Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 16, 2015 09:09PM |

Registered: 9 years ago Posts: 40 |

I looked at it tonight and you are right. Only having two screws in the stepper is causing it to sag a little.Quote

therippa

Quote

sethmo

Therippa,

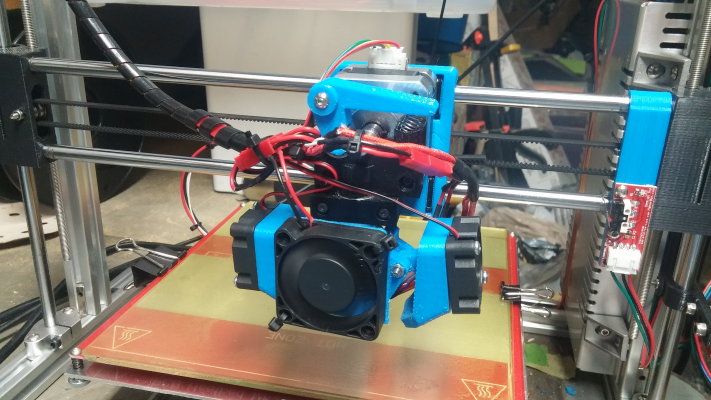

I installed your extruder with my e3dv6 last night. After bolting it together, I noticed that my e3dv6 is not perpendicular to the bed, it is at a slight angle. I am going to try to shim it and adjust the bed level after work, but I think it will work out great.

Mine does that too, it's the x-carriage we're using, not the extruder

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 16, 2015 10:09PM |

Registered: 8 years ago Posts: 430 |

Quote

markts

I'm so embarrassed.

I've been printing up a storm with parts for my quadcopter, replacement parts for the printer, trinkets, etc. The prints have been getting better as I've tweaked things.

Until I printed the fan duct for a second extruder fan. I think my prints are mirrored.Back to square one. lol.

For all those posts I flew by from people asking about X and Y-min, direction, I'm now humbled that I have to visit them.

If I print something with text on it and my prints are mirrored around the Y axis, should I expect the letters to be mirrored? I think I printed something with letters and it came out fine (will try again tonight).

Any good calibration things on Thingiverse to highlight errors in mirroring?

I didnt the same thing it's amazing how many think you can print that still are correct when mirrored.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 16, 2015 10:19PM |

Registered: 8 years ago Posts: 285 |

Quote

Keary123

Quick question.

I had auto bed leveling setup and running using the supplied Z end-stop switch. I am looking to change out the end-stop with a more precise micro-switch.

I was wondering if anyone has used the micro-switch and what connections they wired to the ramps board.

The switch has "C" which i am guessing is signal, "NO" normally open, and "NC" normally closed.

Thanks for the help.

C stands for common, and is the "input" terminal of the switch. I do not have a micro-switch for my setup, but the C terminal would go to the Vcc endstop pin (the furthest pin from the edge of the board), and the NC or NO would go to the endstop signal pin (closest pin to the edge of the board). Put a resistor higher than 250 ohms between the signal pin and the ground pin (middle endstop pin), this will be your pulldown resistor. You may have to reverse your endstop logic in firmware depending on whether of not you used the NO or NC terminal on the switch. Using the NC terminal would be best since you would not have to switch the logic.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 16, 2015 10:31PM |

Registered: 8 years ago Posts: 5 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 16, 2015 10:41PM |

Registered: 8 years ago Posts: 13 |

Quote

Mach

Quote

photo444

Quote

Mach

Quote

photo444

Hi All,

I have been watching this forum with excitement for a while and now I have one built and it still is in its tuning/adjusting sessions. When I was printing lower-profile objects all was OK but when z axis reaches more than 10 cm the motor misses steps. I found out that the left side guide rod and the threaded rod are NOT parallel at all; the spacing at the motor mount between the hardened rod and the stepper axis is far less than the distance between the guiding rod and the threaded rod of the left side x gantry.

Did anyone have this kind of trouble? Is there any quick fix?

Thank you in advance for any suggestions.

Paul

I think all of the printer kits that FT give come with acrylic rod holders that are not cut properly. On my printer, the misalignment does not become troublesome until it moves to the last 1cm near the top, so I am thinking something was not installed properly, or the holders that FT gives with their kits have become even worse. I may make a stl model with the proper measurements to fix the alignment issues with this printer. Let me know if it is desperately needed, I may expedite getting around to doing that if so.

Hi Mach,

Thanks for your reply. I think it is good idea to modify the "rod holding plate". I am now waiting for filaments to come in for any more prints. I will measure necessary modification and let you know.

Added: The center-center distance of the guide rod (8mm) and the stepper axis is 17.0 mm

Here it is. Rod holding plate. I made the holes to hopefully have the right tolerances, but if anything does not quite fit properly, I can make some quick adjustments.

I am printing now! Thank you and I will let you know.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 16, 2015 10:42PM |

Registered: 8 years ago Posts: 285 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 17, 2015 12:16AM |

Registered: 8 years ago Posts: 84 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 17, 2015 12:31AM |

Registered: 8 years ago Posts: 13 |

Mach,

The piece was installed; It helped but needs more. As you see in the picture the angle is still large. I could not go to this height before. The center to center distance should be 18 mm. Could you please draw STL file once more for me? The overall size can be little larger perhaps by 1 mm.

The piece was installed; It helped but needs more. As you see in the picture the angle is still large. I could not go to this height before. The center to center distance should be 18 mm. Could you please draw STL file once more for me? The overall size can be little larger perhaps by 1 mm.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 17, 2015 12:44AM |

Registered: 8 years ago Posts: 84 |

photo444 you need these z motor standoff

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 17, 2015 12:46AM |

Registered: 8 years ago Posts: 2 |

I am having an issue that I can't figure out.

I am getting great quality parts. On the very last 'Y' move of the print, it seems to move in the wrong direction. Since this is the very last move, it doesn't really cause too much of an issue. Usually just extrudes some plastic in mid air. Also after it completes this moves, which also completes the print, it has an issue moving back to the Y home. Instead of stopping at the switch, it tries to drive through it.

Any ideas?

I am getting great quality parts. On the very last 'Y' move of the print, it seems to move in the wrong direction. Since this is the very last move, it doesn't really cause too much of an issue. Usually just extrudes some plastic in mid air. Also after it completes this moves, which also completes the print, it has an issue moving back to the Y home. Instead of stopping at the switch, it tries to drive through it.

Any ideas?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 17, 2015 02:02AM |

Registered: 8 years ago Posts: 276 |

Quote

mizelly41

I am having an issue that I can't figure out.

I am getting great quality parts. On the very last 'Y' move of the print, it seems to move in the wrong direction. Since this is the very last move, it doesn't really cause too much of an issue. Usually just extrudes some plastic in mid air. Also after it completes this moves, which also completes the print, it has an issue moving back to the Y home. Instead of stopping at the switch, it tries to drive through it.

Any ideas?

Read animoose's blog, I think he had some ending gcode that fixes this problem (something to do with memory buffers, I can't remember because it was months ago).

Also, try upgrading to my firmware, it seems to solve a lot of problems around here

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 17, 2015 02:55AM |

Registered: 8 years ago Posts: 285 |

Quote

photo444

Mach,

The piece was installed; It helped but needs more. As you see in the picture the angle is still large. I could not go to this height before. The center to center distance should be 18 mm. Could you please draw STL file once more for me? The overall size can be little larger perhaps by 1 mm.

Here is the piece 18mm and 19mm between centers. let me know which one works, and I will update the one on thingiverse. I also brought out the sides abit.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 17, 2015 08:16AM |

Registered: 8 years ago Posts: 268 |

Quote

built350camaro

Need some help here guys. I want to have my printer to print a line from the home corner to the print area. I cant figure out the gcode to make it do it.

Writing G-Code to get the printer to lay down a bead of filament is pretty easy, but I'm not sure how you'd get it to do that on it's way to the starting point of the print (if I'm reading your request correctly). For example, my printer runs a bead of filament (from both extruders) across the front of the print bed after G29 but prior to starting the actual print.

If you know of a printer that does this move already I can load that profile (if available) into S3D and get you the G-Code...

Just curious, why you want your printer to make this move...

Sonny

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 17, 2015 10:09AM |

Registered: 8 years ago Posts: 57 |

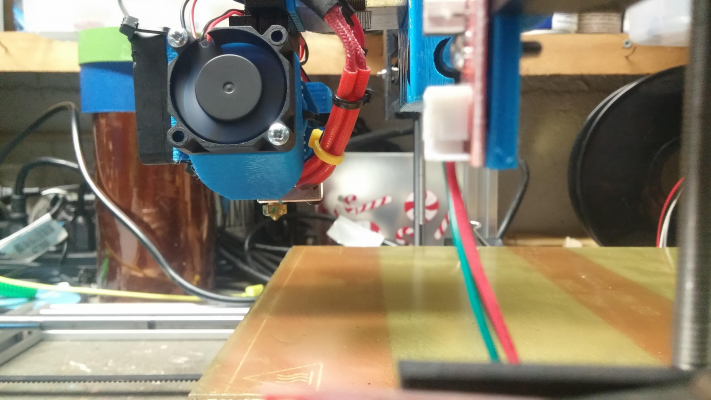

Those of you with leadscrews and Z motor standoffs.. what's your max print height?

Just did this bad boy, arbitrarily scaled down, got lucky as I never really measured. Comes in at 6.5" / 165MM . I have leadscrews and the motor standoffs.

Last print before I mount up the e3d v6 and therippas' extruder

Edited 1 time(s). Last edit at 12/17/2015 10:10AM by srcga.

Just did this bad boy, arbitrarily scaled down, got lucky as I never really measured. Comes in at 6.5" / 165MM . I have leadscrews and the motor standoffs.

Last print before I mount up the e3d v6 and therippas' extruder

Edited 1 time(s). Last edit at 12/17/2015 10:10AM by srcga.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 17, 2015 11:04AM |

Registered: 8 years ago Posts: 13 |

Quote

Mach

Quote

photo444

Mach,

The piece was installed; It helped but needs more. As you see in the picture the angle is still large. I could not go to this height before. The center to center distance should be 18 mm. Could you please draw STL file once more for me? The overall size can be little larger perhaps by 1 mm.

Here is the piece 18mm and 19mm between centers. let me know which one works, and I will update the one on thingiverse. I also brought out the sides abit.

You are so quick! I have printed 18mm version this morning before I went to work. I will try this evening. There is a concern: If I keep increasing the spacing the two rods eventually will not run parallel. This is more headache than what I thought. I may disassemble x gantries and examine what real problem may be. Thank you, Mach!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 17, 2015 11:59AM |

Registered: 8 years ago Posts: 57 |

Quote

Keary123

Quick question.

I had auto bed leveling setup and running using the supplied Z end-stop switch. I am looking to change out the end-stop with a more precise micro-switch.

I was wondering if anyone has used the micro-switch and what connections they wired to the ramps board.

The switch has "C" which i am guessing is signal, "NO" normally open, and "NC" normally closed.

Thanks for the help.

Do you still need help with this?

Yes, I've changed out to microswitch. Info is in this thread if you search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 17, 2015 12:25PM |

Registered: 8 years ago Posts: 367 |

Quote

therippa

Quote

mizelly41

I am having an issue that I can't figure out.

I am getting great quality parts. On the very last 'Y' move of the print, it seems to move in the wrong direction. Since this is the very last move, it doesn't really cause too much of an issue. Usually just extrudes some plastic in mid air. Also after it completes this moves, which also completes the print, it has an issue moving back to the Y home. Instead of stopping at the switch, it tries to drive through it.

Any ideas?

Read animoose's blog, I think he had some ending gcode that fixes this problem (something to do with memory buffers, I can't remember because it was months ago).

It was in this post (http://moosteria.blogspot.com/2015/06/3d-printer-project-part-11-week-of.html). The M400 command waits for the motors to complete the current moves before continuing. It's not really flushing memory buffers, though that is what I said in the original post.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 17, 2015 07:39PM |

Registered: 8 years ago Posts: 84 |

Quote

sonnylowe

Quote

built350camaro

Need some help here guys. I want to have my printer to print a line from the home corner to the print area. I cant figure out the gcode to make it do it.

Writing G-Code to get the printer to lay down a bead of filament is pretty easy, but I'm not sure how you'd get it to do that on it's way to the starting point of the print (if I'm reading your request correctly). For example, my printer runs a bead of filament (from both extruders) across the front of the print bed after G29 but prior to starting the actual print.

If you know of a printer that does this move already I can load that profile (if available) into S3D and get you the G-Code...

Just curious, why you want your printer to make this move...

Sonny

I would be fine with it printing a line like you said. I am wanting it to print a little before it prints the part because if I print something small it doesn't prime enough with a skirt (unless it is crazy amounts of loops) and then it messes up the bottom layer.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 17, 2015 07:42PM |

Registered: 8 years ago Posts: 84 |

Quote

srcga

Those of you with leadscrews and Z motor standoffs.. what's your max print height?

Just did this bad boy, arbitrarily scaled down, got lucky as I never really measured. Comes in at 6.5" / 165MM . I have leadscrews and the motor standoffs.

Last print before I mount up the e3d v6 and therippas' extruder

I am not running lead screws yet but it still works great with the threaded rods. My build height is around 165mm too. I thought about making some spacers for the rod holders at the bottom to get a bit more build height but I haven't needed more height yet.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 17, 2015 08:41PM |

Registered: 8 years ago Posts: 285 |

Quote

built350camaro

Quote

sonnylowe

Quote

built350camaro

Need some help here guys. I want to have my printer to print a line from the home corner to the print area. I cant figure out the gcode to make it do it.

Writing G-Code to get the printer to lay down a bead of filament is pretty easy, but I'm not sure how you'd get it to do that on it's way to the starting point of the print (if I'm reading your request correctly). For example, my printer runs a bead of filament (from both extruders) across the front of the print bed after G29 but prior to starting the actual print.

If you know of a printer that does this move already I can load that profile (if available) into S3D and get you the G-Code...

Just curious, why you want your printer to make this move...

Sonny

I would be fine with it printing a line like you said. I am wanting it to print a little before it prints the part because if I print something small it doesn't prime enough with a skirt (unless it is crazy amounts of loops) and then it messes up the bottom layer.

Just add a G1 E(some desired amount of filament in mm) command to the end of your start gcode. This will make the printer extrude said amount of filament after it homes, but before it starts printing.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 17, 2015 08:58PM |

Registered: 8 years ago Posts: 367 |

As there have been a couple of recent posting about start G code, here is mine. A couple of comments on it: it starts heating the bed and the extruder at the same time, though due to a pecularity of Repetier, it doesn't display the temperature of the bed until the extruder is up to temperature. The LCD shows it correctly. And then it draws a L-shape with the second part of the L rising into the air. I forget who posted this trick originally, and I find it helps to clear any ooze off the nozzle, while usually giving a clean start to the skirt (though this does vary a little with the filament and exact temperature settings).

See my blog at [moosteria.blogspot.com].

G28 ; home all axes G90; absolute coordinates G1 Z0.05 ; move nozzle close to bed M140 S[first_layer_bed_temperature] ; start heating bed M109 S[first_layer_temperature] ; heat nozzle and wait until reached M190 S[first_layer_bed_temperature] ; wait for bed temperature M82 ; use absolute distances for extruder G92 E0 ; zero the extruder position G1 X200 Y0 Z.35 F900; G1 X175 Y0 Z.15 E5 F225; G1 X175 Y25 Z5 F3600; M400 ; wait until we get there G92 E0 ; zero the extruder position

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 18, 2015 01:08AM |

Registered: 8 years ago Posts: 276 |

Quote

animoose

As there have been a couple of recent posting about start G code, here is mine. A couple of comments on it: it starts heating the bed and the extruder at the same time, though due to a pecularity of Repetier, it doesn't display the temperature of the bed until the extruder is up to temperature. The LCD shows it correctly. And then it draws a L-shape with the second part of the L rising into the air. I forget who posted this trick originally, and I find it helps to clear any ooze off the nozzle, while usually giving a clean start to the skirt (though this does vary a little with the filament and exact temperature settings).

G28 ; home all axes G90; absolute coordinates G1 Z0.05 ; move nozzle close to bed M140 S[first_layer_bed_temperature] ; start heating bed M109 S[first_layer_temperature] ; heat nozzle and wait until reached M190 S[first_layer_bed_temperature] ; wait for bed temperature M82 ; use absolute distances for extruder G92 E0 ; zero the extruder position G1 X200 Y0 Z.35 F900; G1 X175 Y0 Z.15 E5 F225; G1 X175 Y25 Z5 F3600; M400 ; wait until we get there G92 E0 ; zero the extruder position

The folks at Simplify3d are the ones who gave me the L-motion trick, you should try out their software

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 18, 2015 09:58AM |

Registered: 8 years ago Posts: 70 |

Quote

therippa

Quote

animoose

As there have been a couple of recent posting about start G code, here is mine. A couple of comments on it: it starts heating the bed and the extruder at the same time, though due to a pecularity of Repetier, it doesn't display the temperature of the bed until the extruder is up to temperature. The LCD shows it correctly. And then it draws a L-shape with the second part of the L rising into the air. I forget who posted this trick originally, and I find it helps to clear any ooze off the nozzle, while usually giving a clean start to the skirt (though this does vary a little with the filament and exact temperature settings).

G28 ; home all axes G90; absolute coordinates G1 Z0.05 ; move nozzle close to bed M140 S[first_layer_bed_temperature] ; start heating bed M109 S[first_layer_temperature] ; heat nozzle and wait until reached M190 S[first_layer_bed_temperature] ; wait for bed temperature M82 ; use absolute distances for extruder G92 E0 ; zero the extruder position G1 X200 Y0 Z.35 F900; G1 X175 Y0 Z.15 E5 F225; G1 X175 Y25 Z5 F3600; M400 ; wait until we get there G92 E0 ; zero the extruder position

The folks at Simplify3d are the ones who gave me the L-motion trick, you should try out their software

that looks like what i am running on mine, works wonders for me

the L-motion is great for purge the hot end and getting it ready for the print.

the L-motion is great for purge the hot end and getting it ready for the print.Edited 1 time(s). Last edit at 12/18/2015 10:05AM by Mopar99.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 18, 2015 10:01AM |

Registered: 8 years ago Posts: 57 |

Quote

therippa

The folks at Simplify3d are the ones who gave me the L-motion trick, you should try out their software

Neat trick, so I don't have to sit there with tweezers before each print grabbing all the gunk

My starting code is similar, but usually I will pre-heat the bed with a piece of insulation on it ahead of time. Once heated then I'll start the print from SD.

I have most of the similar upgrades as you, and animoose.. learned a lot from all your posts. Have a draft blog post but waiting to get this e3d installed before I put it up.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 18, 2015 10:20AM |

Registered: 8 years ago Posts: 268 |

Quote

built350camaro

Quote

srcga

Those of you with leadscrews and Z motor standoffs.. what's your max print height?

Just did this bad boy, arbitrarily scaled down, got lucky as I never really measured. Comes in at 6.5" / 165MM . I have leadscrews and the motor standoffs.

Last print before I mount up the e3d v6 and therippas' extruder

I am not running lead screws yet but it still works great with the threaded rods. My build height is around 165mm too. I thought about making some spacers for the rod holders at the bottom to get a bit more build height but I haven't needed more height yet.

Edit: Wrong post...sorry ;-)

Edited 1 time(s). Last edit at 12/18/2015 10:21AM by sonnylowe.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 18, 2015 10:22AM |

Registered: 8 years ago Posts: 268 |

Quote

built350camaro

Quote

sonnylowe

Quote

built350camaro

Need some help here guys. I want to have my printer to print a line from the home corner to the print area. I cant figure out the gcode to make it do it.

Writing G-Code to get the printer to lay down a bead of filament is pretty easy, but I'm not sure how you'd get it to do that on it's way to the starting point of the print (if I'm reading your request correctly). For example, my printer runs a bead of filament (from both extruders) across the front of the print bed after G29 but prior to starting the actual print.

If you know of a printer that does this move already I can load that profile (if available) into S3D and get you the G-Code...

Just curious, why you want your printer to make this move...

Sonny

I would be fine with it printing a line like you said. I am wanting it to print a little before it prints the part because if I print something small it doesn't prime enough with a skirt (unless it is crazy amounts of loops) and then it messes up the bottom layer.

Looks like there's a lot of good advice posted...have fun :-)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 18, 2015 11:19PM |

Registered: 8 years ago Posts: 84 |

Quote

animoose

As there have been a couple of recent posting about start G code, here is mine. A couple of comments on it: it starts heating the bed and the extruder at the same time, though due to a pecularity of Repetier, it doesn't display the temperature of the bed until the extruder is up to temperature. The LCD shows it correctly. And then it draws a L-shape with the second part of the L rising into the air. I forget who posted this trick originally, and I find it helps to clear any ooze off the nozzle, while usually giving a clean start to the skirt (though this does vary a little with the filament and exact temperature settings).

G28 ; home all axes G90; absolute coordinates G1 Z0.05 ; move nozzle close to bed M140 S[first_layer_bed_temperature] ; start heating bed M109 S[first_layer_temperature] ; heat nozzle and wait until reached M190 S[first_layer_bed_temperature] ; wait for bed temperature M82 ; use absolute distances for extruder G92 E0 ; zero the extruder position G1 X200 Y0 Z.35 F900; G1 X175 Y0 Z.15 E5 F225; G1 X175 Y25 Z5 F3600; M400 ; wait until we get there G92 E0 ; zero the extruder position

That worked great I just removed the M140 M109 and M190 since I usually heat the be before it starts any of the g-code.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 19, 2015 10:07AM |

Registered: 8 years ago Posts: 268 |

More fun with the LED Christmas Tree

The original was a bit boring...

So I added some color...

Much better

Edit:

Here's a one printed from opaque green with clear filament lights

Edited 1 time(s). Last edit at 12/19/2015 01:34PM by sonnylowe.

The original was a bit boring...

So I added some color...

Much better

Edit:

Here's a one printed from opaque green with clear filament lights

Edited 1 time(s). Last edit at 12/19/2015 01:34PM by sonnylowe.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 19, 2015 11:44AM |

Registered: 8 years ago Posts: 268 |

Quote

built350camaro

Quote

animoose

As there have been a couple of recent posting about start G code, here is mine. A couple of comments on it: it starts heating the bed and the extruder at the same time, though due to a pecularity of Repetier, it doesn't display the temperature of the bed until the extruder is up to temperature. The LCD shows it correctly. And then it draws a L-shape with the second part of the L rising into the air. I forget who posted this trick originally, and I find it helps to clear any ooze off the nozzle, while usually giving a clean start to the skirt (though this does vary a little with the filament and exact temperature settings).

G28 ; home all axes G90; absolute coordinates G1 Z0.05 ; move nozzle close to bed M140 S[first_layer_bed_temperature] ; start heating bed M109 S[first_layer_temperature] ; heat nozzle and wait until reached M190 S[first_layer_bed_temperature] ; wait for bed temperature M82 ; use absolute distances for extruder G92 E0 ; zero the extruder position G1 X200 Y0 Z.35 F900; G1 X175 Y0 Z.15 E5 F225; G1 X175 Y25 Z5 F3600; M400 ; wait until we get there G92 E0 ; zero the extruder position

That worked great I just removed the M140 M109 and M190 since I usually heat the be before it starts any of the g-code.

I had to try this as well...I must say, I likey!!! I did change it up a bit, I'm currently running Bowden Extruders so I needed to push a little more filament to get the hotend to prime. I added another 10mm of length to the purge and upped the extrusion to 15mm on the first pass and left the the raise pass at 5mm...it works perfectly for my setup now

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 19, 2015 12:12PM |

Registered: 8 years ago Posts: 84 |

Anyone messed around with Craft Ware yet? It is still early development but looks pretty promising.

Sorry, only registered users may post in this forum.