Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 06, 2015 03:23AM |

Registered: 8 years ago Posts: 5 |

Alright I need help Im starting to throw stuff. The Z axis wont lower after performing a g29. It just starts printing in the air at the height of the endstop tripping. I had it running perfectly and then I started touching files and messed it up. I have my offset set to -9.2 like i had it before and i have the min software endstops set to false. Im still fairly new at this and thought I had a decent understanding but im lost at this point. I can post my config H or wouldnt mind seeing someones. (Im almost positive it has something to do with some endstop setting but who knows) At the moment Im using mechanical switch probe but ill be switching this week when i get the inductive sensor parts in. Appreciate any help.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 06, 2015 04:50AM |

Registered: 8 years ago Posts: 276 |

Quote

tpb0420

Alright I need help Im starting to throw stuff. The Z axis wont lower after performing a g29. It just starts printing in the air at the height of the endstop tripping. I had it running perfectly and then I started touching files and messed it up. I have my offset set to -9.2 like i had it before and i have the min software endstops set to false. Im still fairly new at this and thought I had a decent understanding but im lost at this point. I can post my config H or wouldnt mind seeing someones. (Im almost positive it has something to do with some endstop setting but who knows) At the moment Im using mechanical switch probe but ill be switching this week when i get the inductive sensor parts in. Appreciate any help.

Your Z-offset should never be more than -1.0, and ideally should be below -0.5. Manually move the probe to a spot where it falls within that threshold.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 06, 2015 04:56AM |

Registered: 8 years ago Posts: 276 |

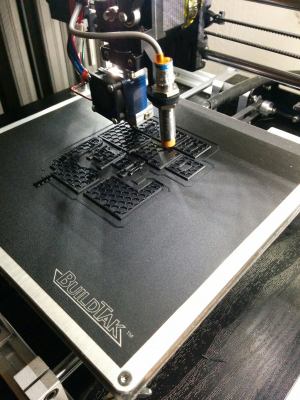

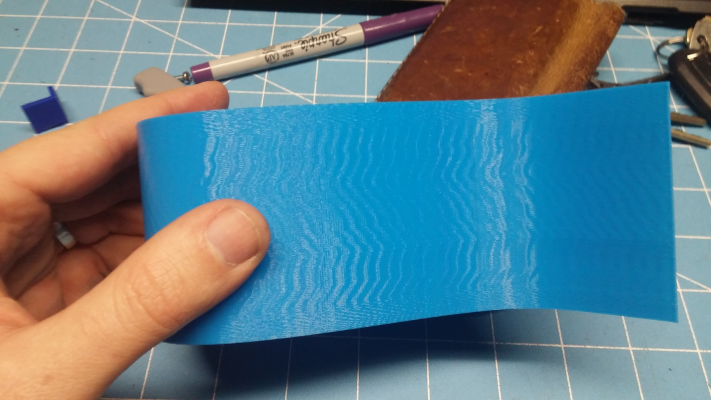

Tonight was such a perfect, calming, Bob Ross-esque experience. I had to go to an xmas party hosted by a friend with a gluten allergy, and I thought it would be fun to print him this item on thingiverse as a gift. First print, after a week of printing Ninjaflex and Taulman Bridge (compounded with about 80 prints since I replaced the sheet of BuildTak) made some permanent marks/problems on my build surface, it was all just messy. I took the aluminum pate off and carefully applied a new layer of BuildTak, and had a very satisfying first print:

Doesn't it just look so clean and crisp?

Anyway, the party was convienent as the hosts live two blocks away, so when I came home I decided to print sonnylowe's Y-carriage pieces, and this is what it looks like so far:

My autolevel height is perfectly calibrated, my speed is as high as it can be without mucking up the print, and my extrusion is perfectly calibrated. With all that, and a virgin build plate, there's nothing better, right?

Edited 4 time(s). Last edit at 12/06/2015 05:21AM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

Doesn't it just look so clean and crisp?

Anyway, the party was convienent as the hosts live two blocks away, so when I came home I decided to print sonnylowe's Y-carriage pieces, and this is what it looks like so far:

My autolevel height is perfectly calibrated, my speed is as high as it can be without mucking up the print, and my extrusion is perfectly calibrated. With all that, and a virgin build plate, there's nothing better, right?

Edited 4 time(s). Last edit at 12/06/2015 05:21AM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 06, 2015 11:08AM |

Registered: 8 years ago Posts: 2 |

Hello all,

I keep on coming up with fixes and basic improvements for the Folger i3 2020. Check out my collection of quick fixes and improvements: [www.thingiverse.com]

I keep on coming up with fixes and basic improvements for the Folger i3 2020. Check out my collection of quick fixes and improvements: [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 06, 2015 02:11PM |

Registered: 8 years ago Posts: 80 |

What aluminum print bed are folks using with an inductive sensor? Is there an aluminum surface that can be added to the top of the MK2B heat bed (instead of the glass), or are people replacing the heat bed altogether? I'm going to add the proximity sensor. Tired of constantly adjusting my print bed alignment...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 06, 2015 02:31PM |

Registered: 8 years ago Posts: 285 |

Quote

elkayem

What aluminum print bed are folks using with an inductive sensor? Is there an aluminum surface that can be added to the top of the MK2B heat bed (instead of the glass), or are people replacing the heat bed altogether? I'm going to add the proximity sensor. Tired of constantly adjusting my print bed alignment...

I just use a 8x8 inch aluminum plate I got for 13 bucks. This one

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 06, 2015 02:36PM |

Registered: 8 years ago Posts: 276 |

Quote

pjvpjv

Hello all,

I keep on coming up with fixes and basic improvements for the Folger i3 2020. Check out my collection of quick fixes and improvements: [www.thingiverse.com]

I printed your filament bearing holder-thingy last week, I see since then you removed the pieces I ended up snipping off

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 06, 2015 03:03PM |

Registered: 8 years ago Posts: 38 |

Thanks so much for your help.

I tried doing what you told me, got a dmm, followed exact instructions, set it to continuity tester mode, touched the 2 leads together and heard a beep meaning the dmm is working, but I get no results when I touch each of the probes to each wire and the other probe to the the prongs. I only get a result when I switch the mode from continuity to resistance and all 3 wires give me values for the right prong and nothing else. Don't know what I'm doing wrong.

I tried doing what you told me, got a dmm, followed exact instructions, set it to continuity tester mode, touched the 2 leads together and heard a beep meaning the dmm is working, but I get no results when I touch each of the probes to each wire and the other probe to the the prongs. I only get a result when I switch the mode from continuity to resistance and all 3 wires give me values for the right prong and nothing else. Don't know what I'm doing wrong.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 06, 2015 03:06PM |

Registered: 8 years ago Posts: 80 |

Quote

Mach

Quote

elkayem

What aluminum print bed are folks using with an inductive sensor? Is there an aluminum surface that can be added to the top of the MK2B heat bed (instead of the glass), or are people replacing the heat bed altogether? I'm going to add the proximity sensor. Tired of constantly adjusting my print bed alignment...

I just use a 8x8 inch aluminum plate I got for 13 bucks. This one

That looks pretty good! Does it stay fairly rigid and flat? Also, any problems getting the MK2B heat bed to keep it above 100 deg for ABS?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 06, 2015 03:25PM |

Registered: 8 years ago Posts: 285 |

Quote

watlooazn

Thanks so much for your help.

I tried doing what you told me, got a dmm, followed exact instructions, set it to continuity tester mode, touched the 2 leads together and heard a beep meaning the dmm is working, but I get no results when I touch each of the probes to each wire and the other probe to the the prongs. I only get a result when I switch the mode from continuity to resistance and all 3 wires give me values for the right prong and nothing else. Don't know what I'm doing wrong.

Not sure what you are doing wrong, but here is a pretty good video that does a step-by-step. Video. The video starts at where he does the cord, but it would be good to go back to the start of it and watch the entire video since it has a lot of good information for beginners.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 06, 2015 03:34PM |

Registered: 8 years ago Posts: 285 |

Quote

elkayem

Quote

Mach

Quote

elkayem

What aluminum print bed are folks using with an inductive sensor? Is there an aluminum surface that can be added to the top of the MK2B heat bed (instead of the glass), or are people replacing the heat bed altogether? I'm going to add the proximity sensor. Tired of constantly adjusting my print bed alignment...

I just use a 8x8 inch aluminum plate I got for 13 bucks. This one

That looks pretty good! Does it stay fairly rigid and flat? Also, any problems getting the MK2B heat bed to keep it above 100 deg for ABS?

The plate is about 3mm thick so it has almost no flex to it. The plate I received was not entirely flat on one side, but the unevenness is within fractions of a mm. I just turn the plate onto the side that had the least curve after putting on the binder clips and it works very well. I only print with pla right now, so I have not tried going to 80c.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 06, 2015 03:45PM |

Registered: 8 years ago Posts: 80 |

Quote

Mach

Quote

elkayem

Quote

Mach

Quote

elkayem

What aluminum print bed are folks using with an inductive sensor? Is there an aluminum surface that can be added to the top of the MK2B heat bed (instead of the glass), or are people replacing the heat bed altogether? I'm going to add the proximity sensor. Tired of constantly adjusting my print bed alignment...

I just use a 8x8 inch aluminum plate I got for 13 bucks. This one

That looks pretty good! Does it stay fairly rigid and flat? Also, any problems getting the MK2B heat bed to keep it above 100 deg for ABS?

The plate is about 3mm thick so it has almost no flex to it. The plate I received was not entirely flat on one side, but the unevenness is within fractions of a mm. I just turn the plate onto the side that had the least curve after putting on the binder clips and it works very well. I only print with pla right now, so I have not tried going to 80c.

Thanks Mach!

Anyone else placing a 3mm aluminum plate on top of their MK2B heatbed? Any issues staying above 100 degC? I think I'm going to jump on it unless anyone has an alternative.

Edited 1 time(s). Last edit at 12/06/2015 05:40PM by elkayem.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 06, 2015 04:16PM |

Registered: 8 years ago Posts: 285 |

Quote

elkayem

Quote

Mach

Quote

elkayem

Quote

Mach

Quote

elkayem

What aluminum print bed are folks using with an inductive sensor? Is there an aluminum surface that can be added to the top of the MK2B heat bed (instead of the glass), or are people replacing the heat bed altogether? I'm going to add the proximity sensor. Tired of constantly adjusting my print bed alignment...

I just use a 8x8 inch aluminum plate I got for 13 bucks. This one

That looks pretty good! Does it stay fairly rigid and flat? Also, any problems getting the MK2B heat bed to keep it above 100 deg for ABS?

The plate is about 3mm thick so it has almost no flex to it. The plate I received was not entirely flat on one side, but the unevenness is within fractions of a mm. I just turn the plate onto the side that had the least curve after putting on the binder clips and it works very well. I only print with pla right now, so I have not tried going to 80c.

Thanks Mach!

Anyone else placing a 3mm aluminum plate on top of their MK2B heatbed? Any issues staying above 100 degC? I think I'm going to jump on it unless anyone has an alternative.

Larry

Two slightly expensive alternatives. Have not used them so who knows how well they work

Build plate 1

Build plate 2

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 06, 2015 07:41PM |

Registered: 8 years ago Posts: 38 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 06, 2015 08:05PM |

Registered: 8 years ago Posts: 430 |

Quote

watlooazn

Nvm it works now! Thanks again,

Also to anyone else on this forum, Im in config mode now. Both my z motors turn but the threaded rods dont move, they kind of like stutter as if something is blocking their movement. Any tips?

You either have too much load from something being misaligned or you need to adjust the driver current.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 07, 2015 06:25AM |

Registered: 8 years ago Posts: 268 |

Quote

elkayem

Quote

Mach

Quote

elkayem

Quote

Mach

Quote

elkayem

What aluminum print bed are folks using with an inductive sensor? Is there an aluminum surface that can be added to the top of the MK2B heat bed (instead of the glass), or are people replacing the heat bed altogether? I'm going to add the proximity sensor. Tired of constantly adjusting my print bed alignment...

I just use a 8x8 inch aluminum plate I got for 13 bucks. This one

That looks pretty good! Does it stay fairly rigid and flat? Also, any problems getting the MK2B heat bed to keep it above 100 deg for ABS?

The plate is about 3mm thick so it has almost no flex to it. The plate I received was not entirely flat on one side, but the unevenness is within fractions of a mm. I just turn the plate onto the side that had the least curve after putting on the binder clips and it works very well. I only print with pla right now, so I have not tried going to 80c.

Thanks Mach!

Anyone else placing a 3mm aluminum plate on top of their MK2B heatbed? Any issues staying above 100 degC? I think I'm going to jump on it unless anyone has an alternative.

I had the 3mm aluminum bed over my MK2B heater, I never got it over 85C...I ran PID and it heated more quickly but still struggled to go past 85C. Could be something in my setup that's wrong...I'm not sure. Either way I printed ABS at 85C with no problem...I do print on Kapton though...

I might be going back to glass and a different sensor, if so I'll have this Build Plate and two sensors up for grabs...

Edited 2 time(s). Last edit at 12/07/2015 07:16AM by sonnylowe.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 07, 2015 08:51AM |

Registered: 8 years ago Posts: 268 |

Quote

therippa

Tonight was such a perfect, calming, Bob Ross-esque experience. I had to go to an xmas party hosted by a friend with a gluten allergy, and I thought it would be fun to print him this item on thingiverse as a gift. First print, after a week of printing Ninjaflex and Taulman Bridge (compounded with about 80 prints since I replaced the sheet of BuildTak) made some permanent marks/problems on my build surface, it was all just messy. I took the aluminum pate off and carefully applied a new layer of BuildTak, and had a very satisfying first print:

Doesn't it just look so clean and crisp?

Anyway, the party was convienent as the hosts live two blocks away, so when I came home I decided to print sonnylowe's Y-carriage pieces, and this is what it looks like so far:

My autolevel height is perfectly calibrated, my speed is as high as it can be without mucking up the print, and my extrusion is perfectly calibrated. With all that, and a virgin build plate, there's nothing better, right?

Rippa,

How long do the BuildTak build plates last...I'm using Katon right now but was thinking about a switch!?!?

Thanks,

Sonny

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 07, 2015 10:31AM |

Registered: 8 years ago Posts: 276 |

Quote

sonnylowe

Quote

therippa

Tonight was such a perfect, calming, Bob Ross-esque experience. I had to go to an xmas party hosted by a friend with a gluten allergy, and I thought it would be fun to print him this item on thingiverse as a gift. First print, after a week of printing Ninjaflex and Taulman Bridge (compounded with about 80 prints since I replaced the sheet of BuildTak) made some permanent marks/problems on my build surface, it was all just messy. I took the aluminum pate off and carefully applied a new layer of BuildTak, and had a very satisfying first print:

Doesn't it just look so clean and crisp?

Anyway, the party was convienent as the hosts live two blocks away, so when I came home I decided to print sonnylowe's Y-carriage pieces, and this is what it looks like so far:

My autolevel height is perfectly calibrated, my speed is as high as it can be without mucking up the print, and my extrusion is perfectly calibrated. With all that, and a virgin build plate, there's nothing better, right?

Rippa,

How long do the BuildTak build plates last...I'm using Katon right now but was thinking about a switch!?!?

Thanks,

Sonny

My first sheet lasted probably about two months, the second sheet (the one just removed) lasted a little over a month, but only because Ninjaflex can be a pain to remove if the first layer is printed too close. And I'd say I average about an houring of printing each day.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 07, 2015 10:54AM |

Registered: 8 years ago Posts: 268 |

Quote

therippa

Quote

sonnylowe

Quote

therippa

Tonight was such a perfect, calming, Bob Ross-esque experience. I had to go to an xmas party hosted by a friend with a gluten allergy, and I thought it would be fun to print him this item on thingiverse as a gift. First print, after a week of printing Ninjaflex and Taulman Bridge (compounded with about 80 prints since I replaced the sheet of BuildTak) made some permanent marks/problems on my build surface, it was all just messy. I took the aluminum pate off and carefully applied a new layer of BuildTak, and had a very satisfying first print:

Doesn't it just look so clean and crisp?

Anyway, the party was convienent as the hosts live two blocks away, so when I came home I decided to print sonnylowe's Y-carriage pieces, and this is what it looks like so far:

My autolevel height is perfectly calibrated, my speed is as high as it can be without mucking up the print, and my extrusion is perfectly calibrated. With all that, and a virgin build plate, there's nothing better, right?

Rippa,

How long do the BuildTak build plates last...I'm using Katon right now but was thinking about a switch!?!?

Thanks,

Sonny

My first sheet lasted probably about two months, the second sheet (the one just removed) lasted a little over a month, but only because Ninjaflex can be a pain to remove if the first layer is printed too close. And I'd say I average about an houring of printing each day.

Cool, I'll be added it to my Christmas list

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 07, 2015 12:44PM |

Registered: 8 years ago Posts: 38 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 07, 2015 01:18PM |

Registered: 8 years ago Posts: 276 |

Quote

watlooazn

Where should I go in the code to adjust the drive current and any suggestions on how much I should increment it by? (New to Arduino stuff)

Are you talking about the voltage for the steppers? There are little pots on the steppers, use the ceramic screwdriver do you don't fry anything.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 07, 2015 10:28PM |

Registered: 8 years ago Posts: 38 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 07, 2015 10:52PM |

Registered: 8 years ago Posts: 285 |

Quote

watlooazn

My top 2 motors turn but the threaded rod doesn't move, it gets stuck and starts stuttering as if something is stopping it, so i was wondering if I needed more current.

They turn but the threaded rod doesn't move? I am guessing you mean they turn when they are not connected to the threaded rods through the couplings, right? If that is the case, did you disconnect the motors from the threaded rods and see if the threaded rods turn freely by hand when they are not coupled?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 07, 2015 11:00PM |

Registered: 8 years ago Posts: 45 |

Finally getting some decent prints.

PLA 205/55; 50mm/sec; 0% infill

Upgrades: X belt tensioner & auto leveling

Photo #1 [www.dropbox.com]

Photo #2 [www.dropbox.com]

Photo #3 [www.dropbox.com]

Edited 1 time(s). Last edit at 12/07/2015 11:03PM by Uncertainty.

PLA 205/55; 50mm/sec; 0% infill

Upgrades: X belt tensioner & auto leveling

Photo #1 [www.dropbox.com]

Photo #2 [www.dropbox.com]

Photo #3 [www.dropbox.com]

Edited 1 time(s). Last edit at 12/07/2015 11:03PM by Uncertainty.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 08, 2015 04:39AM |

Registered: 8 years ago Posts: 268 |

Quote

Uncertainty

Finally getting some decent prints.

PLA 205/55; 50mm/sec; 0% infill

Upgrades: X belt tensioner & auto leveling

Photo #1 [www.dropbox.com]

Photo #2 [www.dropbox.com]

Photo #3 [www.dropbox.com]

Very Nice

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 08, 2015 08:08AM |

Registered: 8 years ago Posts: 268 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 08, 2015 10:16AM |

Registered: 8 years ago Posts: 268 |

Quote

Uncertainty

Finally getting some decent prints.

PLA 205/55; 50mm/sec; 0% infill

Upgrades: X belt tensioner & auto leveling

Photo #1 [www.dropbox.com]

Photo #2 [www.dropbox.com]

Photo #3 [www.dropbox.com]

BTW: Are running a Servo/Micro Switch setup or Proximity Sensor for your auto leveling? If it's a servo/micro setup do you mind sharing you config-h file?

Thanks,

Sonny

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 08, 2015 10:58AM |

Registered: 8 years ago Posts: 45 |

Quote

sonnylowe

BTW: Are running a Servo/Micro Switch setup or Proximity Sensor for your auto leveling? If it's a servo/micro setup do you mind sharing you config-h file?

Thanks,

Sonny

I'm using the LJ18A3-8-Z/BX (NPN-type) 8mm inductive sensor; with a layer of aluminum foil between my glass bed and the heating platform.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 08, 2015 12:34PM |

Registered: 8 years ago Posts: 268 |

Quote

Uncertainty

Quote

sonnylowe

BTW: Are running a Servo/Micro Switch setup or Proximity Sensor for your auto leveling? If it's a servo/micro setup do you mind sharing you config-h file?

Thanks,

Sonny

I'm using the LJ18A3-8-Z/BX (NPN-type) 8mm inductive sensor; with a layer of aluminum foil between my glass bed and the heating platform.

Thanks...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 08, 2015 01:24PM |

Registered: 9 years ago Posts: 40 |

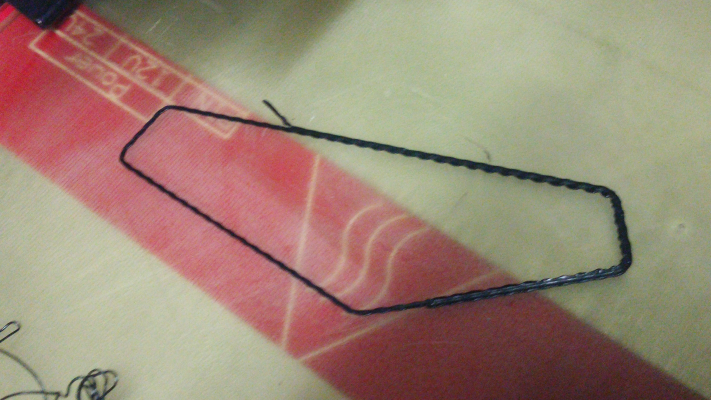

I am getting some odd lines in my print and it seems as though my extruder is not smooth(stock extruder/hot end). In my other printers, my extruder turns at a smooth consistent pace when doing infill or long perimeters. With my Folger Tech, it looks jerky. What should the voltage be on the stepper driver pots? I tried adjusting them, but it did not seem to help.

I am running therippa's Marlin from his sig, with the e-steps adjusted for my filament.

Some Hatchbox PLA:

Skirt of some ABS:

I am running therippa's Marlin from his sig, with the e-steps adjusted for my filament.

Some Hatchbox PLA:

Skirt of some ABS:

Sorry, only registered users may post in this forum.