Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 18, 2016 06:09PM |

Registered: 8 years ago Posts: 25 |

Quote

sonnylowe

Quote

peeejayz

Anyone got a recommended inductive sensor, Mine just arrived and its to big to fit into any of the brackets I've printed. I got the 8mm sensing one.

I think most of the inductive sensor are the same diameter (14mm), the Capacitive Sensor I'm currently testing is 12mm. What bracket are you trying to use and what Extruder?

Sonny

Side Note: I there a way to make my sig show up every time I reply or do I have to check the "Add my sig..." box every time!?!?

I think I found it, it is under Control Center - Options - Forum Setting

New Wikia page: [folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 18, 2016 06:14PM |

Registered: 8 years ago Posts: 13 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 18, 2016 06:17PM |

Registered: 8 years ago Posts: 85 |

Quote

peeejayz

Anyone got a recommended inductive sensor, Mine just arrived and its to big to fit into any of the brackets I've printed. I got the 8mm sensing one.

I'm using the 4mm sense distance one from folger which is 12mm but am thinking about upgrading to an 8mm as it makes me nervous how close it has to be. (I'm using a sheet of 28ga galvanized steel between the glass and heater - had to bump my temp a bit but otherwise working great.)

I could easily tweak the bracket I made for mine to add a different sized loop if you'd like: [www.thingiverse.com]

The OpenSCAD code is here: [gist.github.com] you could probably just tweak lines 16/17 to change the size of the loop, might have to adjust the translation of it on line 13 a bit if it's a big change. (Unfortunately the nested translations make this kind of confusing...but I just kind of tossed it together as I went and can't be bothered to go back and clean it up to make it easier to edit.)

Give it a try - OpenSCAD is a small download and not that scary once you start messing around with a simple model

Edited 1 time(s). Last edit at 01/18/2016 06:17PM by jhitesma.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 18, 2016 06:19PM |

Registered: 8 years ago Posts: 85 |

Quote

therippa

I started the wikia page - [folgertech.wikia.com]

Please go enter info for what you know!

Not a big fan of wikia...but beats doing nothing

I started adding some build tips but then realized I wasn't logged in. Will try and add some more later tonight when I have more time.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 18, 2016 06:20PM |

Registered: 8 years ago Posts: 268 |

Quote

john-i

Quote

sonnylowe

Quote

peeejayz

Anyone got a recommended inductive sensor, Mine just arrived and its to big to fit into any of the brackets I've printed. I got the 8mm sensing one.

I think most of the inductive sensor are the same diameter (14mm), the Capacitive Sensor I'm currently testing is 12mm. What bracket are you trying to use and what Extruder?

Sonny

Side Note: I there a way to make my sig show up every time I reply or do I have to check the "Add my sig..." box every time!?!?

I think I found it, it is under Control Center - Options - Forum Setting

That's it...THANKS!!

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 18, 2016 06:23PM |

Registered: 8 years ago Posts: 268 |

Quote

jhitesma

Quote

peeejayz

Anyone got a recommended inductive sensor, Mine just arrived and its to big to fit into any of the brackets I've printed. I got the 8mm sensing one.

I'm using the 4mm sense distance one from folger which is 12mm but am thinking about upgrading to an 8mm as it makes me nervous how close it has to be. (I'm using a sheet of 28ga galvanized steel between the glass and heater - had to bump my temp a bit but otherwise working great.)

I could easily tweak the bracket I made for mine to add a different sized loop if you'd like: [www.thingiverse.com]

The OpenSCAD code is here: [gist.github.com] you could probably just tweak lines 16/17 to change the size of the loop, might have to adjust the translation of it on line 13 a bit if it's a big change. (Unfortunately the nested translations make this kind of confusing...but I just kind of tossed it together as I went and can't be bothered to go back and clean it up to make it easier to edit.)

Give it a try - OpenSCAD is a small download and not that scary once you start messing around with a simple model

Haha, I screwed the pooch on that one, all of my sensors are 12mm...what the hell was I thinking

Edited 1 time(s). Last edit at 01/18/2016 06:24PM by sonnylowe.

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 18, 2016 06:25PM |

Registered: 8 years ago Posts: 268 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 18, 2016 06:28PM |

Registered: 8 years ago Posts: 70 |

I'm running the stainsmart mega after frying is a ft mega. No issues, even have a spare for just in case.

Upgrades:

-Simple3d

-E3D V6 Direct drive hot end, Animoose's E3D mount for FolgerTech 2020 (version 2)

-Animoose's LCD bracket for Folger 2020

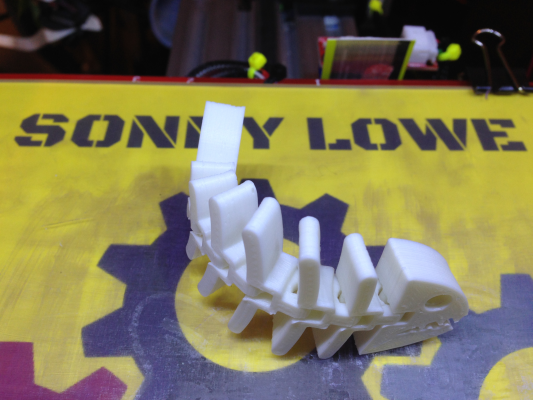

-Sonny's Y-axis Upgrade, Sonny's X-axis Upgrade, Sonny's Mini Gantry Direct Drive Extruder mount

-Acme screw rods (400mm),Z Motor Stand-off for FolgerTech 2020 i3

-Spool Rollers for Folger Tech i3 2020

New Wikia page: [urlhttp://folgertech.wikia.com/wiki/Main_Page][folgertech.wikia.com][/url]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 18, 2016 07:50PM |

Registered: 8 years ago Posts: 16 |

Quote

srcga

Happy with the E3d V6 so far, and the extruder remix that rippa posted.

Venturing back into PETG, did a Benchy without much preparation and surprisingly it turned out great.

Just picked up Simplify3D, getting used to it now..

What temps are you running at the hot end and the bed?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 18, 2016 08:46PM |

Registered: 8 years ago Posts: 16 |

Quote

MMeyer

Any recommendations on a "good" one?

I got my RAMPS at Amazon, I didn't even bother trying to contact FT, as it was said earlier, why have them send me another crappy one.

I also burned up a few stepper drivers, I think they put one extra in the kit, but for $7.50 from Aliexpress.com I upgraded to the Drv8825 stepper drivers, they are quieter and I haven't blown one yet. I also had an issue with the X-axis stepper getting hot, so I replaced that with a stronger one. I went ahead and upgraded the extruder stepper also since I plan to experiment with different extruder designs soon.

My Ramps and stepper motors came from Amazon, filament from Microcenter, and all the other hardware I got from Aliexpress, it takes a while but it's cheap. I can't afford a E3D hot end, so I got 2 E3D clones from Aliexpress for about $10 each, and they're already setup up for going to a bowden setup. It takes a long time to get parts so I like to have spares.

My suggestion is to build it first and after you're happy with the stock setup, your first "upgrade" should be a mount for the LCD (buy it with the printer, or separate). The second upgrade is to upgrade to therippa's Marlin, The third is the auto-bed-level system, it'll save you a lot of time.

I got the 18mm inductive sensor (LJ18A3-8-Z/AX) and it easily detects all the way through my 3/16 glass. I flattened out a very large hose clamp, cut it to length and slid it between the heated bed and the glass, and the sensor picks it up about 2mm away from the glass. I also works fine on the 5v from the RAMPS, no voltage divider is needed, I initially ran it on 12v with a voltage divider, but it didn't work at all, then i tried it on 5v without the divider and it worked great. I should have tried it on 5v before soldering the voltage divider stuff on. oh well.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 18, 2016 10:25PM |

Registered: 8 years ago Posts: 80 |

Quote

marc2912

Quote

MMeyer

Hi

I have an issue. I got my printer built and everything calibrated (end stops, motor voltage, etc..). I printed a couple little parts; filament temp calibration stack, calibration cube and a few other little things. everything was working great. I was printing a couple parts from an SD card when the raft wasn't sticking to the bed. I canceled the print and was going to hook my computer up to use Repetier. When I plugged the USB into my surface pro, the computer shut off instantly and the LCD contrast got extremely high, it was full of white squares. There was also a little smoke coming from the board area (couldn't tell exactly which one).

Here is what I know after this happened:

1. The arduino isn't seen when the RAMPS board is attached. I took it off and connected it by itself and all was fine.

2. The motor voltage is 2x - 3x higher than what I set them to yesterday. I had the motor voltage set to 200mv - 350mv depending on the axis. I set them by lowering them until they stop and then turning them up until they ran smoothly.

3. The SD Card is no longer recognized when inserted into the LCD.

4. The power supply seems okay. Voltage is steady.

5. I've inspected the boards for solder bridging and evidence of where the smoke was coming from but seen nothing.

6. Was working great....

Any help will be greatly appreciated!

Happened to a few people before, reach out to folgertech is option 1 and tell them you got a bad ramps. Personally I would just buy a known good one myself. You'll just get another one from the same crappy batch. Folgertech knows this and has done nothing.

Yes, I'll put money on it that your arduino 5v regulator is fried, and your arduino board is seeing more than 5v now. You'll want to replace it. I had exactly the same symptoms, after working on one of my end stops with a screwdriver while power was live and shorting 5v to ground. My lcd got much brighter, my motor voltages got higher, etc, and when I checked the voltage on the board it was 7v. I thought I would be smart and just replace the onboard regulator, but many of the arduino pins became flaky so I eventually threw it out.

You'll want to check for shorts now. It could be the ramps board as Marc suggested, or it could be somewhere else. Make sure that short is fixed before attaching your next arduino or you'll do it again.

Now I have one of those black sainsmart boards. No problems, but it isn't as pretty as the old one. I don't know what others are getting in their kits but mine was an excellent copy of the official arduino board, with the made in Italy logo and everything. I know FT is too cheap to spring for a real $45 board, so that's the only way I know it was fake.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 18, 2016 10:29PM |

Registered: 8 years ago Posts: 80 |

Quote

peeejayz

Anyone got a recommended inductive sensor, Mine just arrived and its to big to fit into any of the brackets I've printed. I got the 8mm sensing one.

Here's a nice one for an 8mm diameter sensor: [www.thingiverse.com] It fits on an e3d mount with a nice layer fam, if you have an e3dv6. Or you could remix it.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 01:27AM |

Registered: 8 years ago Posts: 8 |

Quote

Mach

Quote

randym

I've had my 2020 up and running for a few weeks now. Build almost completely stock for now. I'm having a problem with the temperature control for the bed. No matter what the temp is set for, it just goes full on. I've even turned it off in Slic3r and it still heats up.

I'm not sure what to try next and wondering if anyone else has seen this problem.

Will the new version of the software help?

Or is it a hardware issue with the Ramps board?

Sounds like a problem with the ramps, possibly a bad mosfet.

I sent an email to FT support and that's what they think it is as well. They're sending me a replacement board. Hopefully that will solve the issue.

Thanks for the help.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 11:05AM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 12:27PM |

Registered: 10 years ago Posts: 477 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 12:29PM |

Registered: 8 years ago Posts: 85 |

Didn't end up having time to add anything else on the wiki last night. Had prints stop sticking and rather than be sensible and clean my glass I started dinking with my inductive sensor and all heck broke loose  Finally got the sensor back at the right height and my firmware setting dialed in again and by then was too tired to work on any kind of writeup.

Finally got the sensor back at the right height and my firmware setting dialed in again and by then was too tired to work on any kind of writeup.

Anyway looking at the wiki I noticed that if you just go to: [folgertech.wikia.com] you get a generic welcome page with no apparent way to get to the actual page with info: [folgertech.wikia.com] not sure if this was on purpose while we flesh things out or if it's just an oversight. Didn't want to make that big of a change without telling anyone first though.

BTW - If anyone wants it I merged theRippa's pre-setup Marlin with the latest 1.1.0-RC3 and have it on my github here: [github.com]

I have a few of the settings a little different from therippa. PID values are changed based on what I got from autotune on my printer, I set my max temps a little lower, I changed INVERT_X_DIR to true and X_HOME_DIR to -1 to work with my endstop on the left and stepper connected the same as Y/Z instead of reversed, I have my esteps a little higher and I have the z steps at 400 to work with leadscrews instead of 4000 for the stock threaded rod, I enabled the eeprom and chitchat, and I enabled FILAMENTCHANGEENABLE in configuration_adv.

If you just want to grab 1.1.0-RC3 and update it you can see the changes I made compared to the official version here:

[github.com]

Finally got the sensor back at the right height and my firmware setting dialed in again and by then was too tired to work on any kind of writeup.

Finally got the sensor back at the right height and my firmware setting dialed in again and by then was too tired to work on any kind of writeup.Anyway looking at the wiki I noticed that if you just go to: [folgertech.wikia.com] you get a generic welcome page with no apparent way to get to the actual page with info: [folgertech.wikia.com] not sure if this was on purpose while we flesh things out or if it's just an oversight. Didn't want to make that big of a change without telling anyone first though.

BTW - If anyone wants it I merged theRippa's pre-setup Marlin with the latest 1.1.0-RC3 and have it on my github here: [github.com]

I have a few of the settings a little different from therippa. PID values are changed based on what I got from autotune on my printer, I set my max temps a little lower, I changed INVERT_X_DIR to true and X_HOME_DIR to -1 to work with my endstop on the left and stepper connected the same as Y/Z instead of reversed, I have my esteps a little higher and I have the z steps at 400 to work with leadscrews instead of 4000 for the stock threaded rod, I enabled the eeprom and chitchat, and I enabled FILAMENTCHANGEENABLE in configuration_adv.

If you just want to grab 1.1.0-RC3 and update it you can see the changes I made compared to the official version here:

[github.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 12:46PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 01:14PM |

Registered: 8 years ago Posts: 93 |

Quote

UltiFix

How much different than the oiginal Prusia I3 is this printer?

The main thing is the much more rigid aluminum frame, motors at the top, and a lot fewer 3d printed parts. The original Prusa i3 uses a flat piece of acrylic or wood as the vertical portion, with rods bolted into the bottom to hold the Y axis setup, which form the entirety of the frame. The acrylic is subject to deformation from the heat and general flexibility, but works well for most people. Folgertech sells this kit also - their acrylic Prusa i3 is pretty much exactly the standard Prusa i3, except the extruder is stronger cast plastic, not 3D printed.

I know the rest of this isn't really related to your question, but I think it is worth saying.

The currently shipping Folgertech 2020 i3 uses a mk9 extruder, which from all accounts works better than the "mk10" on the Wanhao i3. The rigid 2020 aluminum box frame is very solid and the same construction as used in most custom factory and industrial machinery installations. Those small steel L inserts that join the corners hold them firmly at 90 degrees and keep everything square. The results from my printer, in the original stock form, were as good as my friends Wanhao duplicator, and with my modifications, seem to be better.

The Wanhao has a lot going for it. Out of the box it is a working printer. It has better bearings. It has more metal parts, and more solid construction, but the Melzi controller it includes seems less flexible than the Marlin/Ramps combo, and apparently most people don't like the MK10 extruder.

The printer isn't perfect, but you can spend a lot more money and get one that is not as good. I've seen kits for the original Prusa i3 still listed for $600 and more on many websites.

The linear bearings on the Folgertech can be noisy, but the still move freely and work well enough. Like I said, my stock print quality, after dialing it in, was as good or better than the Wanhao duplicator i3.

The real deciding factor between the two, is whether you are looking for a project to build, or for a ready-to-go turn-key printer.

Edited 1 time(s). Last edit at 01/19/2016 01:23PM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 01:19PM |

Registered: 8 years ago Posts: 314 |

Yea...Quote

Bert3D

Quote

UltiFix

How much different than the oiginal Prusia I3 is this printer?

The main thing is the much more rigid aluminum frame, motors at the top, and a lot fewer 3d printed parts. The original Prusa i3 uses a flat piece of acrylic or wood as the vertical portion, with rods bolted into the bottom to hold the Y axis setup, which form the entirety of the frame. The acrylic is subject to deformation from the heat and general flexibility, but works well for most people. Folgertech sells this kit also - their acrylic Prusa i3 is pretty much exactly the standard Prusa i3, except the extruder is stronger cast plastic, not 3D printed.

The currently shipping Folgertech 2020 i3 uses a mk9 extruder, which from all accounts works better than the "mk10" on the Wanhao i3. The rigid 2020 aluminum box frame is very solid and the same construction as used in most custom factory and industrial machinery installations. Those small steel L inserts that join the corners hold them firmly at 90 degrees and keep everything square. The results from my printer, in the original stock form, were as good as my friends Wanhao duplicator, and with my modifications, seem to be better.

The Wanhao has a lot going for it. Out of the box it is a working printer. It has better bearings. It has more metal parts, and more solid construction, but the Melzi controller it includes seems less flexible than the Marlin/Ramps combo, and apparently most people don't like the MK10 extruder.

The printer isn't perfect, but you can spend a lot more money and get one that is not as good.

What other tools should I order along with a printer?

A digital caliper? And maybe a handheld point and shoot heat detector?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 01:42PM |

Registered: 8 years ago Posts: 93 |

I picked up a good digital caliper on sale at my local harbor freight long before getting the printer, and it works well enough that I got another 6-inch version just to keep with the printer. The temp gun is a fun thing to have, and I have a Ryobi one from Home Depot (again, long before getting the 3d printer), but it isn't really necessary. I've never used mine for the printer.

A good set of metric hex drivers would be handy. I keep this set [r.ebay.com] on my printer in this stand [www.thingiverse.com] along with my 6-inch calipers and other tools I use most with the printer. You can see them in the photos on the thingiverse photos for the stand. I also use a 5.5mm socket driver a lot, like this one: DYNAMITE Nut Driver: 5.5mm DYN2803 [r.ebay.com] or like in this set [www.ebay.com] (although mine are blue, not pink.) This is the stand I made for them: [www.thingiverse.com]

I use the longer hex drivers the most, and I think all the nuts on the printer are 5.5 lock nuts on M3 bolts.

This set looks handy, although I don't have one like it: [www.ebay.com]

This set also looks good, and I have a similar hex driver set. These sizes may be the most useful overall: Hex Socket Driver Set 4pcs: 4.0BOX/5.5BOX/7.0BOX/8.0BOX Car/Truck USA Ship [r.ebay.com]

I use to use the ones with the exchangeable tips, but that gets annoying after a while. I still use that set for the 4mm hex driver you need occasionally. Allen wrenches are very awkward to use compared to the drivers, but sometimes fit in places a driver will not.

I also use a putty knife that I ground to a sharp edge for removing prints. I have a more rigid scraper that I sometimes use too, although it is mostly just whichever one I can grab first. The needlenose pliers came from the Walmart tool section. They have a good set of exchangeable tip drivers too. The putty knife and scraper came from the Walmart paint section. The flush diagonal cutters came from the hobby section in with the beads and jewelry kits. The exacto knife was there also. All work well for their purposes.

Edited 6 time(s). Last edit at 01/19/2016 02:03PM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

A good set of metric hex drivers would be handy. I keep this set [r.ebay.com] on my printer in this stand [www.thingiverse.com] along with my 6-inch calipers and other tools I use most with the printer. You can see them in the photos on the thingiverse photos for the stand. I also use a 5.5mm socket driver a lot, like this one: DYNAMITE Nut Driver: 5.5mm DYN2803 [r.ebay.com] or like in this set [www.ebay.com] (although mine are blue, not pink.) This is the stand I made for them: [www.thingiverse.com]

I use the longer hex drivers the most, and I think all the nuts on the printer are 5.5 lock nuts on M3 bolts.

This set looks handy, although I don't have one like it: [www.ebay.com]

This set also looks good, and I have a similar hex driver set. These sizes may be the most useful overall: Hex Socket Driver Set 4pcs: 4.0BOX/5.5BOX/7.0BOX/8.0BOX Car/Truck USA Ship [r.ebay.com]

I use to use the ones with the exchangeable tips, but that gets annoying after a while. I still use that set for the 4mm hex driver you need occasionally. Allen wrenches are very awkward to use compared to the drivers, but sometimes fit in places a driver will not.

I also use a putty knife that I ground to a sharp edge for removing prints. I have a more rigid scraper that I sometimes use too, although it is mostly just whichever one I can grab first. The needlenose pliers came from the Walmart tool section. They have a good set of exchangeable tip drivers too. The putty knife and scraper came from the Walmart paint section. The flush diagonal cutters came from the hobby section in with the beads and jewelry kits. The exacto knife was there also. All work well for their purposes.

Edited 6 time(s). Last edit at 01/19/2016 02:03PM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 01:59PM |

Registered: 8 years ago Posts: 16 |

Ultifix:Quote

UltiFix

Yea...Quote

Bert3D

Quote

UltiFix

How much different than the oiginal Prusia I3 is this printer?

The main thing is the much more rigid aluminum frame, motors at the top, and a lot fewer 3d printed parts. The original Prusa i3 uses a flat piece of acrylic or wood as the vertical portion, with rods bolted into the bottom to hold the Y axis setup, which form the entirety of the frame. The acrylic is subject to deformation from the heat and general flexibility, but works well for most people. Folgertech sells this kit also - their acrylic Prusa i3 is pretty much exactly the standard Prusa i3, except the extruder is stronger cast plastic, not 3D printed.

The currently shipping Folgertech 2020 i3 uses a mk9 extruder, which from all accounts works better than the "mk10" on the Wanhao i3. The rigid 2020 aluminum box frame is very solid and the same construction as used in most custom factory and industrial machinery installations. Those small steel L inserts that join the corners hold them firmly at 90 degrees and keep everything square. The results from my printer, in the original stock form, were as good as my friends Wanhao duplicator, and with my modifications, seem to be better.

The Wanhao has a lot going for it. Out of the box it is a working printer. It has better bearings. It has more metal parts, and more solid construction, but the Melzi controller it includes seems less flexible than the Marlin/Ramps combo, and apparently most people don't like the MK10 extruder.

The printer isn't perfect, but you can spend a lot more money and get one that is not as good.

What other tools should I order along with a printer?

A digital caliper? And maybe a handheld point and shoot heat detector?

I have a small tupperware of tools I keep with my printer:

a small set of wire cutters

utility knife

metric hex key set (must have 2.0mm and 2.5mm, other sizes may be used, but not as often)

metric mini wrench (spanner) set (5.5mm gets used often, I think the nozzle is 7mm)

nozzle cleaning drill set (factory nozzle is .4, get more than one 0.4 drill)

screwdriver

6inch crescent wrench

bundle of 4inch zip ties

3-in-one oil

I had a non-contact laser thermometer until my kids dropped it, so it's nice to have. I keep my digital caliper with my regular tools, so it's also wise to have around.

Another tupperware is full of spare parts, end-stop switches, wires, etc. Some spares are extras I bought such as nuts, locknuts, t-nuts, bolts, cap screws, stepper drivers, etc. I keep it all in a small tool bag that also holds the parts I haven't installed yet (z-leadscrews).

Not to get off topic, but the Wanhao looks very similar to this:

Maker Select 3D Printer from Monoprice.com

I like monoprice, but this seems a little slow, I'm not close to printing at over 100mm/sec right now, but I'd like to get there in the future. With the FT 2020 kit I think over 100mm/sec is possible, maybe with this monoprice it's not.

jhitesma:

Thanks for putting up the Wiki. I couldn't figure out how to make a sub-topic a separate page, it that easy to do on Wikia?

I think the auto-bed leveling and some of the Advanced Upgrades are great candidates for having their own pages.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 02:06PM |

Registered: 8 years ago Posts: 314 |

Wow, so many options!Quote

rollinns

Ultifix:Quote

UltiFix

Quote

Bert3D

Quote

UltiFix

How much different than the oiginal Prusia I3 is this printer?

The main thing is the much more rigid aluminum frame, motors at the top, and a lot fewer 3d printed parts. The original Prusa i3 uses a flat piece of acrylic or wood as the vertical portion, with rods bolted into the bottom to hold the Y axis setup, which form the entirety of the frame. The acrylic is subject to deformation from the heat and general flexibility, but works well for most people. Folgertech sells this kit also - their acrylic Prusa i3 is pretty much exactly the standard Prusa i3, except the extruder is stronger cast plastic, not 3D printed.

The currently shipping Folgertech 2020 i3 uses a mk9 extruder, which from all accounts works better than the "mk10" on the Wanhao i3. The rigid 2020 aluminum box frame is very solid and the same construction as used in most custom factory and industrial machinery installations. Those small steel L inserts that join the corners hold them firmly at 90 degrees and keep everything square. The results from my printer, in the original stock form, were as good as my friends Wanhao duplicator, and with my modifications, seem to be better.

The Wanhao has a lot going for it. Out of the box it is a working printer. It has better bearings. It has more metal parts, and more solid construction, but the Melzi controller it includes seems less flexible than the Marlin/Ramps combo, and apparently most people don't like the MK10 extruder.

The printer isn't perfect, but you can spend a lot more money and get one that is not as good.

Yea...

What other tools should I order along with a printer?

A digital caliper? And maybe a handheld point and shoot heat detector?

I have a small tupperware of tools I keep with my printer:

a small set of wire cutters

utility knife

metric hex key set (must have 2.0mm and 2.5mm, other sizes may be used, but not as often)

metric mini wrench (spanner) set (5.5mm gets used often, I think the nozzle is 7mm)

nozzle cleaning drill set (factory nozzle is .4, get more than one 0.4 drill)

screwdriver

6inch crescent wrench

bundle of 4inch zip ties

3-in-one oil

I had a non-contact laser thermometer until my kids dropped it, so it's nice to have. I keep my digital caliper with my regular tools, so it's also wise to have around.

Another tupperware is full of spare parts, end-stop switches, wires, etc. Some spares are extras I bought such as nuts, locknuts, t-nuts, bolts, cap screws, stepper drivers, etc. I keep it all in a small tool bag that also holds the parts I haven't installed yet (z-leadscrews).

Not to get off topic, but the Wanhao looks very similar to this:

Maker Select 3D Printer from Monoprice.com

I like monoprice, but this seems a little slow, I'm not close to printing at over 100mm/sec right now, but I'd like to get there in the future. With the FT 2020 kit I think over 100mm/sec is possible, maybe with this monoprice it's not.

jhitesma:

Thanks for putting up the Wiki. I couldn't figure out how to make a sub-topic a separate page, it that easy to do on Wikia?

I think the auto-bed leveling and some of the Advanced Upgrades are great candidates for having their own pages.

[www.monoprice.com]

Some people are telling me it's bad to have the motors up high... Im still stuck on what printer to get

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 02:18PM |

Registered: 8 years ago Posts: 13 |

Just realized I may need to order some additional stuff...

Is any solder/kapton tape included in the kit for those sections that need it?

Need help? Visit the Folgertech Wikia Page

Is any solder/kapton tape included in the kit for those sections that need it?

Need help? Visit the Folgertech Wikia Page

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 02:21PM |

Registered: 8 years ago Posts: 85 |

Quote

rollinns

jhitesma:

Thanks for putting up the Wiki. I couldn't figure out how to make a sub-topic a separate page, it that easy to do on Wikia?

I think the auto-bed leveling and some of the Advanced Upgrades are great candidates for having their own pages.

Actually that was therippa who setup the wiki, I just added some of the issues I've heard repeated and ran into myself building mine.

I agree we'll probably have to split some of the advanced stuff off onto it's own pages...I'm just not sure how to do that on wikia yet and haven't had time to add much more.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 02:23PM |

Registered: 8 years ago Posts: 93 |

Quote

nightpanda2810

Just realized I may need to order some additional stuff...

Is any solder/kapton tape included in the kit for those sections that need it?

Some kapton tape is included. You need to supply your on solder and soldering equipment, though.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 02:40PM |

Registered: 8 years ago Posts: 13 |

Quote

Bert3D

Quote

nightpanda2810

Just realized I may need to order some additional stuff...

Is any solder/kapton tape included in the kit for those sections that need it?

Some kapton tape is included. You need to supply your on solder and soldering equipment, though.

Perfect, already have those. Thanks!

Need help? Visit the Folgertech Wikia Page

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 02:40PM |

Registered: 8 years ago Posts: 276 |

Quote

jhitesma

Quote

rollinns

jhitesma:

Thanks for putting up the Wiki. I couldn't figure out how to make a sub-topic a separate page, it that easy to do on Wikia?

I think the auto-bed leveling and some of the Advanced Upgrades are great candidates for having their own pages.

Actually that was therippa who setup the wiki, I just added some of the issues I've heard repeated and ran into myself building mine.

I agree we'll probably have to split some of the advanced stuff off onto it's own pages...I'm just not sure how to do that on wikia yet and haven't had time to add much more.

I think you just make a link to a page that doesn't exist (red link), and when you click on it, it will give you an choice to create a new page.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 02:53PM |

Registered: 10 years ago Posts: 477 |

Quote

Bert3D

Quote

UltiFix

How much different than the oiginal Prusia I3 is this printer?

The original Prusa i3 uses a flat piece of acrylic or wood as the vertical portion, with rods bolted into the bottom to hold the Y axis setup, which form the entirety of the frame. The acrylic is subject to deformation from the heat and general flexibility, but works well for most people.

The original Prusa i3 uses an aluminum frame. Later Grabber designed the plywood frame with braces, then came the acrylic frames.

Steve

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 03:03PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 19, 2016 04:09PM |

Registered: 8 years ago Posts: 93 |

Quote

UltiFix

I can get a duplicator I3 for 350, thats tempting, then I can use that printer to print parts for an old prusa 2 a friend gave me.

I'm not so sure the quality of the Monoprice copy will be as good as the real Wanhao Duplicator I3. A real Wanhao Duplicator I3 V2 is only $399 directly from them.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

Sorry, only registered users may post in this forum.