Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 13, 2016 08:58PM |

Registered: 8 years ago Posts: 541 |

Quote

sonnylowe

Quote

tjnamtiw

Thanks, Rippa! I'll check it out. I don't know if the logic of the BLTouch is any different than prox sensors. Thanks. I've peeked around your github site but didn't see anything labeled 'auto level'.

Sounds like you're going at this perfectly..."one step at a time"Unfortunately I made like three changes at once...it was not fun!!! I believe Charles addressed all the issue with the Yellow version before putting out the White...so hopefully you'll have an easier go of it.

The only difference between the proximity senor and the BLt is you setup the BLtouch like a servo/micro setup. You may also have to speed up the second probe a bit...the Yellow BLt didn't like moving slowly between probes ;-)

Check out this VIDEO, it has a lot of the settings you will need for 1.1.0 RC...there is also some dialog between Greg I as I was trying to get this to work initially. Turned out the time between the first and second hit was too long...

Not sure if it will work, but I have attached my config.h file...

Great info!!! Thanks!

Yea, I've always approached problems one step at a time to eliminate chasing my tail. Gotta be the engineer in me. It used to drive me nuts at work when someone would jump into an electrical or hydraulic problem and just start changing everything.

Anyway, that's some great info. Got your config file too and I see what you did. Now for some free time!!!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 13, 2016 10:31PM |

Registered: 8 years ago Posts: 268 |

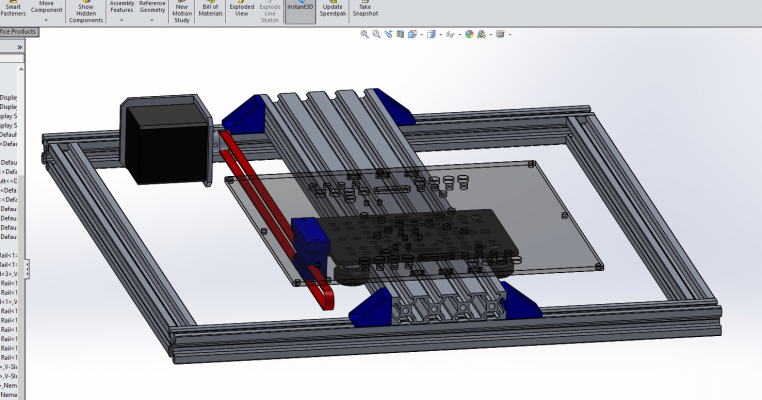

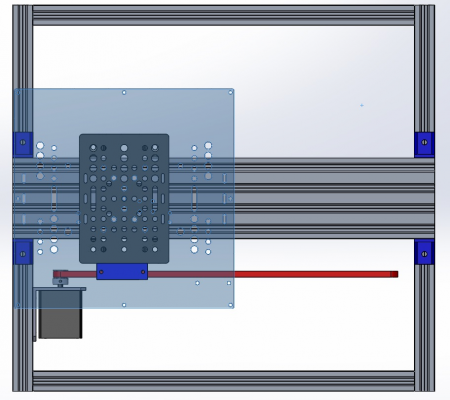

A few people have asked how short the rial could be cut on my Y-Axis upgrade so I decided to look into it. I modeled the setup using an offset belt. Although it is quite a bit "far to the left of center", I think it would be fine running the gantry on the V-Slot bearings.

As I posted earlier, there are printer on OB that are doing very same thing. With this setup the 20x80 rail could be cut the exact length of the printer. The stepper would stay mounted like it was in the original design, I believe the FT idler pulley mount could be used as well. I few current STL's would be eliminated, a few more added, and some simple multiplied. All the hardware could stay the same, you might need a couple extra 1mm spacers to get the Bed Plate high enough to clear the motor!?!?

Here is a quick and dirty model of it, I would have to generate a correct model of the steel stepper mount to determine the proper height of the Y-Belt Mount, but this gives you a general idea of the inner workings of the setup...I have also attached a 3D PDF...you know how much I love them LOL

If anyone is interested in this configuration please let me know, I'd be happy to model the parts correctly and generate the STL files.

BTW: I changed the transparency of the Bed Plate to show the parts underneath.

As I posted earlier, there are printer on OB that are doing very same thing. With this setup the 20x80 rail could be cut the exact length of the printer. The stepper would stay mounted like it was in the original design, I believe the FT idler pulley mount could be used as well. I few current STL's would be eliminated, a few more added, and some simple multiplied. All the hardware could stay the same, you might need a couple extra 1mm spacers to get the Bed Plate high enough to clear the motor!?!?

Here is a quick and dirty model of it, I would have to generate a correct model of the steel stepper mount to determine the proper height of the Y-Belt Mount, but this gives you a general idea of the inner workings of the setup...I have also attached a 3D PDF...you know how much I love them LOL

If anyone is interested in this configuration please let me know, I'd be happy to model the parts correctly and generate the STL files.

BTW: I changed the transparency of the Bed Plate to show the parts underneath.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 13, 2016 11:52PM |

Registered: 8 years ago Posts: 2 |

Hello everyone long time lurker 1st time poster. This past weekend I completed my build and today I finished going thru all the set up in the configuration PDF. At the end of my 1st test cube print the X axis motor froze and now will not move when I try to home the x axis. The motor will not turn by hand now as the other ones. As I am new to this I am not sure what to do now. is the motor bad? is there something I can do to fix this?

Tim

Tim

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 14, 2016 01:43AM |

Registered: 8 years ago Posts: 80 |

You could try swapping the x and y connectors and see if the problem moves to the other motor. Just remember that your endstop will then be on the wrong axis so you don't want to home it.Quote

tperk9784

Hello everyone long time lurker 1st time poster. This past weekend I completed my build and today I finished going thru all the set up in the configuration PDF. At the end of my 1st test cube print the X axis motor froze and now will not move when I try to home the x axis. The motor will not turn by hand now as the other ones. As I am new to this I am not sure what to do now. is the motor bad? is there something I can do to fix this?

Tim

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 14, 2016 01:48AM |

Registered: 8 years ago Posts: 93 |

Quote

sonnylowe

I took a quick look at the OP site, THIS is a basic example of how you could run the drive system on the Y-Carriage. I think you could basically use the old FT belt, stepper and idler pulley mounts and make it work. I'll try to model something in the few days, see what it looks like. The only possible issue I see would be running the belt off center, although I wouldn't suggest it with the old setup, I think with the V-Slot guides it would be fine...

I'm thinking of putting this [www.thingiverse.com] on the gantry plate with the aluminum plate bolted to it in 8 places - 4 in the gantry plate, and 4 more on the arms. I think it will add stiffness to the platform, as well as give enough clearance for the rail to be 405mm (depth of the printer frame) and still have the full range of movement. My cabinet has just enough room in front for the bearing/pully and in back for the motor, if I have a 405mm rail.

I have a 5mm cork insulator under my heated bed, so the aluminum plate doesn't get warm even during a long print, so PLA or ABS should be fine under there.

I first printed it 9mm deep, which is probably too much, but it seems very rigid. The rail setup is not as tall as the stock folger setup, so I wouldn't really lose any build height.

This is similar to Sonny's original rails, but more solid because it is one piece, and it still uses the folger aluminum plate.on top of it. I think this will keep the bed from being wobbly or tippy.

Sonny, Rippa, do you think this would work?

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 14, 2016 06:52AM |

Registered: 8 years ago Posts: 46 |

My first 3d printer build is moving along although somewhat slowly. I'm just at the point of mounting the extruder assembly to the x carriage. When I took the extuder from the box I noticed that the hot end portion was loose and flopping around. Once I removed the fan and heatsink I could see that the set screw was not tightened. My question on putting this back together is should the threaded portion of the hot end butt up against the plastic extruder body or should there be an air gap as a thermal break? Should I run a piece of filament down the extruder to line up the holes or will things naturally line up when i put the fan and heatsink back on? It's sort of annoying that you need to partially dissemble the whole thing just to get at the set screw.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 14, 2016 07:28AM |

Registered: 8 years ago Posts: 268 |

Quote

Bert3D

Quote

sonnylowe

I took a quick look at the OP site, THIS is a basic example of how you could run the drive system on the Y-Carriage. I think you could basically use the old FT belt, stepper and idler pulley mounts and make it work. I'll try to model something in the few days, see what it looks like. The only possible issue I see would be running the belt off center, although I wouldn't suggest it with the old setup, I think with the V-Slot guides it would be fine...

I'm thinking of putting this [www.thingiverse.com] on the gantry plate with the aluminum plate bolted to it in 8 places - 4 in the gantry plate, and 4 more on the arms. I think it will add stiffness to the platform, as well as give enough clearance for the rail to be 405mm (depth of the printer frame) and still have the full range of movement. My cabinet has just enough room in front for the bearing/pully and in back for the motor, if I have a 405mm rail.

I have a 5mm cork insulator under my heated bed, so the aluminum plate doesn't get warm even during a long print, so PLA or ABS should be fine under there.

I first printed it 9mm deep, which is probably too much, but it seems very rigid. The rail setup is not as tall as the stock folger setup, so I wouldn't really lose any build height.

This is similar to Sonny's original rails, but more solid because it is one piece, and it still uses the folger aluminum plate.on top of it. I think this will keep the bed from being wobbly or tippy.

Sonny, Rippa, do you think this would work?

Bert,

The never ending options is one of the main reason I design this project with the OB hardware. It allows people to add their own twist to it, change it to better suit them or what they want to accomplish. That bed mount looks great, your choice of how to install it sounds great and should work just fine. Hell, if it doesn't work up to your expectation all you've lost is some time and filament...you can always drop back to attaching the FT plate directly to gantry...or try something else. Even as crappy as my printed mounts were I was still able to use the printer and make new replacement parts

Looks like you're on track...have fun!!!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 14, 2016 02:34PM |

Registered: 8 years ago Posts: 70 |

So over last weekend, I completed the upgrade of my hotend from the stock ft hotend to e3d v6 direct drive. After resetting it up and running some test prints, I notice that one of the pla filament that I had good luck with when running through the ft hotend doesn't work so well with the new hot end. Swapped filament brand & left the setting along in s3d, end result I got better prints.

So I'm curious to see if anybody else has experienced this when they swapped hotends? I'm also curious to see what everyone is using for the filament? I running hatchbox glow in the dark pla to upgrade to sonny's setup, was using solutech black pla, and makergreek white & black (haven't tried it yet with the new hot end). I went to the hatchbox filament, simple to test if is was the filament causing the issue or not. It's for a project for my kids but now I'll have a semi glow in the dark printer

So I'm curious to see if anybody else has experienced this when they swapped hotends? I'm also curious to see what everyone is using for the filament? I running hatchbox glow in the dark pla to upgrade to sonny's setup, was using solutech black pla, and makergreek white & black (haven't tried it yet with the new hot end). I went to the hatchbox filament, simple to test if is was the filament causing the issue or not. It's for a project for my kids but now I'll have a semi glow in the dark printer

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 14, 2016 02:47PM |

Registered: 8 years ago Posts: 26 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 14, 2016 06:11PM |

Registered: 8 years ago Posts: 51 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 14, 2016 06:13PM |

Registered: 8 years ago Posts: 26 |

Quote

peeejayz

Quote

Jim72

deleted

Just messaged Mr Folger on facebook to make him aware of your problems hopefully you will get a reply soon, I know mine was next day - but thats expected as I'm in the UK.

I don't know if that helped but I did hear from them by email tonight, they are sending new ramps. Thanks peeejayz. I deleted the complaint.

Edited 1 time(s). Last edit at 01/15/2016 04:07PM by Jim72.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 14, 2016 06:24PM |

Registered: 8 years ago Posts: 26 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 14, 2016 06:26PM |

Registered: 8 years ago Posts: 51 |

Quote

Jim72

Quote

peeejayz

Quote

Jim72

Deleted!

Just messaged Mr Folger on facebook to make him aware of your problems hopefully you will get a reply soon, I know mine was next day - but thats expected as I'm in the UK.

I don't know if that helped but I did hear from them by email tonight, they are sending new ramps. Thanks peeejayz. I deleted the complaint.

Not a problem, I think from what hes told me hes had some staffing issues this week. Glad its sorted tho

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 14, 2016 07:55PM |

Registered: 8 years ago Posts: 285 |

Quote

Mopar99

So over last weekend, I completed the upgrade of my hotend from the stock ft hotend to e3d v6 direct drive. After resetting it up and running some test prints, I notice that one of the pla filament that I had good luck with when running through the ft hotend doesn't work so well with the new hot end. Swapped filament brand & left the setting along in s3d, end result I got better prints.

So I'm curious to see if anybody else has experienced this when they swapped hotends? I'm also curious to see what everyone is using for the filament? I running hatchbox glow in the dark pla to upgrade to sonny's setup, was using solutech black pla, and makergreek white & black (haven't tried it yet with the new hot end). I went to the hatchbox filament, simple to test if is was the filament causing the issue or not. It's for a project for my kids but now I'll have a semi glow in the dark printer

I am using esun filament. Good quality filament that does not break the bank

.

.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 14, 2016 08:01PM |

Registered: 8 years ago Posts: 367 |

Quote

Mach

Quote

Mopar99

So over last weekend, I completed the upgrade of my hotend from the stock ft hotend to e3d v6 direct drive. After resetting it up and running some test prints, I notice that one of the pla filament that I had good luck with when running through the ft hotend doesn't work so well with the new hot end. Swapped filament brand & left the setting along in s3d, end result I got better prints.

So I'm curious to see if anybody else has experienced this when they swapped hotends? I'm also curious to see what everyone is using for the filament? I running hatchbox glow in the dark pla to upgrade to sonny's setup, was using solutech black pla, and makergreek white & black (haven't tried it yet with the new hot end). I went to the hatchbox filament, simple to test if is was the filament causing the issue or not. It's for a project for my kids but now I'll have a semi glow in the dark printer

I am using esun filament. Good quality filament that does not break the bank.

My workhorse filament is justpla. I've tried out small samples of many others. See [docs.google.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 14, 2016 08:44PM |

Registered: 8 years ago Posts: 16 |

Thanks for all the help on this, I haven't been on for a while. My printer was running fine, then a few parts went bad, and I got it working again. Now I have a few issues.

I upgraded to theRippa's Marlin (1.1.0 RC3), I was running the stock FT marlin, but I installed a sensor for auto bed level, so I upgraded to theRippa's Marlin and that's what I need to solve. I believe I have all the auto bed leveling stuff correctly setup, but I have an issue, so I'm hoping you can point me to the solution.

1. When I home the machine for the first time, the x-axis homes, and after hitting the x endstop, the stepper continues to spin for a second or two. Cookg had this issue as well, and said he figured it out but several posts later he said he hoped that post would be his last time to stop by, so I've PM'ed him but don't expect a reply. Any one else know where to start?

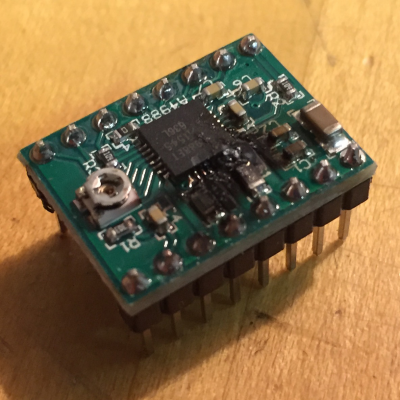

I also had this issue occasionally with the stock FT marlin. I've upgraded the stock stepper drivers for the x & y axis to DRV8825 drivers, set the voltages for all drivers correctly, and doubled the steps in Marlin for the x & y axis to account for the change to 1/32 steps vs the old 1/16 steps. (160, vs old at 80)

2. I do a G28 (to home all the axis in prep for G29) and x and y home (after the issue stated above), It goes to the location I specified in Configuration.h as the "z_safe_homing" location. Then when it goes to slowly home the z axis, it vibrates very loudly and sometimes I have to touch one of the threaded rod couplers to get it moving. I didn't have this issue before before the change to auto bed leveling. Any ideas?

3. I do a G29 and Repetier says "echo:Home X/Y before Z". I only gives me that message and does nothing else. It never goes to any of the auto bed leveling grid locations. All the locations are located in the travel limits of the endstops (none are outside them). I also tried a G28 X0Y0 before the G29 and it made no difference.

Any ideas?

I've not tried to print anything yet since as I'd really like to print with auto-bed level now and avoid manually re-leveling again. Though I've already added the G29 to me start g-code, making sure it homes before starting the G29.

Any help is greatly appreciated.

Thanks,

Rollinns

I upgraded to theRippa's Marlin (1.1.0 RC3), I was running the stock FT marlin, but I installed a sensor for auto bed level, so I upgraded to theRippa's Marlin and that's what I need to solve. I believe I have all the auto bed leveling stuff correctly setup, but I have an issue, so I'm hoping you can point me to the solution.

1. When I home the machine for the first time, the x-axis homes, and after hitting the x endstop, the stepper continues to spin for a second or two. Cookg had this issue as well, and said he figured it out but several posts later he said he hoped that post would be his last time to stop by, so I've PM'ed him but don't expect a reply. Any one else know where to start?

I also had this issue occasionally with the stock FT marlin. I've upgraded the stock stepper drivers for the x & y axis to DRV8825 drivers, set the voltages for all drivers correctly, and doubled the steps in Marlin for the x & y axis to account for the change to 1/32 steps vs the old 1/16 steps. (160, vs old at 80)

2. I do a G28 (to home all the axis in prep for G29) and x and y home (after the issue stated above), It goes to the location I specified in Configuration.h as the "z_safe_homing" location. Then when it goes to slowly home the z axis, it vibrates very loudly and sometimes I have to touch one of the threaded rod couplers to get it moving. I didn't have this issue before before the change to auto bed leveling. Any ideas?

3. I do a G29 and Repetier says "echo:Home X/Y before Z". I only gives me that message and does nothing else. It never goes to any of the auto bed leveling grid locations. All the locations are located in the travel limits of the endstops (none are outside them). I also tried a G28 X0Y0 before the G29 and it made no difference.

Any ideas?

I've not tried to print anything yet since as I'd really like to print with auto-bed level now and avoid manually re-leveling again. Though I've already added the G29 to me start g-code, making sure it homes before starting the G29.

Any help is greatly appreciated.

Thanks,

Rollinns

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 14, 2016 09:17PM |

Registered: 8 years ago Posts: 2 |

Quote

elkayem

You could try swapping the x and y connectors and see if the problem moves to the other motor. Just remember that your endstop will then be on the wrong axis so you don't want to home it.Quote

tperk9784

Hello everyone long time lurker 1st time poster. This past weekend I completed my build and today I finished going thru all the set up in the configuration PDF. At the end of my 1st test cube print the X axis motor froze and now will not move when I try to home the x axis. The motor will not turn by hand now as the other ones. As I am new to this I am not sure what to do now. is the motor bad? is there something I can do to fix this?

Tim

Thanks for the reply but it just sort of came unstuck. not sure what if anything happened to cause it. I lowered the voltage on the motor it now runs cooler than it did before and I have not had any issues since.

Tim

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 15, 2016 01:57AM |

Registered: 8 years ago Posts: 38 |

I just finished my build (minus wire tidying) and did a smoke test. It didn't go so well. One of the drivers died just after I plugged the printer in for the first time.

Just as a reminder to everyone that you should be careful with things, here's the video:

[www.youtube.com]

Here's the driver afterwards:

When I was building the printer, I checked to make sure there was solder on all the pins, but I didn't really look for solder balls or bridges. Has anyone else seen something like this happen on their first power on?

EDIT: I'm not sure if this matters, but the driver that smoked was the spare that FT sent. They attached all 5 drivers to the RAMPS board, so I just left them there. Would not having the driver hooked up to a motor cause it to fail?

Edited 1 time(s). Last edit at 01/15/2016 02:21AM by GrouchoDuke.

Just as a reminder to everyone that you should be careful with things, here's the video:

[www.youtube.com]

Here's the driver afterwards:

When I was building the printer, I checked to make sure there was solder on all the pins, but I didn't really look for solder balls or bridges. Has anyone else seen something like this happen on their first power on?

EDIT: I'm not sure if this matters, but the driver that smoked was the spare that FT sent. They attached all 5 drivers to the RAMPS board, so I just left them there. Would not having the driver hooked up to a motor cause it to fail?

Edited 1 time(s). Last edit at 01/15/2016 02:21AM by GrouchoDuke.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 15, 2016 03:15AM |

Registered: 8 years ago Posts: 51 |

Quote

GrouchoDuke

I just finished my build (minus wire tidying) and did a smoke test. It didn't go so well. One of the drivers died just after I plugged the printer in for the first time.

Just as a reminder to everyone that you should be careful with things, here's the video:

[www.youtube.com]

Here's the driver afterwards:

When I was building the printer, I checked to make sure there was solder on all the pins, but I didn't really look for solder balls or bridges. Has anyone else seen something like this happen on their first power on?

EDIT: I'm not sure if this matters, but the driver that smoked was the spare that FT sent. They attached all 5 drivers to the RAMPS board, so I just left them there. Would not having the driver hooked up to a motor cause it to fail?

Drop them a support ticket and they will get replacement parts out to you quickly

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 15, 2016 08:31AM |

Registered: 8 years ago Posts: 51 |

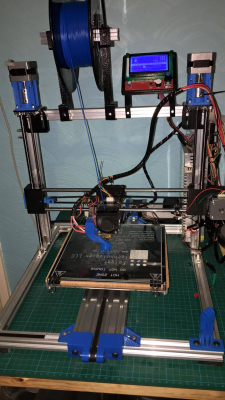

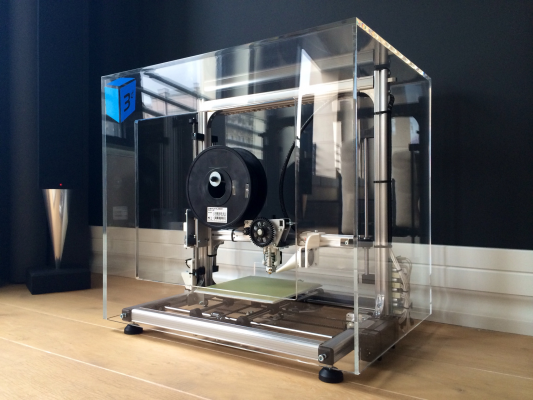

Got my printer all working awesome after the Y axis upgrade.

Just got some other upgrades to come now, Alu bed, inductive sensor and ingus bearings for the X axis - before I look at swapping the x over so Sonny's latest upgrade.

Currently looks like this:

Edited 2 time(s). Last edit at 01/15/2016 08:33AM by peeejayz.

Just got some other upgrades to come now, Alu bed, inductive sensor and ingus bearings for the X axis - before I look at swapping the x over so Sonny's latest upgrade.

Currently looks like this:

Edited 2 time(s). Last edit at 01/15/2016 08:33AM by peeejayz.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 15, 2016 08:35AM |

Registered: 8 years ago Posts: 9 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 15, 2016 09:19AM |

Registered: 8 years ago Posts: 268 |

For you kids considering an enclosure I ran across this one today (for a Velleman K8200)...looks really nice and should be easily adapted to our FT 2020...

Here is the THREAD for the K8200...not sure much would be applicable to our printer, but it might be worth a once over...you never know ;-)

Here is the THREAD for the K8200...not sure much would be applicable to our printer, but it might be worth a once over...you never know ;-)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 15, 2016 09:23AM |

Registered: 8 years ago Posts: 268 |

Quote

peeejayz

Got my printer all working awesome after the Y axis upgrade.

Just got some other upgrades to come now, Alu bed, inductive sensor and ingus bearings for the X axis - before I look at swapping the x over so Sonny's latest upgrade.

Currently looks like this:

[attachment 69833 12528769_10153368249756188_1903212030_o.jpg]

NICE!!! Thanks for posting your results and photo, glad to hear you like the upgrade

Edited 1 time(s). Last edit at 01/15/2016 11:27AM by sonnylowe.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 15, 2016 09:50AM |

Registered: 8 years ago Posts: 268 |

Quote

tnm

Hi all,

First post and new user. Ordered the 2020 is Prusa the other day and while looking for a response from folgertech I found this site. I guess I should have

done a bit more research. But I'm still looking forward to this build. Is the best to to contact these through facebook?

tnm

Welcome to the thread...

Don't worry, you made a good choice with this printer, if you take the time you will learn a lot from this thread, and there are many people her willing to help if you need it. For now just hope you never need to contact FT...I never did

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 15, 2016 09:56AM |

Registered: 8 years ago Posts: 131 |

Quote

tnm

Hi all,

First post and new user. Ordered the 2020 is Prusa the other day and while looking for a response from folgertech I found this site. I guess I should have

done a bit more research. But I'm still looking forward to this build. Is the best to to contact these through facebook?

tnm

Don't expect your printer to ship out fast. It'll take a week if not two. Once you get it take your time putting it together. People here are more than happy to help. Don't expect the screws to match the photos. Use what makes sense. I recommend putting the x-axis end stop on the left and changing your settings accordingly but that's a personal choice. If you have any questions feel free to ask, we've all been there.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 15, 2016 10:12AM |

Registered: 8 years ago Posts: 541 |

Quote

sonnylowe

Quote

tnm

Hi all,

First post and new user. Ordered the 2020 is Prusa the other day and while looking for a response from folgertech I found this site. I guess I should have

done a bit more research. But I'm still looking forward to this build. Is the best to to contact these through facebook?

tnm

Welcome to the thread...

Don't worry, you made a good choice with this printer, if you take the time you will learn a lot from this thread, and there are many people her willing to help if you need it. For now just hope you never need to contact FT...I never did

I emailed them several times with problems such as dead thermistors, missing parts and always got the parts and a reply in a reasonable time. Most companies are slow to respond today. HOWEVER, FT is a very small company and to not respond immediately is curious IMHO. Their FB presence is quite sparse with very few posts since Dan left them. Someone needs to pick up the torch and take charge there. Whoever is running the show appears to have little or no customer support knowledge or urgency.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 15, 2016 10:14AM |

Registered: 8 years ago Posts: 16 |

Quote

rollinns

Thanks for all the help on this, I haven't been on for a while. My printer was running fine, then a few parts went bad, and I got it working again. Now I have a few issues.

I upgraded to theRippa's Marlin (1.1.0 RC3), I was running the stock FT marlin, but I installed a sensor for auto bed level, so I upgraded to theRippa's Marlin and that's what I need to solve. I believe I have all the auto bed leveling stuff correctly setup, but I have an issue, so I'm hoping you can point me to the solution.

1. When I home the machine for the first time, the x-axis homes, and after hitting the x endstop, the stepper continues to spin for a second or two. Cookg had this issue as well, and said he figured it out but several posts later he said he hoped that post would be his last time to stop by, so I've PM'ed him but don't expect a reply. Any one else know where to start?

I also had this issue occasionally with the stock FT marlin. I've upgraded the stock stepper drivers for the x & y axis to DRV8825 drivers, set the voltages for all drivers correctly, and doubled the steps in Marlin for the x & y axis to account for the change to 1/32 steps vs the old 1/16 steps. (160, vs old at 80)

2. I do a G28 (to home all the axis in prep for G29) and x and y home (after the issue stated above), It goes to the location I specified in Configuration.h as the "z_safe_homing" location. Then when it goes to slowly home the z axis, it vibrates very loudly and sometimes I have to touch one of the threaded rod couplers to get it moving. I didn't have this issue before before the change to auto bed leveling. Any ideas?

3. I do a G29 and Repetier says "echo:Home X/Y before Z". I only gives me that message and does nothing else. It never goes to any of the auto bed leveling grid locations. All the locations are located in the travel limits of the endstops (none are outside them). I also tried a G28 X0Y0 before the G29 and it made no difference.

Any ideas?

I've not tried to print anything yet since as I'd really like to print with auto-bed level now and avoid manually re-leveling again. Though I've already added the G29 to me start g-code, making sure it homes before starting the G29.

Any help is greatly appreciated.

Thanks,

Rollinns

After changing the homing_feedrate the second issue is solved, and for anyone who runs across this issue inthe future, I doubled the Z homing rate from 4*60, to 8*60 and the issue disappeared. This line in configuration.h:

#define HOMING_FEEDRATE {50*60, 50*60, 8*60, 0} // set the homing speeds (mm/min) //z was 4*60 feedrate, now 8*60

I'd really like some help on the third issue, I can live with issue 1 (at least until my belt strips), but if someone could just point me to the area of the code to look regarding G29, I'd really appreciate it.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 15, 2016 11:38AM |

Registered: 8 years ago Posts: 268 |

Quote

rollinns

Quote

rollinns

Thanks for all the help on this, I haven't been on for a while. My printer was running fine, then a few parts went bad, and I got it working again. Now I have a few issues.

I upgraded to theRippa's Marlin (1.1.0 RC3), I was running the stock FT marlin, but I installed a sensor for auto bed level, so I upgraded to theRippa's Marlin and that's what I need to solve. I believe I have all the auto bed leveling stuff correctly setup, but I have an issue, so I'm hoping you can point me to the solution.

1. When I home the machine for the first time, the x-axis homes, and after hitting the x endstop, the stepper continues to spin for a second or two. Cookg had this issue as well, and said he figured it out but several posts later he said he hoped that post would be his last time to stop by, so I've PM'ed him but don't expect a reply. Any one else know where to start?

I also had this issue occasionally with the stock FT marlin. I've upgraded the stock stepper drivers for the x & y axis to DRV8825 drivers, set the voltages for all drivers correctly, and doubled the steps in Marlin for the x & y axis to account for the change to 1/32 steps vs the old 1/16 steps. (160, vs old at 80)

2. I do a G28 (to home all the axis in prep for G29) and x and y home (after the issue stated above), It goes to the location I specified in Configuration.h as the "z_safe_homing" location. Then when it goes to slowly home the z axis, it vibrates very loudly and sometimes I have to touch one of the threaded rod couplers to get it moving. I didn't have this issue before before the change to auto bed leveling. Any ideas?

3. I do a G29 and Repetier says "echo:Home X/Y before Z". I only gives me that message and does nothing else. It never goes to any of the auto bed leveling grid locations. All the locations are located in the travel limits of the endstops (none are outside them). I also tried a G28 X0Y0 before the G29 and it made no difference.

Any ideas?

I've not tried to print anything yet since as I'd really like to print with auto-bed level now and avoid manually re-leveling again. Though I've already added the G29 to me start g-code, making sure it homes before starting the G29.

Any help is greatly appreciated.

Thanks,

Rollinns

After changing the homing_feedrate the second issue is solved, and for anyone who runs across this issue inthe future, I doubled the Z homing rate from 4*60, to 8*60 and the issue disappeared. This line in configuration.h:

#define HOMING_FEEDRATE {50*60, 50*60, 8*60, 0} // set the homing speeds (mm/min) //z was 4*60 feedrate, now 8*60

I'd really like some help on the third issue, I can live with issue 1 (at least until my belt strips), but if someone could just point me to the area of the code to look regarding G29, I'd really appreciate it.

I'm not sure this is your problem, but if you take too much time between the G28 and G29 moves the steppers will turn off, once they do Rep (Octoprint in my case) will request that you Home X/Y before Z. Try running G28, while it's still homing input G29, if all goes well it will start as soon as G28 is done.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 15, 2016 12:29PM |

Registered: 8 years ago Posts: 93 |

Quote

rollinns

Quote

rollinns

Thanks for all the help on this, I haven't been on for a while. My printer was running fine, then a few parts went bad, and I got it working again. Now I have a few issues.

I upgraded to theRippa's Marlin (1.1.0 RC3), I was running the stock FT marlin, but I installed a sensor for auto bed level, so I upgraded to theRippa's Marlin and that's what I need to solve. I believe I have all the auto bed leveling stuff correctly setup, but I have an issue, so I'm hoping you can point me to the solution.

1. When I home the machine for the first time, the x-axis homes, and after hitting the x endstop, the stepper continues to spin for a second or two. Cookg had this issue as well, and said he figured it out but several posts later he said he hoped that post would be his last time to stop by, so I've PM'ed him but don't expect a reply. Any one else know where to start?

I also had this issue occasionally with the stock FT marlin. I've upgraded the stock stepper drivers for the x & y axis to DRV8825 drivers, set the voltages for all drivers correctly, and doubled the steps in Marlin for the x & y axis to account for the change to 1/32 steps vs the old 1/16 steps. (160, vs old at 80)

2. I do a G28 (to home all the axis in prep for G29) and x and y home (after the issue stated above), It goes to the location I specified in Configuration.h as the "z_safe_homing" location. Then when it goes to slowly home the z axis, it vibrates very loudly and sometimes I have to touch one of the threaded rod couplers to get it moving. I didn't have this issue before before the change to auto bed leveling. Any ideas?

3. I do a G29 and Repetier says "echo:Home X/Y before Z". I only gives me that message and does nothing else. It never goes to any of the auto bed leveling grid locations. All the locations are located in the travel limits of the endstops (none are outside them). I also tried a G28 X0Y0 before the G29 and it made no difference.

Any ideas?

I've not tried to print anything yet since as I'd really like to print with auto-bed level now and avoid manually re-leveling again. Though I've already added the G29 to me start g-code, making sure it homes before starting the G29.

Any help is greatly appreciated.

Thanks,

Rollinns

After changing the homing_feedrate the second issue is solved, and for anyone who runs across this issue inthe future, I doubled the Z homing rate from 4*60, to 8*60 and the issue disappeared. This line in configuration.h:

#define HOMING_FEEDRATE {50*60, 50*60, 8*60, 0} // set the homing speeds (mm/min) //z was 4*60 feedrate, now 8*60

I'd really like some help on the third issue, I can live with issue 1 (at least until my belt strips), but if someone could just point me to the area of the code to look regarding G29, I'd really appreciate it.

You may be masking the problem rather than fixing it. If you aren't moving at slow step rates, your driver current is probably not correct. You may have just never noticed it because you never tried to move slow before.

Do you have your X endstop on the left and plugged into the min-x position? Auto level doesn't work with x endstop at the max position and the endstop on the right. I have no idea why it wouldn't stop when it hits the x endstop unless the movement and endstop indicators are messed up somehow. But if it worked before, this shouldn't be the case. There are a lot of things than can keep G29 from working right, so it may be related to the x issue. I would fix that first.

Edited 2 time(s). Last edit at 01/15/2016 12:32PM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 15, 2016 01:49PM |

Registered: 8 years ago Posts: 16 |

Now the first issue is solved, I changed some endstop settings, my x endstop is on the right (max), so here's the code that worked in configuration.h

This now gets my G29 a lot further, but now it only probes in two places.

G28, then M114: (this is correct)

X:170.00 Y:0.00 Z:0.60 E:0.00 Count X: 170.00 Y:0.00 Z:0.60

G29, then M114: (not sure why the Y and Z axis are changed)

X:170.00 Y:86.00 Z:0.39 E:0.00 Count X: 170.00 Y:86.01 Z:0.38

When G29 probes it only probes along the front and only in two places. From what I can find, it seems to be a bug:

G92 X0 Y0 before G29 makes no difference, also a

G92 Y-86 also before G29 --I tried this to offset the increase of 86 I was seeing, but it made no difference.

M503 returns a

echo: M206 X0.00 Y0.00 Z0.00 so it appears I don't have an offset setup in the eeprom.

I'm glad to have made some progress, but I'd still like to get these auto bed level issues resolved.

Any ideas?

Thanks again

// Mechanical endstop with COM to ground and NC to Signal uses "false" here (most common setup). const bool X_MIN_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop. const bool Y_MIN_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop. const bool Z_MIN_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop. //changed to false for auto bed level sensor (capacitive type) const bool X_MAX_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop. // changed to true to match the y-min endstop const bool Y_MAX_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop. const bool Z_MAX_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop. const bool Z_MIN_PROBE_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop. //#define DISABLE_MAX_ENDSTOPS was uncommented changed so it will now pay attention to the x_max_enstop //#define DISABLE_MIN_ENDSTOPS

This now gets my G29 a lot further, but now it only probes in two places.

G28, then M114: (this is correct)

X:170.00 Y:0.00 Z:0.60 E:0.00 Count X: 170.00 Y:0.00 Z:0.60

G29, then M114: (not sure why the Y and Z axis are changed)

X:170.00 Y:86.00 Z:0.39 E:0.00 Count X: 170.00 Y:86.01 Z:0.38

When G29 probes it only probes along the front and only in two places. From what I can find, it seems to be a bug:

G92 X0 Y0 before G29 makes no difference, also a

G92 Y-86 also before G29 --I tried this to offset the increase of 86 I was seeing, but it made no difference.

M503 returns a

echo: M206 X0.00 Y0.00 Z0.00 so it appears I don't have an offset setup in the eeprom.

I'm glad to have made some progress, but I'd still like to get these auto bed level issues resolved.

Any ideas?

Thanks again

Sorry, only registered users may post in this forum.