Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 04, 2015 01:57PM |

Registered: 10 years ago Posts: 197 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 04, 2015 02:48PM |

Registered: 8 years ago Posts: 268 |

Quote

Uncertainty

You may be inverting your z axis or you may have forgotten to disable your max endstops. Can you upload your conf?

I'm at work right now, but when I get home I can provide a link to my github page...

The weird thing is, I didn't change anything in the firmware between prints...at least not as far as I can remember...but who knows, I'm always tinker and adjusting stuff.

The other thing that baffles me is that G28 works with the manual endstop (ES) and doesn't work with the Inductive Sensor (IS). I know the Sensor is NO (same as the old one), are the Folger-Tech endstops NC? If so it would make more since that ES works and the IS don't...still doesn't explain why the FM is mucked up...if that's the case!?!?

Thanks,

Sonny

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 04, 2015 07:26PM |

Registered: 8 years ago Posts: 276 |

Quote

sonnylowe

Quote

Uncertainty

You may be inverting your z axis or you may have forgotten to disable your max endstops. Can you upload your conf?

I'm at work right now, but when I get home I can provide a link to my github page...

The weird thing is, I didn't change anything in the firmware between prints...at least not as far as I can remember...but who knows, I'm always tinker and adjusting stuff.

The other thing that baffles me is that G28 works with the manual endstop (ES) and doesn't work with the Inductive Sensor (IS). I know the Sensor is NO (same as the old one), are the Folger-Tech endstops NC? If so it would make more since that ES works and the IS don't...still doesn't explain why the FM is mucked up...if that's the case!?!?

Thanks,

Sonny

You can always build my optocoupler

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 04, 2015 09:20PM |

Registered: 8 years ago Posts: 285 |

Quote

foul_owl

Does anyone use this printer with 3mm filament and an e3dv6?

This printer looks great but I'm already locked into 3mm due to having other printers using it and having a 3mm filastruder.

If I could buy this kit with a standard greg's hinged accessible extruder I would be sold!

I do not use 3mm filament, but the printer can definitely undergo the slight modification to suit the use of such an extruder.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 04, 2015 09:23PM |

Registered: 10 years ago Posts: 197 |

Quote

Mach

Quote

foul_owl

Does anyone use this printer with 3mm filament and an e3dv6?

This printer looks great but I'm already locked into 3mm due to having other printers using it and having a 3mm filastruder.

If I could buy this kit with a standard greg's hinged accessible extruder I would be sold!

I do not use 3mm filament, but the printer can definitely undergo the slight modification to suit the use of such an extruder.

My concern was adding too much weight to the x carriage. Would something like that be an issue?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 04, 2015 09:57PM |

Registered: 8 years ago Posts: 285 |

Quote

foul_owl

Quote

Mach

Quote

foul_owl

Does anyone use this printer with 3mm filament and an e3dv6?

This printer looks great but I'm already locked into 3mm due to having other printers using it and having a 3mm filastruder.

If I could buy this kit with a standard greg's hinged accessible extruder I would be sold!

I do not use 3mm filament, but the printer can definitely undergo the slight modification to suit the use of such an extruder.

My concern was adding too much weight to the x carriage. Would something like that be an issue?

As long as a 2.6kg/cm stepper is used, I would say the weight increase would be minimal. Such an setup would probably be better than the stock setup since the center of gravity would be closer to the rods. I switched my setup to a bowden since the stock configuration sat 3 inches (76mm) from the rods, which caused the extruder to have a small downward angle that was driving me crazy

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 04, 2015 10:22PM |

Registered: 8 years ago Posts: 276 |

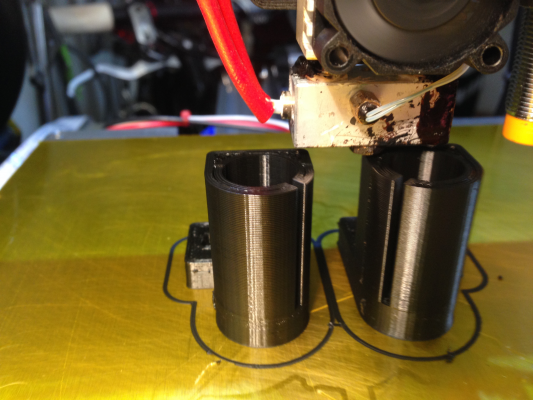

Comparison of printing Ninjaflex with the bowden tiny flex extruder and the direct-drive tiny flex extruder I modified to fit the E3D V6 (I should just call it the RippaStruder)

I've got my NinjaFlex game on lock now

Edited 1 time(s). Last edit at 12/04/2015 10:29PM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

I've got my NinjaFlex game on lock now

Edited 1 time(s). Last edit at 12/04/2015 10:29PM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 04, 2015 11:14PM |

Registered: 8 years ago Posts: 84 |

Quote

therippa

Comparison of printing Ninjaflex with the bowden tiny flex extruder and the direct-drive tiny flex extruder I modified to fit the E3D V6 (I should just call it the RippaStruder)

I've got my NinjaFlex game on lock now

What is your settings? I just got some ninjaflex in. Also got some clear PETG to try out.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 04, 2015 11:26PM |

Registered: 8 years ago Posts: 268 |

Quote

therippa

Comparison of printing Ninjaflex with the bowden tiny flex extruder and the direct-drive tiny flex extruder I modified to fit the E3D V6 (I should just call it the RippaStruder)

I've got my NinjaFlex game on lock now

Me likey ;-)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 04, 2015 11:44PM |

Registered: 8 years ago Posts: 268 |

Quote

Uncertainty

You may be inverting your z axis or you may have forgotten to disable your max endstops. Can you upload your conf?

Thanks for the suggestion, it certainly made me look deeper into the situation...

Simple logic, the FT endstops are NC circuits, the Inductive sensor is NO, so I had to change the following...

From:

const bool X_ENDSTOPS_INVERTING = true;

const bool Y_ENDSTOPS_INVERTING = true;

const bool Z_ENDSTOPS_INVERTING = true;

To:

const bool X_ENDSTOPS_INVERTING = true;

const bool Y_ENDSTOPS_INVERTING = true;

const bool Z_ENDSTOPS_INVERTING = false;

This makes perfect since, X&Y are NC endstops so they need to be true, Z is NO Sensor so it needs to be false...

Now everything seems to be working fine!?!? At least G28 and G29 now run properly, still need to setup the hotend and run the X-Carriage setrup

I still can't remember when or why I would have changed this setting...

Thanks again Uncertainly...you made this much easier to deal wtih than it could have been...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 12:20AM |

Registered: 10 years ago Posts: 197 |

Quote

Mach

Quote

foul_owl

Quote

Mach

Quote

foul_owl

Does anyone use this printer with 3mm filament and an e3dv6?

This printer looks great but I'm already locked into 3mm due to having other printers using it and having a 3mm filastruder.

If I could buy this kit with a standard greg's hinged accessible extruder I would be sold!

I do not use 3mm filament, but the printer can definitely undergo the slight modification to suit the use of such an extruder.

My concern was adding too much weight to the x carriage. Would something like that be an issue?

As long as a 2.6kg/cm stepper is used, I would say the weight increase would be minimal. Such an setup would probably be better than the stock setup since the center of gravity would be closer to the rods. I switched my setup to a bowden since the stock configuration sat 3 inches (76mm) from the rods, which caused the extruder to have a small downward angle that was driving me crazy

Ah gotcha. Do stronger steppers weigh more? Is that a standard stepper motor strength for the Greg's extruder? Thanks!!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 01:49AM |

Registered: 8 years ago Posts: 285 |

Quote

foul_owl

Quote

Mach

Quote

foul_owl

Quote

Mach

Quote

foul_owl

Does anyone use this printer with 3mm filament and an e3dv6?

This printer looks great but I'm already locked into 3mm due to having other printers using it and having a 3mm filastruder.

If I could buy this kit with a standard greg's hinged accessible extruder I would be sold!

I do not use 3mm filament, but the printer can definitely undergo the slight modification to suit the use of such an extruder.

My concern was adding too much weight to the x carriage. Would something like that be an issue?

As long as a 2.6kg/cm stepper is used, I would say the weight increase would be minimal. Such an setup would probably be better than the stock setup since the center of gravity would be closer to the rods. I switched my setup to a bowden since the stock configuration sat 3 inches (76mm) from the rods, which caused the extruder to have a small downward angle that was driving me crazy

Ah gotcha. Do stronger steppers weigh more? Is that a standard stepper motor strength for the Greg's extruder? Thanks!!

Not sure how strong motors for a greg's extruder usually are, but the FT printer's extruder comes with a 2.6kg/cm motor which weighs 200g, so as long as the greg's extruder can work with the same motor, there would be minimal weight increase.

As far as whether a stronger stepper motor will weigh more, typically the power of a motor is proportional to the physical size of the motor (as quoted from the reprap wiki)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 03:17AM |

Registered: 8 years ago Posts: 276 |

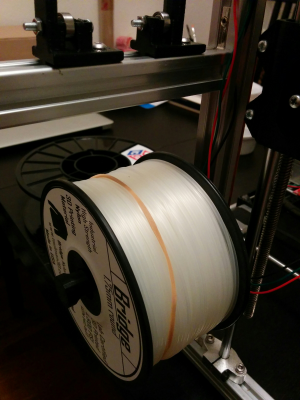

If anyone plans on trying to print Taulman's Bridge Nylon, you'll find the spool hole is way too small to fit the 2020 bar the Foglertech uses, so I made this small secondary holder that fits below the main holder (position it so it gives clearance to a normal spool fitted on the 2020 bar, so you can keep both spool holders mounted at the same time and switch between the two as needed).

Get the STL here - [www.thingiverse.com]

Edited 1 time(s). Last edit at 12/05/2015 03:18AM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

Get the STL here - [www.thingiverse.com]

Edited 1 time(s). Last edit at 12/05/2015 03:18AM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 06:02AM |

Registered: 8 years ago Posts: 276 |

Also, once again completely impressed by Simplify3d. The print below used supports for the angled portion, and even though 3d printed nylon has a tensile strength of 4800psi, while removing this print from the bed it (unexpectedly, but most welcomed) tore free from the supports and left them stuck to the bed. 10/10, would buy Simplify3d again.

Edited 1 time(s). Last edit at 12/05/2015 06:02AM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

Edited 1 time(s). Last edit at 12/05/2015 06:02AM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 10:08AM |

Registered: 8 years ago Posts: 268 |

Quote

therippa

Also, once again completely impressed by Simplify3d. The print below used supports for the angled portion, and even though 3d printed nylon has a tensile strength of 4800psi, while removing this print from the bed it (unexpectedly, but most welcomed) tore free from the supports and left them stuck to the bed. 10/10, would buy Simplify3d again.

NICE!!!

I made the switch to S3D about a week ago...it was not love at first site!!! But after a few days of acclimating to it...I will never go back...LOVE IT NOW!!

Edited 1 time(s). Last edit at 12/05/2015 10:45AM by sonnylowe.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 10:45AM |

Registered: 8 years ago Posts: 268 |

Here's a quick VIDEO of the X-Carriage installed and running it's first print (sorry for the poor camera work).

It needs some refinement and adjusting (belt might be a bit tight) but I am so pleased with its function...so much quieter now

I'm redesigning the printed parts as they are simply too bulky and the carriage is a bit wide as well...

It needs some refinement and adjusting (belt might be a bit tight) but I am so pleased with its function...so much quieter now

I'm redesigning the printed parts as they are simply too bulky and the carriage is a bit wide as well...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 12:23PM |

Registered: 8 years ago Posts: 16 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 12:53PM |

Registered: 8 years ago Posts: 38 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 01:48PM |

Registered: 8 years ago Posts: 268 |

X & Y Carriages are in and I'm printing parts again

I am very pleased with how well these upgrades work, leaps and bonds smoother, so much quieter, and with all sealed bearings, far less maintenance will be required...no more oiling/greasing of rods and bearing.

By the looks of thing they will be producing better prints as well (I'm still tweaking S3D)...it's a nice bonus considering noise reduction was the main reason for the design change and upgrade

Sorry if this is a little blurry, it was taken while still printing

I am very pleased with how well these upgrades work, leaps and bonds smoother, so much quieter, and with all sealed bearings, far less maintenance will be required...no more oiling/greasing of rods and bearing.

By the looks of thing they will be producing better prints as well (I'm still tweaking S3D)...it's a nice bonus considering noise reduction was the main reason for the design change and upgrade

Sorry if this is a little blurry, it was taken while still printing

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 02:25PM |

Registered: 8 years ago Posts: 268 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 03:00PM |

Registered: 8 years ago Posts: 38 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 03:17PM |

Registered: 8 years ago Posts: 38 |

In the picture attached can someone tell me why the Z carriage assembly motor has it's wire with the red most wire on the left while all other motors had their wires with the green most wire on the left? Just trying to make sure my polarities are right

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 03:47PM |

Registered: 8 years ago Posts: 276 |

Quote

watlooazn

My power supply has green, black, and white wires. Which one is which? (Im assuming black is hot, white neutral, green ground) can anyone please confirm?

You have to use a multimeter to figure it out, don't assume color means anything.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 05:32PM |

Registered: 8 years ago Posts: 285 |

Quote

watlooazn

In the picture attached can someone tell me why the Z carriage assembly motor has it's wire with the red most wire on the left while all other motors had their wires with the green most wire on the left? Just trying to make sure my polarities are right

The group of wires that are circled in the picture are the X axis wires, not the Z. The Z axis wires for both motors go under the stepper driver on the far left. Initially, just be sure that these wires have their colors in the same direction and you'll be fine.

Z axis wires in blue box

Edit:

Just realized that you may have meant X axis. If this is the case, then nvm the above.

The polarity initially does not really matter, so you can put it in either way. If it is backwards, all it will do is cause the motor to turn in the reverse direction. Also like therippa said, use a multimeter to verify the wiring of your plug. If you do not have one right now, you can make a simple continuity tester from things like a battery and a led.

Edited 1 time(s). Last edit at 12/05/2015 06:07PM by Mach.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 06:24PM |

Registered: 8 years ago Posts: 38 |

New to electrical stuff, can you help me out? So how would I use the multimeter? Where should I put the black and red wires of the multimeter onto the green,black, and white wires of the power supply to find out which is neutral, hot, and ground?

Sorry for the noob question, appreciate the help!

Sorry for the noob question, appreciate the help!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 07:42PM |

Registered: 8 years ago Posts: 285 |

Quote

watlooazn

New to electrical stuff, can you help me out? So how would I use the multimeter? Where should I put the black and red wires of the multimeter onto the green,black, and white wires of the power supply to find out which is neutral, hot, and ground?

Sorry for the noob question, appreciate the help!

No problem, 3d printer building is one way to learn such things

You would use the dmm (digital multimeter) as a continuity tester to see which wires go to which prongs on the plug. Turn the selector switch on the dmm to the setting that reads resistance. You may have to look at your instruction manual to find where that is on your dmm, but it usually is indicated by a horseshoe shaped symbol (the Omega). Touch one lead, any one, from the dmm to one of the three wires from the cable. Then touch the other lead from the dmm to each of the three prongs on the plug. Once you touch the prong that is linked to the wire that your other lead is connected to, the meter will go from showing a -1 to some other number; this signifies that you have continuity. Place some kind of marker like a piece of tape or something on that prong and its linked wire. Do this same procedure for the other two wires and their prong, and remember to mark each pair with different indicators. If you do not have a dmm right now, you can make a makeshift continuity tester with something like a battery and a led. I would highly suggest getting one as soon as possible though.

You would use the dmm (digital multimeter) as a continuity tester to see which wires go to which prongs on the plug. Turn the selector switch on the dmm to the setting that reads resistance. You may have to look at your instruction manual to find where that is on your dmm, but it usually is indicated by a horseshoe shaped symbol (the Omega). Touch one lead, any one, from the dmm to one of the three wires from the cable. Then touch the other lead from the dmm to each of the three prongs on the plug. Once you touch the prong that is linked to the wire that your other lead is connected to, the meter will go from showing a -1 to some other number; this signifies that you have continuity. Place some kind of marker like a piece of tape or something on that prong and its linked wire. Do this same procedure for the other two wires and their prong, and remember to mark each pair with different indicators. If you do not have a dmm right now, you can make a makeshift continuity tester with something like a battery and a led. I would highly suggest getting one as soon as possible though.The left prong is neutral, the right prong is hot, and the bottom prong is ground.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 08:22PM |

Registered: 8 years ago Posts: 80 |

Quote

therippa

In my attempt to try to fix noise/play, I installed legit high quality ($5/piece) LM8UU's I picked up from Misumi. What. A. Difference. As quiet as a Drylin, but much easier to move along the smooth rods. If you don't feel like going the route of sonnylowe's V-slot system, I'd recommend these.

Holy cow Therippa, you're not exaggerating! On your advice, I placed an order for six of these (3 for X, 3 for Y), and just installed them. After placing the order, I immediately regretted my decision. After repeated applications of silicone lubricant and about a month of printing, my old LM8UU bearings had become fairly smooth and quiet. Replacing them went completely against my mantra "if it ain't broke, ...". However, I'm a believer today. Testing my old broken-in LM8UU alone on the 8mm rod shows it still has a little friction and noise. Not the Misumi bearings. A slight nudge will send them sailing across to the other side of the 8mm rod. Now that they are installed on my machine, I can confidently say that the only noise to be heard from the printer is from the motors and fans. Complete silence from the bearings.

Also, reworking my axes gave me a chance to recheck the alignments. For example, on the Y axis, I found it useful to install the bed on the rails before tightening down the printed bearing holders to the bed. Small misalignments between the 3 bearing axes will still cause some drag, no matter how smooth your bearings are. Now, the bed will just effortlessly sail down the rails.

Is it worth the $40 I spent? Hard to say. It is definitely an improvement.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 09:02PM |

Registered: 8 years ago Posts: 276 |

Quote

elkayem

Quote

therippa

In my attempt to try to fix noise/play, I installed legit high quality ($5/piece) LM8UU's I picked up from Misumi. What. A. Difference. As quiet as a Drylin, but much easier to move along the smooth rods. If you don't feel like going the route of sonnylowe's V-slot system, I'd recommend these.

Holy cow Therippa, you're not exaggerating! On your advice, I placed an order for six of these (3 for X, 3 for Y), and just installed them. After placing the order, I immediately regretted my decision. After repeated applications of silicone lubricant and about a month of printing, my old LM8UU bearings had become fairly smooth and quiet. Replacing them went completely against my mantra "if it ain't broke, ...". However, I'm a believer today. Testing my old broken-in LM8UU alone on the 8mm rod shows it still has a little friction and noise. Not the Misumi bearings. A slight nudge will send them sailing across to the other side of the 8mm rod. Now that they are installed on my machine, I can confidently say that the only noise to be heard from the printer is from the motors and fans. Complete silence from the bearings.

Also, reworking my axes gave me a chance to recheck the alignments. For example, on the Y axis, I found it useful to install the bed on the rails before tightening down the printed bearing holders to the bed. Small misalignments between the 3 bearing axes will still cause some drag, no matter how smooth your bearings are. Now, the bed will just effortlessly sail down the rails.

Is it worth the $40 I spent? Hard to say. It is definitely an improvement.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 11:03PM |

Registered: 8 years ago Posts: 541 |

Quote

Mach

Quote

watlooazn

In the picture attached can someone tell me why the Z carriage assembly motor has it's wire with the red most wire on the left while all other motors had their wires with the green most wire on the left? Just trying to make sure my polarities are right

The group of wires that are circled in the picture are the X axis wires, not the Z. The Z axis wires for both motors go under the stepper driver on the far left. Initially, just be sure that these wires have their colors in the same direction and you'll be fine.

Z axis wires in blue box

Edit:

Just realized that you may have meant X axis. If this is the case, then nvm the above.

The polarity initially does not really matter, so you can put it in either way. If it is backwards, all it will do is cause the motor to turn in the reverse direction. Also like therippa said, use a multimeter to verify the wiring of your plug. If you do not have one right now, you can make a simple continuity tester from things like a battery and a led.

This question stems from the fact that the Folger Assembly manual calls the X stepper motor connector the Z axis a second time. For some reason, they refuse to update their manual knowing that every kit they sell is steering people wrong in several places. Very frustrating as I've had a two way conversation with them a couple of times but nothing gets changed unless they now put an addendum in the kit that nobody reads.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 05, 2015 11:18PM |

Registered: 8 years ago Posts: 80 |

I'm starting to think about a PLA cooling fan as well...Quote

IWantToBeAPrincess

Hello! I'm back I haven't had any time to print in the last few weeks. so I thought I'd jump back in with an enclosure for my ramps board and perhaps a blower for PLA. Anyone have a recommendation for the blower?

Sorry, only registered users may post in this forum.