Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 29, 2015 04:32PM |

Registered: 8 years ago Posts: 38 |

Tried my first ever calibration cube print:

Immediately ran into a problem where The extruder printed first layer

Second layer started to peal off wrapped onto extruder. This continued until a lot of filament wrapped onto extruder tip and none was left on the bed.it almost pealed off.

Some key points:

Bed was only at 60 deg

Half of the bed doesn't even heat up and the cube was printed in centre (my solder connections look solid for the red and black wires so don't know why this is happening)

I'm going to try printing on the front half and use 80-90 deg C.

Any other tips on how to not get the filament to just peal off the bed and get stuck onto extruder while printing ?

Immediately ran into a problem where The extruder printed first layer

Second layer started to peal off wrapped onto extruder. This continued until a lot of filament wrapped onto extruder tip and none was left on the bed.it almost pealed off.

Some key points:

Bed was only at 60 deg

Half of the bed doesn't even heat up and the cube was printed in centre (my solder connections look solid for the red and black wires so don't know why this is happening)

I'm going to try printing on the front half and use 80-90 deg C.

Any other tips on how to not get the filament to just peal off the bed and get stuck onto extruder while printing ?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 29, 2015 04:48PM |

Registered: 8 years ago Posts: 276 |

Quote

jhitesma

I've been wanting to get into 3D printing for years. Started collecting parts to build a reprap a couple of times but never got enough parts to actually get anything working. Last April I tore apart a bunch of old DVD drives and made a little 2 axis motion platform out of some of the parts...but never even implemented a Z axis let alone an extruder. Still it taught me enough about the basics to get me really excited about finally making a real printer.

It was when a friend on another forum found Folger and ordered up a 2020 i3 kit that I got really excited. <$300 for a setup like that?! Ok, I'm REALLY interested. Started saving money to get my own before he even had his assembled.

He ran into the usual set of issues - a few pieces missing, damaged hot end thermister, RAMPS issue causing more thermister issues...but he worked through them and started making prints. Meantime I continued to research. I've read most of this thread and several others on other forums about this kit.

With the addition of a Christmas bonus to my savings I was finally able to pull the trigger a week before Christmas. I ordered late on a Friday direct from Folger. I added in the LCD module, 2 rolls of filament (one ABS one PLA) and an inductive sensor. It shipped in two packages both of which left Folger the following Monday. If it wasn't for Christmas they would have been here that Friday - due to the holiday I got my kit the day after Christmas - but I'm not complaining!

I dug right in that night and made 4 hours of progress getting the frame and Y axis completed, You can view a time lapse of this first building session here: [www.youtube.com]

I was tempted to keep going...but figured a good nights rest would improve my chances of success the next day. The next day my wife had the day off and agreed to watch our daughter so I was able to devote the full day to building. It took me another 6 hours or so to have the printer "done" and ready for me to load firmware and start calibrating things. You can see this build session here: [www.youtube.com]

I then spent the next 6 hours doing "little things" like tensioning belts, final tightening on screws, fine tuning alignments, loading firmware, configuring firmware, setting endstops....

I did run into 2 major issues with my kit:

1) The fan on the extruder didn't work. Every now and then it would move a little bit and that was it. Confirmed it had 12v...just a bad fan. The second day the fan shorted out entirely and melted down it's power wires. I swapped in a fan from an older mother board as a temporary replacement but Folger has said they're sending me a new fan.

2) The hot end thermister was damaged. Where the brass tube was crimped over it it had cut through the teflon tubing and one lead of the thermister. I was able to solder it back together but it's only a temporary fix. Folger says they're sending me a whole new hotend and I ordered some spare thermisters as I can easily see breaking one again.

I used therippa's pre-configured version of Marlin to start from and got about halfway through Triffid's calibration instructions (got to Slicer Settings) before deciding it was time to do a first test. I grabbed the first .stl I had on hand - a LCD bracket, opened it in repetier and send it to slic3r...hit print...and...it worked!

[www.youtube.com]

Seriously! Holy cow! I did NOT expect results like that for my first print. It's not flawless...but for a first print ever I'm overjoyed!

[attachment 68503 12434933_10153177602426805_425572391_o.jpg]

[attachment 68504 12438756_10153177601061805_1922951700_o.jpg]

My X axis is still mirrored. I followed instructions I was given to move the endstop to the left side instead of the right...but am a bit lost in the configuration.h and repetier options...it's working...just everything is mirrored on the X axis. I'm sure I can work it out - just having too much fun printing some tests to worry about dealing with it yet

I printed the other LCD mount and it came out just as good! Then tried to do something complex and grabbed a penguin model off thingiverse for my daughter. Here the broken extruder fan (I hadn't yet put the temporary fan on) came back to bite me. The penguin printed great until about 50% completion and then my extruder stopped extruding. As I suspected the lack of a fan let the filament get too hot and it melted up in the extruder:

[attachment 68505 12443817_10153178495111805_47585620_o.jpg]

Got that cleaned out...and sure enough the thermister lead broke again. Got that fixed, added the temporary fan...and tried to do some more tests.

But this time I couldn't get anything to stick to the bed. Gave the bed a good cleaning, turned the temp up a little bit, and re-leveled the bed...things stuck again so I printed off a stack of 5x5 calibration cubes, a little mermaid for my daughter, and finally a minimug to finish the night.

Calibration cubes look better than I expected. The Y axis seems to be the least accurate even though my X is loudest, Z seems pretty darn close. The 20mm minimug measures in at 19.96mm which I'm happy with for only being roughly calibrated!

Overall not bad!

[attachment 68506 12443401_10153179248706805_1285399487_o.jpg]

Y-axis is a little off:

[attachment 68507 12458624_10153179250676805_171444369_o.jpg]

X looks better than I expected:

[attachment 68508 12438916_10153179250871805_927464188_o.jpg]

Bridging performance could be better...I'm at the upper heat range for PLA so I'm not surprised:

[attachment 68509 12438817_10153179249056805_1813269955_o.jpg]

To fix the X mirroring problem: "This firmware corrects some problems with the Folgertech firmware, namely X-axis issues. Please move your X-endstop plug one set of pins over to position 6, and change the X-Endstop settings in your host to MAX." Everything else in the configuration.h file should be fine and won't need changed.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 29, 2015 05:00PM |

Registered: 8 years ago Posts: 85 |

Quote

therippa

To fix the X mirroring problem: "This firmware corrects some problems with the Folgertech firmware, namely X-axis issues. Please move your X-endstop plug one set of pins over to position 6, and change the X-Endstop settings in your host to MAX." Everything else in the configuration.h file should be fine and won't need changed.

Yeah, I saw that and pretty sure I did that. I know I moved the stop and I changed the setting to max.

But I think the problem is I moved my endstop to the left as you face the machine due to some other advice I got. I think your setup assume the endstop is on the right which is why I'm having issues. But now I probably mixed something else up in my configuration.h.

Basically just got mixed up over endstop position, and the various end stop settings. And been having too much fun printing things to actually fix it

Did a treefrog for my daughter over lunch. Couldn't get it to stick last night but worked first try today...think my bed just wasn't leveled well last night is why things weren't sticking.

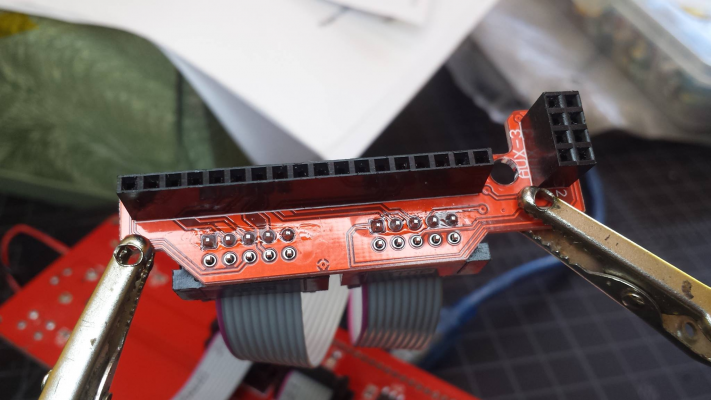

Did a treefrog for my daughter over lunch. Couldn't get it to stick last night but worked first try today...think my bed just wasn't leveled well last night is why things weren't sticking.Also, think I figured out why my LCD from Folger isn't working:

I could be wrong but I assume both rows of pins are meant to be soldered on those headers

Soldered them up over lunch but didn't have time to hook it up and test it since the frog was still printing

Soldered them up over lunch but didn't have time to hook it up and test it since the frog was still printing

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 29, 2015 05:21PM |

Registered: 8 years ago Posts: 276 |

Quote

jhitesma

Quote

therippa

To fix the X mirroring problem: "This firmware corrects some problems with the Folgertech firmware, namely X-axis issues. Please move your X-endstop plug one set of pins over to position 6, and change the X-Endstop settings in your host to MAX." Everything else in the configuration.h file should be fine and won't need changed.

Yeah, I saw that and pretty sure I did that. I know I moved the stop and I changed the setting to max.

But I think the problem is I moved my endstop to the left as you face the machine due to some other advice I got. I think your setup assume the endstop is on the right which is why I'm having issues. But now I probably mixed something else up in my configuration.h.

Basically just got mixed up over endstop position, and the various end stop settings. And been having too much fun printing things to actually fix itDid a treefrog for my daughter over lunch. Couldn't get it to stick last night but worked first try today...think my bed just wasn't leveled well last night is why things weren't sticking.

Also, think I figured out why my LCD from Folger isn't working:

[attachment 68523 12465027_10153180273706805_1420677099_o.jpg]

I could be wrong but I assume both rows of pins are meant to be soldered on those headersSoldered them up over lunch but didn't have time to hook it up and test it since the frog was still printing

Yes, moving the endstop to the left is a good move, especially if you plan on setting up autolevel in the future. In that case, move the X-endstop plug back to the previous pins and set X-end to MIN in repetier.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 29, 2015 05:48PM |

Registered: 8 years ago Posts: 131 |

Hey guys quick question. I'm reading through the thread but only on page 30 so sorry if this is answered somewhere in there. I finished my build (not tested yet) but having built a laser cutter before, I've worked with this kind of setup. I'm hating the bearing we have for x and y axis. Is there an upgrade that people do to change this out or are most people sticking with these?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 29, 2015 06:01PM |

Registered: 8 years ago Posts: 276 |

Quote

marc2912

Hey guys quick question. I'm reading through the thread but only on page 30 so sorry if this is answered somewhere in there. I finished my build (not tested yet) but having built a laser cutter before, I've worked with this kind of setup. I'm hating the bearing we have for x and y axis. Is there an upgrade that people do to change this out or are most people sticking with these?

You can upgrade to igus drylin bushings or misumi real-deal LM8UU's, both of which cost about $6/piece. I think the better upgrade is building out sonnylowe's v-rail setup, which probably ends up costing the same as the pricier bearings but is just better.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 29, 2015 07:46PM |

Registered: 8 years ago Posts: 285 |

Quote

jhitesma

Also, think I figured out why my LCD from Folger isn't working:

[attachment 68523 12465027_10153180273706805_1420677099_o.jpg]

I could be wrong but I assume both rows of pins are meant to be soldered on those headersSoldered them up over lunch but didn't have time to hook it up and test it since the frog was still printing

Hahaha, good ol' folger tech QC, lol

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 29, 2015 09:08PM |

Registered: 8 years ago Posts: 4 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 29, 2015 09:26PM |

Registered: 8 years ago Posts: 131 |

Quote

therippa

Quote

marc2912

Hey guys quick question. I'm reading through the thread but only on page 30 so sorry if this is answered somewhere in there. I finished my build (not tested yet) but having built a laser cutter before, I've worked with this kind of setup. I'm hating the bearing we have for x and y axis. Is there an upgrade that people do to change this out or are most people sticking with these?

You can upgrade to igus drylin bushings or misumi real-deal LM8UU's, both of which cost about $6/piece. I think the better upgrade is building out sonnylowe's v-rail setup, which probably ends up costing the same as the pricier bearings but is just better.

Thanks

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 29, 2015 09:28PM |

Registered: 8 years ago Posts: 131 |

Anyone try installing a cyclops hot end? on a folgertech yet?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 29, 2015 11:43PM |

Registered: 8 years ago Posts: 80 |

Great story! Your experiences sound very familiar. Think about every setback as an opportunity to learn more about your printer. And to upgrade! Think about retiring that failed extruder and ordering a $35 E3D lite6 extruder. In the meantime, if it is clogged there are some fairly straight forward ways to bring it back to life. A tip I picked up from a few google searches: soak the nozzle in acetone, and then hit it with a blowtorch for 1 minute. I've done this a few times on my old extruder (before the upgrade) and it works like a charm. I actually used a kitchen blowtorch we previously only used for creme brulee. My newer E3D has never clogged (knock, knock...).Quote

jhitesma

I've been wanting to get into 3D printing for years. Started collecting parts to build a reprap a couple of times but never got enough parts to actually get anything working. Last April I tore apart a bunch of old DVD drives and made a little 2 axis motion platform out of some of the parts...but never even implemented a Z axis let alone an extruder. Still it taught me enough about the basics to get me really excited about finally making a real printer.

It was when a friend on another forum found Folger and ordered up a 2020 i3 kit that I got really excited. <$300 for a setup like that?! Ok, I'm REALLY interested. Started saving money to get my own before he even had his assembled.

He ran into the usual set of issues - a few pieces missing, damaged hot end thermister, RAMPS issue causing more thermister issues...but he worked through them and started making prints. Meantime I continued to research. I've read most of this thread and several others on other forums about this kit.

With the addition of a Christmas bonus to my savings I was finally able to pull the trigger a week before Christmas. I ordered late on a Friday direct from Folger. I added in the LCD module, 2 rolls of filament (one ABS one PLA) and an inductive sensor. It shipped in two packages both of which left Folger the following Monday. If it wasn't for Christmas they would have been here that Friday - due to the holiday I got my kit the day after Christmas - but I'm not complaining!

I dug right in that night and made 4 hours of progress getting the frame and Y axis completed, You can view a time lapse of this first building session here: [www.youtube.com]

I was tempted to keep going...but figured a good nights rest would improve my chances of success the next day. The next day my wife had the day off and agreed to watch our daughter so I was able to devote the full day to building. It took me another 6 hours or so to have the printer "done" and ready for me to load firmware and start calibrating things. You can see this build session here: [www.youtube.com]

I then spent the next 6 hours doing "little things" like tensioning belts, final tightening on screws, fine tuning alignments, loading firmware, configuring firmware, setting endstops....

I did run into 2 major issues with my kit:

1) The fan on the extruder didn't work. Every now and then it would move a little bit and that was it. Confirmed it had 12v...just a bad fan. The second day the fan shorted out entirely and melted down it's power wires. I swapped in a fan from an older mother board as a temporary replacement but Folger has said they're sending me a new fan.

2) The hot end thermister was damaged. Where the brass tube was crimped over it it had cut through the teflon tubing and one lead of the thermister. I was able to solder it back together but it's only a temporary fix. Folger says they're sending me a whole new hotend and I ordered some spare thermisters as I can easily see breaking one again.

I used therippa's pre-configured version of Marlin to start from and got about halfway through Triffid's calibration instructions (got to Slicer Settings) before deciding it was time to do a first test. I grabbed the first .stl I had on hand - a LCD bracket, opened it in repetier and send it to slic3r...hit print...and...it worked!

[www.youtube.com]

Seriously! Holy cow! I did NOT expect results like that for my first print. It's not flawless...but for a first print ever I'm overjoyed!

My X axis is still mirrored. I followed instructions I was given to move the endstop to the left side instead of the right...but am a bit lost in the configuration.h and repetier options...it's working...just everything is mirrored on the X axis. I'm sure I can work it out - just having too much fun printing some tests to worry about dealing with it yet

I printed the other LCD mount and it came out just as good! Then tried to do something complex and grabbed a penguin model off thingiverse for my daughter. Here the broken extruder fan (I hadn't yet put the temporary fan on) came back to bite me. The penguin printed great until about 50% completion and then my extruder stopped extruding. As I suspected the lack of a fan let the filament get too hot and it melted up in the extruder:

Got that cleaned out...and sure enough the thermister lead broke again. Got that fixed, added the temporary fan...and tried to do some more tests.

But this time I couldn't get anything to stick to the bed. Gave the bed a good cleaning, turned the temp up a little bit, and re-leveled the bed...things stuck again so I printed off a stack of 5x5 calibration cubes, a little mermaid for my daughter, and finally a minimug to finish the night.

Calibration cubes look better than I expected. The Y axis seems to be the least accurate even though my X is loudest, Z seems pretty darn close. The 20mm minimug measures in at 19.96mm which I'm happy with for only being roughly calibrated!

Overall not bad!

Y-axis is a little off:

X looks better than I expected:

Bridging performance could be better...I'm at the upper heat range for PLA so I'm not surprised:

Edited 1 time(s). Last edit at 12/29/2015 11:46PM by elkayem.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 29, 2015 11:57PM |

Registered: 8 years ago Posts: 367 |

Another trick for clearing the extruder. Heat to 100C. Issue gcode M302 to allow cold extrusion. Retract filament. It will sometimes pull out a lump of filament that is blocking the extruder. This was suggested on another thread. I've used it, but have been a little nervous of damaging the PTFE liner in the extruder (I use a E3D lite6).

Best of all is this: get hold of some fine welding wire. You can push it down into a heated extruder from above, then pull it back and often blockages will come with it. There is also a tool used in welding called a tip cleaner. It has fine but rigid metal prongs, and the smallest is small enough to push upwards into the nozzle. I've had great success with these.

See my blog at [moosteria.blogspot.com].

Best of all is this: get hold of some fine welding wire. You can push it down into a heated extruder from above, then pull it back and often blockages will come with it. There is also a tool used in welding called a tip cleaner. It has fine but rigid metal prongs, and the smallest is small enough to push upwards into the nozzle. I've had great success with these.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 02:56AM |

Registered: 8 years ago Posts: 85 |

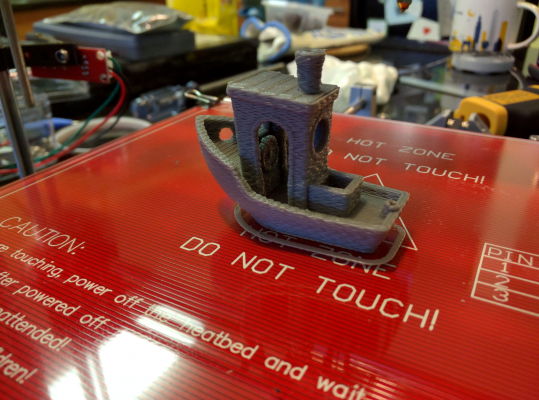

Thanks for the extruder clearing tips guys. I actually got that clog out of there yesterday fairly easily. Been printing all kinds of little things to test it out tonight. Did a bigger penguin for my daughter - hour and a half print - few minor blemishes but overall very nice. Also tried to do a benchy, but just over 50% of the way through it came off the bed

My big problem right now seems to be getting PLA to stick to glass reliably. Most sources seem to say 60c but I have no luck at that temp. I've tried up around 90c and had better luck...but even with my bed freshly leveled it's hit or miss. Usually the skirt will stick but the print itself will come off.

I finally gave in a tried some blue tape, and it's sticking great to that with no heat which is nice since I don't have to wait for it to heat. But I miss the glassy surface on the bottom with just the bare glass. May just have to experiment a bit more on options there.

I did drop my layer height to 0.2mm and it's looking much nicer.

Didn't get around to fixing the reversed X tonight...will try to deal with that tomorrow. Just having too much fun right now to worry about making things perfect Did print a tensioner for the X belt which I hope to install tomorrow. I suspect that's where a lot of the noise on the X axis is coming from since I can see the belt vibrate when it gets loud.

Did print a tensioner for the X belt which I hope to install tomorrow. I suspect that's where a lot of the noise on the X axis is coming from since I can see the belt vibrate when it gets loud.

I probably will try a different hot end at some point, but will probably not do the lite as I want to try printing some higher temp materials and plan on going all metal when I do try a different hot end. Other than the broken thermister and fan this one has been working far better than I expected so far.

I did one of these tonight to test: [www.thingiverse.com]

I get 80.43 in one direction and 80.20 in the other...considering I still haven't got halfway through triffids cal guide I'm REALLY happy with that

My big problem right now seems to be getting PLA to stick to glass reliably. Most sources seem to say 60c but I have no luck at that temp. I've tried up around 90c and had better luck...but even with my bed freshly leveled it's hit or miss. Usually the skirt will stick but the print itself will come off.

I finally gave in a tried some blue tape, and it's sticking great to that with no heat which is nice since I don't have to wait for it to heat. But I miss the glassy surface on the bottom with just the bare glass. May just have to experiment a bit more on options there.

I did drop my layer height to 0.2mm and it's looking much nicer.

Didn't get around to fixing the reversed X tonight...will try to deal with that tomorrow. Just having too much fun right now to worry about making things perfect

Did print a tensioner for the X belt which I hope to install tomorrow. I suspect that's where a lot of the noise on the X axis is coming from since I can see the belt vibrate when it gets loud.

Did print a tensioner for the X belt which I hope to install tomorrow. I suspect that's where a lot of the noise on the X axis is coming from since I can see the belt vibrate when it gets loud.I probably will try a different hot end at some point, but will probably not do the lite as I want to try printing some higher temp materials and plan on going all metal when I do try a different hot end. Other than the broken thermister and fan this one has been working far better than I expected so far.

I did one of these tonight to test: [www.thingiverse.com]

I get 80.43 in one direction and 80.20 in the other...considering I still haven't got halfway through triffids cal guide I'm REALLY happy with that

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 07:51AM |

Registered: 8 years ago Posts: 70 |

Quote

jhitesma

Thanks for the extruder clearing tips guys. I actually got that clog out of there yesterday fairly easily. Been printing all kinds of little things to test it out tonight. Did a bigger penguin for my daughter - hour and a half print - few minor blemishes but overall very nice. Also tried to do a benchy, but just over 50% of the way through it came off the bed

My big problem right now seems to be getting PLA to stick to glass reliably. Most sources seem to say 60c but I have no luck at that temp. I've tried up around 90c and had better luck...but even with my bed freshly leveled it's hit or miss. Usually the skirt will stick but the print itself will come off.

I finally gave in a tried some blue tape, and it's sticking great to that with no heat which is nice since I don't have to wait for it to heat. But I miss the glassy surface on the bottom with just the bare glass. May just have to experiment a bit more on options there.

I did drop my layer height to 0.2mm and it's looking much nicer.

Didn't get around to fixing the reversed X tonight...will try to deal with that tomorrow. Just having too much fun right now to worry about making things perfectDid print a tensioner for the X belt which I hope to install tomorrow. I suspect that's where a lot of the noise on the X axis is coming from since I can see the belt vibrate when it gets loud.

I probably will try a different hot end at some point, but will probably not do the lite as I want to try printing some higher temp materials and plan on going all metal when I do try a different hot end. Other than the broken thermister and fan this one has been working far better than I expected so far.

I did one of these tonight to test: [www.thingiverse.com]

I get 80.43 in one direction and 80.20 in the other...considering I still haven't got halfway through triffids cal guide I'm REALLY happy with that

Try suaved extreme hold #10 hair spray, a light coat on the glass. Are you using a mirror glass?

Edited 1 time(s). Last edit at 12/30/2015 06:27PM by Mopar99.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 08:05AM |

Registered: 8 years ago Posts: 6 |

Need help

Just Built my Printer finished setting the voltage on the motors now my issue is when move the z axis is see the log says "endstops hit: Z:0.00"

Not sure where I need to edit the config file to fix this.. any help and or guidance will be greatly appreciated

Just Built my Printer finished setting the voltage on the motors now my issue is when move the z axis is see the log says "endstops hit: Z:0.00"

Not sure where I need to edit the config file to fix this.. any help and or guidance will be greatly appreciated

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 08:10AM |

Registered: 8 years ago Posts: 8 |

Can someone tell me what the pitch is of these if you have used them and/or the steps/mm when used with the standard Folgertech steppers? Thanks

3D Printer T8 300mm Z Axis Lead Screw 8mm Screw Pitch

3D Printer T8 300mm Z Axis Lead Screw 8mm Screw Pitch

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 08:33AM |

Registered: 8 years ago Posts: 268 |

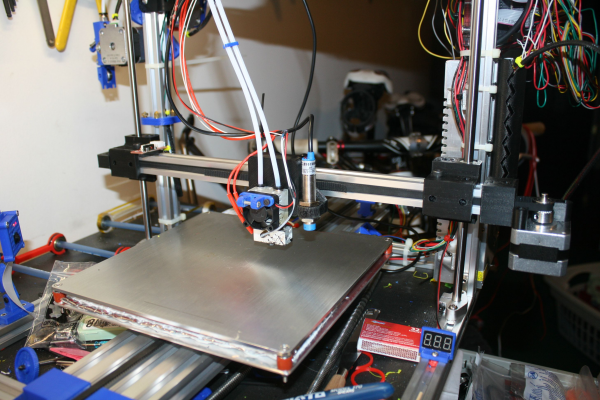

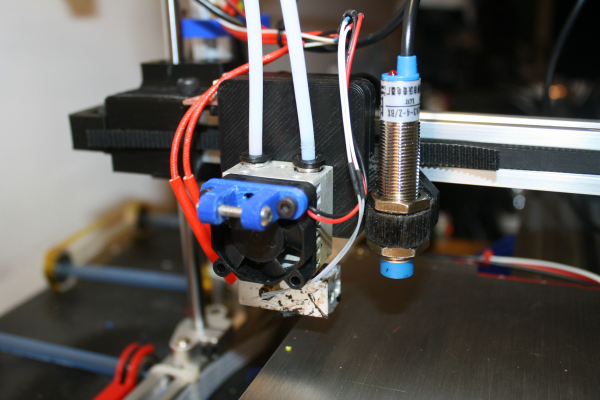

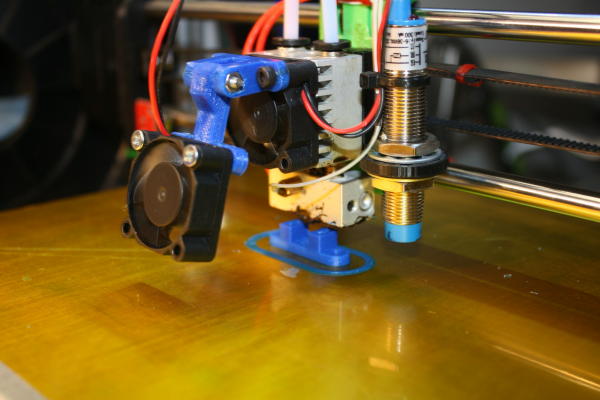

Yes, that is what I'm running currently (well sort of). I bought the kit with both the Cyclops and Chimera hot ends. I am currently running the Chimera Hotends because I damaged the Cyclops Hotend (it was my own stupidity). The Cyclops is repaired and ready to reinstall, I just haven't gotten around to it...

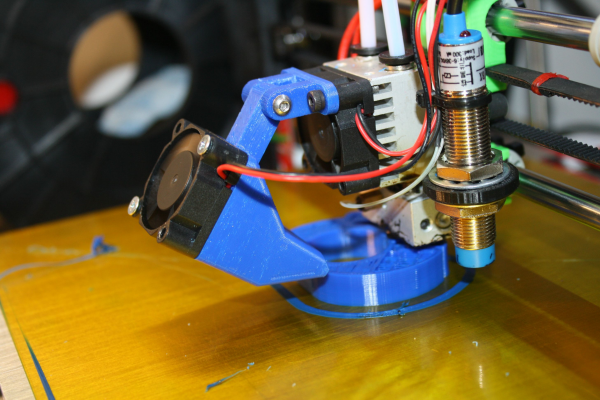

Here are a couple photos of it installed...

It's a bit tricky to get to work, the biggest issue is the fact it's has two extruders with only one heater and thermistor, so you either have to run Repetier Firmware (recommended by E3D...although Marlin X2 might work!?!?) or trick it into thinking there are two thermistors. There are a few ways to do that...

One: You can remove the R11 thermistor resistors from the ramps board and daisy chain the two thermistor circuits together. This allows the Extruder Thermal Override to work properly for both the real and virtual Heater.

Two: Disable Thermal Override on the Extruders.

Three: I connected a 270K resistor (I'd have to confirm that value) to the thermistor input for Extruder 2 and always request 240°C for that extruder (the temperature that resistor indicates on the LCD screen). Although this does override the thermal protection on E-2 I have S3D setup to always run both extruders, so the filament won't feed on either extruder unless both extruders are hot...works great and allows me to use both or either one of the extruders at will...

Although I am designing a Direct Drive Dual Extruder for this setup I am currently running two Bowden Geared Extruders...I reworked them to run flexible filament (which runs okay) but they do cause their own set of problems. Retract is an issue when using the Bowden and the Cyclops, the Cyclops doesn't like a lot of retract, so I'm still dialing that in...not much of an issue when running a single filament, but a little more iffy when running dual filaments.

Cyclops vs Chimera...

I bought the full kit because I simply couldn't decide on one or the other...both have their own benefits. Chimera is nice because you can run two different temps, and two completely different materials. The Cyclops is easier to setup and you can color mix, but both material have of the same type or compatible. I can say I like them both and am torn as to which one I want to run at this point.

You should determine your needs and expectations from a dual extruder and pick one, or simply pull the rigger on both

If you decide to go with a dual extruder setup I think you'll be happy with either one of them...although I have no experience with anything else, I can't imagine there is a more compact or better setup out there!?!?

If you decide to go with a dual extruder setup I think you'll be happy with either one of them...although I have no experience with anything else, I can't imagine there is a more compact or better setup out there!?!?|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 08:38AM |

Registered: 8 years ago Posts: 268 |

Quote

amishboy

Can someone tell me what the pitch is of these if you have used them and/or the steps/mm when used with the standard Folgertech steppers? Thanks

3D Printer T8 300mm Z Axis Lead Screw 8mm Screw Pitch

Those should be a 2mm pitch, if so the steps are right around 400...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 08:45AM |

Registered: 8 years ago Posts: 268 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 09:20AM |

Registered: 8 years ago Posts: 131 |

Quote

sonnylowe

Yes, that is what I'm running currently (well sort of). I bought the kit with both the Cyclops and Chimera hot ends. I am currently running the Chimera Hotends because I damaged the Cyclops Hotend (it was my own stupidity). The Cyclops is repaired and ready to reinstall, I just haven't gotten around to it...

Here are a couple photos of it installed...

It's a bit tricky to get to work, the biggest issue is the fact it's has two extruders with only one heater and thermistor, so you either have to run Repetier Firmware (recommended by E3D...although Marlin X2 might work!?!?) or trick it into thinking there are two thermistors. There are a few ways to do that...

One: You can remove the R11 thermistor resistors from the ramps board and daisy chain the two thermistor circuits together. This allows the Extruder Thermal Override to work properly for both the real and virtual Heater.

Two: Disable Thermal Override on the Extruders.

Three: I connected a 270K resistor (I'd have to confirm that value) to the thermistor input for Extruder 2 and always request 240°C for that extruder (the temperature that resistor indicates on the LCD screen). Although this does override the thermal protection on E-2 I have S3D setup to always run both extruders, so the filament won't feed on either extruder unless both extruders are hot...works great and allows me to use both or either one of the extruders at will...

Although I am designing a Direct Drive Dual Extruder for this setup I am currently running two Bowden Geared Extruders...I reworked them to run flexible filament (which runs okay) but they do cause their own set of problems. Retract is an issue when using the Bowden and the Cyclops, the Cyclops doesn't like a lot of retract, so I'm still dialing that in...not much of an issue when running a single filament, but a little more iffy when running dual filaments.

Cyclops vs Chimera...

I bought the full kit because I simply couldn't decide on one or the other...both have their own benefits. Chimera is nice because you can run two different temps, and two completely different materials. The Cyclops is easier to setup and you can color mix, but both material have of the same type or compatible. I can say I like them both and am torn as to which one I want to run at this point.

You should determine your needs and expectations from a dual extruder and pick one, or simply pull the rigger on bothIf you decide to go with a dual extruder setup I think you'll be happy with either one of them...although I have no experience with anything else, I can't imagine there is a more compact or better setup out there!?!?

Thanks a lot for all that information. I'm already looking down the line and figured it might be really nice to upgrade to be able to print two colors. I really appreciate the time you took to show your setup. I might ping you down the line with more questions if you don't mind.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 09:21AM |

Registered: 8 years ago Posts: 131 |

Quote

sonnylowe

What do you or would you gain from an enclosed printer?

Has anyone here enclosed their FT printer!?!?

I saw THIS on Instructables...looks pretty nice, just wondering if it's worth the effort!?!? .

From what I read enclosing the printer can lead to more stable prints though some are saying that if the steppers are not dialed in properly it can lead to more heating issues and brackets melting.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 02:55PM |

Registered: 8 years ago Posts: 268 |

Quote

marc2912

Thanks a lot for all that information. I'm already looking down the line and figured it might be really nice to upgrade to be able to print two colors. I really appreciate the time you took to show your setup. I might ping you down the line with more questions if you don't mind.

You are very welcome...feel free to ask away, I'm happy to help

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 03:00PM |

Registered: 8 years ago Posts: 268 |

Quote

marc2912

Quote

sonnylowe

What do you or would you gain from an enclosed printer?

Has anyone here enclosed their FT printer!?!?

I saw THIS on Instructables...looks pretty nice, just wondering if it's worth the effort!?!? .

From what I read enclosing the printer can lead to more stable prints though some are saying that if the steppers are not dialed in properly it can lead to more heating issues and brackets melting.

Form what I've researched today that is correct along with better bed adhesion. However I didn't think about the stepper overheating, that's a good point and something to keep in mind...Thanks!!!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 03:04PM |

Registered: 8 years ago Posts: 131 |

Quote

sonnylowe

Quote

marc2912

Quote

sonnylowe

What do you or would you gain from an enclosed printer?

Has anyone here enclosed their FT printer!?!?

I saw THIS on Instructables...looks pretty nice, just wondering if it's worth the effort!?!? .

From what I read enclosing the printer can lead to more stable prints though some are saying that if the steppers are not dialed in properly it can lead to more heating issues and brackets melting.

Form what I've researched today that is correct along with better bed adhesion. However I didn't think about the stepper overheating, that's a good point and something to keep in mind...Thanks!!!

Yeah, just make sure to get your steppers tuned in first.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 03:10PM |

Registered: 8 years ago Posts: 131 |

Finally got my first print after fixing end stops. Also had to reverse wiring for extruder stepper as it was backwards.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 03:55PM |

Registered: 8 years ago Posts: 285 |

Quote

nontech_3der

Need help

Just Built my Printer finished setting the voltage on the motors now my issue is when move the z axis is see the log says "endstops hit: Z:0.00"

Not sure where I need to edit the config file to fix this.. any help and or guidance will be greatly appreciated

I am guessing that you are trying to move the Z axis up? Is the axis triggering the endstop? Could you paste your config to pastebin and give a link, I could not open your config file.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 04:46PM |

Registered: 8 years ago Posts: 25 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 05:21PM |

Registered: 8 years ago Posts: 285 |

Quote

john-i

Hello,

I feel like an idiot.. I have part of a picture of the board and for the life of me I can't figure out where I got it.. has anyone seen this before and if so, do you know where I can get the full pic..

If you got it from this thread, you probably got it from me since I have posted it a few times. Here is the full pic

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 07:20PM |

Registered: 8 years ago Posts: 131 |

Could anyone give me pointer on supports?

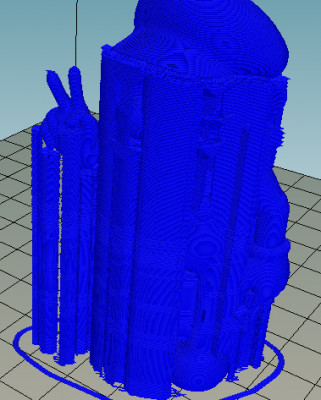

I'm looking to run a print on something like http://www.thingiverse.com/make:173360 but when I try setting up supports it gives me something like this which obviously is way too much support. I think very minor support for the left hand, maybe the nose and the hat should do it. Any pointers?

thanks

I'm looking to run a print on something like http://www.thingiverse.com/make:173360 but when I try setting up supports it gives me something like this which obviously is way too much support. I think very minor support for the left hand, maybe the nose and the hat should do it. Any pointers?

thanks

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 07:43PM |

Registered: 8 years ago Posts: 51 |

Sorry, only registered users may post in this forum.