Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 26, 2016 12:55PM |

Registered: 8 years ago Posts: 85 |

Quote

elkayem

Quote

sonnylowe

Quote

therippa

Quote

tjnamtiw

Quote

sonnylowe

Thanks for the heads up, I think I'll merge my current RC2 into RC3 and see what happens

EDIT: Just merged RC2 into RC3, all went well...I was printing again in less than ten minutes

Might I be missing something? When you say 'merge' the current RC2 into RC3, is there a magic way of doing this besides opening the two up side by side in Arduino and go down line by line making changes to the new one to reflect what's in the old one? That's what I've been doing.

That's part of the magic of git. You can tell it to grab the latest changes from the RC3 branch, and automatically merge them into the branch you are using. I prefer using Sourcetree to git command line, here are some instructions to get you started - [confluence.atlassian.com]

Since you probably didn't use git to pull the initial project, you should do this:

1. Install/open Sourcetree

2. File -> New/Clone -> Clone from URL. Use this URL: [github.com] . Clone it to a new folder somewhere on your computer.

3. You will now have the "RC" branch checked out. On the left nav, expand the Tags section, and right-click the 1.1.0-RC3 branch, and click checkout. Your project is now updated to the latest tagged RC

4. Use something like beyondcompare to compare your configuration.h to the one in the project. If I remember correctly, there were no changes made that I needed to port over.

5. Upload the project to the Arduino

6. Next time a marlin version is released, you can just check that version out and merge it automatically into what you're using.

Make sure you backup your current marlin folder in case you make any mistakes, but once you get the hang of git, you'll realize if you make any mistakes you can revert the changes easilyGit is DEFINITELY worth learning, you can version control pretty much anything with it, and you can host your projects for free on github or bitbucket, so in case your hard drive dies you won't lose any work.

Great explanation rippa, thanks.

This would be good info to add to the Wikia page for those that have slightly different printer setups, it's great for transferring settings like E-steps, PID, Etc.

I merged the RC2/RC3 config-h files using Beyond Compare, although it may not be the best way to do it, up to this point it was the only way I knew how ;-)

However, after reading this post I will definitely try it through Git next time...I'd love to understand it a little better

I use TortoiseGit, which includes its own merge tool. It includes a lot of nice context menus, and is useful for visualizing development log including all branches and commits. However, for someone who is simply modifying the configuration file, I think downloading the latest version off github and merging in your own changes to configuration.h using beyondcompare is a great solution. There is a bit of a learning curve to git that might be difficult for those who don't use it on a regular basis. On the plus side, for those who do use it, git will allow you to track all the changes you make to the files, so you can easily go back to an earlier version of configuration,h, for example, when something breaks. And it does make pulling and merging the latest versions of Marlin with your own mods a snap.

I've used github's git client, tortoise, sourcetree and a few others...but I find I keep going back to the command line

git is a wonderful tool and I can't get enough of it, even though I still get confused by it regularly

I had originally forked therippa's version of Marlin on github so I could maintain my own tree, then added the official repo as a remote and checked out the RC3 code. I then did a rebase on my modified version of therippa's to move his config changes over to the RC3 tree. Had to manually fix a few conflicts in configuration.h but overall it was a pretty clean upgrade.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 26, 2016 01:19PM |

Registered: 8 years ago Posts: 93 |

Quote

rollinns

Quote

XChris

I'm having problems with my extruder motor. The filament isn't being feed through properly, it just oscillates up and down, ie the motor moves forward a step then back as step. Problem remains with various Vref (from 0.1 - 0.6 V). When switching the wires for the x- driver, it feeds filament fine. When I switched the actual drivers on the board, nothing changes so it doesn't seem to be the driver. When I try to drive the x-motor, using the original extruder cables, same motor performance is seen.

Is this a firmware issue? Anyone have solutions or troubleshooting ideas?

I had similar issues a while back. I checked the same things you have.

To be clear on this "When switching the wires for the x- driver, it feeds filament fine." Do you mean the extruder is now plugged into the X-axis stepper pins? Meaning the extruder motor is now receiving power from a different driver and a different set of pins (both the x stepper driver and the x-stepper pins)?

if so then: different driver + different pins = success

And when you plugged a different driver into the extruder position and plugged the extruder into the extruder pins, it didn't work?

if so then: different driver + same pins = fail

I know some people here don't like when people blame the RAMPS board, but a new ramps fixed mine. I originally inspected my RAMPS before installation and found a stray solder blob, which I removed, at this point I knew my RAMPS was one of the poor RAMPS boards FT is known for. It worked for a while, but after the problems you've described came up later, I did the same tests and a new RAMPS fixed it. I didn't suspect firmware since I'd not changed it at all. There may be a component that could be replaced on the RAMPS to fix it (I'm not sure), but if it's a RAMPS that came from FT, my opinion is that it's not worth fixing. If you ever need to fix a RAMPS that way, spend the time and money repairing a higher quality board.

Later, similar problems returned, but I was able to confirm it was a bad driver the second time, so I swapped in dirt cheap DVR8825 drivers from aliexpress and it's a lot quieter.

I really like my FT 2020 i3, it's a lot of kit and education for the money, but I won't stand behind the RAMPS boards they ship at all. Maybe they've recently changed suppliers (again), but it doesn't appear that way.

I would suspect the soldering on the ramps board. I'd reflow all the connections around the affected axis driver, and any others that look suspect. Also try swapping the cable for a different one. I've had that be the problem on several occasions, usually due to bad crimps on the connectors. I'm talking about just using a different cable for the same motor and axis, not just moving the cable to a different motor.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 26, 2016 01:40PM |

Registered: 8 years ago Posts: 541 |

Quote

therippa

Quote

tjnamtiw

Quote

sonnylowe

Thanks for the heads up, I think I'll merge my current RC2 into RC3 and see what happens

EDIT: Just merged RC2 into RC3, all went well...I was printing again in less than ten minutes

Might I be missing something? When you say 'merge' the current RC2 into RC3, is there a magic way of doing this besides opening the two up side by side in Arduino and go down line by line making changes to the new one to reflect what's in the old one? That's what I've been doing.

That's part of the magic of git. You can tell it to grab the latest changes from the RC3 branch, and automatically merge them into the branch you are using. I prefer using Sourcetree to git command line, here are some instructions to get you started - [confluence.atlassian.com]

Since you probably didn't use git to pull the initial project, you should do this:

1. Install/open Sourcetree

2. File -> New/Clone -> Clone from URL. Use this URL: [github.com] . Clone it to a new folder somewhere on your computer.

3. You will now have the "RC" branch checked out. On the left nav, expand the Tags section, and right-click the 1.1.0-RC3 branch, and click checkout. Your project is now updated to the latest tagged RC

4. Use something like beyondcompare to compare your configuration.h to the one in the project. If I remember correctly, there were no changes made that I needed to port over.

5. Upload the project to the Arduino

6. Next time a marlin version is released, you can just check that version out and merge it automatically into what you're using.

Make sure you backup your current marlin folder in case you make any mistakes, but once you get the hang of git, you'll realize if you make any mistakes you can revert the changes easilyGit is DEFINITELY worth learning, you can version control pretty much anything with it, and you can host your projects for free on github or bitbucket, so in case your hard drive dies you won't lose any work.

Do I put my current Marlin file I'm using in the same folder where I just cloned the new RC3? Otherwise, how would it know where my current folder is to update it to the latest version?

Ah, That's where the SourceTree branches come in, right?

Pretty confusing to this old brain and that Sourcetree tutorial with the example is awfully strange and off-topic.

Pretty confusing to this old brain and that Sourcetree tutorial with the example is awfully strange and off-topic.Edited 2 time(s). Last edit at 01/26/2016 01:45PM by tjnamtiw.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 26, 2016 04:24PM |

Registered: 8 years ago Posts: 51 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 26, 2016 10:45PM |

Registered: 8 years ago Posts: 268 |

Quote

peeejayz

I got my leadscrews through today, the nuts have a bit of play in them is this normal?

Do I need to antibacklash them? I havn't needed it on the m5 rods yet.

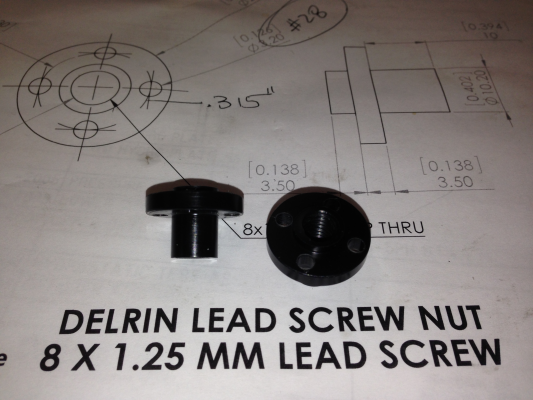

I've seen the same issues with all the LS nuts I've bought so far, my guess is they are cheap and out of tolerance, or I've just been unlucky...three times in a row ;-) It's the reason I made the anti-backlash setup I'm currently running. I like it, however I can tell the Brass Nuts are degrading already, so I made these today...

They are a perfect fit with the threaded robs, no play at all. I hope they will be a better alternative to the brass nut!?!? I'll finish polishing the threaded rod this weekend and hopefully have them shortly after...

I am also in contact with my Igus rep trying to get him to send me a sample of their Drylin round stock so I can machine some out of that

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 26, 2016 10:49PM |

Registered: 8 years ago Posts: 13 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 26, 2016 10:54PM |

Registered: 8 years ago Posts: 46 |

I just installed a BLTouch sensor but I'm a little unsure how to set up the Z axis offsets. I'm running on Marlin RC3 with the changes from the Wiki merged in. I just need a little help in getting the vertical position set right.

I'm using [www.thingiverse.com] as the BLTouch mount on the stock FT extruder head. Anyone recently done this?

I'm using [www.thingiverse.com] as the BLTouch mount on the stock FT extruder head. Anyone recently done this?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 26, 2016 10:57PM |

Registered: 8 years ago Posts: 131 |

Quote

chking

My kit arrived today but I've run into a snag. The printed parts that hold the LM8UU bearings are too tight. I've been able to get two bearings in so far. Should I look at dremeling the printed parts so I can get the bearings to fit? Has anyone else run into this issue?

Yes, mine were out of specs too and I had to work at it with my exacto knife, didn't want to take the dremmel to it in case I took too much off.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 12:07AM |

Registered: 8 years ago Posts: 14 |

That's a good idea. I've been holding off the lead screw because I don't want a shitty product. Might as well make my own. I'd imagine nylon would work better though? If so, might be able to print one.Quote

sonnylowe

Quote

peeejayz

I got my leadscrews through today, the nuts have a bit of play in them is this normal?

Do I need to antibacklash them? I havn't needed it on the m5 rods yet.

I've seen the same issues with all the LS nuts I've bought so far, my guess is they are cheap and out of tolerance, or I've just been unlucky...three times in a row ;-) It's the reason I made the anti-backlash setup I'm currently running. I like it, however I can tell the Brass Nuts are degrading already, so I made these today...

They are a perfect fit with the threaded robs, no play at all. I hope they will be a better alternative to the brass nut!?!? I'll finish polishing the threaded rod this weekend and hopefully have them shortly after...

I am also in contact with my Igus rep trying to get him to send me a sample of their Drylin round stock so I can machine some out of that

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 12:27AM |

Registered: 8 years ago Posts: 93 |

Quote

DaveA

I just installed a BLTouch sensor but I'm a little unsure how to set up the Z axis offsets. I'm running on Marlin RC3 with the changes from the Wiki merged in. I just need a little help in getting the vertical position set right.

I'm using [www.thingiverse.com] as the BLTouch mount on the stock FT extruder head. Anyone recently done this?

With that mount, assuming yours extruder is just like mine, it will be 31mm offset to the left on x, and 0 offset Y. The Z will vary, depending on the adjustment of your BLTouch. I raised mine up a bit to give the probe more clearance. That is a 2mm hex adjustment socket in the top of the BLTouch, which raises and lowers the pin.

Here are my settings, but yours could be different, so consider them just an example:

#define X_PROBE_OFFSET_FROM_EXTRUDER -31 // Z probe to nozzle X offset: -left +right

#define Y_PROBE_OFFSET_FROM_EXTRUDER 0 // Z probe to nozzle Y offset: -front +behind

#define Z_PROBE_OFFSET_FROM_EXTRUDER -4.3 // -3.8 // Z probe to nozzle Z offset: -below (always!)

#define Z_RAISE_BEFORE_HOMING 7 // (in mm) Raise Z axis before homing (G28) for Z probe clearance.

// Be sure you have this distance over your Z_MAX_POS in case.

#define XY_TRAVEL_SPEED 8000 // X and Y axis travel speed between probes, in mm/min.

#define Z_RAISE_BEFORE_PROBING 9 // How much the Z axis will be raised before traveling to the first probing point.

#define Z_RAISE_BETWEEN_PROBINGS 9 // How much the Z axis will be raised when traveling from between next probing points.

#define Z_RAISE_AFTER_PROBING 9 // How much the Z axis will be raised after the last probing point.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 03:47AM |

Registered: 8 years ago Posts: 51 |

Quote

sonnylowe

Quote

peeejayz

I got my leadscrews through today, the nuts have a bit of play in them is this normal?

Do I need to antibacklash them? I havn't needed it on the m5 rods yet.

I've seen the same issues with all the LS nuts I've bought so far, my guess is they are cheap and out of tolerance, or I've just been unlucky...three times in a row ;-) It's the reason I made the anti-backlash setup I'm currently running. I like it, however I can tell the Brass Nuts are degrading already, so I made these today...

They are a perfect fit with the threaded robs, no play at all. I hope they will be a better alternative to the brass nut!?!? I'll finish polishing the threaded rod this weekend and hopefully have them shortly after...

I am also in contact with my Igus rep trying to get him to send me a sample of their Drylin round stock so I can machine some out of that

How long did your setup with 2 brass ones and springs last?

Just wondering what my best option is.

Edited 1 time(s). Last edit at 01/27/2016 05:22AM by peeejayz.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 09:11AM |

Registered: 8 years ago Posts: 46 |

Quote

Bert3D

Quote

DaveA

I just installed a BLTouch sensor but I'm a little unsure how to set up the Z axis offsets. I'm running on Marlin RC3 with the changes from the Wiki merged in. I just need a little help in getting the vertical position set right.

I'm using [www.thingiverse.com] as the BLTouch mount on the stock FT extruder head. Anyone recently done this?

With that mount, assuming yours extruder is just like mine, it will be 31mm offset to the left on x, and 0 offset Y. The Z will vary, depending on the adjustment of your BLTouch. I raised mine up a bit to give the probe more clearance. That is a 2mm hex adjustment socket in the top of the BLTouch, which raises and lowers the pin.

Here are my settings, but yours could be different, so consider them just an example:

#define X_PROBE_OFFSET_FROM_EXTRUDER -31 // Z probe to nozzle X offset: -left +right #define Y_PROBE_OFFSET_FROM_EXTRUDER 0 // Z probe to nozzle Y offset: -front +behind #define Z_PROBE_OFFSET_FROM_EXTRUDER -4.3 // -3.8 // Z probe to nozzle Z offset: -below (always!) #define Z_RAISE_BEFORE_HOMING 7 // (in mm) Raise Z axis before homing (G28) for Z probe clearance. // Be sure you have this distance over your Z_MAX_POS in case. #define XY_TRAVEL_SPEED 8000 // X and Y axis travel speed between probes, in mm/min. #define Z_RAISE_BEFORE_PROBING 9 // How much the Z axis will be raised before traveling to the first probing point. #define Z_RAISE_BETWEEN_PROBINGS 9 // How much the Z axis will be raised when traveling from between next probing points. #define Z_RAISE_AFTER_PROBING 9 // How much the Z axis will be raised after the last probing point.

Thanks Bert3D. How did you arrive at the -4.3 offset for Z. Did you just sneak up on the trip point of the BLTouch with the probe extended and record the position and then sneak up on the nozzle just slightly above the bed and recording that point and then do the arithmetic?

Using that method I came up with -3.9 so maybe that's the correct approach.

I'm going to revert to RC2 and my original Z stop for a test after work. With my current setup the prints are awlful - just a ball of filament. So I'm not sure if it's the bed leveling or something else I missed in RC3

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 09:39AM |

Registered: 8 years ago Posts: 93 |

Quote

DaveA

Quote

Bert3D

Quote

DaveA

I just installed a BLTouch sensor but I'm a little unsure how to set up the Z axis offsets. I'm running on Marlin RC3 with the changes from the Wiki merged in. I just need a little help in getting the vertical position set right.

I'm using [www.thingiverse.com] as the BLTouch mount on the stock FT extruder head. Anyone recently done this?

With that mount, assuming yours extruder is just like mine, it will be 31mm offset to the left on x, and 0 offset Y. The Z will vary, depending on the adjustment of your BLTouch. I raised mine up a bit to give the probe more clearance. That is a 2mm hex adjustment socket in the top of the BLTouch, which raises and lowers the pin.

Here are my settings, but yours could be different, so consider them just an example:

#define X_PROBE_OFFSET_FROM_EXTRUDER -31 // Z probe to nozzle X offset: -left +right #define Y_PROBE_OFFSET_FROM_EXTRUDER 0 // Z probe to nozzle Y offset: -front +behind #define Z_PROBE_OFFSET_FROM_EXTRUDER -4.3 // -3.8 // Z probe to nozzle Z offset: -below (always!) #define Z_RAISE_BEFORE_HOMING 7 // (in mm) Raise Z axis before homing (G28) for Z probe clearance. // Be sure you have this distance over your Z_MAX_POS in case. #define XY_TRAVEL_SPEED 8000 // X and Y axis travel speed between probes, in mm/min. #define Z_RAISE_BEFORE_PROBING 9 // How much the Z axis will be raised before traveling to the first probing point. #define Z_RAISE_BETWEEN_PROBINGS 9 // How much the Z axis will be raised when traveling from between next probing points. #define Z_RAISE_AFTER_PROBING 9 // How much the Z axis will be raised after the last probing point.

Thanks Bert3D. How did you arrive at the -4.3 offset for Z. Did you just sneak up on the trip point of the BLTouch with the probe extended and record the position and then sneak up on the nozzle just slightly above the bed and recording that point and then do the arithmetic?

Using that method I came up with -3.9 so maybe that's the correct approach.

I'm going to revert to RC2 and my original Z stop for a test after work. With my current setup the prints are awlful - just a ball of filament. So I'm not sure if it's the bed leveling or something else I missed in RC3

If you need to see the whole config, and other RC3 files, you can see them here: https://github.com/AlwaysTinkering/Marlin

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 10:15AM |

Registered: 8 years ago Posts: 268 |

Quote

peeejayz

Quote

sonnylowe

Quote

peeejayz

I got my leadscrews through today, the nuts have a bit of play in them is this normal?

Do I need to antibacklash them? I havn't needed it on the m5 rods yet.

I've seen the same issues with all the LS nuts I've bought so far, my guess is they are cheap and out of tolerance, or I've just been unlucky...three times in a row ;-) It's the reason I made the anti-backlash setup I'm currently running. I like it, however I can tell the Brass Nuts are degrading already, so I made these today...

They are a perfect fit with the threaded robs, no play at all. I hope they will be a better alternative to the brass nut!?!? I'll finish polishing the threaded rod this weekend and hopefully have them shortly after...

I am also in contact with my Igus rep trying to get him to send me a sample of their Drylin round stock so I can machine some out of that

How long did your setup with 2 brass ones and springs last?

Just wondering what my best option is.

I ran them a week or two before I could hear a bit of noise out of them, at that point a checked them and they had more slop than before. To be honest it might have been too much tension from the springs...a bit too long, or a bit too strong!?!? I just don't know, so I figured I'd just try the Delrin Nuts.

The problem I ran into with manufactured Delrin Lead Nuts was the size, and/or shape, that's why I decided to make my own as exact replacements for the brass nuts.

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 10:23AM |

Registered: 8 years ago Posts: 11 |

I need to calibrate my printer, but before I do I wanted to I wanted to upgrade my firmware from the stock firmware. I keep seeing talks about a new version (Merging RC2 and RC3) so I am wondering should I wait?

Also since my printer is running well what is the best process for upgrading without messing up all my settings?

Also since my printer is running well what is the best process for upgrading without messing up all my settings?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 10:44AM |

Registered: 8 years ago Posts: 268 |

Quote

DaveA

Quote

Bert3D

Quote

DaveA

I just installed a BLTouch sensor but I'm a little unsure how to set up the Z axis offsets. I'm running on Marlin RC3 with the changes from the Wiki merged in. I just need a little help in getting the vertical position set right.

I'm using [www.thingiverse.com] as the BLTouch mount on the stock FT extruder head. Anyone recently done this?

With that mount, assuming yours extruder is just like mine, it will be 31mm offset to the left on x, and 0 offset Y. The Z will vary, depending on the adjustment of your BLTouch. I raised mine up a bit to give the probe more clearance. That is a 2mm hex adjustment socket in the top of the BLTouch, which raises and lowers the pin.

Here are my settings, but yours could be different, so consider them just an example:

#define X_PROBE_OFFSET_FROM_EXTRUDER -31 // Z probe to nozzle X offset: -left +right #define Y_PROBE_OFFSET_FROM_EXTRUDER 0 // Z probe to nozzle Y offset: -front +behind #define Z_PROBE_OFFSET_FROM_EXTRUDER -4.3 // -3.8 // Z probe to nozzle Z offset: -below (always!) #define Z_RAISE_BEFORE_HOMING 7 // (in mm) Raise Z axis before homing (G28) for Z probe clearance. // Be sure you have this distance over your Z_MAX_POS in case. #define XY_TRAVEL_SPEED 8000 // X and Y axis travel speed between probes, in mm/min. #define Z_RAISE_BEFORE_PROBING 9 // How much the Z axis will be raised before traveling to the first probing point. #define Z_RAISE_BETWEEN_PROBINGS 9 // How much the Z axis will be raised when traveling from between next probing points. #define Z_RAISE_AFTER_PROBING 9 // How much the Z axis will be raised after the last probing point.

Thanks Bert3D. How did you arrive at the -4.3 offset for Z. Did you just sneak up on the trip point of the BLTouch with the probe extended and record the position and then sneak up on the nozzle just slightly above the bed and recording that point and then do the arithmetic?

Using that method I came up with -3.9 so maybe that's the correct approach.

I'm going to revert to RC2 and my original Z stop for a test after work. With my current setup the prints are awlful - just a ball of filament. So I'm not sure if it's the bed leveling or something else I missed in RC3

If your nozzle is too far from the bed you will get the dreaded ball of filament...I would make sure your Z height is correct before heading back to RC2.

This is my method for determining Z height offset:

Run G28

If the nozzle if raised to 5mm above the bed then manually lower it to Z0.0 If it's already at Z0.0 proceed.

Heat the nozzle

Using a post it pad pull off ten sheets still connected (I use ten because I want my nozzle within 1mm of the bed). If the sheets go under the nozzle with NO resistance manually adjust the height of the Bltouch, usually the setscrew can accomplish this, if not, move the sensor.

Slide the bundle of notes under the nozzle, if it hits the nozzle start to remove the sheets one at a time, once the sheets go under the nozzle with a little drag you are set.

Either measure the remaining sheets (the best method) or simply assume they are .1mm each and do the math.

Now put your offset in Marlin.

Run a print and check the adhesion to the bed. If you still get balls of filament or no filament (the nozzle hits the bed) make the appropriate adjustment, either through Marlin or with your slicer (if available). You can adjust Z in Repetier and S3D, but I don't think Cura has that option!?!?

Hope that helps...

NOTE:

If the BLtouch alarms after adjusting the set screw you may need to move it back, it can get flaky if you move it too far out or in.

I believe this issue was corrected in the White version of the BLt, but make sure the setscrew doesn't move after you adjust it, either use a dab of loctite or cover it with a small piece of tape. if you use Loctite make sure it's the low hold version, you are dealing with plastic ;-)

Edited 2 time(s). Last edit at 01/27/2016 10:59AM by sonnylowe.

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 01:24PM |

Registered: 8 years ago Posts: 268 |

Quote

mindstormmaster1

I need to calibrate my printer, but before I do I wanted to I wanted to upgrade my firmware from the stock firmware. I keep seeing talks about a new version (Merging RC2 and RC3) so I am wondering should I wait?

Also since my printer is running well what is the best process for upgrading without messing up all my settings?

You want therippa's version of Marlin (it's in his sig or the Wikia page), it is already RC3. The talk about merging RC2/RC3 was between a few select people. You will most likely still need to merge your current version of marlin with RC3 as there are a few setting that will need to translate over (E-Steps, PID if you ran autotune, Etc.).

As far as waiting to calibrate, it doesn't really matter if you do it now or later, either way those setting (mentioned above) will need to be transferred.

Hmmm, now that I think about it a bit more, I guess if you did it before you calibrated and missed an e-step setting (or got it wrong) it wouldn't matte as much since you'd be calibrating it after anyway...so now might actually be better in the long run!?!?

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 01:32PM |

Registered: 8 years ago Posts: 70 |

found this on Hackaday - 3D Printer Tool: Set Your Extruder Steps With Ease thoughts?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 01:51PM |

Registered: 8 years ago Posts: 70 |

I've been busy upgrading my printer with the parts sonny has shared with us. Here's a look at them glowing with glow in the dark filament. x axis is on bottom, y axis on top. i left the mounting brackets off the y axis and the stepper mounting piece for the y axis wasn't done with this filament. I should of taken another picture with the light on.

Upgrades:

-Simple3d

-E3D V6 Direct drive hot end, Animoose's E3D mount for FolgerTech 2020 (version 2)

-Animoose's LCD bracket for Folger 2020

-Sonny's Y-axis Upgrade, Sonny's X-axis Upgrade, Sonny's Mini Gantry Direct Drive Extruder mount

-Acme screw rods (400mm),Z Motor Stand-off for FolgerTech 2020 i3

-Spool Rollers for Folger Tech i3 2020

New Wikia page: [urlhttp://folgertech.wikia.com/wiki/Main_Page][folgertech.wikia.com][/url]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 02:04PM |

Registered: 8 years ago Posts: 276 |

Quote

sonnylowe

Quote

mindstormmaster1

I need to calibrate my printer, but before I do I wanted to I wanted to upgrade my firmware from the stock firmware. I keep seeing talks about a new version (Merging RC2 and RC3) so I am wondering should I wait?

Also since my printer is running well what is the best process for upgrading without messing up all my settings?

You want therippa's version of Marlin (it's in his sig or the Wikia page), it is already RC3. The talk about merging RC2/RC3 was between a few select people. You will most likely still need to merge your current version of marlin with RC3 as there are a few setting that will need to translate over (E-Steps, PID if you ran autotune, Etc.).

As far as waiting to calibrate, it doesn't really matter if you do it now or later, either way those setting (mentioned above) will need to be transferred.

Hmmm, now that I think about it a bit more, I guess if you did it before you calibrated and missed an e-step setting (or got it wrong) it wouldn't matte as much since you'd be calibrating it after anyway...so now might actually be better in the long run!?!?

The firmware in my sig isn't RC3, it's the latest stable release.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 02:48PM |

Registered: 8 years ago Posts: 85 |

Quote

therippa

Quote

sonnylowe

You want therippa's version of Marlin (it's in his sig or the Wikia page), it is already RC3. The talk about merging RC2/RC3 was between a few select people. You will most likely still need to merge your current version of marlin with RC3 as there are a few setting that will need to translate over (E-Steps, PID if you ran autotune, Etc.).

The firmware in my sig isn't RC3, it's the latest stable release.

For a minute there I thought you had updated yours to RC3 and I missed it

I have RC3 with therippa's configurations merged in on my git here:

[github.com]

But I made a few additional small changes:

Lower max temps

Different PID values from my autotune (though bed PID isn't enabled yet...I've since enabled it and it's working fine though.)

X endstop settings changed a bit - I was getting mirrored prints with therippas setup even with my endstop on the left so I had to make a few additional changes.

Default Z steps set to 400 instead of 4000 since I'm using leadscrews.

EEPROM enabled (though therippa has since enabled this on his as well)

Quick Home enabled

FILAMENTCHANGEENABLE enabled

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 03:17PM |

Registered: 8 years ago Posts: 93 |

Quote

DaveA

Quote

Bert3D

Quote

DaveA

I just installed a BLTouch sensor but I'm a little unsure how to set up the Z axis offsets. I'm running on Marlin RC3 with the changes from the Wiki merged in. I just need a little help in getting the vertical position set right.

I'm using [www.thingiverse.com] as the BLTouch mount on the stock FT extruder head. Anyone recently done this?

With that mount, assuming yours extruder is just like mine, it will be 31mm offset to the left on x, and 0 offset Y. The Z will vary, depending on the adjustment of your BLTouch. I raised mine up a bit to give the probe more clearance. That is a 2mm hex adjustment socket in the top of the BLTouch, which raises and lowers the pin.

Here are my settings, but yours could be different, so consider them just an example:

#define X_PROBE_OFFSET_FROM_EXTRUDER -31 // Z probe to nozzle X offset: -left +right #define Y_PROBE_OFFSET_FROM_EXTRUDER 0 // Z probe to nozzle Y offset: -front +behind #define Z_PROBE_OFFSET_FROM_EXTRUDER -4.3 // -3.8 // Z probe to nozzle Z offset: -below (always!) #define Z_RAISE_BEFORE_HOMING 7 // (in mm) Raise Z axis before homing (G28) for Z probe clearance. // Be sure you have this distance over your Z_MAX_POS in case. #define XY_TRAVEL_SPEED 8000 // X and Y axis travel speed between probes, in mm/min. #define Z_RAISE_BEFORE_PROBING 9 // How much the Z axis will be raised before traveling to the first probing point. #define Z_RAISE_BETWEEN_PROBINGS 9 // How much the Z axis will be raised when traveling from between next probing points. #define Z_RAISE_AFTER_PROBING 9 // How much the Z axis will be raised after the last probing point.

Thanks Bert3D. How did you arrive at the -4.3 offset for Z. Did you just sneak up on the trip point of the BLTouch with the probe extended and record the position and then sneak up on the nozzle just slightly above the bed and recording that point and then do the arithmetic?

Using that method I came up with -3.9 so maybe that's the correct approach.

I'm going to revert to RC2 and my original Z stop for a test after work. With my current setup the prints are awlful - just a ball of filament. So I'm not sure if it's the bed leveling or something else I missed in RC3

I just homed using G28, then started lowering the printhead using negative Z movements, like G1 Z-0.5 then G1 Z-1, etc., until I got the nozzle to just touch the bed. Then I noted the distance that made it just barely make contact, which was G1 Z-4.3. To insure accuracy, I raised the head to 2mm using G1 Z2, then lowered it again, verifying he nozzle stopped just where I wanted it. Tweak the number until it goes down to the exact right height, and that number is your z offset.

If you can't get it to move to negative coordinates, you can compare with my config here https://github.com/AlwaysTinkering/Marlin to see what's different.

My other code changes are for my hardware setup with the Graphic controller, Z Lead Screws, and X endstop on the left. I'm using the stock extruder and hot end setup.

Edited 1 time(s). Last edit at 01/27/2016 06:53PM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 06:21PM |

Registered: 8 years ago Posts: 314 |

Yay, printer just showed up! After being delayed in the awful snow storms. Oh well it's here! Nothing more, nothing less! They didn't forget anything

Gosh, they just take ALL of the hardware and chuck it in a bag LOL

Sorry I can't attach pics, there prob to big...

[imgur.com]

[imgur.com]

[imgur.com]

Gosh, they just take ALL of the hardware and chuck it in a bag LOL

Sorry I can't attach pics, there prob to big...

[imgur.com]

[imgur.com]

[imgur.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 06:27PM |

Registered: 8 years ago Posts: 51 |

Quote

UltiFix

Yay, printer just showed up! After being delayed in the awful snow storms. Oh well it's here! Nothing more, nothing less! They didn't forget anything

Gosh, they just take ALL of the hardware and chuck it in a bag LOL

Sorry I can't attach pics, there prob to big...

[imgur.com]

[imgur.com]

[imgur.com]

You got lucky, mine was mssing 6bits

Edited 1 time(s). Last edit at 01/27/2016 06:27PM by peeejayz.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 07:13PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 07:14PM |

Registered: 8 years ago Posts: 541 |

Quote

Bert3D

Quote

DaveA

Quote

Bert3D

Quote

DaveA

I just installed a BLTouch sensor but I'm a little unsure how to set up the Z axis offsets. I'm running on Marlin RC3 with the changes from the Wiki merged in. I just need a little help in getting the vertical position set right.

I'm using [www.thingiverse.com] as the BLTouch mount on the stock FT extruder head. Anyone recently done this?

With that mount, assuming yours extruder is just like mine, it will be 31mm offset to the left on x, and 0 offset Y. The Z will vary, depending on the adjustment of your BLTouch. I raised mine up a bit to give the probe more clearance. That is a 2mm hex adjustment socket in the top of the BLTouch, which raises and lowers the pin.

Here are my settings, but yours could be different, so consider them just an example:

#define X_PROBE_OFFSET_FROM_EXTRUDER -31 // Z probe to nozzle X offset: -left +right #define Y_PROBE_OFFSET_FROM_EXTRUDER 0 // Z probe to nozzle Y offset: -front +behind #define Z_PROBE_OFFSET_FROM_EXTRUDER -4.3 // -3.8 // Z probe to nozzle Z offset: -below (always!) #define Z_RAISE_BEFORE_HOMING 7 // (in mm) Raise Z axis before homing (G28) for Z probe clearance. // Be sure you have this distance over your Z_MAX_POS in case. #define XY_TRAVEL_SPEED 8000 // X and Y axis travel speed between probes, in mm/min. #define Z_RAISE_BEFORE_PROBING 9 // How much the Z axis will be raised before traveling to the first probing point. #define Z_RAISE_BETWEEN_PROBINGS 9 // How much the Z axis will be raised when traveling from between next probing points. #define Z_RAISE_AFTER_PROBING 9 // How much the Z axis will be raised after the last probing point.

Thanks Bert3D. How did you arrive at the -4.3 offset for Z. Did you just sneak up on the trip point of the BLTouch with the probe extended and record the position and then sneak up on the nozzle just slightly above the bed and recording that point and then do the arithmetic?

Using that method I came up with -3.9 so maybe that's the correct approach.

I'm going to revert to RC2 and my original Z stop for a test after work. With my current setup the prints are awlful - just a ball of filament. So I'm not sure if it's the bed leveling or something else I missed in RC3

I just homed using G28, then started lowering the printhead using negative Z movements, like G1 Z-0.5 then G1 Z-1, etc., until I got the nozzle to just touch the bed. Then I noted the distance that made it just barely make contact, which was G1 Z-4.3. To insure accuracy, I raised the head to 2mm using G1 Z2, then lowered it again, verifying he nozzle stopped just where I wanted it. Tweak the number until it goes down to the exact right height, and that number is your z offset.

If you can't get it to move to negative coordinates, you can compare with my config here https://github.com/AlwaysTinkering/Marlin to see what's different.

My other code changes are for my hardware setup with the Graphic controller, Z Lead Screws, and X endstop on the left. I'm using the stock extruder and hot end setup.

I too am in the short strokes of installing/setting up the BLTouch. Mounted, wiring done, etc. I was under the impression that the Z offset was how high the nozzle was when the BLTouch tripped but it sounds like you used the point where the probe, while extended, hits the plate as the height below when the nozzle hits. I wonder which it is.

Incidentally, to get the X and Y offsets, I put a piece of masking tape on the table, raised the Z axis, put a little lipstick on the probe tip and nozzle and then lowered them down until they both made marks. Worked great.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 07:19PM |

Registered: 8 years ago Posts: 38 |

Quote

UltiFix

Anybody elses printer come with L brackets that had huge holes? And the Bolts nearly fall through? Nice way to start off the build -_- They keep falling out on me.. I might need some washers for it. The L brackets are differen't than in the picture..

Yeah, I put M4 washers on mine then pushed them to the end of the hole. Seems to work fine...messy, but fine.

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 07:24PM |

Registered: 8 years ago Posts: 314 |

Thanks, I was super ticked, like I can't even complete step 2 -_- I was wondering if I was using the wrong bolts or what... Whatever. Washers to the rescue!Quote

GrouchoDuke

Quote

UltiFix

Anybody elses printer come with L brackets that had huge holes? And the Bolts nearly fall through? Nice way to start off the build -_- They keep falling out on me.. I might need some washers for it. The L brackets are differen't than in the picture..

Yeah, I put M4 washers on mine then pushed them to the end of the hole. Seems to work fine...messy, but fine.

Edited 1 time(s). Last edit at 01/27/2016 07:24PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 07:53PM |

Registered: 8 years ago Posts: 268 |

Quote

therippa

Quote

sonnylowe

Quote

mindstormmaster1

I need to calibrate my printer, but before I do I wanted to I wanted to upgrade my firmware from the stock firmware. I keep seeing talks about a new version (Merging RC2 and RC3) so I am wondering should I wait?

Also since my printer is running well what is the best process for upgrading without messing up all my settings?

You want therippa's version of Marlin (it's in his sig or the Wikia page), it is already RC3. The talk about merging RC2/RC3 was between a few select people. You will most likely still need to merge your current version of marlin with RC3 as there are a few setting that will need to translate over (E-Steps, PID if you ran autotune, Etc.).

As far as waiting to calibrate, it doesn't really matter if you do it now or later, either way those setting (mentioned above) will need to be transferred.

Hmmm, now that I think about it a bit more, I guess if you did it before you calibrated and missed an e-step setting (or got it wrong) it wouldn't matte as much since you'd be calibrating it after anyway...so now might actually be better in the long run!?!?

The firmware in my sig isn't RC3, it's the latest stable release.

My bad...I thought you were running RC3!?!?

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 07:57PM |

Registered: 8 years ago Posts: 16 |

This forum really needs some thread specific search instead of the whole entire forum....

Anyway, I just finished putting together my printer and followed the guide to upload the firmware and configure repetier here [drive.google.com]

Unfortunately, when I come to step 8 to home my x and y axis, nothing happens. My motors don't turn, nothing. Any ideas?

Anyway, I just finished putting together my printer and followed the guide to upload the firmware and configure repetier here [drive.google.com]

Unfortunately, when I come to step 8 to home my x and y axis, nothing happens. My motors don't turn, nothing. Any ideas?

Sorry, only registered users may post in this forum.