Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 09:27AM |

Registered: 8 years ago Posts: 541 |

Quote

elkayem

Quote

tjnamtiw

Wow, I just had my first bitch-slap from J-MAX >> [forums.reprap.org]

This guy hates FT and apparently is God, at least in his own mind. In his words, anyone who's only been around for 3 months has NOTHING to contribute to the forum. They should just sit quietly and learn even though I spent my entire working career of 50 years in electrical and electronic engineering.

Sad, really.

That guy is an arrogant jerk, and really has it in for FT. I've read a number of his posts, and he repetitively posts about how much he hates FT. It seems to be personal for him.

My experience is similar to yours. I have nothing but good things to say about the kit I received. Well, perhaps a few things could get cleaned up in the build manual. Before this printer, my experience is with the ones we have at the office, an Ultimaker 2 and a Taz 5. Most of my printing there is on the Ultimaker 2, which is a $2500 printer. I can honestly say that it's prints are no better than my FT 2020. Not just my opinion. I've brought some examples of my prints into work, and my coworkers have been equally impressed. The only upgrades I made to the FT2020 are a new E3D lite hot end, and an LCD screen. Other than that, strictly stock.

When I went shopping for a printer, I wanted to go the DIY route. I initially compiled the list of parts for a RepRap Prusa and priced them out on eBay and Amazon. Then I discovered the FT2020, which had all the same parts, but at $50 cheaper than I could do by myself. I can't say that any of the parts in the kit are different than ones I would have picked out myself. The way I look at it, I can take that $50 savings and apply it to upgrade any parts that fall short. So far, it's just been the hot end and I'm still ahead. I see that a number of other people on this thread have upgraded bearings, threaded rods, etc, but I suspect a lot of that is just for the fun of tinkering rather than getting noticeable improvement in print quality,

Anyway, it must really irk J-MAX that this thread is one of the most popular on this forum, filled with people who love the FT2020. So there!

That's good to hear that I'm not the only one taken aback by the guy's arrogance and insensitivity toward us. I think you hit the nail on the head with the desire to tinker as the main motivation to modify. It's in the blood.

Have a great Turkey Day.

Have a great Turkey Day.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 12:43PM |

Registered: 8 years ago Posts: 367 |

Quote

elkayem

Quote

tjnamtiw

Wow, I just had my first bitch-slap from J-MAX >> [forums.reprap.org]

This guy hates FT and apparently is God, at least in his own mind. In his words, anyone who's only been around for 3 months has NOTHING to contribute to the forum. They should just sit quietly and learn even though I spent my entire working career of 50 years in electrical and electronic engineering.

Sad, really.

That guy is an arrogant jerk, and really has it in for FT. I've read a number of his posts, and he repetitively posts about how much he hates FT. It seems to be personal for him.

My experience is similar to yours. I have nothing but good things to say about the kit I received. Well, perhaps a few things could get cleaned up in the build manual. Before this printer, my experience is with the ones we have at the office, an Ultimaker 2 and a Taz 5. Most of my printing there is on the Ultimaker 2, which is a $2500 printer. I can honestly say that it's prints are no better than my FT 2020. Not just my opinion. I've brought some examples of my prints into work, and my coworkers have been equally impressed. The only upgrades I made to the FT2020 are a new E3D lite hot end, and an LCD screen. Other than that, strictly stock.

When I went shopping for a printer, I wanted to go the DIY route. I initially compiled the list of parts for a RepRap Prusa and priced them out on eBay and Amazon. Then I discovered the FT2020, which had all the same parts, but at $50 cheaper than I could do by myself. I can't say that any of the parts in the kit are different than ones I would have picked out myself. The way I look at it, I can take that $50 savings and apply it to upgrade any parts that fall short. So far, it's just been the hot end and I'm still ahead. I see that a number of other people on this thread have upgraded bearings, threaded rods, etc, but I suspect a lot of that is just for the fun of tinkering rather than getting noticeable improvement in print quality,

Anyway, it must really irk J-MAX that this thread is one of the most popular on this forum, filled with people who love the FT2020. So there!

I agree with both of you. I've seen several posts from J-max and made a decision not to engage with them. I like my printer and get good results from it, and I built it and come to these forums to have fun. Getting into an argument would just leave me feel angry. We probably all know this: [www.explainxkcd.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 12:46PM |

Registered: 8 years ago Posts: 367 |

Quote

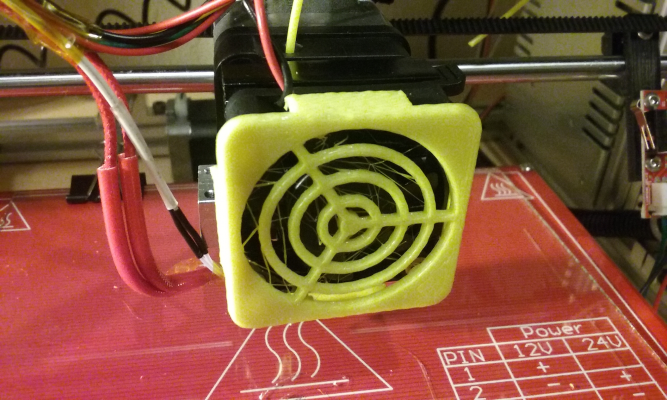

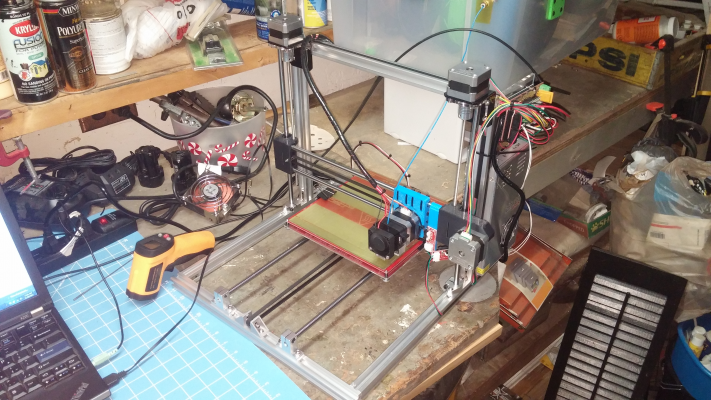

catbagan

Greetings! I received my 2020 last week. It's my first printer and I stayed up all night building it. Unfortunately, I wasn't able to get any decent and my hot end got terribly clogged. It turns out the PTFE tube was damaged. I ordered a few replacement throats with the PTFE but I figured I check out the electronic surplus store over the hill. I was amazed that they had the exact PTFE tube that I needed! For $0.44/foot!!!

I just got back and decided enough with the test cubes; let's just try print something semi-useful using the stock PLA .ini config. And here it is! My first not completely failed print, a fan shroud (still need to clean it up though)! I'm super excited and wish that my Thanksgiving break from school was longer so I could get this printer calibrated and dialed in!

Cheers all!

Nice work! You may be able to clean up the stringiness a little with extra retraction. See the last paragraph of [moosteria.blogspot.com] for the settings that worked for me.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 12:52PM |

Registered: 8 years ago Posts: 38 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 01:05PM |

Registered: 8 years ago Posts: 367 |

Quote

watlooazn

Can we use any glass plate as long as its within the required dimensions? 213*200*3mm

I use some ordinary 3mm window glass. I've read that using glass less than 3mm thick might be risky, as it could crack. Some people like borosilicate glass, but I've found the window glass has worked fine for me. Mostly I print PLA and PETG.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 01:19PM |

Registered: 8 years ago Posts: 80 |

Quote

animoose

I agree with both of you. I've seen several posts from J-max and made a decision not to engage with them. I like my printer and get good results from it, and I built it and come to these forums to have fun. Getting into an argument would just leave me feel angry. We probably all know this: [www.explainxkcd.com].

That sounds like the best course of action. You're the better man, I broke down and had to respond to his ridiculous post here. It's just pent up for me after seeing a number of his prior posts. So now I've just wasted 30 minutes of my life replying to some anonymous person on the internet. Just like that guy on that comic you forwarded! Oh no, now I'm that guy!

Honestly, if I didn't buy the FT2020 kit, I would still be trying to round up dozens of parts from all over the internet, some of which would probably still be in transit on a boat from China. This kit is a huge convenience!

Edited 1 time(s). Last edit at 11/26/2015 01:20PM by elkayem.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 01:48PM |

Registered: 8 years ago Posts: 80 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 03:04PM |

Registered: 9 years ago Posts: 40 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 03:22PM |

Registered: 8 years ago Posts: 541 |

Quote

animoose

Quote

watlooazn

Can we use any glass plate as long as its within the required dimensions? 213*200*3mm

I use some ordinary 3mm window glass. I've read that using glass less than 3mm thick might be risky, as it could crack. Some people like borosilicate glass, but I've found the window glass has worked fine for me. Mostly I print PLA and PETG.

The advantage of using the tempered glass that I noted is that tempered glass is stronger AND if it DOES break, it shatters into little pieces with no sharp edges, just like your side windows in your car. For $12 it's worth it IMHO.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 05:07PM |

Registered: 8 years ago Posts: 80 |

Quote

sethmo

Elkayem that is pretty impressive. What mods have you done?

I've added an E3D lite6 hotend, and a full graphic LCD.

I also added a beefier X stepper motor, but I doubt that has made a bit of difference. A few weeks back, I thought my extruder was missing steps so I ordered a better stepper. Since then, I discovered it was a loose set screw, but not before I received the stepper. I put the new stepper on the X axis since the old one was running a bit hot.

Anyway, I'll bet you can get similar quality going 100% stock parts. The hotend was an inexpensive upgrade, and was added only to convince myself I was getting the most out of my printer.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 05:34PM |

Registered: 8 years ago Posts: 276 |

Quote

elkayem

New prints from yesterday. 0% infill and no support material.

[attachment 66632 IMG_0907.JPG]

[attachment 66633 IMG_0903.JPG]

That is such a pretty filament.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

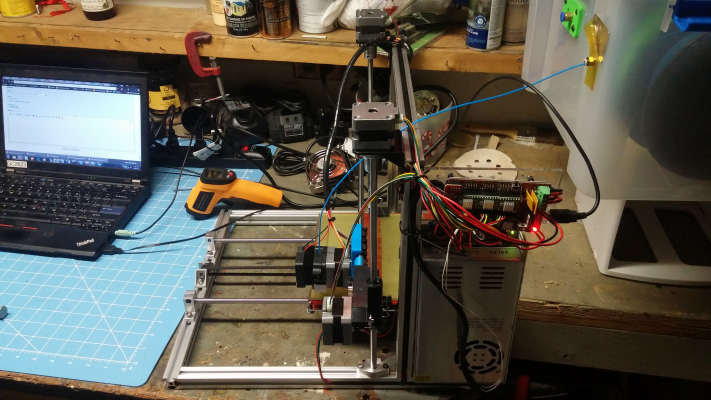

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 05:59PM |

Registered: 8 years ago Posts: 367 |

Does anyone have a note of the size and positions of the holes in the acrylic plate used to mount the electronics? Mine is a bit inaccessible right now, and I want to fit something to it.

Later: NVM - got it.

Edited 1 time(s). Last edit at 11/26/2015 07:12PM by animoose.

See my blog at [moosteria.blogspot.com].

Later: NVM - got it.

Edited 1 time(s). Last edit at 11/26/2015 07:12PM by animoose.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 06:46PM |

Registered: 9 years ago Posts: 40 |

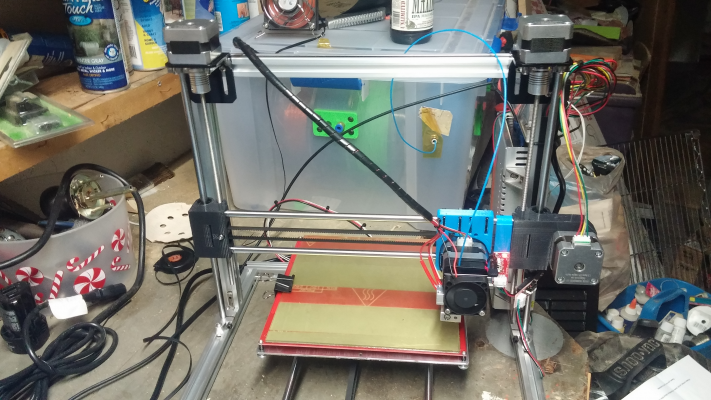

I like my borosilicate glass + pei sheet. I just got mine together yesterday. Some calibrations to do and adjusting of the stepper driver pots, these steppers are picky. I will print a mount for my e3dv6 this weekend and my leadscrews come Monday. I really dislike threaded rod for the z axis.

I have the extended mounts and bearing holders printed for the z axis, just waiting on the leadscrews.

I have the extended mounts and bearing holders printed for the z axis, just waiting on the leadscrews.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 07:23PM |

Registered: 8 years ago Posts: 276 |

I love how it's thanksgiving day and this is the most active the thread has been in a while. We are all thankful for our Folgertechs, happy thanksgiving, turkeys!

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 07:58PM |

Registered: 8 years ago Posts: 268 |

Quote

msaeger

Quote

sonnylowe

Quote

msaeger

Quote

sonnylowe

Y-Carriage installed and running

This VIDEO shows significant noise reduction of the previous SETUP. Now all I can hear are the stepper motors and some noise from the X-Carriage (I'm working that redesign now).

I printer a couple cal blocks prior to the change and the same block afterwards. I added more photos to the FOLDER, some of the cal blocks, and the y-carriage installed. The blocks on the right were prior to the upgrade and left were after. I cannot see a significant change in quality one way or the other. However, this upgrade was not about print quality as much as it was about building a better, quieter, and more easily aligned Y-Carriage (no bearing alignment needed only making sure the rail was aligned wit hthe frame), all of which I feel was achieved.

As usual things never go as planned...the endstop mount cause a foul between the endstop and the bed mount bracket prior to initiating. I had to improvise and move the endstop while still using the mount. I was able to do this by added the longer screws and a few nuts. Luckily I had tapped threads into the mount which made this last miunte change pretty easy. I'll design and print a new mount tonight.

I am so pleased with this setup I just order everything I need to the X-Carriage...I have designed and redesign X several times...it is proving to be a bit more difficult. I have a plan just need to get everything aligned prior to printing parts. therippa had asked about lead screws, but after seeing the cost more than double and the bulkiness of the setup would increase I'm going to try to make the belt drive work...at least for now ;-)

I'd be happy to generate a BOM and upload all the STL (and step) files if anyone that is interested...

Sonny

It's hard to tell the difference in noise from the video but I can't see how it wouldn't be quieter. I defiantly would like to see the BOM and STL's. Did you see any of the X axis's using vslot on thingiverse? [www.thingiverse.com]

If you listen to the "previous SETUP" video you can hear clicking/grinding sounds...they were the most annoying and completely eliminated :-)

I'll work on uploading the BOM and STL's this week...

I'll take another look at thingi, hopefully it will inspire me ;-)

Definitely could hear the clicking I just don't get the clicking on my stock setup so I am thinking that could have been eliminated. What I have heard on mine and others is a vibration kind of sound.

Gotcha,

I have the same sound out of the X-Carriage (definitely the belt...I can see it vibrating!!!).

BTW: Found a great example of a V-slot setup on thingi and was able to solidify my X-Axis design...those parts are due in Saturday, hopefully I'll have time to work on it over the weekend

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 08:00PM |

Registered: 8 years ago Posts: 268 |

Quote

tjnamtiw

[attachment 66503 tn_WP_20151124_006.jpg]

So far so good. PLA at 185, 0.2 layer, 65 speed. This thing is WAY too much fun! Stock extruder, stock carriages (although new ones are on my to-do list).

This one was awesome. So says my grand daughter, who confiscated it! Still hadn't trimmed him from all the support material. Also, my new roll of brown tangled up and starved the extruder, which is why the legs look sick! I'm glad I caught it before it was a total loss.

[attachment 66504 tn_WP_20151122_006.jpg]

And it's finally done!!! Smooth as baby's behind!

[attachment 66509 tn_WP_20151124_008.jpg]

Nice work!!!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 08:33PM |

Registered: 8 years ago Posts: 268 |

Quote

therippa

sonny - would you mind sharing the STL's? I think I'm going to get started on the y-axis thing soon.

Not at all...here ya go Y-Carriage STL Files (let me know if this link works!?!?)

FYI: I haven't tried V-4 of the endstop yet...but if it doesn't work I'm sure you can come with something quickly, or let me know how to adjust and I'll be happy to...

If you going to buy the OB parts do it tomorrow, they have a 10-25% off sale...

BOM

(1) V-Slot Gantry Set Plate: 20mm - 80mm (Universal) Wheel: Delrin Solid V Wheels (look at the bundles)

(1) V-Slot™ Linear Rail Size: 20mm x 80mm Length: 500mm Color: Silver

(1) Precision Shim - 10x5x1mm (for idle pulley bearings)

(2) 5x13x4 (FLANGED) Metal Shielded Bearing F695-ZZ

(1) 20 GT2 20 tooth Pulley

(1.5M) GT2 Timing Belt

Misc: screws, tie raps, etc...

You can either buy more or use the 5mm T-Nut from the SK8s...the short screw that FT sent are the perfect length to mount it with the brackets I used.

BTW: I had an epiphany yesterday concerning the Lead Screws (LS) for Y or X axis...I am constantly moving the hotend carriage or bed manually (printer on or off), you cannot do that if you run the LSs, that in itself is enough for me not to do it...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 08:34PM |

Registered: 8 years ago Posts: 268 |

Quote

catbagan

Greetings! I received my 2020 last week. It's my first printer and I stayed up all night building it. Unfortunately, I wasn't able to get any decent and my hot end got terribly clogged. It turns out the PTFE tube was damaged. I ordered a few replacement throats with the PTFE but I figured I check out the electronic surplus store over the hill. I was amazed that they had the exact PTFE tube that I needed! For $0.44/foot!!!

I just got back and decided enough with the test cubes; let's just try print something semi-useful using the stock PLA .ini config. And here it is! My first not completely failed print, a fan shroud (still need to clean it up though)! I'm super excited and wish that my Thanksgiving break from school was longer so I could get this printer calibrated and dialed in!

Cheers all!

Congrats...it only gets better and more additive from here ;-)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 08:41PM |

Registered: 8 years ago Posts: 276 |

Quote

sonnylowe

Quote

therippa

sonny - would you mind sharing the STL's? I think I'm going to get started on the y-axis thing soon.

Not at all...here ya go Y-Carriage STL Files (let me know if this link works!?!?)

FYI: I haven't tried V-4 of the endstop yet...but if it doesn't work I'm sure you can come with something quickly, or let me know how to adjust and I'll be happy to...

If you going to buy the OB parts do it tomorrow, they have a 10-25% off sale...

BOM

(1) V-Slot Gantry Set Plate: 20mm - 80mm (Universal) Wheel: Delrin Solid V Wheels (look at the bundles)

(1) V-Slot™ Linear Rail Size: 20mm x 80mm Length: 500mm Color: Silver

(1) Precision Shim - 10x5x1mm (for idle pulley bearings)

(2) 5x13x4 (FLANGED) Metal Shielded Bearing F695-ZZ

(1) 20 GT2 20 tooth Pulley

(1.5M) GT2 Timing Belt

Misc: screws, tie raps, etc...

You can either buy more or use the 5mm T-Nut from the SK8s...the short screw that FT sent are the perfect length to mount it with the brackets I used.

BTW: I had an epiphany yesterday concerning the Lead Screws (LS) for Y or X axis...I am constantly moving the hotend carriage or bed manually (printer on or off), you cannot do that if you run the LSs, that in itself is enough for me not to do it...

Awesome, thanks for the files!

Edited 1 time(s). Last edit at 11/26/2015 08:42PM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 08:50PM |

Registered: 8 years ago Posts: 268 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 09:57PM |

Registered: 8 years ago Posts: 541 |

Quote

elkayem

Quote

sethmo

Elkayem that is pretty impressive. What mods have you done?

I've added an E3D lite6 hotend, and a full graphic LCD.

I also added a beefier X stepper motor, but I doubt that has made a bit of difference. A few weeks back, I thought my extruder was missing steps so I ordered a better stepper. Since then, I discovered it was a loose set screw, but not before I received the stepper. I put the new stepper on the X axis since the old one was running a bit hot.

Anyway, I'll bet you can get similar quality going 100% stock parts. The hotend was an inexpensive upgrade, and was added only to convince myself I was getting the most out of my printer.

With the E3D mounted on the X carriage, IF you still have the FT drive but just a new mounting block, how much lower does it extend than the stock hot end? I'm just wondering how much Z distance you lose.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 10:28PM |

Registered: 8 years ago Posts: 276 |

Quote

tjnamtiw

Quote

elkayem

Quote

sethmo

Elkayem that is pretty impressive. What mods have you done?

I've added an E3D lite6 hotend, and a full graphic LCD.

I also added a beefier X stepper motor, but I doubt that has made a bit of difference. A few weeks back, I thought my extruder was missing steps so I ordered a better stepper. Since then, I discovered it was a loose set screw, but not before I received the stepper. I put the new stepper on the X axis since the old one was running a bit hot.

Anyway, I'll bet you can get similar quality going 100% stock parts. The hotend was an inexpensive upgrade, and was added only to convince myself I was getting the most out of my printer.

With the E3D mounted on the X carriage, IF you still have the FT drive but just a new mounting block, how much lower does it extend than the stock hot end? I'm just wondering how much Z distance you lose.

I've been drinking wine all day and am a thousand miles away from my printer, but from anecdotal memories, it depends on which mount you use for it, and even then it's negligible overall.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 10:38PM |

Registered: 8 years ago Posts: 430 |

Quote

tjnamtiw

Quote

elkayem

Quote

sethmo

Elkayem that is pretty impressive. What mods have you done?

I've added an E3D lite6 hotend, and a full graphic LCD.

I also added a beefier X stepper motor, but I doubt that has made a bit of difference. A few weeks back, I thought my extruder was missing steps so I ordered a better stepper. Since then, I discovered it was a loose set screw, but not before I received the stepper. I put the new stepper on the X axis since the old one was running a bit hot.

Anyway, I'll bet you can get similar quality going 100% stock parts. The hotend was an inexpensive upgrade, and was added only to convince myself I was getting the most out of my printer.

With the E3D mounted on the X carriage, IF you still have the FT drive but just a new mounting block, how much lower does it extend than the stock hot end? I'm just wondering how much Z distance you lose.

You don't lose any space if you use animoose's trick.

Quote

I also changed the way the motor attached to the X carriage, so it is mounted using the bottom two screw holes in the back of the motor rather than the top two. This reclaims all of the extra Z space taken up by the E3D.

[moosteria.blogspot.com]

The only issue I had doing it this was was the screws from the front hit the ones coming from the rear so I had to get shorter screws.

Edited 1 time(s). Last edit at 11/26/2015 10:41PM by msaeger.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 11:10PM |

Registered: 8 years ago Posts: 541 |

Quote

msaeger

Quote

tjnamtiw

Quote

elkayem

Quote

sethmo

Elkayem that is pretty impressive. What mods have you done?

I've added an E3D lite6 hotend, and a full graphic LCD.

I also added a beefier X stepper motor, but I doubt that has made a bit of difference. A few weeks back, I thought my extruder was missing steps so I ordered a better stepper. Since then, I discovered it was a loose set screw, but not before I received the stepper. I put the new stepper on the X axis since the old one was running a bit hot.

Anyway, I'll bet you can get similar quality going 100% stock parts. The hotend was an inexpensive upgrade, and was added only to convince myself I was getting the most out of my printer.

With the E3D mounted on the X carriage, IF you still have the FT drive but just a new mounting block, how much lower does it extend than the stock hot end? I'm just wondering how much Z distance you lose.

You don't lose any space if you use animoose's trick.

Quote

I also changed the way the motor attached to the X carriage, so it is mounted using the bottom two screw holes in the back of the motor rather than the top two. This reclaims all of the extra Z space taken up by the E3D.

[moosteria.blogspot.com]

The only issue I had doing it this was was the screws from the front hit the ones coming from the rear so I had to get shorter screws.

Thanks to you and rippa! It was Marker's Mark for me, not wine so I didn't dare turn on the pppppppriiinnttuur......

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 26, 2015 11:42PM |

Registered: 8 years ago Posts: 59 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 01:35AM |

Registered: 8 years ago Posts: 268 |

Quote

therippa

Quote

sonnylowe

Quote

therippa

sonny - would you mind sharing the STL's? I think I'm going to get started on the y-axis thing soon.

Not at all...here ya go Y-Carriage STL Files (let me know if this link works!?!?)

FYI: I haven't tried V-4 of the endstop yet...but if it doesn't work I'm sure you can come with something quickly, or let me know how to adjust and I'll be happy to...

If you going to buy the OB parts do it tomorrow, they have a 10-25% off sale...

BOM

(1) V-Slot Gantry Set Plate: 20mm - 80mm (Universal) Wheel: Delrin Solid V Wheels (look at the bundles)

(1) V-Slot™ Linear Rail Size: 20mm x 80mm Length: 500mm Color: Silver

(1) Precision Shim - 10x5x1mm (for idle pulley bearings)

(2) 5x13x4 (FLANGED) Metal Shielded Bearing F695-ZZ

(1) 20 GT2 20 tooth Pulley

(1.5M) GT2 Timing Belt

Misc: screws, tie raps, etc...

You can either buy more or use the 5mm T-Nut from the SK8s...the short screw that FT sent are the perfect length to mount it with the brackets I used.

BTW: I had an epiphany yesterday concerning the Lead Screws (LS) for Y or X axis...I am constantly moving the hotend carriage or bed manually (printer on or off), you cannot do that if you run the LSs, that in itself is enough for me not to do it...

Awesome, thanks for the files!

Also, did you see open builds is having a pretty good black friday/cyber monday sale? 25% most stuff.Yes, you did see that as well

You're welcome!!

If you haven't placed your order with OB yet, I'd suggest enough SLOT COVER to close off all the top of the rail...I'm finding a lot of little bits get stuck in there...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 02:11AM |

Registered: 8 years ago Posts: 268 |

Kapton Tape: I like it, especially for ABS prints, it's clean, easy to install, and my prints stick like crazy...well, sort of.

When I first put it down I scotch-bite it a bit to give it some texture. I can print half to a dozen parts and they will literal be hard to get of the bed without damaging the tape. After that I can't seem to get a part to stick anymore...not sure if it's the heat cycles or what...any ideas, or alternative suggest!?!?

BTW: I am running an aluminum build plate (heated to 80C).

When I first put it down I scotch-bite it a bit to give it some texture. I can print half to a dozen parts and they will literal be hard to get of the bed without damaging the tape. After that I can't seem to get a part to stick anymore...not sure if it's the heat cycles or what...any ideas, or alternative suggest!?!?

BTW: I am running an aluminum build plate (heated to 80C).

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 02:25AM |

Registered: 8 years ago Posts: 276 |

Quote

sonnylowe

Quote

therippa

Quote

sonnylowe

Quote

therippa

sonny - would you mind sharing the STL's? I think I'm going to get started on the y-axis thing soon.

Not at all...here ya go Y-Carriage STL Files (let me know if this link works!?!?)

FYI: I haven't tried V-4 of the endstop yet...but if it doesn't work I'm sure you can come with something quickly, or let me know how to adjust and I'll be happy to...

If you going to buy the OB parts do it tomorrow, they have a 10-25% off sale...

BOM

(1) V-Slot Gantry Set Plate: 20mm - 80mm (Universal) Wheel: Delrin Solid V Wheels (look at the bundles)

(1) V-Slot™ Linear Rail Size: 20mm x 80mm Length: 500mm Color: Silver

(1) Precision Shim - 10x5x1mm (for idle pulley bearings)

(2) 5x13x4 (FLANGED) Metal Shielded Bearing F695-ZZ

(1) 20 GT2 20 tooth Pulley

(1.5M) GT2 Timing Belt

Misc: screws, tie raps, etc...

You can either buy more or use the 5mm T-Nut from the SK8s...the short screw that FT sent are the perfect length to mount it with the brackets I used.

BTW: I had an epiphany yesterday concerning the Lead Screws (LS) for Y or X axis...I am constantly moving the hotend carriage or bed manually (printer on or off), you cannot do that if you run the LSs, that in itself is enough for me not to do it...

Awesome, thanks for the files!

Also, did you see open builds is having a pretty good black friday/cyber monday sale? 25% most stuff.Yes, you did see that as well

You're welcome!!

If you haven't placed your order with OB yet, I'd suggest enough SLOT COVER to close off all the top of the rail...I'm finding a lot of little bits get stuck in there...

I placed an order for your BOM, plus an extra grantry kit (and needed pulleys, shims, etc), for the inevitable x-carraige rework. Let me know what you have going on with the x-carriage, or I might be tempted to make my own

Edited 1 time(s). Last edit at 11/27/2015 02:34AM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 08:28AM |

Registered: 8 years ago Posts: 268 |

Quote

therippa

Quote

sonnylowe

Quote

therippa

Quote

sonnylowe

Quote

therippa

sonny - would you mind sharing the STL's? I think I'm going to get started on the y-axis thing soon.

Not at all...here ya go Y-Carriage STL Files (let me know if this link works!?!?)

FYI: I haven't tried V-4 of the endstop yet...but if it doesn't work I'm sure you can come with something quickly, or let me know how to adjust and I'll be happy to...

If you going to buy the OB parts do it tomorrow, they have a 10-25% off sale...

BOM

(1) V-Slot Gantry Set Plate: 20mm - 80mm (Universal) Wheel: Delrin Solid V Wheels (look at the bundles)

(1) V-Slot™ Linear Rail Size: 20mm x 80mm Length: 500mm Color: Silver

(1) Precision Shim - 10x5x1mm (for idle pulley bearings)

(2) 5x13x4 (FLANGED) Metal Shielded Bearing F695-ZZ

(1) 20 GT2 20 tooth Pulley

(1.5M) GT2 Timing Belt

Misc: screws, tie raps, etc...

You can either buy more or use the 5mm T-Nut from the SK8s...the short screw that FT sent are the perfect length to mount it with the brackets I used.

BTW: I had an epiphany yesterday concerning the Lead Screws (LS) for Y or X axis...I am constantly moving the hotend carriage or bed manually (printer on or off), you cannot do that if you run the LSs, that in itself is enough for me not to do it...

Awesome, thanks for the files!

Also, did you see open builds is having a pretty good black friday/cyber monday sale? 25% most stuff.Yes, you did see that as well

You're welcome!!

If you haven't placed your order with OB yet, I'd suggest enough SLOT COVER to close off all the top of the rail...I'm finding a lot of little bits get stuck in there...

I placed an order for your BOM, plus an extra grantry kit (and needed pulleys, shims, etc), for the inevitable x-carraige rework. Let me know what you have going on with the x-carriage, or I might be tempted to make my own

Two things:

1 - I had to rework the Endstop Mount...see V-5 in the folder. (printing it as we type...results to follow).

2 - I get my parts today so I'll be assembling the X-carriage this weekend. However, if you want to take a swag at it please go for it....sometimes, two heads are better than on ;-)

BTW: the last "CAD" photo in the Y-carriage folder shows the latest design of the X-Carriage

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 09:20AM |

Registered: 8 years ago Posts: 59 |

Quote

tjnamtiw

I'm happier than a pig in poop! I just finished three of these babies! It took a loooooooooong time but well worth it! They are beautiful. I also added the Z axis extension. I did note that the extensions' holes are too small for the boss on the bottom of the Z motors so I've changed the .stl file and will be printing new ones.

Oh, 190 C on first layer and 185 on the rest. 70 C on the bed with just hair spray on the tempered borosilicate glass from Amazon. Sticks like heck!

[attachment 65428 tn_WP_20151105_001.jpg]

[attachment 65429 tn_WP_20151105_003.jpg]

[attachment 65430 tn_WP_20151105_007.jpg]

[attachment 65431 tn_WP_20151106_002.jpg]

TJ this looks great! is this abs or pla? Also are you using the stock z threaded rods here still? I've got to look back in the thread for the extension instructions.

Sorry, only registered users may post in this forum.