://www.youtube.com/watch?v=h2u34zXZj_k). At first I thought it might have been due to removing a very stuck-on print (possibly bending a chrome rod slightly, compressing the drylin too much, or messing up the y-axis bearing mounts, in which case, I hope one of you wonderful people would be willing to print me a new set and mail them out to me if I paypal'd you a few bucks), but I have a set of brand new high-quality LM8UU bearings arriving tomorrow and I will at least be replacing them on the y-axis and hoping for the best.

2/10 would not use again.

Edited 1 time(s). Last edit at 11/20/2015 01:59AM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 03:18AM |

Registered: 8 years ago Posts: 276 |

Quote

Yelloow-Snow

I'm thinking about converting my printer into a CoreXY

[www.mcmaster.com]

Who wants to go first? therippa? animoose? haha

[www.google.com]

Unlimited weight on the X axis!

It's funny you mention this. The latest issue of Make Magazine was delivered to me yesterday, and the entire issues is literally (in the proper sense) dedicated to 3d printers (both FFF and SLA), filament, laser cutters, CNC machines, etc. I saw the Fusion3 F306 while flipping through the pages, mesmerized on the crapper, and my first though was "...if I had a cube frame of 2020 rails, building an enclosure would be easy and cheaper than having wood laser cut for a folgertech enclosure (I have a design for a simple enclosure for the folgertech, but the local laser cutter wants roughly $300 for it)". Screw that. I'm about to embark on building my third quadcopter, a 180-class racer, and maybe after that I'll tackle framing this thing.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 09:48AM |

Registered: 8 years ago Posts: 268 |

Quote

Yelloow-Snow

I'm thinking about converting my printer into a CoreXY

[www.mcmaster.com]

Who wants to go first? therippa? animoose? haha

[www.google.com]

Unlimited weight on the X axis!

I love the C-Bot...thoughts of building one have run through my mind often. I also love the Open Builds "OB" site, so many great ideas, and having all the parts readily available at their store is a huge bonus. I've done a little price comparison and their stuff seems reasonable!?!?

Open Builds

Open Build Store

I'm not worried about the X-axis strength (I only run the Cyclops HotEnd on X), but I'm tired of the crappy linear bearings, the noise, the slop, the vibration and everything else bad that goes along with them, I know their cheap, but they're also a pain, and basically junk. I switched over to Igus bearings, but they have their own issues as well (see therippa's post). I really like the V-Slot design, and the eccentric spacers which allow adjustment in the bearings (to take out the slop).

So I'm working on a couple redesigns of my own using the OB stuff. I started with the Y-Carriage as it gives me the most noise, slop and vibration...if this goes well I'll do X and then Z later down the road.

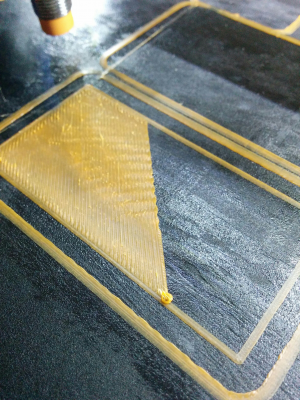

Here is Version-1 of the Y-Carriage.

This will be the most costly, but I believe the most sturdy as well and easiest to setup. I have two other designs in mind, both less expensive, and both a bit more traditional. I have used the bare minimum parts for OB and decides to print as much as possible. I just started the project but I do have the parts from OB so I hope to update the project over the weekend with actual photos and video of the prototype.

Sonny

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 10:01AM |

Registered: 8 years ago Posts: 268 |

Quote

twigtree

Does anybody knew where I can get some replacement set screws for the hotend? Or at least what size they are?

Thanks

I got 3 x 4mm set screws at Hobby Town USA. Not sure that's the size you need, but it's a good place to find small metric screws and such locally. If you need SHCS, Bolts, Screws, nuts Etc, Home Depot sells metric hardware done to 2mm diameter. They are a bit pricey (still less than the hobby shop) but if you have a HD close its well worth it....

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 10:25AM |

Registered: 8 years ago Posts: 268 |

Is there anyway to speed up the auto-leveling process ? My bed is not flat, it runs out about .010" (.254mm) in the center which is causing problems on larger prints. I leveled my bed with a travel indicator and the four corners are within .002". I can adjust the probe grid size (make it small and in the middle) and that works great for small prints, but again does not for larger ones.

So I want to go to a 3 grid probe process to see if that helps, but damn, that takes over 3 minutes to run (not including G28). I know that's not a long time, but I've seen other printers running the inductive probe that are both moving faster and not traveling up as high on the second probe. If the 3 grids helps I can live with the extra time, but it would be nice to speed this up if I could keep the accuracy...thoughts!?!?

So I want to go to a 3 grid probe process to see if that helps, but damn, that takes over 3 minutes to run (not including G28). I know that's not a long time, but I've seen other printers running the inductive probe that are both moving faster and not traveling up as high on the second probe. If the 3 grids helps I can live with the extra time, but it would be nice to speed this up if I could keep the accuracy...thoughts!?!?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 10:28AM |

Registered: 8 years ago Posts: 541 |

Quote

sonnylowe

Quote

twigtree

Does anybody knew where I can get some replacement set screws for the hotend? Or at least what size they are?

Thanks

I got 3 x 4mm set screws at Hobby Town USA. Not sure that's the size you need, but it's a good place to find small metric screws and such locally. If you need SHCS, Bolts, Screws, nuts Etc, Home Depot sells metric hardware done to 2mm diameter. They are a bit pricey (still less than the hobby shop) but if you have a HD close its well worth it....

My Home Depot doesn't go below 4mm! I went through every drawer and came away totally frustrated. And Small Parts is no more. Just a branch of Amazon that is p@#$ poor by comparison.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 10:36AM |

Registered: 8 years ago Posts: 1 |

Hello Everyone,

I've been stalking this thread for a while but finally have need to ask a few things specifically.

Last weekend I took the plunge and started my Folger 2020 i3. Took me pretty much all day Sat. to assemble and then all day Sunday to calibrate correctly. End results started looking really good and I started printing the typical random crap just to get the hang of 3D printing (kudos to MakerGeeks for sending me 2x the cheapo filament I ordered to test with). Along the way I've run into a few things I was hoping you experienced guys might be able to help me with.

I've noticed that my Z threaded rods have a serious bend to them towards the top of the Z axis, causing enough friction to throw my X alignment off when it gets close to the top. It looks like this is either insufficient spacing between the threaded and smooth rods on the acrylic Z motor mounts, or maybe on the printed X ends. I can't tell which it is.

After having a look at the i3 reworks available, I was thinking that setup might solve this issue, however I don't see how I could make the rework (Z steppers on bottom) work with the aluminium channel frame.Has anyone made this conversion with the metal Folger frame?

I would also like to upgrade to auto-Z homing (I prefer this term to bed leveling, cause......well.....that's not really what it does). I have everything I need to make the servo based sensor, but I like the idea of the proximity sensor a little more. The only thing that bothers me about it is the sensor sticking out the whole time its printing, which may lead to unwanted sensor-plastic collisions. Would love to get some advice from people who have done both if possible.

Thank you all for everything you've done for me thus far, even if this is my first post, I've been reading about your exploits for months which basically allowed me to build the thing in the first place. Couldn't have done it without you

I've been stalking this thread for a while but finally have need to ask a few things specifically.

Last weekend I took the plunge and started my Folger 2020 i3. Took me pretty much all day Sat. to assemble and then all day Sunday to calibrate correctly. End results started looking really good and I started printing the typical random crap just to get the hang of 3D printing (kudos to MakerGeeks for sending me 2x the cheapo filament I ordered to test with). Along the way I've run into a few things I was hoping you experienced guys might be able to help me with.

I've noticed that my Z threaded rods have a serious bend to them towards the top of the Z axis, causing enough friction to throw my X alignment off when it gets close to the top. It looks like this is either insufficient spacing between the threaded and smooth rods on the acrylic Z motor mounts, or maybe on the printed X ends. I can't tell which it is.

After having a look at the i3 reworks available, I was thinking that setup might solve this issue, however I don't see how I could make the rework (Z steppers on bottom) work with the aluminium channel frame.Has anyone made this conversion with the metal Folger frame?

I would also like to upgrade to auto-Z homing (I prefer this term to bed leveling, cause......well.....that's not really what it does). I have everything I need to make the servo based sensor, but I like the idea of the proximity sensor a little more. The only thing that bothers me about it is the sensor sticking out the whole time its printing, which may lead to unwanted sensor-plastic collisions. Would love to get some advice from people who have done both if possible.

Thank you all for everything you've done for me thus far, even if this is my first post, I've been reading about your exploits for months which basically allowed me to build the thing in the first place. Couldn't have done it without you

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 10:57AM |

Registered: 8 years ago Posts: 3 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 11:33AM |

Registered: 8 years ago Posts: 5 |

Hi I have the folger tech prusa I3 and I am getting some wavy lines in my prints. I have read that other people switched to cura so last night I tried it. I was wondering if anyone has some setitng they can share with more for using cura with this printer. Also when I hit usb print in cura the little that that alows me to move the axises and change the heat does not come up. The only thing that coms up is a little window showing you the print progress. Can any one help me with this.

Thanks

Thanks

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 11:57AM |

Registered: 8 years ago Posts: 268 |

Quote

tjnamtiw

Quote

sonnylowe

Quote

twigtree

Does anybody knew where I can get some replacement set screws for the hotend? Or at least what size they are?

Thanks

I got 3 x 4mm set screws at Hobby Town USA. Not sure that's the size you need, but it's a good place to find small metric screws and such locally. If you need SHCS, Bolts, Screws, nuts Etc, Home Depot sells metric hardware done to 2mm diameter. They are a bit pricey (still less than the hobby shop) but if you have a HD close its well worth it....

My Home Depot doesn't go below 4mm! I went through every drawer and came away totally frustrated. And Small Parts is no more. Just a branch of Amazon that is p@#$ poor by comparison.

That sucks, ours does go down to 2mm and has a huge variety to choose from...I assume different stores stock items based on what they can (or think) sells!?!?

Edited 1 time(s). Last edit at 11/20/2015 12:15PM by sonnylowe.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 12:12PM |

Registered: 8 years ago Posts: 268 |

Quote

kebauc

If you need screws, skip the big box guys. Find an Ace Hardware or True Value. After going there, you will declare the prices at HD a ripoff.

Hmmm, I found it quite the opposite, I can usually get 3-4 screws in a small pack at HD for price I pay for one screw at our local Ace. It's the only thing I dislike about shopping at Ace, my store only sells the small metric screws in singles, it gets expensive when you need a half dozen or so. Either way they are both places I shop, usually if I can't find them at one, I can find them at the other...

Another option is to buy a large (50) pack of long (30mm) screws from McMaster-Carr (~$6.00) then use a screw cutter to cut them down to the length you need. It's not necessarily cheaper but I find this comes in handy especial when you need an odd length screw...or when you don't want to run out to buy one or two screws.

Edited 1 time(s). Last edit at 11/20/2015 12:36PM by sonnylowe.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 01:30PM |

Registered: 8 years ago Posts: 276 |

Quote

sonnylowe

Is there anyway to speed up the auto-leveling process ? My bed is not flat, it runs out about .010" (.254mm) in the center which is causing problems on larger prints. I leveled my bed with a travel indicator and the four corners are within .002". I can adjust the probe grid size (make it small and in the middle) and that works great for small prints, but again does not for larger ones.

So I want to go to a 3 grid probe process to see if that helps, but damn, that takes over 3 minutes to run (not including G28). I know that's not a long time, but I've seen other printers running the inductive probe that are both moving faster and not traveling up as high on the second probe. If the 3 grids helps I can live with the extra time, but it would be nice to speed this up if I could keep the accuracy...thoughts!?!?

3 minutes? That's especially long, and unusual. You can bump XY_TRAVEL_SPEED up in the autolevel section (I have mine at 8000), and you can use these speed settings under mechanical (I bumped up the speed recently and haven't suffered any negative effects)

#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,400,152.25} // default steps per unit for Ultimaker

#define DEFAULT_MAX_FEEDRATE {300, 300, 5, 25} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {1000,1000,5,1000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for Skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 500 // X, Y, Z and E acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 500 // E acceleration in mm/s^2 for retracts

#define DEFAULT_TRAVEL_ACCELERATION 500 // X, Y, Z acceleration in mm/s^2 for travel (non printing) moves

make sure to adjust the extruder steps per unit to whatever your extruder needs.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 01:34PM |

Registered: 8 years ago Posts: 276 |

Quote

WadeWatts

Hello Everyone,

I've been stalking this thread for a while but finally have need to ask a few things specifically.

Last weekend I took the plunge and started my Folger 2020 i3. Took me pretty much all day Sat. to assemble and then all day Sunday to calibrate correctly. End results started looking really good and I started printing the typical random crap just to get the hang of 3D printing (kudos to MakerGeeks for sending me 2x the cheapo filament I ordered to test with). Along the way I've run into a few things I was hoping you experienced guys might be able to help me with.

I've noticed that my Z threaded rods have a serious bend to them towards the top of the Z axis, causing enough friction to throw my X alignment off when it gets close to the top. It looks like this is either insufficient spacing between the threaded and smooth rods on the acrylic Z motor mounts, or maybe on the printed X ends. I can't tell which it is.

After having a look at the i3 reworks available, I was thinking that setup might solve this issue, however I don't see how I could make the rework (Z steppers on bottom) work with the aluminium channel frame.Has anyone made this conversion with the metal Folger frame?

I would also like to upgrade to auto-Z homing (I prefer this term to bed leveling, cause......well.....that's not really what it does). I have everything I need to make the servo based sensor, but I like the idea of the proximity sensor a little more. The only thing that bothers me about it is the sensor sticking out the whole time its printing, which may lead to unwanted sensor-plastic collisions. Would love to get some advice from people who have done both if possible.

Thank you all for everything you've done for me thus far, even if this is my first post, I've been reading about your exploits for months which basically allowed me to build the thing in the first place. Couldn't have done it without you

For the z-axis issue, your motors need to be realigned.

For the proximity sensor question: the sensor sits a millimeter or two above the nozzle plane, so it will never run into what's printing.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 01:38PM |

Registered: 8 years ago Posts: 268 |

Quote

therippa

Quote

sonnylowe

Is there anyway to speed up the auto-leveling process ? My bed is not flat, it runs out about .010" (.254mm) in the center which is causing problems on larger prints. I leveled my bed with a travel indicator and the four corners are within .002". I can adjust the probe grid size (make it small and in the middle) and that works great for small prints, but again does not for larger ones.

So I want to go to a 3 grid probe process to see if that helps, but damn, that takes over 3 minutes to run (not including G28). I know that's not a long time, but I've seen other printers running the inductive probe that are both moving faster and not traveling up as high on the second probe. If the 3 grids helps I can live with the extra time, but it would be nice to speed this up if I could keep the accuracy...thoughts!?!?

3 minutes? That's especially long, and unusual. You can bump XY_TRAVEL_SPEED up in the autolevel section (I have mine at 8000), and you can use these speed settings under mechanical (I bumped up the speed recently and haven't suffered any negative effects)

#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,400,152.25} // default steps per unit for Ultimaker

#define DEFAULT_MAX_FEEDRATE {300, 300, 5, 25} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {1000,1000,5,1000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for Skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 500 // X, Y, Z and E acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 500 // E acceleration in mm/s^2 for retracts

#define DEFAULT_TRAVEL_ACCELERATION 500 // X, Y, Z acceleration in mm/s^2 for travel (non printing) moves

make sure to adjust the extruder steps per unit to whatever your extruder needs.

I'll give it a shot...as always, Thanks!!!

Edit:

I just checked my settings, all of mine are the same as your with this exception...

#define DEFAULT_MAX_FEEDRATE {250, 250, 2, 22} // (mm/sec)

I think the slowest part of the auto-leveling is the second probe down in Z so I'm hoping changing from 2 to 5 will help!?!?

I'm in the middle of a print but I'll post my results as soon as I get a chance to update the firmware...thanks again!!!

Edited 1 time(s). Last edit at 11/20/2015 02:03PM by sonnylowe.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 04:56PM |

Registered: 8 years ago Posts: 367 |

Quote

Yelloow-Snow

I'm thinking about converting my printer into a CoreXY

[www.mcmaster.com]

Who wants to go first? therippa? animoose? haha

[www.google.com]

Unlimited weight on the X axis!

I admit I have thought about what to do next, and this is an option, but I think I'm probably going to spend more time in developing CAD skills for a bit. (Well, that and playing Sunless Sea.)

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 04:57PM |

Registered: 8 years ago Posts: 367 |

Quote

sonnylowe

Quote

twigtree

Does anybody knew where I can get some replacement set screws for the hotend? Or at least what size they are?

Thanks

I got 3 x 4mm set screws at Hobby Town USA. Not sure that's the size you need, but it's a good place to find small metric screws and such locally. If you need SHCS, Bolts, Screws, nuts Etc, Home Depot sells metric hardware done to 2mm diameter. They are a bit pricey (still less than the hobby shop) but if you have a HD close its well worth it....

I've not checked to see if they have what you want, but I like these guys: [www.boltdepot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 08:01PM |

Registered: 8 years ago Posts: 268 |

Quote

animoose

Quote

sonnylowe

Quote

twigtree

Does anybody knew where I can get some replacement set screws for the hotend? Or at least what size they are?

Thanks

I got 3 x 4mm set screws at Hobby Town USA. Not sure that's the size you need, but it's a good place to find small metric screws and such locally. If you need SHCS, Bolts, Screws, nuts Etc, Home Depot sells metric hardware done to 2mm diameter. They are a bit pricey (still less than the hobby shop) but if you have a HD close its well worth it....

I've not checked to see if they have what you want, but I like these guys: [www.boltdepot.com].

They do look really promising, I like the assortments they offer...I'll have to take a closer look

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 08:30PM |

Registered: 8 years ago Posts: 430 |

Quote

sonnylowe

Quote

Yelloow-Snow

Here is Version-1 of the Y-Carriage.

This will be the most costly, but I believe the most sturdy as well and easiest to setup. I have two other designs in mind, both less expensive, and both a bit more traditional. I have used the bare minimum parts for OB and decides to print as much as possible. I just started the project but I do have the parts from OB so I hope to update the project over the weekend with actual photos and video of the prototype. M

Sonny

I'm waiting are you done yet :-) That looks like a good idea how much did the parts cost?

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 20, 2015 08:37PM |

Registered: 8 years ago Posts: 430 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 21, 2015 03:28AM |

Registered: 8 years ago Posts: 276 |

Replaced the igus drylin's today on the y-axis with some LM8UU's I got off Amazon... that grinding noise of shitty bearings. I just invested in some very high quality ones - [us.misumi-ec.com]

Can't wait to get them on, I'm tired of dealing with this nonsense :-/

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

Can't wait to get them on, I'm tired of dealing with this nonsense :-/

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 21, 2015 04:12PM |

Registered: 8 years ago Posts: 268 |

Quote

msaeger

Quote

sonnylowe

Quote

Yelloow-Snow

Here is Version-1 of the Y-Carriage.

This will be the most costly, but I believe the most sturdy as well and easiest to setup. I have two other designs in mind, both less expensive, and both a bit more traditional. I have used the bare minimum parts for OB and decides to print as much as possible. I just started the project but I do have the parts from OB so I hope to update the project over the weekend with actual photos and video of the prototype. M

Sonny

I'm waiting are you done yet :-) That looks like a good idea how much did the parts cost?

Haha, I guess I need to tighten up ;-)

I got it all assembled, and it runs soooooo smooth. I'm printing corner bracket and I'm waiting on some T-Nuts to arrive (they'll be here Monday). I might print some temporary T-nuts so I can install it this weekend to so how well it works!?!? I am very happy with the outcome and testing so far

My total cost for parts was ~$55.00 shipped. You can save a little by buying the V-Slot Gantry Set, but only a couple bucks. As far as assembly this is all bolt together, easy to align and again, oh so smooth.

Here are a few of the actual build PHOTOS I'll detail them once uploaded to Openbuilds...

Here's a VIDEO of it running a G28 command. I had the Y-Carriage temporarily wired into the printer to run the test, so you can hear the other steppers running in the background.

BTW: The Heated Bed will attach to the top of the gantry via a couple brackets I also need to print...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 21, 2015 05:11PM |

Registered: 8 years ago Posts: 541 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 21, 2015 08:19PM |

Registered: 8 years ago Posts: 430 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 21, 2015 08:32PM |

Registered: 8 years ago Posts: 268 |

Quote

tjnamtiw

Now THAT'S the way to build the axes! Not these rods that can be so easily misaligned by the 'mechanically challenged' with cheapo linear bearings rattling along them. I can't wait for THAT kit to come to market!

Thanks, I think it's a much better setup, and I hope will be well worth the investment. As far as a Kit, I'll have all the hardware/parts detailed in my Openbuilds page, I'll also upload all the STL files, Soldiworks files and step files (for those that want to play more).

It is very easy to assemble and requires no special tools. The only thing that would require any cutting would be the 2080 rail. I had to buy a 500mm piece and do plan to cut it down once I decide it's final placement. I also wondered if anyone sells a 200 x 300 heated bed...if so this rig might be able increase the Y travel to 300 or so

Hopefully I can spend some of my day tomorrow updating the Openbuilds Page...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 21, 2015 08:49PM |

Registered: 8 years ago Posts: 268 |

Quote

msaeger

Should be much smoother than the rods and bearings. Are you planning on doing the X axis too? I have seen V-slot X axis on thingiverse.

Yes, that is the plan. I picked out most of the hardware for the X-Axis today and just need to decide on a mounting options. It should be another $50.00 or so with shipping. I think that's going to be the average cost to setup any of these rail systems!?!? Not too bad considering the cost of good quality linear bearings, and you're still stuff with those flimsy rods...

I'll most likely use my current Z setup (I have lead screws installed already) but need to keep the possibility of upgrading it in mind. It would be nice for this to be straight bolt in like the Y-Carriage with only a few new printed parts required...I think that's doable. I just need to give it some further thought.

I also scoured thingi today looking at all sorts of V-Slot and Openbuilds stuff...so many great ideas!!! I'll be sticking to the aluminum gantry plates though, I think you need them for a really good bearing mount!?!? I'll design and print whatever adapter I need for the Cyclops

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 21, 2015 10:14PM |

Registered: 8 years ago Posts: 430 |

There are PCB heat beds in many sizes. I think you can get those silicone ones in any size you want.

[www.ebay.com]

Edited 1 time(s). Last edit at 11/21/2015 10:16PM by msaeger.

Newbie with Folgertech 2020 i3.

[www.ebay.com]

Edited 1 time(s). Last edit at 11/21/2015 10:16PM by msaeger.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 21, 2015 11:43PM |

Registered: 8 years ago Posts: 276 |

Quote

sonnylowe

Quote

msaeger

Should be much smoother than the rods and bearings. Are you planning on doing the X axis too? I have seen V-slot X axis on thingiverse.

Yes, that is the plan. I picked out most of the hardware for the X-Axis today and just need to decide on a mounting options. It should be another $50.00 or so with shipping. I think that's going to be the average cost to setup any of these rail systems!?!? Not too bad considering the cost of good quality linear bearings, and you're still stuff with those flimsy rods...

I'll most likely use my current Z setup (I have lead screws installed already) but need to keep the possibility of upgrading it in mind. It would be nice for this to be straight bolt in like the Y-Carriage with only a few new printed parts required...I think that's doable. I just need to give it some further thought.

I also scoured thingi today looking at all sorts of V-Slot and Openbuilds stuff...so many great ideas!!! I'll be sticking to the aluminum gantry plates though, I think you need them for a really good bearing mount!?!? I'll design and print whatever adapter I need for the Cyclops

This is EXCELLENT work, I look forward to seeing what your final results are, and if you want someone who is willing to also order the parts you are using and help you debug any problems, I'm more than down

Edited 1 time(s). Last edit at 11/21/2015 11:43PM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 22, 2015 06:33AM |

Registered: 8 years ago Posts: 276 |

Also, I rescind my rescission of the Igus Drylin bushings.

After installing them on the Y and X axis, I reported I had some nasty vibration on Y. I replaced them with some Amazon 5-star rated LM8UU's (that were crap), and while there was noise, there was no vibration that affected prints and I was able to print some new Y-axis holders with no problems. Actually, even with the bearing noise, these were some of the best prints to ever come out of my printer, and it bothered me a bit to take the Y-carriage apart, again (for the fifth time?) tonight to install them.

Instead of printing the Folgertech Y-axis holders, I went with these (but don't use them, use my remix below) - [www.thingiverse.com] . What I like about them is they don't use zip ties so you don't have to remove them to swap out bearings/bushings. Just be careful not to tighten them too much or they will crack.

They printed very well, but after installing them I learned that they are too short (bed hits the motor before homing all the way), so I offset their height with M3 nuts as a quick fix, shortened my Y print space to 130mm (to compensate for them hitting the motor and the Y belt holder on the other side of the printer), added some height to them in Sketchup, and the new set are printing right now. I decided to try the Igus bushings again, and they are working wonderfully now, so I'll chalk this one up to the crappy print quality of the Y holders Folgertech provides.

So... those new expensive LM8UU equivalents I ordered will go into the box of ordered-but-forgotten components until a problem with the Igus potentially comes up and I have to readdress the situation.

Here is the STL for anyone who might want to use it - [www.thingiverse.com]

And of course, this is all moot once I get my SonnYcarriage up and running

Edited 4 time(s). Last edit at 11/22/2015 07:11AM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

After installing them on the Y and X axis, I reported I had some nasty vibration on Y. I replaced them with some Amazon 5-star rated LM8UU's (that were crap), and while there was noise, there was no vibration that affected prints and I was able to print some new Y-axis holders with no problems. Actually, even with the bearing noise, these were some of the best prints to ever come out of my printer, and it bothered me a bit to take the Y-carriage apart, again (for the fifth time?) tonight to install them.

Instead of printing the Folgertech Y-axis holders, I went with these (but don't use them, use my remix below) - [www.thingiverse.com] . What I like about them is they don't use zip ties so you don't have to remove them to swap out bearings/bushings. Just be careful not to tighten them too much or they will crack.

They printed very well, but after installing them I learned that they are too short (bed hits the motor before homing all the way), so I offset their height with M3 nuts as a quick fix, shortened my Y print space to 130mm (to compensate for them hitting the motor and the Y belt holder on the other side of the printer), added some height to them in Sketchup, and the new set are printing right now. I decided to try the Igus bushings again, and they are working wonderfully now, so I'll chalk this one up to the crappy print quality of the Y holders Folgertech provides.

So... those new expensive LM8UU equivalents I ordered will go into the box of ordered-but-forgotten components until a problem with the Igus potentially comes up and I have to readdress the situation.

Here is the STL for anyone who might want to use it - [www.thingiverse.com]

And of course, this is all moot once I get my SonnYcarriage up and running

Edited 4 time(s). Last edit at 11/22/2015 07:11AM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 22, 2015 08:47AM |

Registered: 8 years ago Posts: 268 |

Quote

msaeger

There are PCB heat beds in many sizes. I think you can get those silicone ones in any size you want.

[www.ebay.com]

That's the one, I'll sketch it up to see if there is enough movement in the Y-Carriage...Thanks!!!

Sorry, only registered users may post in this forum.