Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 09, 2015 05:01PM |

Registered: 8 years ago Posts: 131 |

Quote

markts

Quote

fewyn

I'm having some problems with my Y axis, the print jumps back a bit (here's a video [youtu.be] ) it makes a thudding/clicking noise. My stepper drivers seem cool and not overheating when I touch them and the motor itself is cool too. I've retightened all my set screws and everything and the belt is tight. I'm out of ideas, any help?

Is the print skipping steps? Sure sounds like the belt is slipping/jumping. I had that happen once when I tried a belt tensioner and made the belt pretty tight.

Yeah, it sounds like a belt skipping to me too. I might not have my printer yet but my laser cutter is the same thing and the sounds is very familiar. Tensioners are the way to go. Also leaning this way because it looks like this happens on fast reversing which would put a large amount of torque on the belt.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 09, 2015 08:02PM |

Registered: 8 years ago Posts: 285 |

Quote

sonnylowe

Quote

sonnylowe

Quote

Mach

Quote

sonnylowe

Quote

Mach

Quote

sonnylowe

Quote

Mach

Quote

sonnylowe

I think I've asked this before, but is anyone running Repetier Firmware on these printers?

Yes, I changed from marlin to repetier a couple of months ago. So far it has mostly worked to my liking, accept that it only offer the three point method for auto bed leveling.

Mach,

Very Cool...I'm running a E3D Cyclops and they recommend using Repetier Firmware as it supports the dual extruders single nozzle setup and also allows extruder mixing (something I'd like to try) so I'm curios!?!?

How hard was it to set up, did you basically run the Configuration Tool and upload the file through Adruino to get it going...dare I believe it could be that simple!?!? If I try it and it doesn't work can I simply reload my old Marlin Firmware and be back were I left off? I'm not afraid to try it, I just want to make sure I can get back where I was if I need too!?!? If I go this route would be okay to pick your brain if need be??

Thanks,

Sonny

For the most part, yes it is as easy as using the config tool. Some of the options that I selected did not get put into the config.h file, so I had to do it manually, but otherwise it was mostly pretty simple. One things that was a big pain in the rear was a safety feature that prevents decoupling accidents with the bed. It kept on triggering even though nothing was decoupled, but that may have been my thermistor's fault. Yes, you can revert back to your old firmware if it does not work out. I could even provide you with my config to get you started if you would like.

Mach,

I'd like to give it a try so having a copy of your config-h would be great!! What setup are you using for Auto Leveling...servo/micro or Proximity? I have both but not sure which I want to use yet.

Thanks again,

Sonny

I am not actually using the autobed leveling feature, just using a inductive sensor for the Z endstop. I have it enabled and configured in firmware so that all I need to do is add the g29 command and it is set. I would suggest using the proximity sensor.

Config file attached. You may want to look through it first since some of my temperature settings may be abit bizarre.

I'll take a look before I upload it, and will go with the proximity sensor. If needed would you suggest making changes in Arduino, a text editor or use the configuration tool?

Thanks again,

Sonny

PM sent...

Sorry, really untimely reply by me. Pm sent. Also, I would say arduino is the best way to go for editting it.

Edited 1 time(s). Last edit at 12/09/2015 10:04PM by Mach.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 10, 2015 04:45AM |

Registered: 8 years ago Posts: 276 |

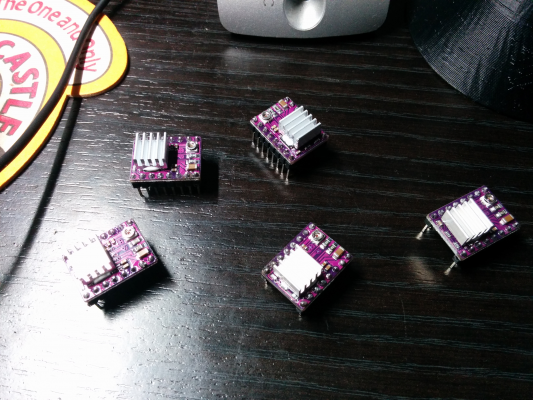

Upgrade Warning

You might read that the DRV8825 steppers run at 1/32 resolution, whereas our stock steppers (A4988) run at a lowly 1/16 resolution. You might say to yourself, "hey, a set of them are only $15 on Amazon, and they might improve the print quality since the stepper position will be 50% more accurate".

For us, they don't. After installing them and having to turn the pots almost all the way up to get any sort of reliable motion, I learned they are meant for 24V setups, which is not what we have. I pulled them and reinstalled the A4988's and all was well in the 3d printing world again.

DRV8825's are like meth. Not even once.

Edited 2 time(s). Last edit at 12/10/2015 04:48AM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

You might read that the DRV8825 steppers run at 1/32 resolution, whereas our stock steppers (A4988) run at a lowly 1/16 resolution. You might say to yourself, "hey, a set of them are only $15 on Amazon, and they might improve the print quality since the stepper position will be 50% more accurate".

For us, they don't. After installing them and having to turn the pots almost all the way up to get any sort of reliable motion, I learned they are meant for 24V setups, which is not what we have. I pulled them and reinstalled the A4988's and all was well in the 3d printing world again.

DRV8825's are like meth. Not even once.

Edited 2 time(s). Last edit at 12/10/2015 04:48AM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 10, 2015 06:27AM |

Registered: 8 years ago Posts: 268 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 10, 2015 06:33AM |

Registered: 8 years ago Posts: 268 |

Quote

Mach

Quote

sonnylowe

Quote

sonnylowe

Quote

Mach

Quote

sonnylowe

Quote

Mach

Quote

sonnylowe

Quote

Mach

Quote

sonnylowe

I think I've asked this before, but is anyone running Repetier Firmware on these printers?

Yes, I changed from marlin to repetier a couple of months ago. So far it has mostly worked to my liking, accept that it only offer the three point method for auto bed leveling.

Mach,

Very Cool...I'm running a E3D Cyclops and they recommend using Repetier Firmware as it supports the dual extruders single nozzle setup and also allows extruder mixing (something I'd like to try) so I'm curios!?!?

How hard was it to set up, did you basically run the Configuration Tool and upload the file through Adruino to get it going...dare I believe it could be that simple!?!? If I try it and it doesn't work can I simply reload my old Marlin Firmware and be back were I left off? I'm not afraid to try it, I just want to make sure I can get back where I was if I need too!?!? If I go this route would be okay to pick your brain if need be??

Thanks,

Sonny

For the most part, yes it is as easy as using the config tool. Some of the options that I selected did not get put into the config.h file, so I had to do it manually, but otherwise it was mostly pretty simple. One things that was a big pain in the rear was a safety feature that prevents decoupling accidents with the bed. It kept on triggering even though nothing was decoupled, but that may have been my thermistor's fault. Yes, you can revert back to your old firmware if it does not work out. I could even provide you with my config to get you started if you would like.

Mach,

I'd like to give it a try so having a copy of your config-h would be great!! What setup are you using for Auto Leveling...servo/micro or Proximity? I have both but not sure which I want to use yet.

Thanks again,

Sonny

I am not actually using the autobed leveling feature, just using a inductive sensor for the Z endstop. I have it enabled and configured in firmware so that all I need to do is add the g29 command and it is set. I would suggest using the proximity sensor.

Config file attached. You may want to look through it first since some of my temperature settings may be abit bizarre.

I'll take a look before I upload it, and will go with the proximity sensor. If needed would you suggest making changes in Arduino, a text editor or use the configuration tool?

Thanks again,

Sonny

PM sent...

Sorry, really untimely reply by me. Pm sent. Also, I would say arduino is the best way to go for editting it.

No worries, thanks for the help!!!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 10, 2015 06:39AM |

Registered: 8 years ago Posts: 268 |

Quote

therippa

Upgrade Warning

You might read that the DRV8825 steppers run at 1/32 resolution, whereas our stock steppers (A4988) run at a lowly 1/16 resolution. You might say to yourself, "hey, a set of them are only $15 on Amazon, and they might improve the print quality since the stepper position will be 50% more accurate".

For us, they don't. After installing them and having to turn the pots almost all the way up to get any sort of reliable motion, I learned they are meant for 24V setups, which is not what we have. I pulled them and reinstalled the A4988's and all was well in the 3d printing world again.

DRV8825's are like meth. Not even once.

Darn it, I did the same exact thing...I should have posted it and saved you some grief!!! When I found one of my drivers from FT bad out of the gate I ordered these as backups, based on the theory "bigger is always better". When I added my second extruder I installed these on both extruders...it was a long day of research and reconfiguring only to final gave up and ordered a set of A4 series replacements/spares.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 10, 2015 09:40AM |

Registered: 8 years ago Posts: 268 |

G28 question.

Can I change the Z-probe location on the build bed when running G28? Currently it is Z-probing in the center of the bed, I'd like to have it probe for Z- 0.0 at X-0.0 Y-200.0...is that possible!?!? I've search the interwebs the last couple days with no luck...

Thanks,

Sonny

Can I change the Z-probe location on the build bed when running G28? Currently it is Z-probing in the center of the bed, I'd like to have it probe for Z- 0.0 at X-0.0 Y-200.0...is that possible!?!? I've search the interwebs the last couple days with no luck...

Thanks,

Sonny

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 10, 2015 10:03AM |

Registered: 8 years ago Posts: 5 |

Hello Forum!

I'm new to the 3D printing scene and just finished the build of my FT 2020 last week. Once I "finished" the build I went over all the electrical connections to be sure they were all correct at least twice prior to ever plugging the unit into the USB or wall outlet. All the connections as listed in the build manual are correct. The configuration given by FT on the Google site was downloaded and I thought this was easy. I will be printing in a couple hours. So I go to home the unit. That's when things go bad. The home position is supposed to be where the extruder tip is located in the back right corner o f the bed. The X and Z axis seem to move to the correct positions however my Y axis is opposite they way it is supposed to move. During some iterations I also found that the Z axis is only responsive when it wants to be??? I ran M119 command and found that Y Max and Z Max are triggered all the time, even if the end stops are unplugged.

To make matters worse whatever is causing this issue also made my arduino smoke. Some forums suggest it is the voltage regulator as it seems to still work from USB.

I have tried the FT support site 4 days ago but have not heard anything from them. I believe the Ramps board may be defective but want to get some suggestions before replacing it.

I'm new to the 3D printing scene and just finished the build of my FT 2020 last week. Once I "finished" the build I went over all the electrical connections to be sure they were all correct at least twice prior to ever plugging the unit into the USB or wall outlet. All the connections as listed in the build manual are correct. The configuration given by FT on the Google site was downloaded and I thought this was easy. I will be printing in a couple hours. So I go to home the unit. That's when things go bad. The home position is supposed to be where the extruder tip is located in the back right corner o f the bed. The X and Z axis seem to move to the correct positions however my Y axis is opposite they way it is supposed to move. During some iterations I also found that the Z axis is only responsive when it wants to be??? I ran M119 command and found that Y Max and Z Max are triggered all the time, even if the end stops are unplugged.

To make matters worse whatever is causing this issue also made my arduino smoke. Some forums suggest it is the voltage regulator as it seems to still work from USB.

I have tried the FT support site 4 days ago but have not heard anything from them. I believe the Ramps board may be defective but want to get some suggestions before replacing it.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 10, 2015 10:09AM |

Registered: 8 years ago Posts: 8 |

Quote

wowzerz

Hello Forum!

I'm new to the 3D printing scene and just finished the build of my FT 2020 last week. Once I "finished" the build I went over all the electrical connections to be sure they were all correct at least twice prior to ever plugging the unit into the USB or wall outlet. All the connections as listed in the build manual are correct. The configuration given by FT on the Google site was downloaded and I thought this was easy. I will be printing in a couple hours. So I go to home the unit. That's when things go bad. The home position is supposed to be where the extruder tip is located in the back right corner o f the bed. The X and Z axis seem to move to the correct positions however my Y axis is opposite they way it is supposed to move. During some iterations I also found that the Z axis is only responsive when it wants to be??? I ran M119 command and found that Y Max and Z Max are triggered all the time, even if the end stops are unplugged.

To make matters worse whatever is causing this issue also made my arduino smoke. Some forums suggest it is the voltage regulator as it seems to still work from USB.

I have tried the FT support site 4 days ago but have not heard anything from them. I believe the Ramps board may be defective but want to get some suggestions before replacing it.

Check your ground connections, i smoked 2 arduinos before i realized i had a bad ground on the power supply and it was grounding through the USB cable. Mine and others solution was to put a wire between the AC Ground and V- on the power supply. This is recommended on the RepRap wiki, [reprap.org]

Edited 1 time(s). Last edit at 12/10/2015 10:14AM by amishboy.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 10, 2015 10:12AM |

Registered: 8 years ago Posts: 131 |

So I introduced myself just a few days ago saying I'm waiting for my printer to come in. After extensive reading and the last post showing it is NOT a fixed issue, it seems the Ramps board are just crap. Would I be better off just ordering a new one straight out and not chancing anything with the one from FT?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 10, 2015 10:44AM |

Registered: 8 years ago Posts: 268 |

Quote

marc2912

So I introduced myself just a few days ago saying I'm waiting for my printer to come in. After extensive reading and the last post showing it is NOT a fixed issue, it seems the Ramps board are just crap. Would I be better off just ordering a new one straight out and not chancing anything with the one from FT?

This is great foresight, and if your wallet can handle it I'd suggest getting a Ramps/Adruino Combo, and a set of Stepper Drivers (make sure you stick with the A4 series), have spares of both. Even if you make it through the build without needing them, they are pretty inexpensive and could save you some grief down the road, and more importantly...keep your printer up and running

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 10, 2015 10:55AM |

Registered: 8 years ago Posts: 285 |

Quote

sonnylowe

G28 question.

Can I change the Z-probe location on the build bed when running G28? Currently it is Z-probing in the center of the bed, I'd like to have it probe for Z- 0.0 at X-0.0 Y-200.0...is that possible!?!? I've search the interwebs the last couple days with no luck...

Thanks,

Sonny

Those settings can be changed in the start gcode of your slicer or host.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 10, 2015 11:02AM |

Registered: 8 years ago Posts: 285 |

Quote

wowzerz

Hello Forum!

I'm new to the 3D printing scene and just finished the build of my FT 2020 last week. Once I "finished" the build I went over all the electrical connections to be sure they were all correct at least twice prior to ever plugging the unit into the USB or wall outlet. All the connections as listed in the build manual are correct. The configuration given by FT on the Google site was downloaded and I thought this was easy. I will be printing in a couple hours. So I go to home the unit. That's when things go bad. The home position is supposed to be where the extruder tip is located in the back right corner o f the bed. The X and Z axis seem to move to the correct positions however my Y axis is opposite they way it is supposed to move. During some iterations I also found that the Z axis is only responsive when it wants to be??? I ran M119 command and found that Y Max and Z Max are triggered all the time, even if the end stops are unplugged.

To make matters worse whatever is causing this issue also made my arduino smoke. Some forums suggest it is the voltage regulator as it seems to still work from USB.

I have tried the FT support site 4 days ago but have not heard anything from them. I believe the Ramps board may be defective but want to get some suggestions before replacing it.

Make sure that your endstops are plugged into the actual places they are on your printer, there is a min and max row of endstop pins for each endstop. Having the endstops triggered all the time sound like the endstop positions that the firmware is using is not plugged in so it always reads high. Here is a picture of the positions

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 10, 2015 12:48PM |

Registered: 8 years ago Posts: 268 |

Quote

Mach

Quote

sonnylowe

G28 question.

Can I change the Z-probe location on the build bed when running G28? Currently it is Z-probing in the center of the bed, I'd like to have it probe for Z- 0.0 at X-0.0 Y-200.0...is that possible!?!? I've search the interwebs the last couple days with no luck...

Thanks,

Sonny

Those settings can be changed in the start gcode of your slicer or host.

Thanks mach,

I'll take a look at S3D tonight and see if I can figure it out (wish me luck ;-)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 10, 2015 12:52PM |

Registered: 8 years ago Posts: 5 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 10, 2015 03:47PM |

Registered: 8 years ago Posts: 541 |

Quote

wowzerz

Hello Forum!

I'm new to the 3D printing scene and just finished the build of my FT 2020 last week. Once I "finished" the build I went over all the electrical connections to be sure they were all correct at least twice prior to ever plugging the unit into the USB or wall outlet. All the connections as listed in the build manual are correct. The configuration given by FT on the Google site was downloaded and I thought this was easy. I will be printing in a couple hours. So I go to home the unit. That's when things go bad. The home position is supposed to be where the extruder tip is located in the back right corner o f the bed. The X and Z axis seem to move to the correct positions however my Y axis is opposite they way it is supposed to move. During some iterations I also found that the Z axis is only responsive when it wants to be??? I ran M119 command and found that Y Max and Z Max are triggered all the time, even if the end stops are unplugged.

To make matters worse whatever is causing this issue also made my arduino smoke. Some forums suggest it is the voltage regulator as it seems to still work from USB.

I have tried the FT support site 4 days ago but have not heard anything from them. I believe the Ramps board may be defective but want to get some suggestions before replacing it.

According to the instruction manual, The plug for the X motor should have the red wire to the left. Put it just like the picture shows. The instructions call this the 'Z' motor again. Also these things need to be done that are different from the instructions.>>

Change the following in configuration.h

#define INVERT_X_DIR true to #define INVERT_X_DIR false

#define X_HOME_DIR -1 to #define X_HOME_DIR 1

With the printer off PHYSICALLY move the x-axis stopper to the left one set of pins (this makes it so it's the x max instead of x-min)

Now if you are using rep host, you need to go to printer settings > printer shape and change home X: from min to Max.

One big glaring mistake in the build manual is putting the X stop plug in the wrong place on the board. It should be right next to the Y stop plug, not two over as the manual says. Also, for the X motor plug wires, keep them as you see. It's not a mistake to have them reversed from the others. I DID end up reversing the extruder motor plug because it was pushing the filament out the top!

The new spring design extruder has a brass feed gear that, for me, was rubbing inside the motor housing and causing it to drag and skip steps

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 10, 2015 07:22PM |

Registered: 8 years ago Posts: 57 |

Quote

therippa

Upgrade Warning

You might read that the DRV8825 steppers run at 1/32 resolution, whereas our stock steppers (A4988) run at a lowly 1/16 resolution. You might say to yourself, "hey, a set of them are only $15 on Amazon, and they might improve the print quality since the stepper position will be 50% more accurate".

For us, they don't. After installing them and having to turn the pots almost all the way up to get any sort of reliable motion, I learned they are meant for 24V setups, which is not what we have. I pulled them and reinstalled the A4988's and all was well in the 3d printing world again.

DRV8825's are like meth. Not even once.

I run A4988 Black Editions from Polulu

[www.pololu.com]

along with 400 steps/rev steppers for everything but the extruder right now

[www.sparkfun.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 11, 2015 01:06AM |

Registered: 8 years ago Posts: 45 |

For those of you who have x&y belt tensioners, what do you use?

For my X-axis I use [www.thingiverse.com]

I need something for my Y-axis. I found this [www.thingiverse.com], but I do not like the design.

Also, without changing the Z-threaded rods, what would you all recommend for reducing backlash? I was thinking of replacing the nut with a long nut...

For my X-axis I use [www.thingiverse.com]

I need something for my Y-axis. I found this [www.thingiverse.com], but I do not like the design.

Also, without changing the Z-threaded rods, what would you all recommend for reducing backlash? I was thinking of replacing the nut with a long nut...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 11, 2015 04:48AM |

Registered: 8 years ago Posts: 268 |

Quote

Uncertainty

For those of you who have x&y belt tensioners, what do you use?

For my X-axis I use [www.thingiverse.com]

I need something for my Y-axis. I found this [www.thingiverse.com], but I do not like the design.

Also, without changing the Z-threaded rods, what would you all recommend for reducing backlash? I was thinking of replacing the nut with a long nut...

Not used either, but they look nice ;-)

Z-Backlash

Y-Belt

I have a much more compact design for the Y-Carriage that mounts to the 2020 rail, let me look through my CAD files and see if I can find it.

Edit: Found my files and uploaded them to Thingi SL Y-Belt, this is one I did use and it worked well. I liked this one over the one that mounts underneath the bed just because it was easy to access and you could adjust it on the fly...

Edited 1 time(s). Last edit at 12/11/2015 06:02AM by sonnylowe.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 11, 2015 09:27AM |

Registered: 8 years ago Posts: 5 |

Quote

tjnamtiw

Quote

wowzerz

Hello Forum!

I'm new to the 3D printing scene and just finished the build of my FT 2020 last week. Once I "finished" the build I went over all the electrical connections to be sure they were all correct at least twice prior to ever plugging the unit into the USB or wall outlet. All the connections as listed in the build manual are correct. The configuration given by FT on the Google site was downloaded and I thought this was easy. I will be printing in a couple hours. So I go to home the unit. That's when things go bad. The home position is supposed to be where the extruder tip is located in the back right corner o f the bed. The X and Z axis seem to move to the correct positions however my Y axis is opposite they way it is supposed to move. During some iterations I also found that the Z axis is only responsive when it wants to be??? I ran M119 command and found that Y Max and Z Max are triggered all the time, even if the end stops are unplugged.

To make matters worse whatever is causing this issue also made my arduino smoke. Some forums suggest it is the voltage regulator as it seems to still work from USB.

I have tried the FT support site 4 days ago but have not heard anything from them. I believe the Ramps board may be defective but want to get some suggestions before replacing it.

According to the instruction manual, The plug for the X motor should have the red wire to the left. Put it just like the picture shows. The instructions call this the 'Z' motor again. Also these things need to be done that are different from the instructions.>>

Change the following in configuration.h

#define INVERT_X_DIR true to #define INVERT_X_DIR false

#define X_HOME_DIR -1 to #define X_HOME_DIR 1

With the printer off PHYSICALLY move the x-axis stopper to the left one set of pins (this makes it so it's the x max instead of x-min)

Now if you are using rep host, you need to go to printer settings > printer shape and change home X: from min to Max.

One big glaring mistake in the build manual is putting the X stop plug in the wrong place on the board. It should be right next to the Y stop plug, not two over as the manual says. Also, for the X motor plug wires, keep them as you see. It's not a mistake to have them reversed from the others. I DID end up reversing the extruder motor plug because it was pushing the filament out the top!

The new spring design extruder has a brass feed gear that, for me, was rubbing inside the motor housing and causing it to drag and skip steps

I did these things last evening and now all the travels seem to work in the correct direction. However, I still am getting a YMAX and ZMAX triggered at all times. Currently if I try to home my Y axis the bed moves to the front of the machine and doesn't stop it just wants to keep going and grinds on the belt. The Z axis will home to the endstop but will be locked there - as in I cannot even manually move it away from the endstop.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 11, 2015 10:02AM |

Registered: 8 years ago Posts: 541 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 11, 2015 10:05AM |

Registered: 8 years ago Posts: 5 |

Quote

tjnamtiw

In your attempts to getting the printer working, you probably have changed some other settings in the files. I suggest that you reload the Folger Tech files again and then make JUST the changes outlined above.

I wish this was the case - I have created a new uniquely named file for each change I have made. The changes you suggested were made to the original file and then uniquely saved and uploaded. So they should be stock FT with only your suggestions.

I will try to download the stock FT file again tonight and do it over just in case I did make an error during some save.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 11, 2015 10:43AM |

Registered: 8 years ago Posts: 80 |

You can fix this in the configure file by enabling the max end stop pull-up resistors or disabling the max end stops altogether.Quote

wowzerz

I did these things last evening and now all the travels seem to work in the correct direction. However, I still am getting a YMAX and ZMAX triggered at all times. Currently if I try to home my Y axis the bed moves to the front of the machine and doesn't stop it just wants to keep going and grinds on the belt. The Z axis will home to the endstop but will be locked there - as in I cannot even manually move it away from the endstop.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 11, 2015 10:50AM |

Registered: 8 years ago Posts: 5 |

Quote

elkayem

You can fix this in the configure file by enabling the max end stop pull-up resistors or disabling the max end stops altogether.Quote

wowzerz

I did these things last evening and now all the travels seem to work in the correct direction. However, I still am getting a YMAX and ZMAX triggered at all times. Currently if I try to home my Y axis the bed moves to the front of the machine and doesn't stop it just wants to keep going and grinds on the belt. The Z axis will home to the endstop but will be locked there - as in I cannot even manually move it away from the endstop.

Thanks - I'll give this a try tonight! I assume this is done in the Config.h file.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 11, 2015 11:12AM |

Registered: 8 years ago Posts: 80 |

Quote

sonnylowe

Quote

elkayem

Quote

Mach

Quote

elkayem

Quote

Mach

Quote

elkayem

What aluminum print bed are folks using with an inductive sensor? Is there an aluminum surface that can be added to the top of the MK2B heat bed (instead of the glass), or are people replacing the heat bed altogether? I'm going to add the proximity sensor. Tired of constantly adjusting my print bed alignment...

I just use a 8x8 inch aluminum plate I got for 13 bucks. This one

That looks pretty good! Does it stay fairly rigid and flat? Also, any problems getting the MK2B heat bed to keep it above 100 deg for ABS?

The plate is about 3mm thick so it has almost no flex to it. The plate I received was not entirely flat on one side, but the unevenness is within fractions of a mm. I just turn the plate onto the side that had the least curve after putting on the binder clips and it works very well. I only print with pla right now, so I have not tried going to 80c.

Thanks Mach!

Anyone else placing a 3mm aluminum plate on top of their MK2B heatbed? Any issues staying above 100 degC? I think I'm going to jump on it unless anyone has an alternative.

I had the 3mm aluminum bed over my MK2B heater, I never got it over 85C...I ran PID and it heated more quickly but still struggled to go past 85C. Could be something in my setup that's wrong...I'm not sure. Either way I printed ABS at 85C with no problem...I do print on Kapton though...

I might be going back to glass and a different sensor, if so I'll have this Build Plate and two sensors up for grabs...

I ended up purchasing the same aluminum plate short kit from Leap3D that you have. I placed my order before I saw your note, otherwise would have asked if yours is available.

I just installed it, and the plate has no problem getting above 100 deg C. Phew! Was concerned after seeing your note. A couple of thoughts on why your setup might be different... 1) Are the copper traces on your MK2B on the top side? If not, that could be your problem. 2) Have you checked the resistance of your heat bed? I've heard there is some variation between units, but spec says 1.0 a 1.2 Ohms. Lower is better, so if it is above 1.2, that may indicate you need a new heated bed. 3) Are you getting close to 12 V at the heated bed? If not, could be a power supply issue.

Also, I personally wouldn't use PID for the heated bed. It is useful if you want the temperature control to be very accurate, but it will cause the heated bed to heat more slowly, especially at the end. The bang-bang is just fine, with the only downside that the temperature will wander around the 2 deg deadband.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 11, 2015 11:28AM |

Registered: 8 years ago Posts: 80 |

Quote

wowzerz

Quote

elkayem

You can fix this in the configure file by enabling the max end stop pull-up resistors or disabling the max end stops altogether.Quote

wowzerz

I did these things last evening and now all the travels seem to work in the correct direction. However, I still am getting a YMAX and ZMAX triggered at all times. Currently if I try to home my Y axis the bed moves to the front of the machine and doesn't stop it just wants to keep going and grinds on the belt. The Z axis will home to the endstop but will be locked there - as in I cannot even manually move it away from the endstop.

Thanks - I'll give this a try tonight! I assume this is done in the Config.h file.

Yes. I ran into the same problem, and frankly don't understand why more people don't see this issue.

The following lines in Config.h fixed my problem:

#define ENDSTOPPULLUP_YMAX

#define ENDSTOPPULLUP_ZMAX

The endstops output 5V when open and 0V when closed. By enabling the pullup resistors on the Arduino board, the endstop pins are pulled up to 5V when unconnected, making Marlin believe the endstops are open.

Edited 1 time(s). Last edit at 12/11/2015 11:30AM by elkayem.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 11, 2015 11:31AM |

Registered: 8 years ago Posts: 32 |

Hi All, also waiting to build my FT2020 i3 (so probably a lot more questions to come after xmas - sorry!) I've already posted something similar on Reddit but have a few more things I'd like to get clarified and this place seems more active.

Marlin:

1. I was planning on using therippa's Marlin from the start and skipping the FT version completely. Is this advised? (I'm assuming 'Yes!')

2. If I move the X-Endstop to the left (MIN) side of the printer as seems to be the advice, does therippa's Marlin already account for this? I've looked in the 'ENDSTOP SETTINGS' in '@section homing' in config.h and they are all set to -1 (MIN). Is this the correct section to check?

3. In '@section temperature' I noticed that TEMP_SENSOR_BED is set to 0. Does this need to be changed if using a heated bed?

4. I will be installing a 128x64 LCD when building the printer. Is this already enabled? I've looked through '@section lcd' and nothing seems to be enabled..... Is DOGLCD the correct one?

Electronics:

5. Is it possible to test the RAMPS before installation? I know I can test the Arduino by uploading the blink sketch but wanted to test the RAMPS without connecting up the PSU, Steppers, Drivers, etc. If it'd be easier just to wire up all the electronics to test (i.e. before they are installed during the build) then I'm happy to do that if I have to.

That's it for now thanks!

Marlin:

1. I was planning on using therippa's Marlin from the start and skipping the FT version completely. Is this advised? (I'm assuming 'Yes!')

2. If I move the X-Endstop to the left (MIN) side of the printer as seems to be the advice, does therippa's Marlin already account for this? I've looked in the 'ENDSTOP SETTINGS' in '@section homing' in config.h and they are all set to -1 (MIN). Is this the correct section to check?

3. In '@section temperature' I noticed that TEMP_SENSOR_BED is set to 0. Does this need to be changed if using a heated bed?

4. I will be installing a 128x64 LCD when building the printer. Is this already enabled? I've looked through '@section lcd' and nothing seems to be enabled..... Is DOGLCD the correct one?

Electronics:

5. Is it possible to test the RAMPS before installation? I know I can test the Arduino by uploading the blink sketch but wanted to test the RAMPS without connecting up the PSU, Steppers, Drivers, etc. If it'd be easier just to wire up all the electronics to test (i.e. before they are installed during the build) then I'm happy to do that if I have to.

That's it for now thanks!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 11, 2015 11:57AM |

Registered: 8 years ago Posts: 276 |

Quote

Boffster

Hi All, also waiting to build my FT2020 i3 (so probably a lot more questions to come after xmas - sorry!) I've already posted something similar on Reddit but have a few more things I'd like to get clarified and this place seems more active.

Marlin:

1. I was planning on using therippa's Marlin from the start and skipping the FT version completely. Is this advised? (I'm assuming 'Yes!')

2. If I move the X-Endstop to the left (MIN) side of the printer as seems to be the advice, does therippa's Marlin already account for this? I've looked in the 'ENDSTOP SETTINGS' in '@section homing' in config.h and they are all set to -1 (MIN). Is this the correct section to check?

3. In '@section temperature' I noticed that TEMP_SENSOR_BED is set to 0. Does this need to be changed if using a heated bed?

4. I will be installing a 128x64 LCD when building the printer. Is this already enabled? I've looked through '@section lcd' and nothing seems to be enabled..... Is DOGLCD the correct one?

Electronics:

5. Is it possible to test the RAMPS before installation? I know I can test the Arduino by uploading the blink sketch but wanted to test the RAMPS without connecting up the PSU, Steppers, Drivers, etc. If it'd be easier just to wire up all the electronics to test (i.e. before they are installed during the build) then I'm happy to do that if I have to.

That's it for now thanks!

1. Yes!

2. No, there are a couple settings you have to change, look at my personal settings (https://github.com/therippa/Marlin/blob/E3D_V6/Marlin/Configuration.h) from the top of my head you have to change X_HOME_DIR to -1 and set X endstop position to MIN in your host software (which it should already be by default)

3. ...what file are you looking at? TEMP_SENSOR_BED is set to 1 in my file (line 110)

4. Look to my personal settings branch for the settings to enable that LCD (line 569, and you have to load u8glib, google it)

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 11, 2015 12:27PM |

Registered: 8 years ago Posts: 32 |

Quote

therippa

1. Yes!

2. No, there are a couple settings you have to change, look at my personal settings (https://github.com/therippa/Marlin/blob/E3D_V6/Marlin/Configuration.h) from the top of my head you have to change X_HOME_DIR to -1 and set X endstop position to MIN in your host software (which it should already be by default)

3. ...what file are you looking at? TEMP_SENSOR_BED is set to 1 in my file (line 110)

4. Look to my personal settings branch for the settings to enable that LCD (line 569, and you have to load u8glib, google it)

Thanks for the reply - my apologies, I must have downloaded the original Marlin or something. Downloaded again from your link and line 110 is correct for TEMP_SENSOR_BED.

I've looked at your personal settings branch and can see the line for the LCD thanks (also for the u8glib info).

Just to check - the version I've downloaded is the release branch (https://github.com/therippa/Marlin/tree/Release/) > 'Download ZIP'. This is the one I was planning on using.

And I should IGNORE this advice from your page: "Changes you must make to the RAMPS board and Host This firmware corrects some problems with the Folgertech firmware, namely X-axis issues. Please move your X-endstop plug one set of pins over to position 6, and change the X-Endstop settings in your host to MAX."

Cheers

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 11, 2015 01:40PM |

Registered: 8 years ago Posts: 276 |

Quote

Boffster

Just to check - the version I've downloaded is the release branch (https://github.com/therippa/Marlin/tree/Release/) > 'Download ZIP'. This is the one I was planning on using.

And I should IGNORE this advice from your page: "Changes you must make to the RAMPS board and Host This firmware corrects some problems with the Folgertech firmware, namely X-axis issues. Please move your X-endstop plug one set of pins over to position 6, and change the X-Endstop settings in your host to MAX."

Cheers

Correct, if the endstop is on the left you should not do that stuff.

Edited 1 time(s). Last edit at 12/11/2015 01:41PM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

Sorry, only registered users may post in this forum.