Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 24, 2016 07:04PM |

Registered: 8 years ago Posts: 541 |

Quote

therippa

Quote

sonnylowe

Quote

Bert3D

Quote

tjnamtiw

I put this message in a separate message rather than put it where everyone hangs out.

In preparation for my installation of the BLTouch probe for ABL, I moved the X end stop, made the appropriate changes, and tested to be sure everything was OK. Now I loaded Marlin's 1.1.0 RC2 and changed what needed to be changed but upon homing, X and Y both went correctly and Z went toward home but both Z steppers went nuts making racket, which I assumed was skipping steps. I saw in config.h "#define HOMING_FEEDRATE {50*60, 50*60, 4*60, 0} // set the homing speeds (mm/min)". In therippa's version and my old version, the Z feedrate was set at 50, no 240, so I changed that to 50 and all was good. Before making that change, however, even if I RAISED the Z axis, it made that racket. I'm not sure if there is somewhere else that sets Z axis speed very high.

In any event, in the new Wikia, where BLTouch is addressed a comment is made that BLTouch doesn't like to move slowly between probes and you may have to put the Z feedrate at 4*60 (240). I don't think that's going to work without some other workaround, if indeed, you need that much speed. I did raise my Z driver voltage from .240 to .350 with no change. I didn't go any higher.

Any suggestions from those who are using BLTouch??

Also, the suggested changes in the Wikia are tailored to RC3, I think, rather than theRippa's version. eg:servo section.

If you are using 1.1.0-RC3, be sure to set the motherboard type to BOARD_RAMPS_14_EFB or the servo won't work due to a pin conflict.

#define MOTHERBOARD BOARD_RAMPS_14_EFB

Also 4*60 is the default homing rate for 1.1.0-RC3, I think, so no change will be necessary there.

You can get a copy of my Configuration.h file for 1.1.0-RC3 here:

[www.thetechwizard.us]

It is for a x-endstop on the left, and stock extruder.

The instruction on Wikia were based on 1.1.0RC2, which is the firmware I'm running. I have changed the wikia page to reflect this. I'm not sure what version therippa is running!?!? If it is in fact RC3 we must all keep in mind the following statement on github...

Release Candidate -- Marlin 1.1.0-RC3 - 01 December 2015

"Not for production use – use with caution!"

To honest I'm not familiar enough with Marlin to know exactly what that means, nor whether it really matters or not. But it seems to me to be indicating it is a living firmware, that can be changed at anytime!?!?

That's the reason I pick RC2, it was latest so called released version I could find.

Maybe once rippa forks it, his version doesn't change, again, I don't know, but I'm sure rippa can clarify.

I also changed the note referring to the speed change, it was only necessary if you were having issues between probing (alarm) which I was having and I believe only related to the Yellow version!?!? It was one of those things that took me literally days to figure out, so I wanted to bring it to light to maybe same other some time...

The motherboard changes Bert recommend did not apply to RC2, at least not for me, my motherboard is MOTHERBOARD BOARD_RAMPS_13_EEB (note: EEB is require over EFB for dual extruders).

tjnamtiw,

As far as the racketing, I never experienced it with my Z setup (8mm Lead Screws Igus bearings) running between probes at 4*60 (hell I even ran them at 4*100 for a while, but it was scary fast...still worked though), so I'm not sure what's going on there. If you're running lead screws there might be a bit of an alignment issues or binding you simply don't see at lower speeds, if you're still running the M5 allthread that very well might be it!?!? But if it's working now at 50 I would leave it there.

Thanks for bringing this up, the Wikia needs to be proofed by everyone so we can catch these errors and the instruction that might make since to some of use but not explained well enough for everyone to get it. It always sounds good in the author head when he's writing it, but that doesn't mean it's written well LOL

It sounds like you used the Wikia guide to get the BLtouch setup, if so please let me know what you think and how we can improve it...

Edit: This reply is a prime example of how easy it is to make mistakes when writing (or at least for me)...I just reread it and found two types

You should be using the RC3 version, they fixed a bunch of bugs in it and it is more stable than RC2. They give that disclaimer for all of the release candidates, it just means "we aren't sure we've worked all of the kinks out, use with caution". I've been running RC3 since it came out in early December with no issues.

WILCO

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 24, 2016 07:10PM |

Registered: 8 years ago Posts: 268 |

Quote

jabu32

Quote

sonnylowe

This

Equals This

Which in turn Equals This

what are the parts for?

Y-Axis Offset Belt Parts

X-Axis Gen-2 Rail Mounts

OB Gantry Direct Drive E3D V6 Mount w/Proximity Sensor

Z-Axis Upgrade Parts

Corner Braces

M5 Adapter for the X-Axis Rail Mounts (the mounts are configured for M8 lead screws, so these will allow you to still run M5 lead screws)

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 24, 2016 07:16PM |

Registered: 8 years ago Posts: 314 |

Is this the right guide to use when asembling my printer?

[github.com]

In my last post I forgot to add the link

[github.com]

In my last post I forgot to add the link

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 24, 2016 07:39PM |

Registered: 8 years ago Posts: 268 |

Quote

tjnamtiw

Quote

therippa

Quote

sonnylowe

Quote

Bert3D

Quote

tjnamtiw

I put this message in a separate message rather than put it where everyone hangs out.

In preparation for my installation of the BLTouch probe for ABL, I moved the X end stop, made the appropriate changes, and tested to be sure everything was OK. Now I loaded Marlin's 1.1.0 RC2 and changed what needed to be changed but upon homing, X and Y both went correctly and Z went toward home but both Z steppers went nuts making racket, which I assumed was skipping steps. I saw in config.h "#define HOMING_FEEDRATE {50*60, 50*60, 4*60, 0} // set the homing speeds (mm/min)". In therippa's version and my old version, the Z feedrate was set at 50, no 240, so I changed that to 50 and all was good. Before making that change, however, even if I RAISED the Z axis, it made that racket. I'm not sure if there is somewhere else that sets Z axis speed very high.

In any event, in the new Wikia, where BLTouch is addressed a comment is made that BLTouch doesn't like to move slowly between probes and you may have to put the Z feedrate at 4*60 (240). I don't think that's going to work without some other workaround, if indeed, you need that much speed. I did raise my Z driver voltage from .240 to .350 with no change. I didn't go any higher.

Any suggestions from those who are using BLTouch??

Also, the suggested changes in the Wikia are tailored to RC3, I think, rather than theRippa's version. eg:servo section.

If you are using 1.1.0-RC3, be sure to set the motherboard type to BOARD_RAMPS_14_EFB or the servo won't work due to a pin conflict.

#define MOTHERBOARD BOARD_RAMPS_14_EFB

Also 4*60 is the default homing rate for 1.1.0-RC3, I think, so no change will be necessary there.

You can get a copy of my Configuration.h file for 1.1.0-RC3 here:

[www.thetechwizard.us]

It is for a x-endstop on the left, and stock extruder.

The instruction on Wikia were based on 1.1.0RC2, which is the firmware I'm running. I have changed the wikia page to reflect this. I'm not sure what version therippa is running!?!? If it is in fact RC3 we must all keep in mind the following statement on github...

Release Candidate -- Marlin 1.1.0-RC3 - 01 December 2015

"Not for production use – use with caution!"

To honest I'm not familiar enough with Marlin to know exactly what that means, nor whether it really matters or not. But it seems to me to be indicating it is a living firmware, that can be changed at anytime!?!?

That's the reason I pick RC2, it was latest so called released version I could find.

Maybe once rippa forks it, his version doesn't change, again, I don't know, but I'm sure rippa can clarify.

I also changed the note referring to the speed change, it was only necessary if you were having issues between probing (alarm) which I was having and I believe only related to the Yellow version!?!? It was one of those things that took me literally days to figure out, so I wanted to bring it to light to maybe same other some time...

The motherboard changes Bert recommend did not apply to RC2, at least not for me, my motherboard is MOTHERBOARD BOARD_RAMPS_13_EEB (note: EEB is require over EFB for dual extruders).

tjnamtiw,

As far as the racketing, I never experienced it with my Z setup (8mm Lead Screws Igus bearings) running between probes at 4*60 (hell I even ran them at 4*100 for a while, but it was scary fast...still worked though), so I'm not sure what's going on there. If you're running lead screws there might be a bit of an alignment issues or binding you simply don't see at lower speeds, if you're still running the M5 allthread that very well might be it!?!? But if it's working now at 50 I would leave it there.

Thanks for bringing this up, the Wikia needs to be proofed by everyone so we can catch these errors and the instruction that might make since to some of use but not explained well enough for everyone to get it. It always sounds good in the author head when he's writing it, but that doesn't mean it's written well LOL

It sounds like you used the Wikia guide to get the BLtouch setup, if so please let me know what you think and how we can improve it...

Edit: This reply is a prime example of how easy it is to make mistakes when writing (or at least for me)...I just reread it and found two types

You should be using the RC3 version, they fixed a bunch of bugs in it and it is more stable than RC2. They give that disclaimer for all of the release candidates, it just means "we aren't sure we've worked all of the kinks out, use with caution". I've been running RC3 since it came out in early December with no issues.

WILCO

Thanks for the heads up, I think I'll merge my current RC2 into RC3 and see what happens

EDIT: Just merged RC2 into RC3, all went well...I was printing again in less than ten minutes

Edited 1 time(s). Last edit at 01/24/2016 07:52PM by sonnylowe.

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 12:36AM |

Registered: 8 years ago Posts: 14 |

Quote

Boffster

Quote

sonnylowe

This is great advice, maybe we should add a trouble shooting section to the Wikia Page!?!?

I think would be a huge benefit to have a definitive build guide and configuration.h that the majority agree on that we can point people to (here and from the wiki), that way everyone will have the same setup and same config starting out. E.g. Endstops on Min and Stepper cables all connected the same way round.

That should help with 90% of the problems people seem to be having.

I've been working on a step-by-step build guide and photographing almost every line. I have to finish the last step, but I can't do that until I get a cast off my hand.

Once that happens, I can share it with you guys for review.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 08:33AM |

Registered: 8 years ago Posts: 13 |

Got everything together Saturday morning, but still having an issue with a mirrored X axis.

I've tried several things I found in this thread but nothing is working.

Using therippa's Marlin, and my end-stop is on the left.

Other than this and some needed calibration, everything else is working great!

(Shoddy printed parts excluded... working on replacing those!)

Need help? Visit the Folgertech Wikia Page

I've tried several things I found in this thread but nothing is working.

Using therippa's Marlin, and my end-stop is on the left.

Other than this and some needed calibration, everything else is working great!

(Shoddy printed parts excluded... working on replacing those!)

Need help? Visit the Folgertech Wikia Page

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 08:52AM |

Registered: 8 years ago Posts: 131 |

Quote

sonnylowe

Quote

marc2912

So I don't want to sound like a broken record but I'm getting some serious lift issues. Not just the corners lifting off the build bed but also lifting on edges higher up in the print. I've printed something where there is an overhang higher up (about 25mm high) and it build appropriate support, The support adhered to the print and when the corner started lifting there it ripped the support of the bed.

I am printing on a borosilicate glass plate.

I'm getting the bed itself up to 120C (mostly because I think I'm losing a bit during the heat transfer to the glass)

I've had better results when printing directly on the bed but the FT bed are warped and far from a level surface.

I've considered a raft but if an overhang 25mm up rips the support off the bed as they warp I don't see how a raft would fare any better.

This is my main issue as my prints are otherwise looking great.

Thanks

Check out the two guides below (also posted on the Wikia Page), they may help with your issue. I print on the same glass, 80C with Glue Stick...I have no real lifting issues...maybe your filament temp is a bit too high!?!?

S3D Guide

Ultimaker

Went through the guides, nothing makes much of a difference. I've read that glass while great for being flat is not the best to use due to it's heat transfer properties... Ordered some Kapton tape to print directly on the bed since those are the best results I've gotten.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 09:00AM |

Registered: 8 years ago Posts: 131 |

Quote

nightpanda2810

Got everything together Saturday morning, but still having an issue with a mirrored X axis.

I've tried several things I found in this thread but nothing is working.

Using therippa's Marlin, and my end-stop is on the left.

Other than this and some needed calibration, everything else is working great!

(Shoddy printed parts excluded... working on replacing those!)

Someone will correct me if I'm wrong but did you try change the way you have it plugged in to the ramps board. Flipping it should reverse the rotation. Had to do that when I built, for some reason my extruder was de-struding.

Edited 1 time(s). Last edit at 01/25/2016 09:00AM by marc2912.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 09:10AM |

Registered: 8 years ago Posts: 13 |

Quote

marc2912

Quote

nightpanda2810

Got everything together Saturday morning, but still having an issue with a mirrored X axis.

I've tried several things I found in this thread but nothing is working.

Using therippa's Marlin, and my end-stop is on the left.

Other than this and some needed calibration, everything else is working great!

(Shoddy printed parts excluded... working on replacing those!)

Someone will correct me if I'm wrong but did you try change the way you have it plugged in to the ramps board. Flipping it should reverse the rotation. Had to do that when I built, for some reason my extruder was de-struding.

I had to flip the extruder motor as well. Didn't help with the X carriage though (at least not by itself)

Although if I change endstop to MIN with the flip that may work. Will have to try tonight.

Need help? Visit the Folgertech Wikia Page

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 11:13AM |

Registered: 8 years ago Posts: 276 |

Quote

nightpanda2810

Got everything together Saturday morning, but still having an issue with a mirrored X axis.

I've tried several things I found in this thread but nothing is working.

Using therippa's Marlin, and my end-stop is on the left.

Other than this and some needed calibration, everything else is working great!

(Shoddy printed parts excluded... working on replacing those!)

The firmware I posted is meant for the stock folgertech setup, so it thinks the endstop is on the right.

Off the top of my head, in configuration.h you'd have to set the following:

X_HOME_DIR -1

INVERT_X_DIR true (but this can also be changed by just reversing the plug)

and in your host you would set X-endstop to MIN

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 12:21PM |

Registered: 8 years ago Posts: 16 |

Quote

UltiFix

Is this the right guide to use when asembling my printer?

[github.com]

In my last post I forgot to add the link

Until bstern's build guide is done, it's the best place to start.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 01:56PM |

Registered: 8 years ago Posts: 13 |

Quote

rollinns

Quote

UltiFix

Is this the right guide to use when asembling my printer?

[github.com]

In my last post I forgot to add the link

Until bstern's build guide is done, it's the best place to start.

It's the one I used. Had some minor troubleshooting to do after done but all simple stuff.

Need help? Visit the Folgertech Wikia Page

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 05:27PM |

Registered: 8 years ago Posts: 25 |

Found this and thought it may be useful especially for us newbies

It is a visual guide to troubleshooting your prints... note: it is for an ultimaker printer but the concepts should still translate well..

[support.3dverkstan.se]

New Wikia page: [folgertech.wikia.com]

It is a visual guide to troubleshooting your prints... note: it is for an ultimaker printer but the concepts should still translate well..

[support.3dverkstan.se]

New Wikia page: [folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 05:48PM |

Registered: 8 years ago Posts: 13 |

Quote

therippa

Quote

nightpanda2810

Got everything together Saturday morning, but still having an issue with a mirrored X axis.

I've tried several things I found in this thread but nothing is working.

Using therippa's Marlin, and my end-stop is on the left.

Other than this and some needed calibration, everything else is working great!

(Shoddy printed parts excluded... working on replacing those!)

The firmware I posted is meant for the stock folgertech setup, so it thinks the endstop is on the right.

Off the top of my head, in configuration.h you'd have to set the following:

X_HOME_DIR -1

INVERT_X_DIR true (but this can also be changed by just reversing the plug)

and in your host you would set X-endstop to MIN

This was exactly it. Thanks!

I'd add to the wiki but not sure how to put it in there and get it worded properly, lol.

Need help? Visit the Folgertech Wikia Page

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 07:16PM |

Registered: 8 years ago Posts: 84 |

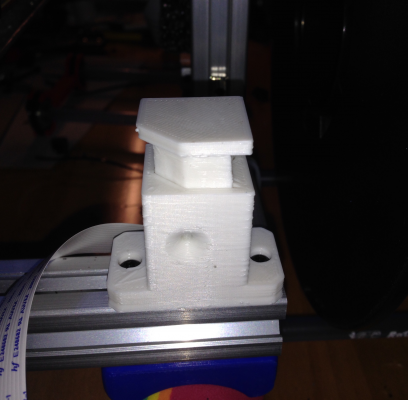

Got all of the parts printed to convert my printer to v-slot using SonnyLowes setup. Just waiting on all of the parts to arrive that I cant print now lol

Printed this the other day, I do believe it turned out great, after I had to run it through makeprintable.com because the model had holes in it.

Printed this the other day, I do believe it turned out great, after I had to run it through makeprintable.com because the model had holes in it.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 08:17PM |

Registered: 8 years ago Posts: 268 |

Quote

bstern

Quote

Boffster

Quote

sonnylowe

This is great advice, maybe we should add a trouble shooting section to the Wikia Page!?!?

I think would be a huge benefit to have a definitive build guide and configuration.h that the majority agree on that we can point people to (here and from the wiki), that way everyone will have the same setup and same config starting out. E.g. Endstops on Min and Stepper cables all connected the same way round.

That should help with 90% of the problems people seem to be having.

I've been working on a step-by-step build guide and photographing almost every line. I have to finish the last step, but I can't do that until I get a cast off my hand.

Once that happens, I can share it with you guys for review.

Great...can't wait :-)

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 08:23PM |

Registered: 8 years ago Posts: 268 |

Quote

marc2912

Quote

sonnylowe

Quote

marc2912

So I don't want to sound like a broken record but I'm getting some serious lift issues. Not just the corners lifting off the build bed but also lifting on edges higher up in the print. I've printed something where there is an overhang higher up (about 25mm high) and it build appropriate support, The support adhered to the print and when the corner started lifting there it ripped the support of the bed.

I am printing on a borosilicate glass plate.

I'm getting the bed itself up to 120C (mostly because I think I'm losing a bit during the heat transfer to the glass)

I've had better results when printing directly on the bed but the FT bed are warped and far from a level surface.

I've considered a raft but if an overhang 25mm up rips the support off the bed as they warp I don't see how a raft would fare any better.

This is my main issue as my prints are otherwise looking great.

Thanks

Check out the two guides below (also posted on the Wikia Page), they may help with your issue. I print on the same glass, 80C with Glue Stick...I have no real lifting issues...maybe your filament temp is a bit too high!?!?

S3D Guide

Ultimaker

Went through the guides, nothing makes much of a difference. I've read that glass while great for being flat is not the best to use due to it's heat transfer properties... Ordered some Kapton tape to print directly on the bed since those are the best results I've gotten.

I used to run Kapton tape over my Alm build plate (and over glass now that I think about it), I found that if you went over it with some Green Scotch-Brite and rough up surface a bit the parts stuck like crazy...good luck!!!

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 08:27PM |

Registered: 8 years ago Posts: 268 |

I just printer this fun little gadget...I am constantly losing track of my cutters, so I remixed it to attach to the 2020 rail, now this is mounted directly under my extruder, oh so convenient...and it works really well...

Filament Cutter

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

Filament Cutter

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 10:15PM |

Registered: 8 years ago Posts: 92 |

Hello fellow FT2020ers! Let me start of by saying a huge THANK YOU to all of you who have contributed to the thread over the past several months. It has been an invaluable resource to me these past couple weeks since I received my FT 2020. (I'm reading through it, but am still back at page 92 - I'm getting caught up!)

I had a couple issues out of the gate (the same things as many of you). I also had a bad hot-end termistor which prevented me doing anything until I diagnosed that. I pulled the one off the bed to get things going, and have stuck with PLA for now.(The good folks at FT have taken good care of me, and sent out replacement parts immediately.)

So when I got things up and running, I ran my first print (without doing any other extruder calibration or anything) and it came out beautifully (I turned down the temp to 195c from the default 219). From that cube, I did some calibration to the XYZ steppers, and have calibrated the extruder to accurate 100mm runs.

Attached is a pic of my 6th or 7th print, and I think Benchy came out great.(.2mm, 30% Infill)

I'm having a couple issues that I can' figure out. First, the middle of my print bed is higher than the corners.It doesn't matter what I do, but I can get the corners all the same height, but I can't print anything in the middle unless my first layer is set to .4mm, as at .2, the nozzle touches hard, and can't extrude anything. I have checked the heat bed with a straight edge, and it looks good and flat. I've used multiple sheets of glass, and all have the same issue. Anyone else deal with something like this?

The second problem I'm having is with object scale. I printed out a set of the Z motor standoffs, to raise them up and reclaim my height, but they came out small. I couldn't insert the 608 bearings for the life of me, so I pulled out the calipers and sure enough, they measured small. I had to upscale them to 1.024 for them to print the right size. Now before you yell Calibrate! I have. When I print a 20mm cube, it comes right in at 20x20x20mm. I have a number things I want to print, but I need accurate dimensions, and I can't print each thing a second time (after seeing the results, then scaling up to compensate). So do any of you have any recommendations?

I had a couple issues out of the gate (the same things as many of you). I also had a bad hot-end termistor which prevented me doing anything until I diagnosed that. I pulled the one off the bed to get things going, and have stuck with PLA for now.(The good folks at FT have taken good care of me, and sent out replacement parts immediately.)

So when I got things up and running, I ran my first print (without doing any other extruder calibration or anything) and it came out beautifully (I turned down the temp to 195c from the default 219). From that cube, I did some calibration to the XYZ steppers, and have calibrated the extruder to accurate 100mm runs.

Attached is a pic of my 6th or 7th print, and I think Benchy came out great.(.2mm, 30% Infill)

I'm having a couple issues that I can' figure out. First, the middle of my print bed is higher than the corners.It doesn't matter what I do, but I can get the corners all the same height, but I can't print anything in the middle unless my first layer is set to .4mm, as at .2, the nozzle touches hard, and can't extrude anything. I have checked the heat bed with a straight edge, and it looks good and flat. I've used multiple sheets of glass, and all have the same issue. Anyone else deal with something like this?

The second problem I'm having is with object scale. I printed out a set of the Z motor standoffs, to raise them up and reclaim my height, but they came out small. I couldn't insert the 608 bearings for the life of me, so I pulled out the calipers and sure enough, they measured small. I had to upscale them to 1.024 for them to print the right size. Now before you yell Calibrate! I have. When I print a 20mm cube, it comes right in at 20x20x20mm. I have a number things I want to print, but I need accurate dimensions, and I can't print each thing a second time (after seeing the results, then scaling up to compensate). So do any of you have any recommendations?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 11:01PM |

Registered: 8 years ago Posts: 276 |

Quote

iamquestar

Hello fellow FT2020ers! Let me start of by saying a huge THANK YOU to all of you who have contributed to the thread over the past several months. It has been an invaluable resource to me these past couple weeks since I received my FT 2020. (I'm reading through it, but am still back at page 92 - I'm getting caught up!)

I had a couple issues out of the gate (the same things as many of you). I also had a bad hot-end termistor which prevented me doing anything until I diagnosed that. I pulled the one off the bed to get things going, and have stuck with PLA for now.(The good folks at FT have taken good care of me, and sent out replacement parts immediately.)

So when I got things up and running, I ran my first print (without doing any other extruder calibration or anything) and it came out beautifully (I turned down the temp to 195c from the default 219). From that cube, I did some calibration to the XYZ steppers, and have calibrated the extruder to accurate 100mm runs.

Attached is a pic of my 6th or 7th print, and I think Benchy came out great.(.2mm, 30% Infill)

I'm having a couple issues that I can' figure out. First, the middle of my print bed is higher than the corners.It doesn't matter what I do, but I can get the corners all the same height, but I can't print anything in the middle unless my first layer is set to .4mm, as at .2, the nozzle touches hard, and can't extrude anything. I have checked the heat bed with a straight edge, and it looks good and flat. I've used multiple sheets of glass, and all have the same issue. Anyone else deal with something like this?

The second problem I'm having is with object scale. I printed out a set of the Z motor standoffs, to raise them up and reclaim my height, but they came out small. I couldn't insert the 608 bearings for the life of me, so I pulled out the calipers and sure enough, they measured small. I had to upscale them to 1.024 for them to print the right size. Now before you yell Calibrate! I have. When I print a 20mm cube, it comes right in at 20x20x20mm. I have a number things I want to print, but I need accurate dimensions, and I can't print each thing a second time (after seeing the results, then scaling up to compensate). So do any of you have any recommendations?

For your first problem, sounds like a rod may be bent, there's no reason it shouldn't be perfectly flat if you're printing on glass

For the second problem, a lot of people have problems with holes being too small (I'm in that camp, by like a fraction of a millimeter, I just design around it). Try googling for potential solutions (there's a bunch)

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 11:12PM |

Registered: 8 years ago Posts: 541 |

Quote

sonnylowe

Thanks for the heads up, I think I'll merge my current RC2 into RC3 and see what happens

EDIT: Just merged RC2 into RC3, all went well...I was printing again in less than ten minutes

Might I be missing something? When you say 'merge' the current RC2 into RC3, is there a magic way of doing this besides opening the two up side by side in Arduino and go down line by line making changes to the new one to reflect what's in the old one? That's what I've been doing.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 25, 2016 11:35PM |

Registered: 8 years ago Posts: 276 |

Quote

tjnamtiw

Quote

sonnylowe

Thanks for the heads up, I think I'll merge my current RC2 into RC3 and see what happens

EDIT: Just merged RC2 into RC3, all went well...I was printing again in less than ten minutes

Might I be missing something? When you say 'merge' the current RC2 into RC3, is there a magic way of doing this besides opening the two up side by side in Arduino and go down line by line making changes to the new one to reflect what's in the old one? That's what I've been doing.

That's part of the magic of git. You can tell it to grab the latest changes from the RC3 branch, and automatically merge them into the branch you are using. I prefer using Sourcetree to git command line, here are some instructions to get you started - [confluence.atlassian.com]

Since you probably didn't use git to pull the initial project, you should do this:

1. Install/open Sourcetree

2. File -> New/Clone -> Clone from URL. Use this URL: [github.com] . Clone it to a new folder somewhere on your computer.

3. You will now have the "RC" branch checked out. On the left nav, expand the Tags section, and right-click the 1.1.0-RC3 branch, and click checkout. Your project is now updated to the latest tagged RC

4. Use something like beyondcompare to compare your configuration.h to the one in the project. If I remember correctly, there were no changes made that I needed to port over.

5. Upload the project to the Arduino

6. Next time a marlin version is released, you can just check that version out and merge it automatically into what you're using.

Make sure you backup your current marlin folder in case you make any mistakes, but once you get the hang of git, you'll realize if you make any mistakes you can revert the changes easily

Git is DEFINITELY worth learning, you can version control pretty much anything with it, and you can host your projects for free on github or bitbucket, so in case your hard drive dies you won't lose any work.

Git is DEFINITELY worth learning, you can version control pretty much anything with it, and you can host your projects for free on github or bitbucket, so in case your hard drive dies you won't lose any work.Edited 2 time(s). Last edit at 01/25/2016 11:44PM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 26, 2016 01:47AM |

Registered: 8 years ago Posts: 92 |

Quote

therippa

Quote

iamquestar

Hello fellow FT2020ers! Let me start of by saying a huge THANK YOU to all of you who have contributed to the thread over the past several months. It has been an invaluable resource to me these past couple weeks since I received my FT 2020. (I'm reading through it, but am still back at page 92 - I'm getting caught up!)

I had a couple issues out of the gate (the same things as many of you). I also had a bad hot-end termistor which prevented me doing anything until I diagnosed that. I pulled the one off the bed to get things going, and have stuck with PLA for now.(The good folks at FT have taken good care of me, and sent out replacement parts immediately.)

So when I got things up and running, I ran my first print (without doing any other extruder calibration or anything) and it came out beautifully (I turned down the temp to 195c from the default 219). From that cube, I did some calibration to the XYZ steppers, and have calibrated the extruder to accurate 100mm runs.

Attached is a pic of my 6th or 7th print, and I think Benchy came out great.(.2mm, 30% Infill)

I'm having a couple issues that I can' figure out. First, the middle of my print bed is higher than the corners.It doesn't matter what I do, but I can get the corners all the same height, but I can't print anything in the middle unless my first layer is set to .4mm, as at .2, the nozzle touches hard, and can't extrude anything. I have checked the heat bed with a straight edge, and it looks good and flat. I've used multiple sheets of glass, and all have the same issue. Anyone else deal with something like this?

The second problem I'm having is with object scale. I printed out a set of the Z motor standoffs, to raise them up and reclaim my height, but they came out small. I couldn't insert the 608 bearings for the life of me, so I pulled out the calipers and sure enough, they measured small. I had to upscale them to 1.024 for them to print the right size. Now before you yell Calibrate! I have. When I print a 20mm cube, it comes right in at 20x20x20mm. I have a number things I want to print, but I need accurate dimensions, and I can't print each thing a second time (after seeing the results, then scaling up to compensate). So do any of you have any recommendations?

For your first problem, sounds like a rod may be bent, there's no reason it shouldn't be perfectly flat if you're printing on glass

For the second problem, a lot of people have problems with holes being too small (I'm in that camp, by like a fraction of a millimeter, I just design around it). Try googling for potential solutions (there's a bunch)

Thanks for the quick reply. You have provided many words of advice I have benefited from.

The first issue may be caused by the build plate. When I received it from FT, it was bent. I *thought* I had been able to bend it back to OK flatness (not perfect, but I figured if the heat bead was "floating" above it, it should be good enough.

The second issue us not just holes being too small. (although I realize my mention of the bearing made it sound like that.) I can deal with that. It's the whole part that is printing small. For example, on the z motor standoffs, they measure 39mm in the software. When I first printed them, the result was about 38.05 wide. Almost a full mm off for the screw hole alignment (at the base). Up-scaling by 2.4% got me to the proper size. If that was required for everything, I would expect the 20mm cube to print out at about 19.5mm but its printing right at 20. That's what has me so puzzled.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 26, 2016 03:21AM |

Registered: 8 years ago Posts: 1 |

I'm having problems with my extruder motor. The filament isn't being feed through properly, it just oscillates up and down, ie the motor moves forward a step then back as step. Problem remains with various Vref (from 0.1 - 0.6 V). When switching the wires for the x- driver, it feeds filament fine. When I switched the actual drivers on the board, nothing changes so it doesn't seem to be the driver. When I try to drive the x-motor, using the original extruder cables, same motor performance is seen.

Is this a firmware issue? Anyone have solutions or troubleshooting ideas?

Is this a firmware issue? Anyone have solutions or troubleshooting ideas?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 26, 2016 06:56AM |

Registered: 8 years ago Posts: 268 |

Quote

therippa

Quote

tjnamtiw

Quote

sonnylowe

Thanks for the heads up, I think I'll merge my current RC2 into RC3 and see what happens

EDIT: Just merged RC2 into RC3, all went well...I was printing again in less than ten minutes

Might I be missing something? When you say 'merge' the current RC2 into RC3, is there a magic way of doing this besides opening the two up side by side in Arduino and go down line by line making changes to the new one to reflect what's in the old one? That's what I've been doing.

That's part of the magic of git. You can tell it to grab the latest changes from the RC3 branch, and automatically merge them into the branch you are using. I prefer using Sourcetree to git command line, here are some instructions to get you started - [confluence.atlassian.com]

Since you probably didn't use git to pull the initial project, you should do this:

1. Install/open Sourcetree

2. File -> New/Clone -> Clone from URL. Use this URL: [github.com] . Clone it to a new folder somewhere on your computer.

3. You will now have the "RC" branch checked out. On the left nav, expand the Tags section, and right-click the 1.1.0-RC3 branch, and click checkout. Your project is now updated to the latest tagged RC

4. Use something like beyondcompare to compare your configuration.h to the one in the project. If I remember correctly, there were no changes made that I needed to port over.

5. Upload the project to the Arduino

6. Next time a marlin version is released, you can just check that version out and merge it automatically into what you're using.

Make sure you backup your current marlin folder in case you make any mistakes, but once you get the hang of git, you'll realize if you make any mistakes you can revert the changes easilyGit is DEFINITELY worth learning, you can version control pretty much anything with it, and you can host your projects for free on github or bitbucket, so in case your hard drive dies you won't lose any work.

Great explanation rippa, thanks.

This would be good info to add to the Wikia page for those that have slightly different printer setups, it's great for transferring settings like E-steps, PID, Etc.

I merged the RC2/RC3 config-h files using Beyond Compare, although it may not be the best way to do it, up to this point it was the only way I knew how ;-)

However, after reading this post I will definitely try it through Git next time...I'd love to understand it a little better

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 26, 2016 09:48AM |

Registered: 8 years ago Posts: 541 |

Quote

therippa

Quote

tjnamtiw

Quote

sonnylowe

Thanks for the heads up, I think I'll merge my current RC2 into RC3 and see what happens

EDIT: Just merged RC2 into RC3, all went well...I was printing again in less than ten minutes

Might I be missing something? When you say 'merge' the current RC2 into RC3, is there a magic way of doing this besides opening the two up side by side in Arduino and go down line by line making changes to the new one to reflect what's in the old one? That's what I've been doing.

That's part of the magic of git. You can tell it to grab the latest changes from the RC3 branch, and automatically merge them into the branch you are using. I prefer using Sourcetree to git command line, here are some instructions to get you started - [confluence.atlassian.com]

Since you probably didn't use git to pull the initial project, you should do this:

1. Install/open Sourcetree

2. File -> New/Clone -> Clone from URL. Use this URL: [github.com] . Clone it to a new folder somewhere on your computer.

3. You will now have the "RC" branch checked out. On the left nav, expand the Tags section, and right-click the 1.1.0-RC3 branch, and click checkout. Your project is now updated to the latest tagged RC

4. Use something like beyondcompare to compare your configuration.h to the one in the project. If I remember correctly, there were no changes made that I needed to port over.

5. Upload the project to the Arduino

6. Next time a marlin version is released, you can just check that version out and merge it automatically into what you're using.

Make sure you backup your current marlin folder in case you make any mistakes, but once you get the hang of git, you'll realize if you make any mistakes you can revert the changes easilyGit is DEFINITELY worth learning, you can version control pretty much anything with it, and you can host your projects for free on github or bitbucket, so in case your hard drive dies you won't lose any work.

Thanks a lot for taking the time and effort to document this, theRippa! Man, have I been wasting my time! Well, in any event, by doing it the hard way I got to really dig into each step and maybe, just maybe, I learned a little more about how Marlin works. HOWEVER, I'm going to do it your way from now on!

Thanks again.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 26, 2016 10:40AM |

Registered: 8 years ago Posts: 16 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 26, 2016 11:02AM |

Registered: 8 years ago Posts: 16 |

Quote

XChris

I'm having problems with my extruder motor. The filament isn't being feed through properly, it just oscillates up and down, ie the motor moves forward a step then back as step. Problem remains with various Vref (from 0.1 - 0.6 V). When switching the wires for the x- driver, it feeds filament fine. When I switched the actual drivers on the board, nothing changes so it doesn't seem to be the driver. When I try to drive the x-motor, using the original extruder cables, same motor performance is seen.

Is this a firmware issue? Anyone have solutions or troubleshooting ideas?

I had similar issues a while back. I checked the same things you have.

To be clear on this "When switching the wires for the x- driver, it feeds filament fine." Do you mean the extruder is now plugged into the X-axis stepper pins? Meaning the extruder motor is now receiving power from a different driver and a different set of pins (both the x stepper driver and the x-stepper pins)?

if so then: different driver + different pins = success

And when you plugged a different driver into the extruder position and plugged the extruder into the extruder pins, it didn't work?

if so then: different driver + same pins = fail

I know some people here don't like when people blame the RAMPS board, but a new ramps fixed mine. I originally inspected my RAMPS before installation and found a stray solder blob, which I removed, at this point I knew my RAMPS was one of the poor RAMPS boards FT is known for. It worked for a while, but after the problems you've described came up later, I did the same tests and a new RAMPS fixed it. I didn't suspect firmware since I'd not changed it at all. There may be a component that could be replaced on the RAMPS to fix it (I'm not sure), but if it's a RAMPS that came from FT, my opinion is that it's not worth fixing. If you ever need to fix a RAMPS that way, spend the time and money repairing a higher quality board.

Later, similar problems returned, but I was able to confirm it was a bad driver the second time, so I swapped in dirt cheap DVR8825 drivers from aliexpress and it's a lot quieter.

I really like my FT 2020 i3, it's a lot of kit and education for the money, but I won't stand behind the RAMPS boards they ship at all. Maybe they've recently changed suppliers (again), but it doesn't appear that way.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 26, 2016 11:19AM |

Registered: 8 years ago Posts: 80 |

Quote

sonnylowe

Quote

therippa

Quote

tjnamtiw

Quote

sonnylowe

Thanks for the heads up, I think I'll merge my current RC2 into RC3 and see what happens

EDIT: Just merged RC2 into RC3, all went well...I was printing again in less than ten minutes

Might I be missing something? When you say 'merge' the current RC2 into RC3, is there a magic way of doing this besides opening the two up side by side in Arduino and go down line by line making changes to the new one to reflect what's in the old one? That's what I've been doing.

That's part of the magic of git. You can tell it to grab the latest changes from the RC3 branch, and automatically merge them into the branch you are using. I prefer using Sourcetree to git command line, here are some instructions to get you started - [confluence.atlassian.com]

Since you probably didn't use git to pull the initial project, you should do this:

1. Install/open Sourcetree

2. File -> New/Clone -> Clone from URL. Use this URL: [github.com] . Clone it to a new folder somewhere on your computer.

3. You will now have the "RC" branch checked out. On the left nav, expand the Tags section, and right-click the 1.1.0-RC3 branch, and click checkout. Your project is now updated to the latest tagged RC

4. Use something like beyondcompare to compare your configuration.h to the one in the project. If I remember correctly, there were no changes made that I needed to port over.

5. Upload the project to the Arduino

6. Next time a marlin version is released, you can just check that version out and merge it automatically into what you're using.

Make sure you backup your current marlin folder in case you make any mistakes, but once you get the hang of git, you'll realize if you make any mistakes you can revert the changes easilyGit is DEFINITELY worth learning, you can version control pretty much anything with it, and you can host your projects for free on github or bitbucket, so in case your hard drive dies you won't lose any work.

Great explanation rippa, thanks.

This would be good info to add to the Wikia page for those that have slightly different printer setups, it's great for transferring settings like E-steps, PID, Etc.

I merged the RC2/RC3 config-h files using Beyond Compare, although it may not be the best way to do it, up to this point it was the only way I knew how ;-)

However, after reading this post I will definitely try it through Git next time...I'd love to understand it a little better

I use TortoiseGit, which includes its own merge tool. It includes a lot of nice context menus, and is useful for visualizing development log including all branches and commits. However, for someone who is simply modifying the configuration file, I think downloading the latest version off github and merging in your own changes to configuration.h using beyondcompare is a great solution. There is a bit of a learning curve to git that might be difficult for those who don't use it on a regular basis. On the plus side, for those who do use it, git will allow you to track all the changes you make to the files, so you can easily go back to an earlier version of configuration,h, for example, when something breaks. And it does make pulling and merging the latest versions of Marlin with your own mods a snap.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 26, 2016 11:29AM |

Registered: 8 years ago Posts: 80 |

Quote

rollinns

Quote

XChris

I'm having problems with my extruder motor. The filament isn't being feed through properly, it just oscillates up and down, ie the motor moves forward a step then back as step. Problem remains with various Vref (from 0.1 - 0.6 V). When switching the wires for the x- driver, it feeds filament fine. When I switched the actual drivers on the board, nothing changes so it doesn't seem to be the driver. When I try to drive the x-motor, using the original extruder cables, same motor performance is seen.

Is this a firmware issue? Anyone have solutions or troubleshooting ideas?

I had similar issues a while back. I checked the same things you have.

To be clear on this "When switching the wires for the x- driver, it feeds filament fine." Do you mean the extruder is now plugged into the X-axis stepper pins? Meaning the extruder motor is now receiving power from a different driver and a different set of pins (both the x stepper driver and the x-stepper pins)?

if so then: different driver + different pins = success

And when you plugged a different driver into the extruder position and plugged the extruder into the extruder pins, it didn't work?

if so then: different driver + same pins = fail

I know some people here don't like when people blame the RAMPS board, but a new ramps fixed mine. I originally inspected my RAMPS before installation and found a stray solder blob, which I removed, at this point I knew my RAMPS was one of the poor RAMPS boards FT is known for. It worked for a while, but after the problems you've described came up later, I did the same tests and a new RAMPS fixed it. I didn't suspect firmware since I'd not changed it at all. There may be a component that could be replaced on the RAMPS to fix it (I'm not sure), but if it's a RAMPS that came from FT, my opinion is that it's not worth fixing. If you ever need to fix a RAMPS that way, spend the time and money repairing a higher quality board.

Later, similar problems returned, but I was able to confirm it was a bad driver the second time, so I swapped in dirt cheap DVR8825 drivers from aliexpress and it's a lot quieter.

I really like my FT 2020 i3, it's a lot of kit and education for the money, but I won't stand behind the RAMPS boards they ship at all. Maybe they've recently changed suppliers (again), but it doesn't appear that way.

It certainly does seem reasonable to suspect the ramps board here. I would probably pull off the ramps board and use my multimeter to verify that all of the pins to the driver are connected to the mega. The ramps schematic will show where everything needs to go. If not, start looking at the ramps board for bad soldering connections.

Sorry, only registered users may post in this forum.