Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 09:06PM |

Registered: 8 years ago Posts: 285 |

Quote

marc2912

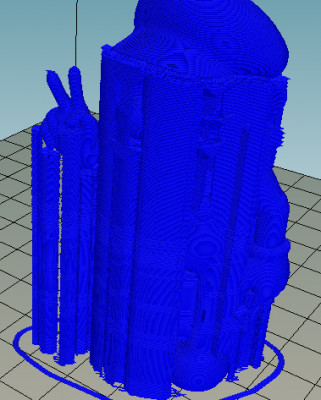

Could anyone give me pointer on supports?

I'm looking to run a print on something like http://www.thingiverse.com/make:173360 but when I try setting up supports it gives me something like this which obviously is way too much support. I think very minor support for the left hand, maybe the nose and the hat should do it. Any pointers?

thanks

Use cura. It give much better quality prints including supports.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 10:18PM |

Registered: 8 years ago Posts: 131 |

Quote

Mach

Quote

marc2912

Could anyone give me pointer on supports?

I'm looking to run a print on something like http://www.thingiverse.com/make:173360 but when I try setting up supports it gives me something like this which obviously is way too much support. I think very minor support for the left hand, maybe the nose and the hat should do it. Any pointers?

thanks

Use cura. It give much better quality prints including supports.

I saw quite a few post while reading back post saying the opposite, that cura was giving people inconsistent prints and that's why they switched to slic3r. Either way even if I switch some pointers on how to set this up properly was more what I was looking for.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 10:38PM |

Registered: 8 years ago Posts: 268 |

Quote

peeejayz

Ordered all of my parts today for Sonny's Y axis upgrade. Also got a Mk3 Alu heated bed, buildtack and inductive sensor comming, could improve my prints no end

Very cool, hope you like the upgrade...I can say with the utmost certainty, I LOVE IT (I might be a bit bias LOL) If you need anything just don't hesitate to PM me, I'm more than happy to help, and make any adjustments you might need...

Sonny

BTW: I've been meaning to make a template to drill the FT Bed Plate, if you get to the point that you need it please yell at me...it will give me no choice but to get it done ;-)

Edit: There is no time like the present...I decided to go ahead and generate the template...it's in the appropriate STL folder.

Edited 1 time(s). Last edit at 12/30/2015 11:13PM by sonnylowe.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 30, 2015 10:58PM |

Registered: 8 years ago Posts: 14 |

Quote

jhitesma

Thanks for the extruder clearing tips guys. I actually got that clog out of there yesterday fairly easily. Been printing all kinds of little things to test it out tonight. Did a bigger penguin for my daughter - hour and a half print - few minor blemishes but overall very nice. Also tried to do a benchy, but just over 50% of the way through it came off the bed

My big problem right now seems to be getting PLA to stick to glass reliably. Most sources seem to say 60c but I have no luck at that temp. I've tried up around 90c and had better luck...but even with my bed freshly leveled it's hit or miss. Usually the skirt will stick but the print itself will come off.

I finally gave in a tried some blue tape, and it's sticking great to that with no heat which is nice since I don't have to wait for it to heat. But I miss the glassy surface on the bottom with just the bare glass. May just have to experiment a bit more on options there.

I did drop my layer height to 0.2mm and it's looking much nicer.

Didn't get around to fixing the reversed X tonight...will try to deal with that tomorrow. Just having too much fun right now to worry about making things perfectDid print a tensioner for the X belt which I hope to install tomorrow. I suspect that's where a lot of the noise on the X axis is coming from since I can see the belt vibrate when it gets loud.

I probably will try a different hot end at some point, but will probably not do the lite as I want to try printing some higher temp materials and plan on going all metal when I do try a different hot end. Other than the broken thermister and fan this one has been working far better than I expected so far.

I did one of these tonight to test: [www.thingiverse.com]

I get 80.43 in one direction and 80.20 in the other...considering I still haven't got halfway through triffids cal guide I'm REALLY happy with that

Try slowing down on the first layer. That helped things for me.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 31, 2015 01:12AM |

Registered: 8 years ago Posts: 14 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 31, 2015 06:31AM |

Registered: 8 years ago Posts: 51 |

Quote

sonnylowe

Quote

peeejayz

Ordered all of my parts today for Sonny's Y axis upgrade. Also got a Mk3 Alu heated bed, buildtack and inductive sensor comming, could improve my prints no end

Very cool, hope you like the upgrade...I can say with the utmost certainty, I LOVE IT (I might be a bit bias LOL) If you need anything just don't hesitate to PM me, I'm more than happy to help, and make any adjustments you might need...

Sonny

BTW: I've been meaning to make a template to drill the FT Bed Plate, if you get to the point that you need it please yell at me...it will give me no choice but to get it done ;-)

Edit: There is no time like the present...I decided to go ahead and generate the template...it's in the appropriate STL folder.

Ledgend, Hows the X axis working out? That will be my next plan. Want to get this as silent as possible.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 31, 2015 10:58AM |

Registered: 8 years ago Posts: 268 |

Quote

peeejayz

Quote

sonnylowe

Quote

peeejayz

Ordered all of my parts today for Sonny's Y axis upgrade. Also got a Mk3 Alu heated bed, buildtack and inductive sensor comming, could improve my prints no end

Very cool, hope you like the upgrade...I can say with the utmost certainty, I LOVE IT (I might be a bit bias LOL) If you need anything just don't hesitate to PM me, I'm more than happy to help, and make any adjustments you might need...

Sonny

BTW: I've been meaning to make a template to drill the FT Bed Plate, if you get to the point that you need it please yell at me...it will give me no choice but to get it done ;-)

Edit: There is no time like the present...I decided to go ahead and generate the template...it's in the appropriate STL folder.

Ledgend, Hows the X axis working out? That will be my next plan. Want to get this as silent as possible.

That axis is working well, I've got a bit of noise from something rattling (elsewhere on the printer) sometimes when it's doing a rapid move. I'm sure I can get rid of it when I have time to chase it down.

Although that axis is running well it is however still in development. I find it a bit bulky in it's current configuration, and have since redesigned much smaller Z Axis mounts. They will use a very unconventional means of guiding the Z-Axis while moving up and down. I'm not sure it will work, and even if it does, I'm not sure it would last long LOL.

I am also moving the X-Axis motor to the back side of the Hotend Gantry Plate, I run Bowden Extruders so it will be the only motor on the rail. if the design works it will shorten the width X-Carriage by ~120mm but not reduce the build volume. The complete redesign will also allow me to remove the Z-Motor Standoffs and still keep the Z build height. Again, if it all works ;-)

I'll do the motor swap first, make sure that aspect of the upgrade works. If it does I'll decide if that's good enough and whether or not I go for the full X-Z combo upgrade!?!?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 31, 2015 11:17AM |

Registered: 8 years ago Posts: 6 |

Yes I am trying to move the Z axis up. axis is not triggering the endstop, I only have an end stop at the bottom. Question should the kit have two endstops for the Z axis? here is the link [pastebin.com]

And Thank you for your help

And Thank you for your help

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 31, 2015 11:23AM |

Registered: 8 years ago Posts: 6 |

Quote

Mach

Quote

nontech_3der

Need help

Just Built my Printer finished setting the voltage on the motors now my issue is when move the z axis is see the log says "endstops hit: Z:0.00"

Not sure where I need to edit the config file to fix this.. any help and or guidance will be greatly appreciated

I am guessing that you are trying to move the Z axis up? Is the axis triggering the endstop? Could you paste your config to pastebin and give a link, I could not open your config file.

Yes I am trying to move the Z axis up. axis is not triggering the endstop, I only have an end stop at the bottom. Question should the kit have two endstops for the Z axis? here is the link [pastebin.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 31, 2015 11:57AM |

Registered: 8 years ago Posts: 285 |

Quote

nontech_3der

Quote

Mach

Quote

nontech_3der

Need help

Just Built my Printer finished setting the voltage on the motors now my issue is when move the z axis is see the log says "endstops hit: Z:0.00"

Not sure where I need to edit the config file to fix this.. any help and or guidance will be greatly appreciated

I am guessing that you are trying to move the Z axis up? Is the axis triggering the endstop? Could you paste your config to pastebin and give a link, I could not open your config file.

Yes I am trying to move the Z axis up. axis is not triggering the endstop, I only have an end stop at the bottom. Question should the kit have two endstops for the Z axis? here is the link [pastebin.com]

I did not see anything anything wrong with the Z axis configs, so the only thing I can think of is that the Z axis was not homed before trying to move it.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) December 31, 2015 12:30PM |

Registered: 8 years ago Posts: 85 |

Finally got pushed into fixing my mirrored X axis yesterday. Tried printing a new X axis endstop (the stock one is driving me crazy because it keeps falling and then doesn't trigger because the extruder cold break hits the mount before the switch hits anything.) and it came out great...but the slot for the endstop is on the wrong side due to the mirroring  So I decided to finally dig in on fixing the mirroring.

So I decided to finally dig in on fixing the mirroring.

Turned out not to be too difficult. I had to reconfigure repetier for X-MIN homing and in Marlin I had to change X_HOME_DIR to -1 and INVERT_X_DIR to true in configuration.h AND flip the wire from the stepper to the RAMPS board. With those changes made it finally homes correctly AND prints non-mirrored. Horray. For anyone curious here's the version of RAMPS I'm using - forked from therippa's pre-configured fork: [github.com]

With the mirroring fixed I printed another copy of the endstop. The first one I had made with a sample of PLA from Quantum and it worked great, Snapped right on and off. But I used up the last of that sample printing an X belt tensioner and a Wall-E for my daughter. (Actually ran out halfway through Wall-E and had to pause to swap filaments partway through...which was easier than I expected.) So the next copy was with the orange PLA I got from Folger. But this PLA seems much more brittle than the Quantum PLA. And sure enough when I snapped it onto the rails it broke. It's on there...and works better than the stock one...but I'll have to print a replacement because it's not on there as well as I'd like.

So major problems fixed. Now I'm trying to deal with noises. I turned down the current on my steppers yesterday, measured them all at 0.42v (+/- about .04v They had been at about 0.61v from the factory!) but things were still noisy. The Y noise was new and I tracked it down to a loose screw on the belt attachment piece. Y is now super nice and quiet, just a bit of a "swish" noise when it moves really fast.

X though, x is driving me crazy. It makes a horribly annoying noise that seems to be getting worse and I can't isolate it. I took the belt off and confirmed that the carriage moves freely and quietly. It's free enough that if I tilt the machine it will slide by itself, not as easily as the Y will...but it will move by itself. In fact X almost feels smoother than Y. And the stepper is quiet running by itself. I did find that the X stepper was loose, all 3 screws had backed off, so I tightened those up. But it's still just as loud as ever when actually moving. Here's a video of it in action:

[www.youtube.com]

I tried turning the stepper current down even more, but then it wasn't moving reliably. I also tried adding a tension spring, but that didn't make any difference.

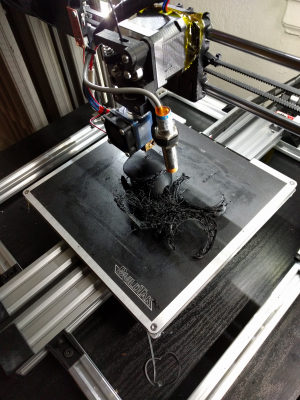

I'm trying to print a 4 bearing X carriage next - you can see it printing in the video above showing the noise. Unfortunately that print failed, 1/8" from the top things suddenly shifted in the Y axis. I wasn't paying close attention so I'm not sure why, but I haven't had that issue before I'll try reprinting it today but I'm not convinced that it will solve the problem. Figure it can't hurt.

I'll try reprinting it today but I'm not convinced that it will solve the problem. Figure it can't hurt.

Also need to get going on printing my Z axis parts. The leadscrews I wasn't expecting until Monday are out for delivery today! Looks like I've got my weekend plans figured out now Once I get the leadscrews in I'll dig back in on fine tuning the calibration. Just didn't want to put a lot of effort into that before tearing the machine apart as much as necessary for the Z upgrade

Once I get the leadscrews in I'll dig back in on fine tuning the calibration. Just didn't want to put a lot of effort into that before tearing the machine apart as much as necessary for the Z upgrade

So I decided to finally dig in on fixing the mirroring.

So I decided to finally dig in on fixing the mirroring.Turned out not to be too difficult. I had to reconfigure repetier for X-MIN homing and in Marlin I had to change X_HOME_DIR to -1 and INVERT_X_DIR to true in configuration.h AND flip the wire from the stepper to the RAMPS board. With those changes made it finally homes correctly AND prints non-mirrored. Horray. For anyone curious here's the version of RAMPS I'm using - forked from therippa's pre-configured fork: [github.com]

With the mirroring fixed I printed another copy of the endstop. The first one I had made with a sample of PLA from Quantum and it worked great, Snapped right on and off. But I used up the last of that sample printing an X belt tensioner and a Wall-E for my daughter. (Actually ran out halfway through Wall-E and had to pause to swap filaments partway through...which was easier than I expected.) So the next copy was with the orange PLA I got from Folger. But this PLA seems much more brittle than the Quantum PLA. And sure enough when I snapped it onto the rails it broke. It's on there...and works better than the stock one...but I'll have to print a replacement because it's not on there as well as I'd like.

So major problems fixed. Now I'm trying to deal with noises. I turned down the current on my steppers yesterday, measured them all at 0.42v (+/- about .04v They had been at about 0.61v from the factory!) but things were still noisy. The Y noise was new and I tracked it down to a loose screw on the belt attachment piece. Y is now super nice and quiet, just a bit of a "swish" noise when it moves really fast.

X though, x is driving me crazy. It makes a horribly annoying noise that seems to be getting worse and I can't isolate it. I took the belt off and confirmed that the carriage moves freely and quietly. It's free enough that if I tilt the machine it will slide by itself, not as easily as the Y will...but it will move by itself. In fact X almost feels smoother than Y. And the stepper is quiet running by itself. I did find that the X stepper was loose, all 3 screws had backed off, so I tightened those up. But it's still just as loud as ever when actually moving. Here's a video of it in action:

[www.youtube.com]

I tried turning the stepper current down even more, but then it wasn't moving reliably. I also tried adding a tension spring, but that didn't make any difference.

I'm trying to print a 4 bearing X carriage next - you can see it printing in the video above showing the noise. Unfortunately that print failed, 1/8" from the top things suddenly shifted in the Y axis. I wasn't paying close attention so I'm not sure why, but I haven't had that issue before

I'll try reprinting it today but I'm not convinced that it will solve the problem. Figure it can't hurt.

I'll try reprinting it today but I'm not convinced that it will solve the problem. Figure it can't hurt.Also need to get going on printing my Z axis parts. The leadscrews I wasn't expecting until Monday are out for delivery today! Looks like I've got my weekend plans figured out now

Once I get the leadscrews in I'll dig back in on fine tuning the calibration. Just didn't want to put a lot of effort into that before tearing the machine apart as much as necessary for the Z upgrade

Once I get the leadscrews in I'll dig back in on fine tuning the calibration. Just didn't want to put a lot of effort into that before tearing the machine apart as much as necessary for the Z upgrade

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 01, 2016 11:57AM |

Registered: 8 years ago Posts: 84 |

I just had something strange happen.

I printed a test cube to check if my settings were still correct after I replaced some parts and my z height was off a little.

I took the difference and changed the z number in marlin and uploaded it and it didn't change the print. Still the same exact height.

The model is the 20mm cube and I got 20.74.

I printed a test cube to check if my settings were still correct after I replaced some parts and my z height was off a little.

I took the difference and changed the z number in marlin and uploaded it and it didn't change the print. Still the same exact height.

The model is the 20mm cube and I got 20.74.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 01, 2016 01:14PM |

Registered: 8 years ago Posts: 85 |

My X is much quieter now. Instead of just going by the numbers to adjust the current on the steppers I gave in and did it by feel. Just kept turning down the current and doing test moves to make sure things were still responding correctly. The X driver is now showing about 0.23v and the stepper is about 5c cooler...and there's no more annoying noise. Also turned down Y the same way and the swish of the bearings is now the loudest noise it makes.

Printed off all of the parts for the Z axis rebuild - except for the motor raisers. But was only printing PLA and I really want ABS for that. So after successfully printing a full set of parts I gave my roll of ABS a try. Was easier than I expected, Heating the bed to 110 takes a little bit but not much longer than it did to get to 90 when I was having PLA issues and tried a hotter bed. Did a long skinny X endstop mount as my first ABS part figuring it would be prone to warping...but came out great. In fact better than the versions I did in PLA since it snaps onto the rods easier and holds better.

So now I'm re-printing all of the leadscrew upgrade parts in ABS and assuming they come out well I'll be doing the motor raisers next - by this evening hopefully I'll be up and going with leadscrews and extra Z height

Printed off all of the parts for the Z axis rebuild - except for the motor raisers. But was only printing PLA and I really want ABS for that. So after successfully printing a full set of parts I gave my roll of ABS a try. Was easier than I expected, Heating the bed to 110 takes a little bit but not much longer than it did to get to 90 when I was having PLA issues and tried a hotter bed. Did a long skinny X endstop mount as my first ABS part figuring it would be prone to warping...but came out great. In fact better than the versions I did in PLA since it snaps onto the rods easier and holds better.

So now I'm re-printing all of the leadscrew upgrade parts in ABS and assuming they come out well I'll be doing the motor raisers next - by this evening hopefully I'll be up and going with leadscrews and extra Z height

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 01, 2016 01:27PM |

Registered: 8 years ago Posts: 57 |

Quote

jhitesma

My X is much quieter now. Instead of just going by the numbers to adjust the current on the steppers I gave in and did it by feel. Just kept turning down the current and doing test moves to make sure things were still responding correctly. The X driver is now showing about 0.23v and the stepper is about 5c cooler...and there's no more annoying noise. Also turned down Y the same way and the swish of the bearings is now the loudest noise it makes.

Printed off all of the parts for the Z axis rebuild - except for the motor raisers. But was only printing PLA and I really want ABS for that. So after successfully printing a full set of parts I gave my roll of ABS a try. Was easier than I expected, Heating the bed to 110 takes a little bit but not much longer than it did to get to 90 when I was having PLA issues and tried a hotter bed. Did a long skinny X endstop mount as my first ABS part figuring it would be prone to warping...but came out great. In fact better than the versions I did in PLA since it snaps onto the rods easier and holds better.

So now I'm re-printing all of the leadscrew upgrade parts in ABS and assuming they come out well I'll be doing the motor raisers next - by this evening hopefully I'll be up and going with leadscrews and extra Z height

I preheat my bed to 110 and leave a piece of reflectix on it while heating... will speed up that time

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 01, 2016 10:09PM |

Registered: 8 years ago Posts: 276 |

First print of the year - Happy New Year Everyone!!!!

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 01, 2016 10:39PM |

Registered: 8 years ago Posts: 367 |

Happy New Year to you, and thank you for all your awesome contributions to this forum.

I hoped we would make it to page 100 by the end of 2015 - so close!

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 02, 2016 12:05PM |

Registered: 9 years ago Posts: 45 |

Ok, so I've been working on this printer almost exclusively for the last few months for a variety of reasons. So I've racked up a lot of experience on this thing. After getting past the initial quality issues with the sk8's, the obnoxious t nuts, firmware issues (3840 steps/mm z axis?! Try 4000!). I've been changing extruders a lot. My hot end is still the e3d cyclops/chimera. But I've iterated a bit on the cold side. Currently using a self designed (read terrible) dual bondtech direct drive. (Running off a gear motor anyhow). Since self designed parts of sufficient complexity pretty much suck the first time around (and possibly the 2nd, 3rd etc), I had the joy of trying to strip it back down, which resulted in the destruction of two of the linear bearings. I had spares on hand from another project so it wasn't a big deal.

Which leads me to the reason for posting. The original linear bearings stunk big time. It's been a while since I put smooth rod through a linear bearing. (My other printer, a delta, uses linear guides). So when the originals were tight and jerky I thought nothing of it. It wasn't until I put the spares on that I noticed the difference! My x carriage has 4 bearings. I replaced the top two. The top rod now glides through the bearings like its floating on oil. Perfectly smooth almost 0 resistance. The bottom rod can still be fed with gravity, but it jerks a bit, it's just not smooth, and takes noticeably more force to move it. I've now ordered a complete set of new bearings for the printer and will replace them all. I suspect I'll see some major improvements in the motion of the printer. I think some things I was attributing to ringing, and random missed steps (especially on the y axis) may actually have been linear bearing quality!

Again, like the sk8's, and the obnoxious t nuts, I suspect this is a tolerance issue, as such, I'm sure there will be some who are experiencing the same, and others who assume I must be an idiot because they didn't have any problems. Maybe I'll see if it shows up in a video . Anyhow, reality is I think you'd be better served by raising the price of the printer $5 and ordering quality linear bearings. The t nuts are obnoxious, but can be forced to work. The sk8's could be dremeled into submission (it was the height of the feet, they're forged with minimal machining. Height of the rod is important. Thickness of the feet is not), so again, annoying but maybe not worth a price increase. The linear bearings, however, requires ordering a new set if you get an out of spec set (or two in my case!). I grabbed mine off amazon, 12 for $21. So instead of like $264 it cost me $285. I'd have rather just paid $269 and had good linear bearings from that start!

. Anyhow, reality is I think you'd be better served by raising the price of the printer $5 and ordering quality linear bearings. The t nuts are obnoxious, but can be forced to work. The sk8's could be dremeled into submission (it was the height of the feet, they're forged with minimal machining. Height of the rod is important. Thickness of the feet is not), so again, annoying but maybe not worth a price increase. The linear bearings, however, requires ordering a new set if you get an out of spec set (or two in my case!). I grabbed mine off amazon, 12 for $21. So instead of like $264 it cost me $285. I'd have rather just paid $269 and had good linear bearings from that start!

Again though, I love the kit. I love the aluminum extrusion instead of laser cut acrylic. I can make the print area bigger with ease (and will be doing so soon!). I can build an enclosure for it with ease. This is a great idea for a kit. Just needs a few tweaks

Which leads me to the reason for posting. The original linear bearings stunk big time. It's been a while since I put smooth rod through a linear bearing. (My other printer, a delta, uses linear guides). So when the originals were tight and jerky I thought nothing of it. It wasn't until I put the spares on that I noticed the difference! My x carriage has 4 bearings. I replaced the top two. The top rod now glides through the bearings like its floating on oil. Perfectly smooth almost 0 resistance. The bottom rod can still be fed with gravity, but it jerks a bit, it's just not smooth, and takes noticeably more force to move it. I've now ordered a complete set of new bearings for the printer and will replace them all. I suspect I'll see some major improvements in the motion of the printer. I think some things I was attributing to ringing, and random missed steps (especially on the y axis) may actually have been linear bearing quality!

Again, like the sk8's, and the obnoxious t nuts, I suspect this is a tolerance issue, as such, I'm sure there will be some who are experiencing the same, and others who assume I must be an idiot because they didn't have any problems. Maybe I'll see if it shows up in a video

. Anyhow, reality is I think you'd be better served by raising the price of the printer $5 and ordering quality linear bearings. The t nuts are obnoxious, but can be forced to work. The sk8's could be dremeled into submission (it was the height of the feet, they're forged with minimal machining. Height of the rod is important. Thickness of the feet is not), so again, annoying but maybe not worth a price increase. The linear bearings, however, requires ordering a new set if you get an out of spec set (or two in my case!). I grabbed mine off amazon, 12 for $21. So instead of like $264 it cost me $285. I'd have rather just paid $269 and had good linear bearings from that start!

. Anyhow, reality is I think you'd be better served by raising the price of the printer $5 and ordering quality linear bearings. The t nuts are obnoxious, but can be forced to work. The sk8's could be dremeled into submission (it was the height of the feet, they're forged with minimal machining. Height of the rod is important. Thickness of the feet is not), so again, annoying but maybe not worth a price increase. The linear bearings, however, requires ordering a new set if you get an out of spec set (or two in my case!). I grabbed mine off amazon, 12 for $21. So instead of like $264 it cost me $285. I'd have rather just paid $269 and had good linear bearings from that start!Again though, I love the kit. I love the aluminum extrusion instead of laser cut acrylic. I can make the print area bigger with ease (and will be doing so soon!). I can build an enclosure for it with ease. This is a great idea for a kit. Just needs a few tweaks

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 02, 2016 12:09PM |

Registered: 8 years ago Posts: 84 |

Ok I figured out why me changing the config.h file wasn't changing my prints.

I just checked the settings with the LCD screen and they weren't changing after I loaded the new file and hit the reset button.

I do have eeprom chitchat and eeprom settings turned on in the firmware would that cause it?

I can manually change them on the LCD and it effected the print. I hit store to memory and then reopened the marlin file and it hadn't changed the settings.

What am I doing wrong?

I just checked the settings with the LCD screen and they weren't changing after I loaded the new file and hit the reset button.

I do have eeprom chitchat and eeprom settings turned on in the firmware would that cause it?

I can manually change them on the LCD and it effected the print. I hit store to memory and then reopened the marlin file and it hadn't changed the settings.

What am I doing wrong?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 02, 2016 12:19PM |

Registered: 8 years ago Posts: 541 |

Quote

corry

Ok, so I've been working on this printer almost exclusively for the last few months for a variety of reasons. So I've racked up a lot of experience on this thing. After getting past the initial quality issues with the sk8's, the obnoxious t nuts, firmware issues (3840 steps/mm z axis?! Try 4000!). I've been changing extruders a lot. My hot end is still the e3d cyclops/chimera. But I've iterated a bit on the cold side. Currently using a self designed (read terrible) dual bondtech direct drive. (Running off a gear motor anyhow). Since self designed parts of sufficient complexity pretty much suck the first time around (and possibly the 2nd, 3rd etc), I had the joy of trying to strip it back down, which resulted in the destruction of two of the linear bearings. I had spares on hand from another project so it wasn't a big deal.

Which leads me to the reason for posting. The original linear bearings stunk big time. It's been a while since I put smooth rod through a linear bearing. (My other printer, a delta, uses linear guides). So when the originals were tight and jerky I thought nothing of it. It wasn't until I put the spares on that I noticed the difference! My x carriage has 4 bearings. I replaced the top two. The top rod now glides through the bearings like its floating on oil. Perfectly smooth almost 0 resistance. The bottom rod can still be fed with gravity, but it jerks a bit, it's just not smooth, and takes noticeably more force to move it. I've now ordered a complete set of new bearings for the printer and will replace them all. I suspect I'll see some major improvements in the motion of the printer. I think some things I was attributing to ringing, and random missed steps (especially on the y axis) may actually have been linear bearing quality!

Again, like the sk8's, and the obnoxious t nuts, I suspect this is a tolerance issue, as such, I'm sure there will be some who are experiencing the same, and others who assume I must be an idiot because they didn't have any problems. Maybe I'll see if it shows up in a video. Anyhow, reality is I think you'd be better served by raising the price of the printer $5 and ordering quality linear bearings. The t nuts are obnoxious, but can be forced to work. The sk8's could be dremeled into submission (it was the height of the feet, they're forged with minimal machining. Height of the rod is important. Thickness of the feet is not), so again, annoying but maybe not worth a price increase. The linear bearings, however, requires ordering a new set if you get an out of spec set (or two in my case!). I grabbed mine off amazon, 12 for $21. So instead of like $264 it cost me $285. I'd have rather just paid $269 and had good linear bearings from that start!

Again though, I love the kit. I love the aluminum extrusion instead of laser cut acrylic. I can make the print area bigger with ease (and will be doing so soon!). I can build an enclosure for it with ease. This is a great idea for a kit. Just needs a few tweaks

Obnoxious T nuts? Clearly, after saying that 3 times, you had trouble with them? What kind of trouble? I love the things as a quick way to add items and adjust position..

The SK8's are machined, not forged, as far as I can tell and mine are all the same height. The big problem was that FT didn't supply the right height bolts for them, right? Granted the bearings aren't the greatest, but it appears to be hit or miss no matter where you buy them unless you buy the $6 apiece ones. From my experience, the biggest problems are that people can't fathom the precision that must be achieved to align the rods exactly. The fact that my bearing HOLDERS were undersized and wouldn't allow the bearings to seat completely and in alignment was the main problem, not the bearings themselves. After Dremeling the holders and aligning everything, I have zero bearing noise now after almost 4 months of daily printing.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 02, 2016 12:43PM |

Registered: 8 years ago Posts: 15 |

First time posting,just ordered the 2020.

Does anyone know why it takes so long to ship? I know there was just a holiday,but I paid the 28th shipping label created the 29th and it still hasn't moved.

I paid for 2 day shipping,and ideas? Are the kits not already put together? I'm not trying to be a butt just was curious

Hope you guys/gals look forward to my upcoming I have no idea questions my first printer was a xyz da Vinci 1.0 a and was looking for something more customizable.

my first printer was a xyz da Vinci 1.0 a and was looking for something more customizable.

Thanks

Does anyone know why it takes so long to ship? I know there was just a holiday,but I paid the 28th shipping label created the 29th and it still hasn't moved.

I paid for 2 day shipping,and ideas? Are the kits not already put together? I'm not trying to be a butt just was curious

Hope you guys/gals look forward to my upcoming I have no idea questions

my first printer was a xyz da Vinci 1.0 a and was looking for something more customizable.

my first printer was a xyz da Vinci 1.0 a and was looking for something more customizable.Thanks

|

Re: Having Problems with connecting the printer January 02, 2016 04:46PM |

Registered: 8 years ago Posts: 8 |

|

Re: Having Problems with connecting the printer January 02, 2016 07:05PM |

Registered: 8 years ago Posts: 285 |

Quote

cookg

Is the only way to fix a fried voltage regulator to buy a new board? I don't need that info atm because i'm going to try the setup on a different computer, but if you could get back to me that would be nice.

You could also replace the voltage regulator, but since you can get a arduino mega for about ten bucks, it may be easier just to buy a new one.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 02, 2016 07:52PM |

Registered: 8 years ago Posts: 38 |

I've been mostly a lurker here, but I finally ordered a 2020 kit yesterday. Besides the printer, I also ordered a 12864 LCD, borosilicate glass bed, BuildTak, a set of linear bearings from Misumi, a BLTouch sensor, and some PLA, ABS & PETG filament. I also have a Raspberry Pi that I plan on messing around with Octoprint. I'll probably pick up Simplify3d soon too. Hopefully that'll get me going enough to start some of of the other mods in this thread.

Thanks to everybody for the 98 pages of great info on the Folgertech. I'm really looking forward to getting it going. Are there any obvious things I'm missing?

It seems pretty typical to wait about a week before they ship. Their website says to expect 2-4 days. With the holidays, I wouldn't expect those 2-4 days to start for you & I until Monday. Just guessing.

Thanks to everybody for the 98 pages of great info on the Folgertech. I'm really looking forward to getting it going. Are there any obvious things I'm missing?

Quote

Zeegzeigler

Does anyone know why it takes so long to ship?

It seems pretty typical to wait about a week before they ship. Their website says to expect 2-4 days. With the holidays, I wouldn't expect those 2-4 days to start for you & I until Monday. Just guessing.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 02, 2016 08:13PM |

Registered: 8 years ago Posts: 131 |

Quote

GrouchoDuke

I've been mostly a lurker here, but I finally ordered a 2020 kit yesterday. Besides the printer, I also ordered a 12864 LCD, borosilicate glass bed, BuildTak, a set of linear bearings from Misumi, a BLTouch sensor, and some PLA, ABS & PETG filament. I also have a Raspberry Pi that I plan on messing around with Octoprint. I'll probably pick up Simplify3d soon too. Hopefully that'll get me going enough to start some of of the other mods in this thread.

Thanks to everybody for the 98 pages of great info on the Folgertech. I'm really looking forward to getting it going. Are there any obvious things I'm missing?

Quote

Zeegzeigler

Does anyone know why it takes so long to ship?

It seems pretty typical to wait about a week before they ship. Their website says to expect 2-4 days. With the holidays, I wouldn't expect those 2-4 days to start for you & I until Monday. Just guessing.

Sounds like a pretty sweet setup...

|

Re: Having Problems with connecting the printer January 02, 2016 10:36PM |

Registered: 8 years ago Posts: 8 |

|

Re: Having Problems with connecting the printer January 02, 2016 10:46PM |

Registered: 8 years ago Posts: 8 |

Sorry, I meant to say that whenever I send an action, it will say "Endstops Hit" in the command log, even though none of them are even touching the endstops.Quote

cookg

I got the board fixed- My computer was acting up. Now I have a new problem: The printer is connected on Repetier-Host and I have homed it, but the manual commands will not go through. Any help?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 02, 2016 11:55PM |

Registered: 8 years ago Posts: 541 |

Quote

jhitesma

My X is much quieter now. Instead of just going by the numbers to adjust the current on the steppers I gave in and did it by feel. Just kept turning down the current and doing test moves to make sure things were still responding correctly. The X driver is now showing about 0.23v and the stepper is about 5c cooler...and there's no more annoying noise. Also turned down Y the same way and the swish of the bearings is now the loudest noise it makes.

Printed off all of the parts for the Z axis rebuild - except for the motor raisers. But was only printing PLA and I really want ABS for that. So after successfully printing a full set of parts I gave my roll of ABS a try. Was easier than I expected, Heating the bed to 110 takes a little bit but not much longer than it did to get to 90 when I was having PLA issues and tried a hotter bed. Did a long skinny X endstop mount as my first ABS part figuring it would be prone to warping...but came out great. In fact better than the versions I did in PLA since it snaps onto the rods easier and holds better.

So now I'm re-printing all of the leadscrew upgrade parts in ABS and assuming they come out well I'll be doing the motor raisers next - by this evening hopefully I'll be up and going with leadscrews and extra Z height

PLA is plenty good enough for those Z motor risers IMHO. At least, mine are fine and really they have no stress on them except compression so it's no problem.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 03, 2016 01:50AM |

Registered: 8 years ago Posts: 5 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 03, 2016 01:57AM |

Registered: 8 years ago Posts: 85 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 03, 2016 12:32PM |

Registered: 8 years ago Posts: 15 |

Quote

GrouchoDuke

I've been mostly a lurker here, but I finally ordered a 2020 kit yesterday. Besides the printer, I also ordered a 12864 LCD, borosilicate glass bed, BuildTak, a set of linear bearings from Misumi, a BLTouch sensor, and some PLA, ABS & PETG filament. I also have a Raspberry Pi that I plan on messing around with Octoprint. I'll probably pick up Simplify3d soon too. Hopefully that'll get me going enough to start some of of the other mods in this thread.

Thanks to everybody for the 98 pages of great info on the Folgertech. I'm really looking forward to getting it going. Are there any obvious things I'm missing?

Quote

Zeegzeigler

Does anyone know why it takes so long to ship?

It seems pretty typical to wait about a week before they ship. Their website says to expect 2-4 days. With the holidays, I wouldn't expect those 2-4 days to start for you & I until Monday. Just guessing.

Thanks,Thats what i thought,but I guess Im too anxious

Sorry, only registered users may post in this forum.