Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 10:12AM |

Registered: 8 years ago Posts: 59 |

Yelloow-Snow I might just buy the FT Cloner kit. I have mods planned that will significantly add to the weight of my i3 build surface. If anyone has ideas for a conversion I'd love to hear them too.Quote

Yelloow-Snow

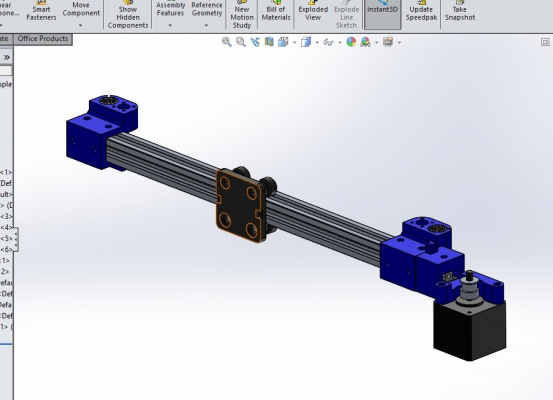

I'm thinking about converting my printer into a CoreXY

[www.mcmaster.com]

Who wants to go first? therippa? animoose? haha

[www.google.com]

Unlimited weight on the X axis!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 10:37AM |

Registered: 8 years ago Posts: 80 |

Quote

tjnamtiw

Quote

elkayem

Quote

sethmo

Elkayem that is pretty impressive. What mods have you done?

I've added an E3D lite6 hotend, and a full graphic LCD.

I also added a beefier X stepper motor, but I doubt that has made a bit of difference. A few weeks back, I thought my extruder was missing steps so I ordered a better stepper. Since then, I discovered it was a loose set screw, but not before I received the stepper. I put the new stepper on the X axis since the old one was running a bit hot.

Anyway, I'll bet you can get similar quality going 100% stock parts. The hotend was an inexpensive upgrade, and was added only to convince myself I was getting the most out of my printer.

With the E3D mounted on the X carriage, IF you still have the FT drive but just a new mounting block, how much lower does it extend than the stock hot end? I'm just wondering how much Z distance you lose.

tjnamtiw,

As others have suggested, use animoose's suggestion to mount the stepper motor by the bottom two holes instead of the top, and you regain all the Z distance you lose.

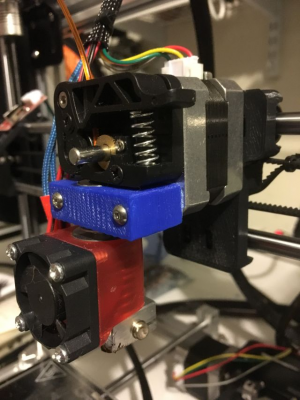

Mounting was a cinch thanks to animoose's design: http://www.thingiverse.com/thing:1091103. He has several different designs based on the extruder FolgerTech sent you. They sent me the MK9, so I used the one from the link above (uploaded Oct 24). The E3D lite6 is nice. It has the feel of a quality, well designed part. I can't say how much a difference it makes on the prints, as I didn't spend too much time with the old one. But I figured that was one area where a small investment could pay off.

Here's a picture. Hope this helps:

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 10:55AM |

Registered: 8 years ago Posts: 80 |

Speaking of Z-axis distance... The one thing that really bugs me about this printer is the limited Z axis range. I can get up to about 140 mm, with a bunch of wasted space up on top. The big problem is that the distance between the holes for the M5 threaded rod and M8 smooth rods on the X-end printed mounts do not quite match the hole spacing on the acrylic mounts underneath the Z-axis motors. This mismatch becomes a problem as the X-carriage gets closer to the Z-axis motors.

I see that some people have worked around this with Z-axis motor standoffs. I haven't done this yet, but am curious how much space this allows you to recover.

It seems another solution would be to fix the hole spacing on the X-end parts or the acrylic mount. Has anyone tried this? Are there other X-end parts with better spacing? I'm tempted to print out the parts directly from Josef Prusa's site and try those.

Of course yet another solution would be to simply use longer 2020 aluminum parts and longer M8 smooth rods! With that setup, the sky's the limit.

I see that some people have worked around this with Z-axis motor standoffs. I haven't done this yet, but am curious how much space this allows you to recover.

It seems another solution would be to fix the hole spacing on the X-end parts or the acrylic mount. Has anyone tried this? Are there other X-end parts with better spacing? I'm tempted to print out the parts directly from Josef Prusa's site and try those.

Of course yet another solution would be to simply use longer 2020 aluminum parts and longer M8 smooth rods! With that setup, the sky's the limit.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 11:10AM |

Registered: 8 years ago Posts: 80 |

One more question, since it's a holiday and I have nothing better to do... For those who have migrated to 8mm lead screws rather than the M5 threaded rods (e.g., this from banggood), why did you make that change? I confess, I don't get it. Those lead screws have an 8 mm lead (meaning travels 8 mm for one rotation) as opposed to the M5 threaded rods which have 0.8 mm. That's a 10X reduction in precision! I get that the stepper motors are very precise (1/16 of 1.8 deg, or 0.03% of a rotation) so the theoretical imit is stepping in 0.0025 mm steps even for the 8 mm lead. But at some point stiction effects take over, and even laying down 0.1 mm layers, precision could be an issue. 0.1 mm is only a 4.5 deg turn of that 8 mm lead screw, which is still pretty small.

So, is there some big advantage of the 8 mm lead screw that I'm missing? Just curious. I have time to wonder about these things today...

So, is there some big advantage of the 8 mm lead screw that I'm missing? Just curious. I have time to wonder about these things today...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 11:40AM |

Registered: 8 years ago Posts: 268 |

Quote

sonnylowe

Quote

therippa

Quote

sonnylowe

Quote

therippa

Quote

sonnylowe

Quote

therippa

sonny - would you mind sharing the STL's? I think I'm going to get started on the y-axis thing soon.

Not at all...here ya go Y-Carriage STL Files (let me know if this link works!?!?)

FYI: I haven't tried V-4 of the endstop yet...but if it doesn't work I'm sure you can come with something quickly, or let me know how to adjust and I'll be happy to...

If you going to buy the OB parts do it tomorrow, they have a 10-25% off sale...

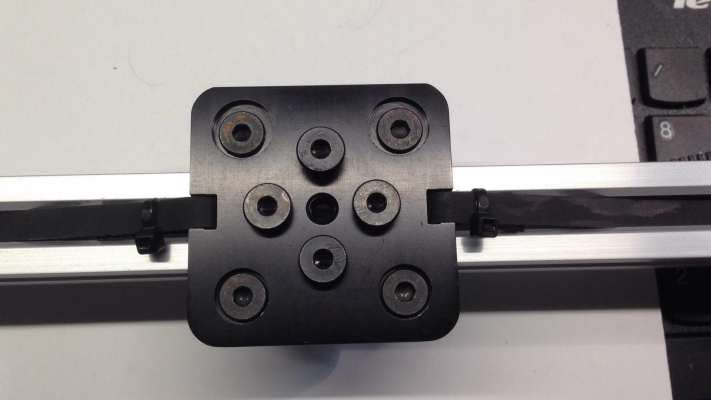

BOM

(1) V-Slot Gantry Set Plate: 20mm - 80mm (Universal) Wheel: Delrin Solid V Wheels (look at the bundles)

(1) V-Slot™ Linear Rail Size: 20mm x 80mm Length: 500mm Color: Silver

(1) Precision Shim - 10x5x1mm (for idle pulley bearings)

(2) 5x13x4 (FLANGED) Metal Shielded Bearing F695-ZZ

(1) 20 GT2 20 tooth Pulley

(1.5M) GT2 Timing Belt

Misc: screws, tie raps, etc...

You can either buy more or use the 5mm T-Nut from the SK8s...the short screw that FT sent are the perfect length to mount it with the brackets I used.

BTW: I had an epiphany yesterday concerning the Lead Screws (LS) for Y or X axis...I am constantly moving the hotend carriage or bed manually (printer on or off), you cannot do that if you run the LSs, that in itself is enough for me not to do it...

Awesome, thanks for the files!

Also, did you see open builds is having a pretty good black friday/cyber monday sale? 25% most stuff.Yes, you did see that as well

You're welcome!!

If you haven't placed your order with OB yet, I'd suggest enough SLOT COVER to close off all the top of the rail...I'm finding a lot of little bits get stuck in there...

I placed an order for your BOM, plus an extra grantry kit (and needed pulleys, shims, etc), for the inevitable x-carraige rework. Let me know what you have going on with the x-carriage, or I might be tempted to make my own

Two things:

1 - I had to rework the Endstop Mount...see V-5 in the folder. (printing it as we type...results to follow).

2 - I get my parts today so I'll be assembling the X-carriage this weekend. However, if you want to take a swag at it please go for it....sometimes, two heads are better than on ;-)

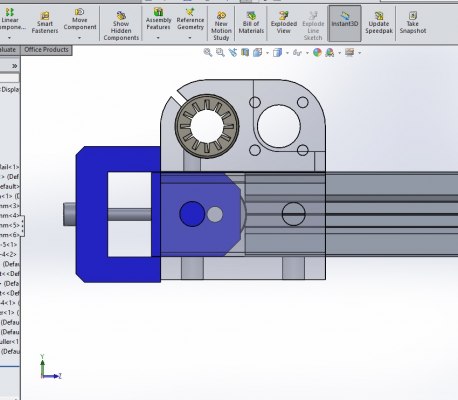

BTW: the last "CAD" photo in the Y-carriage folder shows the latest design of the X-Carriage

Endstop Mount V-5 installed...works great

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 04:16PM |

Registered: 8 years ago Posts: 59 |

Elkayem I will be working on these standoffs tomorrow. I believe the additional z space you get is equal to the height of the standoffs and utlizes the full length of the stock threaded rod. Not exactly sure what you are referring to regarding the acrylic mounts.Quote

elkayem

Speaking of Z-axis distance... The one thing that really bugs me about this printer is the limited Z axis range. I can get up to about 140 mm, with a bunch of wasted space up on top. The big problem is that the distance between the holes for the M5 threaded rod and M8 smooth rods on the X-end printed mounts do not quite match the hole spacing on the acrylic mounts underneath the Z-axis motors. This mismatch becomes a problem as the X-carriage gets closer to the Z-axis motors.

I see that some people have worked around this with Z-axis motor standoffs. I haven't done this yet, but am curious how much space this allows you to recover.

It seems another solution would be to fix the hole spacing on the X-end parts or the acrylic mount. Has anyone tried this? Are there other X-end parts with better spacing? I'm tempted to print out the parts directly from Josef Prusa's site and try those.

Of course yet another solution would be to simply use longer 2020 aluminum parts and longer M8 smooth rods! With that setup, the sky's the limit.

Also I have the same question as you about the lead screws. Only thing I can figure is that backlash may be reduced in the lead screws.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 04:41PM |

Registered: 8 years ago Posts: 80 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 04:53PM |

Registered: 8 years ago Posts: 80 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 05:10PM |

Registered: 8 years ago Posts: 80 |

Quote

Putzer

elkayem

A way to look at it. The rods you refer to at Banggood has a 2mm pitch (2mm travel for one revolution. Common stepper motors have 1.8 degree per step meaning 200 steps per revolution. 200 into 2mm gives you .01 mm per step.

Hi Putzer,

The banggood lead screws have a 2mm pitch and 4 starts, with 2mm x 4 = 8mm lead. You can see in the picture that the thread angle is pretty steep. Maybe it is all academic, because clearly these lead screws are working well for people.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 05:25PM |

Registered: 8 years ago Posts: 80 |

Here is an interesting discussion of lead screws vs threaded rods for 3D printers:

Accuracy vs Precision and Threaded Rod vs Leadscrews in 3D Printers

One pertinant quote from the web site:

The banggood leadscrews have a thread angle that is 10x the angle of the threaded rods iincluded in the kit, which appears to go against the recommendation provided on this page. On the other hand, this page generally recommends leadscrews over threaded rods due to higher quality, smoothness, and surface finish.

Accuracy vs Precision and Threaded Rod vs Leadscrews in 3D Printers

One pertinant quote from the web site:

Quote

In general, FFF/FDM printers use relatively infrequent, small, precise movements on the z-axis and consistent, fast movements on the x and y axes. A single start leadscrew with the tightest pitch possible (highest thread density, smallest pitch) is generally going to be your best bet for the z-axis, while you may or may not need something a little steeper to get the speeds you'd like from your x and y axes. While this may seem somewhat arbitrary given the precision of movement you can get from a stepper motor, an important factor to remember here is torque.

A more aggressive leadscrew will require more torque to drive. We have one kit printer we bought a couple years ago that has an overly aggressive multi-start leadscrew for the z-axis. The small motors included in the kit do not have the torque required to reliably start upward movement of the carriage, leaving it sitting there skipping steps until the carriage is given a little upward nudge to get it going (no, it's not a lubrication issue or a driver that needs turning up).

The banggood leadscrews have a thread angle that is 10x the angle of the threaded rods iincluded in the kit, which appears to go against the recommendation provided on this page. On the other hand, this page generally recommends leadscrews over threaded rods due to higher quality, smoothness, and surface finish.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 05:30PM |

Registered: 8 years ago Posts: 80 |

Quote

LancelotL

Also I have the same question as you about the lead screws. Only thing I can figure is that backlash may be reduced in the lead screws.

I agree that backlash reduction would be one advantage, though backlash isn't an issue for the Z axis since it moves only in one direction. (At least for those of us who don't use auto bed leveling.)

See the link I posted above. Another pertinant quote:

Quote

Threaded rod is not good, however, for precision. Because of the rough finish, the poor tolerances, potential slop between the rod and the nut, and other potential issues either in the rod itself or a printer design that utilizes the rods, you never know that each step on your motors is going to move your tool head by the precise distance you thought it would. The standard pitches on threaded rod are generally tight enough to make the accuracy high enough that the loss of precision may be acceptable, but for truly exceptional prints you'll likely find this to be a limitation.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 08:43PM |

Registered: 8 years ago Posts: 80 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 09:57PM |

Registered: 8 years ago Posts: 80 |

Quote

Putzer

elkayem

The picture is wrong. I have the same 8m from Banggood with 2mm pitch. Nothing like the picture shone. They only move 2mm per rev, not 8mm.

You must have ordered one with only one start then. However, the banggood ad I forwarded says it has an 8mm lead. Also, looking at the picture inside the brass nut, one can see that unit has four starts.

If I do decide to make that change, I will look for one with a 2mm lead. Good to know they are around.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 11:03PM |

Registered: 8 years ago Posts: 541 |

Quote

elkayem

Quote

tjnamtiw

With the E3D mounted on the X carriage, IF you still have the FT drive but just a new mounting block, how much lower does it extend than the stock hot end? I'm just wondering how much Z distance you lose.

Thanks!

tjnamtiw,

As others have suggested, use animoose's suggestion to mount the stepper motor by the bottom two holes instead of the top, and you regain all the Z distance you lose.

Mounting was a cinch thanks to animoose's design: http://www.thingiverse.com/thing:1091103. He has several different designs based on the extruder FolgerTech sent you. They sent me the MK9, so I used the one from the link above (uploaded Oct 24). The E3D lite6 is nice. It has the feel of a quality, well designed part. I can't say how much a difference it makes on the prints, as I didn't spend too much time with the old one. But I figured that was one area where a small investment could pay off.

Here's a picture. Hope this helps:

[attachment 66680 Extruder.jpg]

Thanks a lot!

Edited 1 time(s). Last edit at 11/28/2015 11:02PM by tjnamtiw.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 11:48PM |

Registered: 8 years ago Posts: 430 |

Any E3D other upgraders extruder motor getting really hot? Mine is getting probably hotter than it should and was starting to skip steps after printing 30 minutes. I tweaked the driver and now was able to run a 6 hour print but the motor still gets pretty hot. I am thinking part of the problem may be with the stock hot end there was the fan blowing on the extruder and now with the E3D the fan is below the extruder. I am thinking about putting a fan blowing on the motor but I don't really want the added noise.

Newbie with Folgertech 2020 i3.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 27, 2015 11:53PM |

Registered: 8 years ago Posts: 367 |

Quote

msaeger

Any E3D other upgraders extruder motor getting really hot? Mine is getting probably hotter than it should and was starting to skip steps after printing 30 minutes. I tweaked the driver and now was able to run a 6 hour print but the motor still gets pretty hot. I am thinking part of the problem may be with the stock hot end there was the fan blowing on the extruder and now with the E3D the fan is below the extruder. I am thinking about putting a fan blowing on the motor but I don't really want the added noise.

I've not noticed any problems with this - it may be a little hot but not enough to skip any steps. The longest print I've done with it was probably about 2.5 hours, maybe 3.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 28, 2015 12:43AM |

Registered: 8 years ago Posts: 3 |

Quote

animoose

Quote

msaeger

Any E3D other upgraders extruder motor getting really hot? Mine is getting probably hotter than it should and was starting to skip steps after printing 30 minutes. I tweaked the driver and now was able to run a 6 hour print but the motor still gets pretty hot. I am thinking part of the problem may be with the stock hot end there was the fan blowing on the extruder and now with the E3D the fan is below the extruder. I am thinking about putting a fan blowing on the motor but I don't really want the added noise.

I've not noticed any problems with this - it may be a little hot but not enough to skip any steps. The longest print I've done with it was probably about 2.5 hours, maybe 3.

Same here with e3d v6. It gets pretty warm, but never had any issues. Also big thanks to Animoose for the mount! I remixed it a bit to add an autolevel probe and it works great!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 28, 2015 08:47AM |

Registered: 8 years ago Posts: 268 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 28, 2015 08:47AM |

Registered: 8 years ago Posts: 268 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 28, 2015 09:17AM |

Registered: 8 years ago Posts: 430 |

Looks good can't wait to see it running.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 28, 2015 10:49AM |

Registered: 8 years ago Posts: 541 |

Beautiful!!!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 28, 2015 11:37AM |

Registered: 8 years ago Posts: 268 |

Quote

tjnamtiw

Beautiful!!!

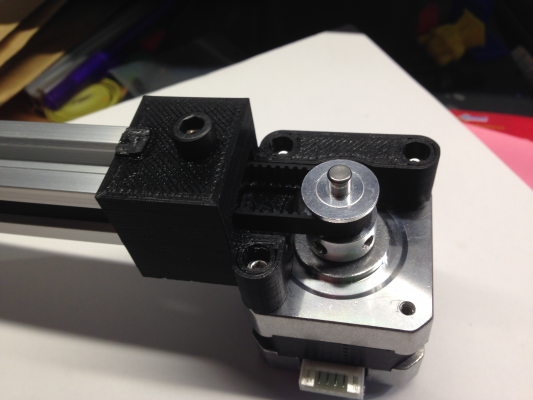

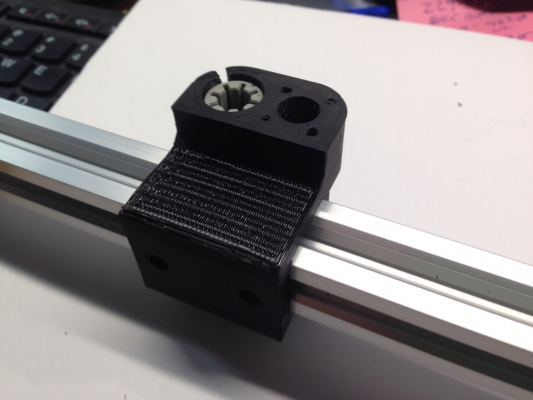

Thanks guys, it's really taking shape...I just completed the design on the Belt Tensioner...

BTW: I'm reprinting the Z Bearing Holders (photo two)...I just can't live with that raggedy ass surface ;-)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 28, 2015 07:30PM |

Registered: 8 years ago Posts: 38 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 28, 2015 08:50PM |

Registered: 8 years ago Posts: 3 |

Quote

watlooazn

Hey guys, I dont have a multimeter but want to know which contacts to put the power cable wires in. I have green, black white. Im assuming the black and white (hot and neutral) go into contacts 8 and 9 while green (ground) goes into 7.

Mine were green, blue, and red. Green was my ground... I do highly recommend getting a multimeter because you'll need one when you tune your pots.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 29, 2015 07:10PM |

Registered: 8 years ago Posts: 38 |

Need help with clarifying how to attach the extruder's fan's wire

According to the picture I attached, I should be using 1 meter of 22 gauge wire. But Ive only had 16 gauge wire that ive been using so far. I cant find any 22 gauge in my kit.

1) Was the 22 gauge a typo? Can I just use the 16 gauge?

2) Is it necessary to use 1 meter or just enough for it to reach from the extruder's fan to the power supply/ramps board

According to the picture I attached, I should be using 1 meter of 22 gauge wire. But Ive only had 16 gauge wire that ive been using so far. I cant find any 22 gauge in my kit.

1) Was the 22 gauge a typo? Can I just use the 16 gauge?

2) Is it necessary to use 1 meter or just enough for it to reach from the extruder's fan to the power supply/ramps board

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 29, 2015 07:17PM |

Registered: 8 years ago Posts: 276 |

Quote

watlooazn

Need help with clarifying how to attach the extruder's fan's wire

According to the picture I attached, I should be using 1 meter of 22 gauge wire. But Ive only had 16 gauge wire that ive been using so far. I cant find any 22 gauge in my kit.

1) Was the 22 gauge a typo? Can I just use the 16 gauge?

2) Is it necessary to use 1 meter or just enough for it to reach from the extruder's fan to the power supply/ramps board

It's fine using the 16 gauge, I don't think mine included 16 either. You can also do it as a last step, after you've cut the hot end power wire down to the size you'll need it to be, since you'll want to wrap those wires together with the sleeve they provided or use zipties.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 29, 2015 08:27PM |

Registered: 9 years ago Posts: 40 |

So I have had surprisingly good luck with the stock hot end and MK9 extruder. I have an E3DV6 from another printer that I wanted to try so I printed elkayem's mount and it printed PLA just fine, then I tried some Ninjaflex and the MK9 extruder does not like it. Does anyone know of a direct drive extruder with E3DV6 mount that works with flexible filament? I already have an MK8 extruder gear and also an Ultibots gear.

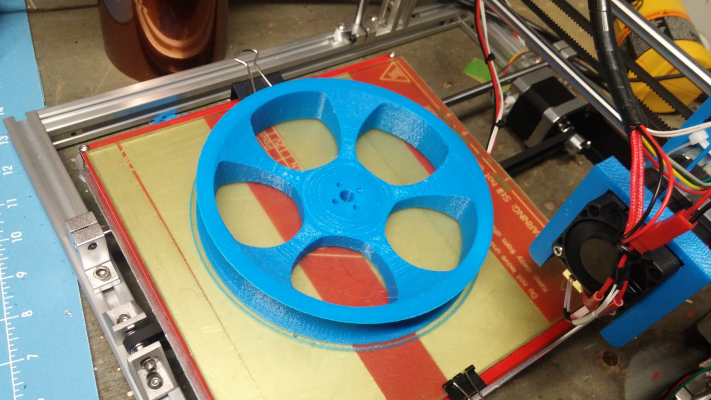

Large wheel for our FTC robotics club.

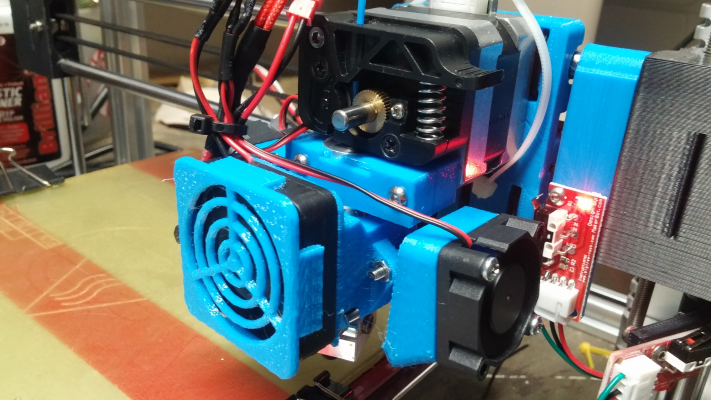

E3D setup with dual print fans

Edited 1 time(s). Last edit at 11/29/2015 08:28PM by sethmo.

Large wheel for our FTC robotics club.

E3D setup with dual print fans

Edited 1 time(s). Last edit at 11/29/2015 08:28PM by sethmo.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 29, 2015 08:31PM |

Registered: 8 years ago Posts: 367 |

I have managed to get a few prints with Ninjaflex using the MK9/E3D lite6 combination, but it's chancy. Running it a very slow rate with no retraction helps. If you need flexible filament, but not quite as flexible as Ninjaflex, you could try Ninjaflex Semiflex or Taulman PCTPE. They are both a lot easier. I have a few example at [docs.google.com] (pages 10, 12 and 17).

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 29, 2015 08:39PM |

Registered: 9 years ago Posts: 40 |

I have not tried the Ninjaflex Semiflex, but I do have some Sainsmart TPU that will probably work, just not as elastic as Ninjaflex. I may give it another go with Ninjaflex. I think if I drilled out the hole in the MK9 extruder so I could slip a bowden tube right up to the extruder gear, I tihnk it would help a lot.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 29, 2015 08:56PM |

Registered: 8 years ago Posts: 268 |

Quote

sethmo

So I have had surprisingly good luck with the stock hot end and MK9 extruder. I have an E3DV6 from another printer that I wanted to try so I printed elkayem's mount and it printed PLA just fine, then I tried some Ninjaflex and the MK9 extruder does not like it. Does anyone know of a direct drive extruder with E3DV6 mount that works with flexible filament? I already have an MK8 extruder gear and also an Ultibots gear.

Large wheel for our FTC robotics club.

E3D setup with dual print fans

I've used Ninjaflex but only with my modified Bowden extruder. Therippa design one for flexible filament...I've not used it but knowing the therippa, my bet is it's damn good one!!

Tiny Flex Estruder

That wheel is crazy good!!!

Edited 1 time(s). Last edit at 11/29/2015 10:39PM by sonnylowe.

Sorry, only registered users may post in this forum.