Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 09:03PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 10:19PM |

Registered: 8 years ago Posts: 93 |

Quote

tjnamtiw

Quote

Bert3D

Quote

DaveA

Quote

Bert3D

Quote

DaveA

I just installed a BLTouch sensor but I'm a little unsure how to set up the Z axis offsets. I'm running on Marlin RC3 with the changes from the Wiki merged in. I just need a little help in getting the vertical position set right.

I'm using [www.thingiverse.com] as the BLTouch mount on the stock FT extruder head. Anyone recently done this?

With that mount, assuming yours extruder is just like mine, it will be 31mm offset to the left on x, and 0 offset Y. The Z will vary, depending on the adjustment of your BLTouch. I raised mine up a bit to give the probe more clearance. That is a 2mm hex adjustment socket in the top of the BLTouch, which raises and lowers the pin.

Here are my settings, but yours could be different, so consider them just an example:

#define X_PROBE_OFFSET_FROM_EXTRUDER -31 // Z probe to nozzle X offset: -left +right #define Y_PROBE_OFFSET_FROM_EXTRUDER 0 // Z probe to nozzle Y offset: -front +behind #define Z_PROBE_OFFSET_FROM_EXTRUDER -4.3 // -3.8 // Z probe to nozzle Z offset: -below (always!) #define Z_RAISE_BEFORE_HOMING 7 // (in mm) Raise Z axis before homing (G28) for Z probe clearance. // Be sure you have this distance over your Z_MAX_POS in case. #define XY_TRAVEL_SPEED 8000 // X and Y axis travel speed between probes, in mm/min. #define Z_RAISE_BEFORE_PROBING 9 // How much the Z axis will be raised before traveling to the first probing point. #define Z_RAISE_BETWEEN_PROBINGS 9 // How much the Z axis will be raised when traveling from between next probing points. #define Z_RAISE_AFTER_PROBING 9 // How much the Z axis will be raised after the last probing point.

Thanks Bert3D. How did you arrive at the -4.3 offset for Z. Did you just sneak up on the trip point of the BLTouch with the probe extended and record the position and then sneak up on the nozzle just slightly above the bed and recording that point and then do the arithmetic?

Using that method I came up with -3.9 so maybe that's the correct approach.

I'm going to revert to RC2 and my original Z stop for a test after work. With my current setup the prints are awlful - just a ball of filament. So I'm not sure if it's the bed leveling or something else I missed in RC3

I just homed using G28, then started lowering the printhead using negative Z movements, like G1 Z-0.5 then G1 Z-1, etc., until I got the nozzle to just touch the bed. Then I noted the distance that made it just barely make contact, which was G1 Z-4.3. To insure accuracy, I raised the head to 2mm using G1 Z2, then lowered it again, verifying he nozzle stopped just where I wanted it. Tweak the number until it goes down to the exact right height, and that number is your z offset.

If you can't get it to move to negative coordinates, you can compare with my config here https://github.com/AlwaysTinkering/Marlin to see what's different.

My other code changes are for my hardware setup with the Graphic controller, Z Lead Screws, and X endstop on the left. I'm using the stock extruder and hot end setup.

I too am in the short strokes of installing/setting up the BLTouch. Mounted, wiring done, etc. I was under the impression that the Z offset was how high the nozzle was when the BLTouch tripped but it sounds like you used the point where the probe, while extended, hits the plate as the height below when the nozzle hits. I wonder which it is.

Incidentally, to get the X and Y offsets, I put a piece of masking tape on the table, raised the Z axis, put a little lipstick on the probe tip and nozzle and then lowered them down until they both made marks. Worked great.

The offset is the distance between the trigger point of the BLTouch, which will be at Z=0 once you home the Z axis, and the tip of the nozzle. When you home (G28) the BLTouch will trigger, and that sets the Z=0 height. Then move the head further down than zero using negative Z coordinates (ie G1 Z-1.5) just until the nozzle touches. Mine touched at G1 Z-4.3, so I knew the nozzle was that the trigger point was 4.3mm below the nozzle.

The only thing to be careful of, is to insure that the Z_RAISE_BEFORE_HOMING is enough that the BLTouch can deploy, and that your BLTouch is mounted such that it will trigger before the nozzle hits. (This is true for the bracket you listed and the BLTouch as it comes).

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 10:24PM |

Registered: 8 years ago Posts: 276 |

Quote

sonnylowe

Quote

therippa

Quote

sonnylowe

Quote

mindstormmaster1

I need to calibrate my printer, but before I do I wanted to I wanted to upgrade my firmware from the stock firmware. I keep seeing talks about a new version (Merging RC2 and RC3) so I am wondering should I wait?

Also since my printer is running well what is the best process for upgrading without messing up all my settings?

You want therippa's version of Marlin (it's in his sig or the Wikia page), it is already RC3. The talk about merging RC2/RC3 was between a few select people. You will most likely still need to merge your current version of marlin with RC3 as there are a few setting that will need to translate over (E-Steps, PID if you ran autotune, Etc.).

As far as waiting to calibrate, it doesn't really matter if you do it now or later, either way those setting (mentioned above) will need to be transferred.

Hmmm, now that I think about it a bit more, I guess if you did it before you calibrated and missed an e-step setting (or got it wrong) it wouldn't matte as much since you'd be calibrating it after anyway...so now might actually be better in the long run!?!?

The firmware in my sig isn't RC3, it's the latest stable release.

My bad...I thought you were running RC3!?!?

I am personally running RC3, but the link in my sig is for the latest stable with the Folgertech stock settings

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 10:46PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 10:50PM |

Registered: 8 years ago Posts: 268 |

Quote

therippa

Quote

sonnylowe

Quote

therippa

Quote

sonnylowe

Quote

mindstormmaster1

I need to calibrate my printer, but before I do I wanted to I wanted to upgrade my firmware from the stock firmware. I keep seeing talks about a new version (Merging RC2 and RC3) so I am wondering should I wait?

Also since my printer is running well what is the best process for upgrading without messing up all my settings?

You want therippa's version of Marlin (it's in his sig or the Wikia page), it is already RC3. The talk about merging RC2/RC3 was between a few select people. You will most likely still need to merge your current version of marlin with RC3 as there are a few setting that will need to translate over (E-Steps, PID if you ran autotune, Etc.).

As far as waiting to calibrate, it doesn't really matter if you do it now or later, either way those setting (mentioned above) will need to be transferred.

Hmmm, now that I think about it a bit more, I guess if you did it before you calibrated and missed an e-step setting (or got it wrong) it wouldn't matte as much since you'd be calibrating it after anyway...so now might actually be better in the long run!?!?

The firmware in my sig isn't RC3, it's the latest stable release.

My bad...I thought you were running RC3!?!?

I am personally running RC3, but the link in my sig is for the latest stable with the Folgertech stock settings

Okay, I feel a bit better now, I thought I was losing my mind LOL

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 10:51PM |

Registered: 8 years ago Posts: 268 |

Quote

UltiFix

I can't get the aluminum bed baring to pop in, did you guys sand it down?

Do whatever it takes to make it fit, you can always print out therippa's version once your printer in up and running

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 11:08PM |

Registered: 8 years ago Posts: 268 |

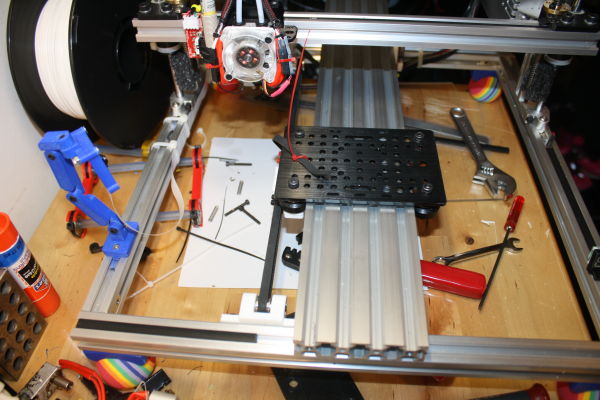

Well I had some printer downtime tonight so I decided to install the Gen-2 Offset Belt version of my Y-Axis upgrade. Here's a couple pix and a short video of it homing. I have used a lot of force to try to get the gantry to wobble, shift, sway, pitch, roll, yaw, move in any way other than right down the rail...I am happy to say it is as stable as the center belt version, but we all know time (and printing) will tell the full story ;-)

ALBUM

VIDEO

BTW: I am currently testing a Capacitive Sensor, I used my finger to trip it when probing Z...pretty damn cool if you ask me

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

ALBUM

VIDEO

BTW: I am currently testing a Capacitive Sensor, I used my finger to trip it when probing Z...pretty damn cool if you ask me

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 27, 2016 11:18PM |

Registered: 8 years ago Posts: 131 |

Quote

sonnylowe

Well I had some printer downtime tonight so I decided to install the Gen-2 Offset Belt version of my Y-Axis upgrade. Here's a couple pix and a short video of it homing. I have used a lot of force to try to get the gantry to wobble, shift, sway, pitch, roll, yaw, move in any way other than right down the rail...I am happy to say it is as stable as the center belt version, but we all know time (and printing) will tell the full story ;-)

ALBUM

VIDEO

BTW: I am currently testing a Capacitive Sensor, I used my finger to trip it when probing Z...pretty damn cool if you ask me

Pretty cool, printer seems nice and quiet. Does the capacitive sensor plug right where the z min sensor goes?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 28, 2016 12:41AM |

Registered: 8 years ago Posts: 314 |

Dremel works nice, It's all in place nowQuote

sonnylowe

Quote

UltiFix

I can't get the aluminum bed baring to pop in, did you guys sand it down?

Do whatever it takes to make it fit, you can always print out therippa's version once your printer in up and running

Sadly I need to go to bed soon -_- and I have a busy day tomarrow. But the weekend is coming! Wahoo! I hope to have it done by sunday night... If all goes according to plan, which it definetly will not LOL

Sadly I need to go to bed soon -_- and I have a busy day tomarrow. But the weekend is coming! Wahoo! I hope to have it done by sunday night... If all goes according to plan, which it definetly will not LOLThanks guys! That wiki is AWESOME!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 28, 2016 03:33AM |

Registered: 8 years ago Posts: 51 |

Quote

sonnylowe

Well I had some printer downtime tonight so I decided to install the Gen-2 Offset Belt version of my Y-Axis upgrade. Here's a couple pix and a short video of it homing. I have used a lot of force to try to get the gantry to wobble, shift, sway, pitch, roll, yaw, move in any way other than right down the rail...I am happy to say it is as stable as the center belt version, but we all know time (and printing) will tell the full story ;-)

ALBUM

VIDEO

BTW: I am currently testing a Capacitive Sensor, I used my finger to trip it when probing Z...pretty damn cool if you ask me

Looks awesome. Might be tempted to swap mine over to this.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 28, 2016 03:55AM |

Registered: 8 years ago Posts: 268 |

Quote

marc2912

Quote

sonnylowe

Well I had some printer downtime tonight so I decided to install the Gen-2 Offset Belt version of my Y-Axis upgrade. Here's a couple pix and a short video of it homing. I have used a lot of force to try to get the gantry to wobble, shift, sway, pitch, roll, yaw, move in any way other than right down the rail...I am happy to say it is as stable as the center belt version, but we all know time (and printing) will tell the full story ;-)

ALBUM

VIDEO

BTW: I am currently testing a Capacitive Sensor, I used my finger to trip it when probing Z...pretty damn cool if you ask me

Pretty cool, printer seems nice and quiet. Does the capacitive sensor plug right where the z min sensor goes?

Yeah, it should run just as quiet as Gen-1

Yes, a Capacitive Proximity Sensor wires up exactly like the Inductive Prox Sensor...if it's NO it will also have the same exact firmware changes. In the case of this particular sensor, it is NC so the firmware setting are a bit different.

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 28, 2016 09:20AM |

Registered: 8 years ago Posts: 13 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 28, 2016 04:37PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 28, 2016 04:57PM |

Registered: 8 years ago Posts: 314 |

Im stuck on a supposedly simple step, I need to attach the motor's to the mounts and use an acrylic rod keeper, they don't picture it and im not sure were it goes or what it is...

Edit

Im assuming the clear pieces are what they are talking about? In the picture they are black and blend in....

Edited 1 time(s). Last edit at 01/28/2016 05:00PM by UltiFix.

Edit

Im assuming the clear pieces are what they are talking about? In the picture they are black and blend in....

Edited 1 time(s). Last edit at 01/28/2016 05:00PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 28, 2016 05:34PM |

Registered: 8 years ago Posts: 171 |

Quote

UltiFix

Im stuck on a supposedly simple step, I need to attach the motor's to the mounts and use an acrylic rod keeper, they don't picture it and im not sure were it goes or what it is...

Edit

Im assuming the clear pieces are what they are talking about? In the picture they are black and blend in....

Yes, it's hard to see in the picture because they're clear. Just get the orientation correct where the hole goes (that holds the rod). It's explained in the text of the manual.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 28, 2016 05:44PM |

Registered: 8 years ago Posts: 314 |

Awesome thanks! I don't think having the bearing holders 3d printed was a good idea...Quote

markts

Quote

UltiFix

Im stuck on a supposedly simple step, I need to attach the motor's to the mounts and use an acrylic rod keeper, they don't picture it and im not sure were it goes or what it is...

Edit

Im assuming the clear pieces are what they are talking about? In the picture they are black and blend in....

Yes, it's hard to see in the picture because they're clear. Just get the orientation correct where the hole goes (that holds the rod). It's explained in the text of the manual.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 28, 2016 06:19PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 28, 2016 06:56PM |

Registered: 8 years ago Posts: 314 |

When I installed the bearings into the left side 3d printed part the side cracked, think it will still hold up fine? Not exactly sure why it's attached there anyway.

[prntscr.com]

[prntscr.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 28, 2016 08:26PM |

Registered: 8 years ago Posts: 430 |

Quote

UltiFix

When I installed the bearings into the left side 3d printed part the side cracked, think it will still hold up fine? Not exactly sure why it's attached there anyway.

[prntscr.com]

That's supposed to have a seam there so it can expand to let you get the bearing in there.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 28, 2016 08:33PM |

Registered: 8 years ago Posts: 25 |

Quick question: My X-Axis motor is pretty hot to the touch, I can leave my thumb on it for about 30-45 seconds before I have to pull it off. Whereas my Y-Axis motor is warm but not at all hot.. Is the X-Axis motor suppose to run so warm? If not, what do I need to do to run it cooler?

New Wikia page: [folgertech.wikia.com]

New Wikia page: [folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 28, 2016 08:37PM |

Registered: 8 years ago Posts: 131 |

Quote

john-i

Quick question: My X-Axis motor is pretty hot to the touch, I can leave my thumb on it for about 30-45 seconds before I have to pull it off. Whereas my Y-Axis motor is warm but not at all hot.. Is the X-Axis motor suppose to run so warm? If not, what do I need to do to run it cooler?

You need to tune the driver, it's probably sending too much current and is very common. Be careful when you do this, many have fried their board doing this.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 28, 2016 08:39PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

Am I supposed to cut the 2 meter belt in half? It doesn't say in the instructions... It just calls for a 1 meter belt. Also I didn't see anything in the build blog. Just don't want to mess up the parts!

Thanks!

Sam

When I built mine, I just connected the entire belt to one side of the X carriage, and then fed it around to the other side so that I knew where to cut to have a proper length. You can cut the belt a bit long, and you should have enough for the other axis if I remember correctly.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 28, 2016 08:48PM |

Registered: 8 years ago Posts: 541 |

Quote

sonnylowe

Well I had some printer downtime tonight so I decided to install the Gen-2 Offset Belt version of my Y-Axis upgrade. Here's a couple pix and a short video of it homing. I have used a lot of force to try to get the gantry to wobble, shift, sway, pitch, roll, yaw, move in any way other than right down the rail...I am happy to say it is as stable as the center belt version, but we all know time (and printing) will tell the full story ;-)

ALBUM

VIDEO

BTW: I am currently testing a Capacitive Sensor, I used my finger to trip it when probing Z...pretty damn cool if you ask me

That is downright beautiful work!

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 28, 2016 11:23PM |

Registered: 8 years ago Posts: 541 |

Still working to get the BLTouch to work with my 2020 and RC3. I tried the settings on the Wikia as well as those on Bert's git page. My Z axis goes up instead of down, which it never did before. Strange.

The biggest head scratcher is that with the laptop hooked up via USB, the BLTouch goes through it's self test and then solid red waiting for a probe. If I unhook the USB and go strictly off of the power supply, I get no self test and just flashing on the BlTouch. Any idea what that might be? Searches yield nothing.

Thanks! I WILL PREVAIL!!!! Grrrrrrrrrr.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

The biggest head scratcher is that with the laptop hooked up via USB, the BLTouch goes through it's self test and then solid red waiting for a probe. If I unhook the USB and go strictly off of the power supply, I get no self test and just flashing on the BlTouch. Any idea what that might be? Searches yield nothing.

Thanks! I WILL PREVAIL!!!! Grrrrrrrrrr.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 12:42AM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 01:54AM |

Registered: 8 years ago Posts: 314 |

I got it on, after drilling out a hole... Did you guys tape your extruder on at all or attach it any other way than the screws?

Edited 1 time(s). Last edit at 01/29/2016 02:03AM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 02:09AM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

Well I can't attach the extruder to the 3d printed part... The holes arent lined up and I may have stripped the motor a bit. Am I screwed?

The holes on my X carriage did not line up either. What I had to do is hold the motor as far away from the X carriage as I could while having the screws in all the way into the carriage, and then work the motor towards the carriage by screwing the screws into the motor equally.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 04:28AM |

Registered: 8 years ago Posts: 268 |

Quote

tjnamtiw

Still working to get the BLTouch to work with my 2020 and RC3. I tried the settings on the Wikia as well as those on Bert's git page. My Z axis goes up instead of down, which it never did before. Strange.

The biggest head scratcher is that with the laptop hooked up via USB, the BLTouch goes through it's self test and then solid red waiting for a probe. If I unhook the USB and go strictly off of the power supply, I get no self test and just flashing on the BlTouch. Any idea what that might be? Searches yield nothing.

Thanks! I WILL PREVAIL!!!! Grrrrrrrrrr.

If it moves up instead of down most likely the "endstop inverted" setting needs to be changed. The BLtouch like the Prox sensor are NO unlike the FT endstops that are NC

// Mechanical endstop with COM to ground and NC to Signal uses "false" here (most common setup).

const bool X_MIN_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop.

const bool Y_MIN_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop.

const bool Z_MIN_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

const bool X_MAX_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop.

const bool Y_MAX_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop.

const bool Z_MAX_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop.

const bool Z_MIN_PROBE_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

//#define DISABLE_MAX_ENDSTOPS

//#define DISABLE_MIN_ENDSTOPS

Is your BLt getting power directly from the Ramps, if so there could be a lack of power from the ramps, usually the BLt can run off the lower current on those contacts!?!? Does it go into alarm mode when you unplug the laptop? In that case the simple fix might be to unplug the BLt power leads from the Ramps to reset it. These is a command prompt that will do that as well but I can't think of it off the top of my head!?!?

Here's my config-h

Edit: Check your ednstop status to see what's triggered, I really think this is an endstop issue... The command is M119 I think!?!?

Edited 1 time(s). Last edit at 01/29/2016 05:28AM by sonnylowe.

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 04:50AM |

Registered: 8 years ago Posts: 38 |

Quote

sonnylowe

Quote

tjnamtiw

Still working to get the BLTouch to work with my 2020 and RC3. I tried the settings on the Wikia as well as those on Bert's git page. My Z axis goes up instead of down, which it never did before. Strange.

The biggest head scratcher is that with the laptop hooked up via USB, the BLTouch goes through it's self test and then solid red waiting for a probe. If I unhook the USB and go strictly off of the power supply, I get no self test and just flashing on the BlTouch. Any idea what that might be? Searches yield nothing.

Thanks! I WILL PREVAIL!!!! Grrrrrrrrrr.

Is your BLt getting power directly from the Ramps, if so there could be a lack of power from the ramps, usually the BLt can run off the lower current on those contacts!?!? Does it go into alarm mode when you unplug the laptop? In that case the simple fix might be to unplug the BLt power leads from the Ramps to reset it. These is a command prompt that will do that as well but I can't think of it off the top of my head!?!?

Here's my config-h

I'm seeing pretty much the same thing on mine...except my BLTouch gives me a fast flashing LED no matter what I do. Is that a power issue? If so, where besides the servo pins is good to get power to it?

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 05:26AM |

Registered: 8 years ago Posts: 268 |

Quote

GrouchoDuke

Quote

sonnylowe

Quote

tjnamtiw

Still working to get the BLTouch to work with my 2020 and RC3. I tried the settings on the Wikia as well as those on Bert's git page. My Z axis goes up instead of down, which it never did before. Strange.

The biggest head scratcher is that with the laptop hooked up via USB, the BLTouch goes through it's self test and then solid red waiting for a probe. If I unhook the USB and go strictly off of the power supply, I get no self test and just flashing on the BlTouch. Any idea what that might be? Searches yield nothing.

Thanks! I WILL PREVAIL!!!! Grrrrrrrrrr.

Is your BLt getting power directly from the Ramps, if so there could be a lack of power from the ramps, usually the BLt can run off the lower current on those contacts!?!? Does it go into alarm mode when you unplug the laptop? In that case the simple fix might be to unplug the BLt power leads from the Ramps to reset it. These is a command prompt that will do that as well but I can't think of it off the top of my head!?!?

Here's my config-h

I'm seeing pretty much the same thing on mine...except my BLTouch gives me a fast flashing LED no matter what I do. Is that a power issue? If so, where besides the servo pins is good to get power to it?

I'm honestly not sure as I never had a power problem, I just know it's not recommended to drive a servo from the board due to low current. However the current draw on the BLt is super low, so mine always worked...I beleive the draw on the White version is even lower!?!?

As far as 5V from elsewhere, you could just use a phone changer and hack the connect...although I wouldn't use a cheap wimpy one, maybe one from a table would be better...

The other option would be a step-down circuit, just like dropping the voltage on the Prox Sensors...Tom's guide shows you how to do that, then you could pull power directly from the PS or the aux 12V pins.

I am currently running a different sensor, but if I went back, I'd use a Tablet Charger to be on the safe side

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

Sorry, only registered users may post in this forum.